Health monitoring technologies could soon be far more precise following research by Southern University of Science and Technology (SUSTech) in Shenzhen. The new flexible pressure sensors are significantly more sensitive and highly stable that provides enormous potential for commercial applications in a wide range of health fields.

SUSTech Department of Materials Science and Engineering (MSE) Associate Professor Guo Chuanfei has worked with collaborators at the Massachusetts Institute of Technology (MIT) to make a significant breakthrough in flexible pressure sensors. Nature Communications recently published their paper under the title, “Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity.”

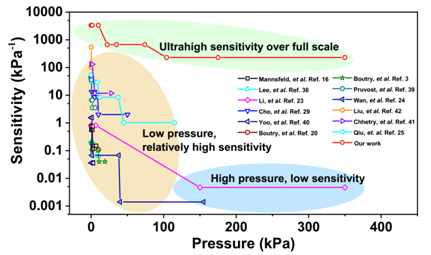

Flexible pressure sensors and electronic skin (e-skin) have been the focus of considerable research, due to how well they react to external stimuli like real human skin. The current challenge is the range of pressure sensitivity. Most skin and pressure sensors are highly sensitive under low pressure (a small amount of weight), but become insensitive or lose all responsiveness under high pressure (a large amount of weight). The perfect example is humans can feel a small insect crawling across their hand, but once their hand is under a heavy object, the small insect cannot be felt if it walks across the hand again.

Thus, practical applications require a pressure sensor that can deal with both light and heavy pressure, as well as when a light amount of pressure is added to a substantial amount of pressure. However, sensors had not previously existed due to the lack of soft compressible materials.

The research team dealt with this challenge by designing a “self-compensating non-steady-state structure,” which they call “graded intrafillable architecture.” A self-compensating non-steady state structure is one where the structure adjusts itself based on the location and amount of the pressure being placed on it. The surface grooves and undercuts, combined with unstable protrusions, enable a steady increase in contact with the electrode interface. The undercuts are vital to allowing more interior space for the buckled protrusions under high pressure, and the increased structural compressibility leads to a broader pressure response range.

The researchers have also introduced the principle of ion-interface sensing. They have adopted a new film infused with mobile H3PO4 ions in the dielectric layer. Positive and negative charges collect at the electrode film interface, significantly improving the specific capacitance by several orders of magnitude.

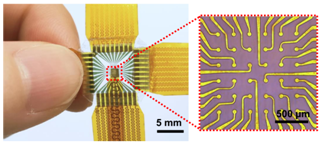

The sensor could sense a pressure change of 0.08 Pa at low pressure, and 18 Pa at extremely high pressure (3.2 atmospheres). Their sensor is also highly sensitive, with a sensitivity more than ten thousand times higher than the best results previously reports, and three times faster than the human skin response speed. Following miniaturization, the sensor maintains a high signal-to-noise ratio, with dozens of sensors that are the size of sesame seeds. These tiny sensors could be used for extremely high spatial resolution pressure sensors.

The co-first authors of the thesis are SUSTech Ph.D. student Ningning Bai and MIT postdoctoral fellow Liu Wang. The correspondent author is MSE Associate Professor Guo Chuanfei, and his collaborator is MIT Department of Mechanical Engineering Professor Zhao Xuanhe.

The research was supported by the National Natural Science Foundation of China (NSFC), the Innovation Committee of Shenzhen Municipality, the Shenzhen Technology Sci-Tech Fund, and the Guangdong Innovative and Entrepreneurial Research Team Program. The research teams thank the SUSTech Core Research Facilities for their support.

Paper link: https://doi.org/10.1038/s41467-019-14054-9

Proofread ByXia Yingying

Photo ByDepartment of Materials Science and Engineering