Recently, Professor Hui Li’s group from the Department of Materials Science and Engineering, at the Southern University of Science and Technology (SUSTech), published a review paper in Nature Energy, entitled “Bridging the gap between highly active oxygen reduction reaction catalysts and effective catalyst layers for proton exchange membrane fuel cells”. This review discusses the performance discrepancy between ex-situ thin-film rotating disk electrode (RDE) and real membrane electrode assembly (MEA). Furthermore, it elucidates various intrinsic limitations that have resulted in a persistent failure to transfer the high RDE activities of catalysts into maximized energy output at the MEA level.

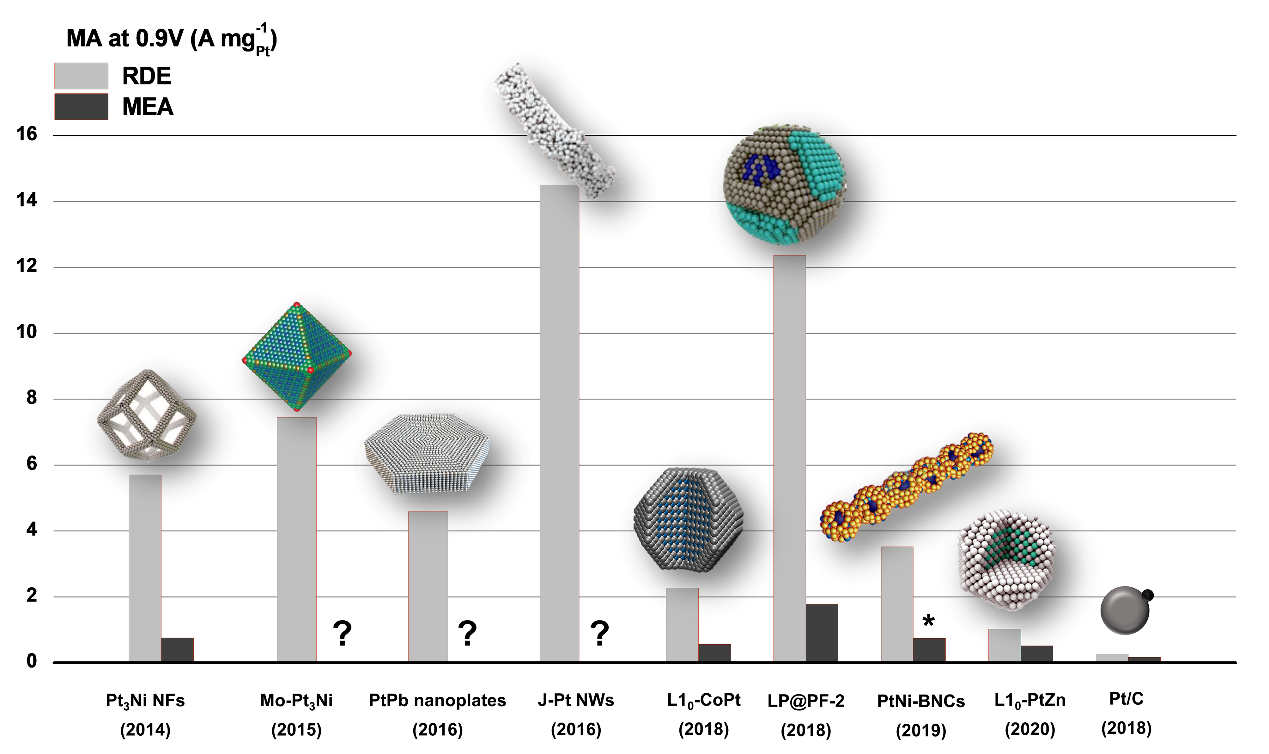

Proton exchange membrane fuel cells (PEMFC) are considered an integral part of a Hydrogen Energy System, which has been heatedly deemed important strategies to achieve the goal of carbon peak in 2030 and carbon neutralization in 2060. Ultralow platinum (Pt) loading and high catalytic performance at the MEA level are essential to make vehicles powered by PEMFCs affordable for mass commercialization. The last decade saw significant progress in developing a variety of highly active Pt-based catalysts for the O2 reduction reaction (ORR), including alloys, core-shell structures, and size- or shape-controlled as well as nanoframe/nanocage materials. In some cases, performance improvement of up to 100 times the ORR mass activity was reported compared to the commercial Pt/C catalysts. However, these high mass activities are almost exclusively obtained from RDE measurements that only evaluate the kinetics of the catalysts. The high activities have rarely been translated into real MEA performance (Figure 1).

Figure 1. Performance of state-of-the-art catalysts evaluated in RDE and MEA

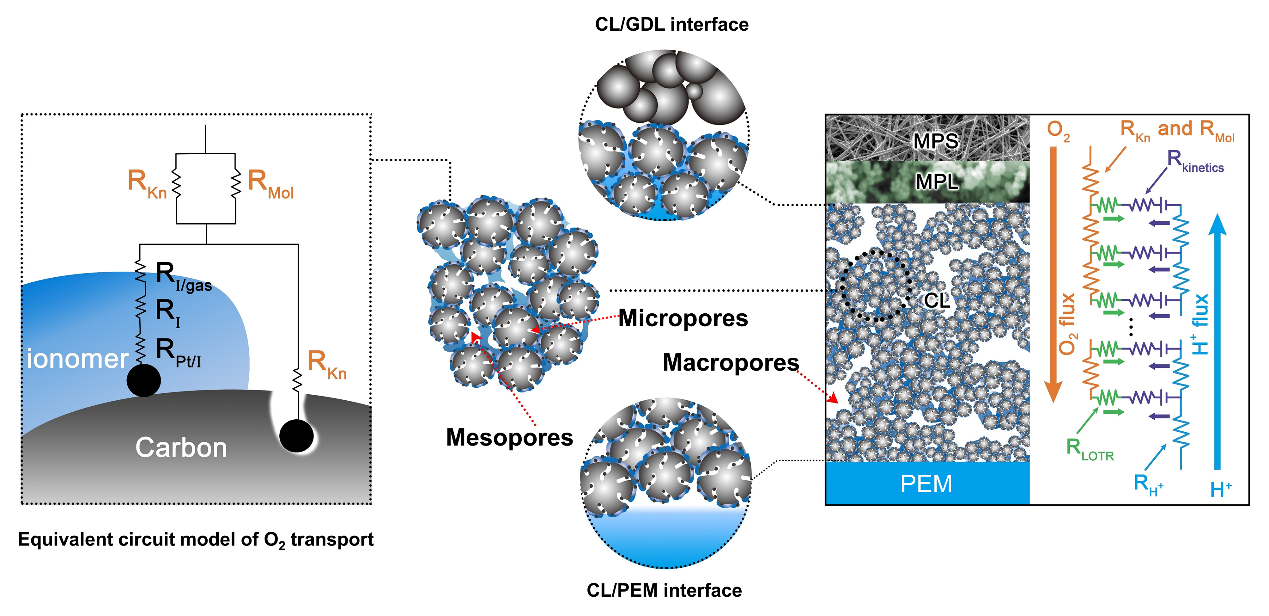

In this context, their review describes the remaining challenges for translating high RDE performance of catalysts into high-performance MEAs (Figure 2). This includes testing platforms, scale-up of the catalysts, and the design of catalysts and catalyst layers. It also outlines strategies for achieving high-performance MEAs with ultralow Pt loading through rationally designed catalysts and catalyst supports, ionomer chemistry, and mass transport enhancement at the interfaces in the MEA.

Figure 2. Sources of mass transport resistance inside the MEA of a PEMFC

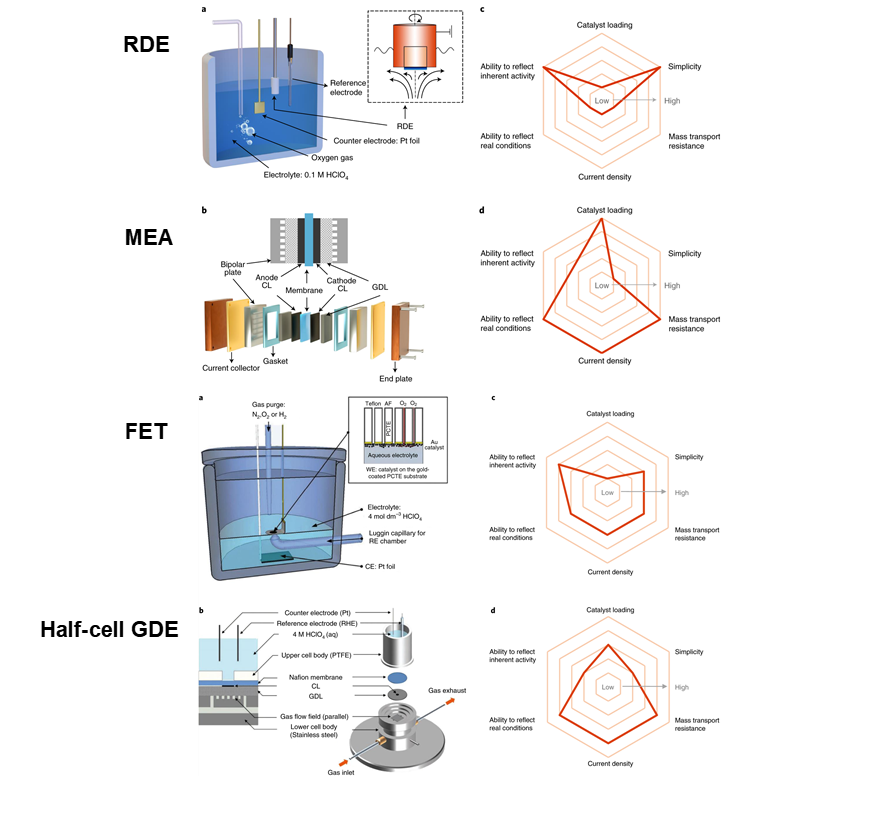

In addition, they examined several intermediate methods for evaluating and screening catalysts as steppingstones from RDE tests to MEA tests (Figure 3). The research provides current and emerging developmental roadmaps for achieving ultralow Pt loadings in catalyst layers and sheds more light on several catalyst layer engineering strategies to meet the aggressive targets for realizing the widespread commercialization of PEMFCs.

Figure 3. Comparison of RDE and MEA in catalyst assessment and intermediate testing configurations (FET and half-cell GDE configuration)

Professor Hui Li from SUSTech is the corresponding author of this paper. Dr. Fan Jiantao, an Associate Professor at the SUSTech Academy for Advanced Interdisciplinary Studies, is the first author. This research work is supported by the National Key R&D Plan, Guangdong Provincial Key Laboratory of Energy Materials for Electric Power, Shenzhen Hydrogen Energy Key Laboratory, Shenzhen Natural Science Fund, and the Shenzhen Special Fund for Sustainable Development Science and Technology.

Paper link: https://www.nature.com/articles/s41560-021-00824-7

Proofread ByAdrian Cremin, Yingying XIA

Photo By