The conflict between hyperelasticity and adhesiveness is inherent in a homogeneous polymer network. Hyperelasticity is a bulk property and relates to the reversible change of the entropy of polymer chains, which dictates that the change in the configuration of the polymer chain takes place without a dissipative process, such as intermolecular friction. In comparison, the adhesiveness of a polymer network is mostly a surface property and relates to intermolecular interactions.

It is inexpedient to resolve the hyperelasticity-adhesiveness conflict based on monolithic polymer networks. The need for a general strategy to design and synthesize hyperelastic adhesives is urgent for the field yet remains unmet.

Associate Professor Canhui Yang and Professor Wei Hong’s research teams from the Southern University of Science and Technology (SUSTech) have recently developed a hyperelastic adhesive with a heterogeneous polymer network.

This paper, entitled “Stretchable Heterogeneous Polymer Networks of High Adhesion and Low Hysteresis,” was published in ACS Applied Materials & Interfaces, an interdisciplinary journal publishing research at the interface of materials science, engineering, bio-related sciences, and chemistry.

In general, a hyperelastic polymer network is highly cross-linked that the number of polymer chains per unit volume is large and the length of the polymer chain between two crosslinks is short (Fig. 1A). Entropic elasticity predominates in such a polymer network, which is hyperelastic in bulk but non-adhesive at the interface. In cyclic tension, the stress-strain curves almost coincide, showing negligible hysteresis.

In T-peeling, the non-adhesive surface cannot bear a high stress and only activates a small fracture process zone in front of the crack tip, rendering a low adhesion energy. By contrast, a viscoelastic polymer network is loosely cross-linked or even just physically entangled. The number of polymer chains per unit volume is small, and the polymer chains are long (Fig. 1B). Viscoelasticity prevails due to the time-dependent molecular processes such as the release of chain entanglements or the relaxation of dangling chains. Such a polymer network is adhesive at the interface but viscoelastic in bulk, showing a high adhesion energy but enormous hysteresis.

Profs. Yang’s and Hong’s teams report a strategy to resolve the conflict by designating hyperelasticity and adhesiveness to the bulk polymers and the surface polymers, respectively (Fig. 1C). The resulting heterogeneous polymer network is stretchable and resilient, yet sticky, and will be termed as a hyperelastic adhesive (HEA). In a HEA, the bulk polymers are highly cross-linked to be resilient, and the surface polymers are loosely cross-linked to be sticky. The bulk is much thicker than the surface to dominate the hyperelastic characters. The surface polymers are interlinked robustly to the bulk polymers to invoke the elastic dissipater mechanism for elevated adhesion energy. Such robust interlinks can be achieved via covalent/physical bonds and/or topological entanglements.

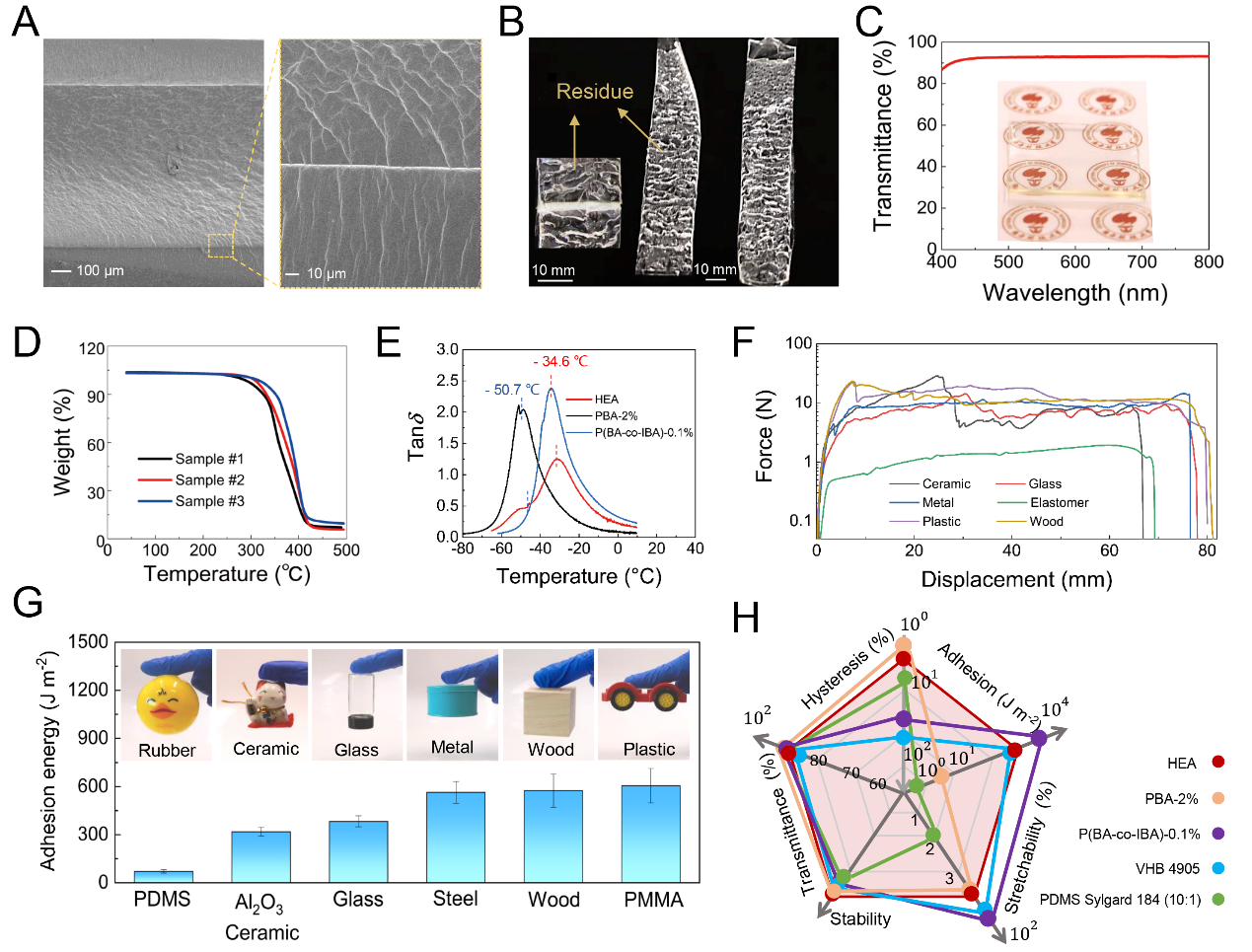

To demonstrate the proposed principle, the researchers select the acrylate polymers and synthesize a series of HEAs. The optimized version shows a hysteresis as low as 4% at 100% strain and adhesion energy of 270 J m-2. The HEA is optically transparent, thermally stable, and spontaneously adhesive to diverse solids, including ceramic, glass, metal, elastomer, plastic, and wood. Within the reliability paradigm, HEA exhibits superior stability to the viscoelastic adhesive counterparts against cyclic load, relaxation, and creep. The unique combination of hyperelasticity and adhesiveness enables novel applications, such as ionic sensors with highly stable electrical performances, rapid response and recovery speed, and lamellar structures with suppressed wrinkling under cyclic bending.

The general design strategy of HEA opens ample space not only to investigate the fundamentals of soft adhesives in physics, chemistry, and materials science, but also to practical applications of stretchable and resilient adhesives across various fields.

Figure 1. Schematics of various polymer networks

The researchers used poly (butyl acrylate) as the bulk and poly (butyl acrylate co-isobornyl acrylate) as the surface to illustrate this principle by adjusting the crosslink density. Hysteresis values and adhesion energy of various polymer networks are summarized in Figure 2.

Figure 2. Synthesis and optimizations of HEA

For better application in engineering, the lamellar structure HEA has a robust interface, good optical transparency with an average transmittance of 91%, good thermal stability below 250℃, and two glass transition temperatures: one is the glass transition temperature of the bulk polymer, which is -50.7℃; the other is the glass transition temperature of the surface bonded polymer, which is -34.6℃. In addition, HEA has the property of spontaneously adhering to various materials. The stretchable HEA exhibits excellent low hysteresis with strong adhesion, high transparency, and stability (Figure 3).

Figure 3. Characterizations of HEA

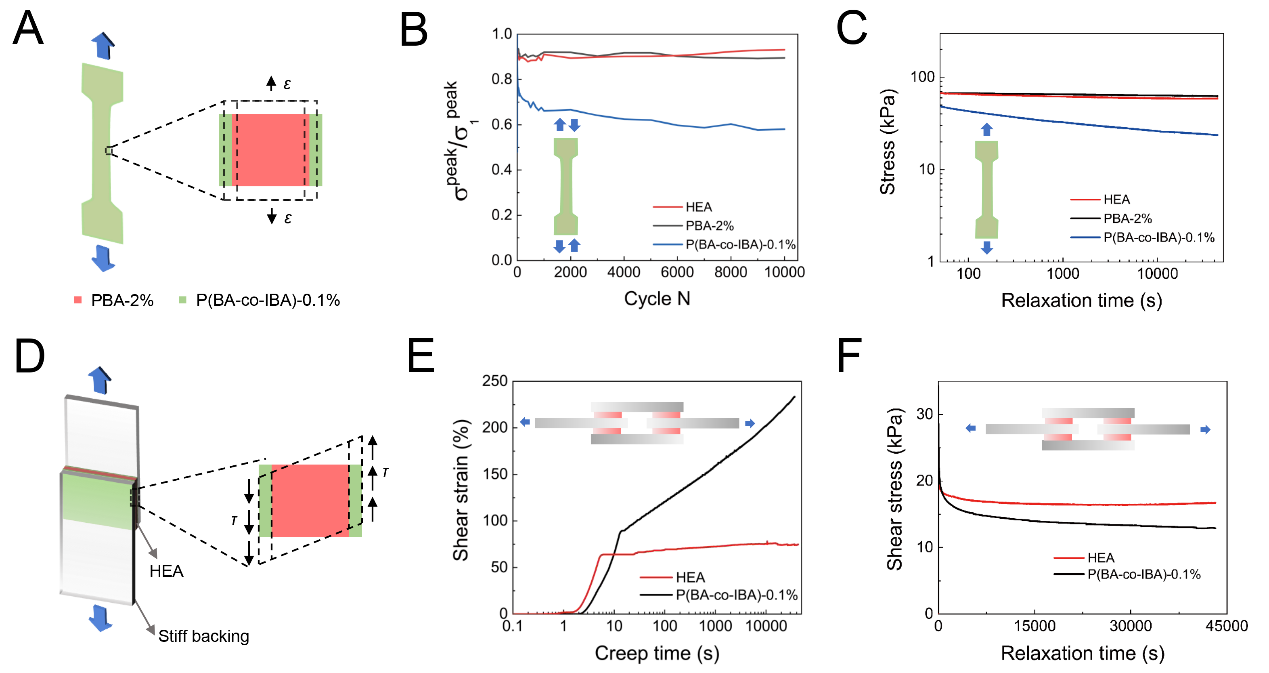

During its lifespan, an adhesive often needs to carry prolonged static/cyclic loads. The researchers probed the long-term stability of HEA using uniaxial tension and shear (Figure 4). The stability of HEA is understood as follows. The hyperelastic PBA-2% can be modelled as a spring, and the viscoelastic P(BA-co-IBA)-0.1% can be described by the Zener model.

Under uniaxial tension, PBA-2% and P(BA-co-IBA)-0.1% are in parallel. Since the modulus (378.6 kPa) and the thickness (1 mm) of PBA-2% are larger than those of P(BA-co-IBA)-0.1% (191.4 kPa and 0.1 mm), the mechanical responses of HEA are dominated by the hyperelastic PBA-2%. For example, the stiffness of HEA is EHEAhHEA = EPBAhPBA + EP(BA-co-IBA)hP(BA-co-IBA) ≈ EPBAhPBA. In the lap-shear scenario, PBA-2% and P(BA-co-IBA)-0.1% are in series. Subjected to a step constant shear stress, the PBA-2% layer barely creeps. Whereas the P(BA-co-IBA)-0.1% layer may creep somewhat, the creep displacement is small due to the thin thickness, the covalent crosslinks, and the robust interfacial interlinks. Likewise, the PBA-2% layer relaxes negligibly, but the P(BA-co-IBA)-0.1% layer relaxes under a constant shear strain.

Figure 4. Stability of HEA

The unique combination of hyperelasticity and adhesiveness enables new functionalities that were previously inaccessible based on monolithic polymer networks in Figure 5. For example, ionic sensors need not only to be soft and stretchable to accommodate deformation, but also to be adhesive to firmly anchor on the object monitored. The researchers also demonstrated the uses of HEA for assembling thin laminates. Such a scenario of using soft adhesives to assemble multiple layers of distinct mechanical properties is becoming pervasive, for instance, in the flexible/stretchable screens of portable devices, whereby repeated deformation is unavoidable.

Figure 5. Applications of HEA

This study reports a design strategy to synthesize stretchable and resilient adhesives by decoupling the hyperelasticity and adhesiveness in a heterogeneous polymer network. The resulting HEA possesses a low hysteresis of 4% at 100% strain and a high adhesion energy of 270 J m-2. Excellent optical transparency, thermal stability, non-specificity, as well as long-term stability against cyclic fatigue, relaxation, and creep are manifested. Two applications are enabled by the unique combination of the marked performances of HEA. Design and synthesis of HEAs with various attributes provide plentiful possibilities for broad engineering applications.

Ping Zhang, a Ph.D. student in Assoc. Prof. Canhui Yang’s research group, is the first author of this paper. Profs. Canhui Yang and Wei Hong are the co-corresponding authors. SUSTech is the first affiliation.

This work was supported by the Science, Technology, and Innovation Commission of Shenzhen Municipality, Stable Support Plan Program of Shenzhen Natural Science Fund Grant, and National Natural Science Foundation of China (NSFC).

Paper link: https://doi.org/10.1021/acsami.2c12658

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By