Over the past decades, photovoltaic technologies as power supply systems have received much attention due to the increased need for energy-harvesting devices. Among the various techniques, perovskite solar cells are the most popular topic. However, stability and scalability are essential, and urgent requirements are needed for the commercialization of perovskite solar cells.

Assistant Professor Longbin Qiu’s research team from the Department of Mechanical and Energy Engineering (MEE) at the Southern University of Science and Technology (SUSTech) has recently conducted a comprehensive study on interface charge recombination and scalable deposition processes for perovskite modules and tandem devices. They have made a series of research advancements and published four papers in international journals, including Advanced Functional Materials, Advanced Science, Small, and the Journal of Alloys and Compounds.

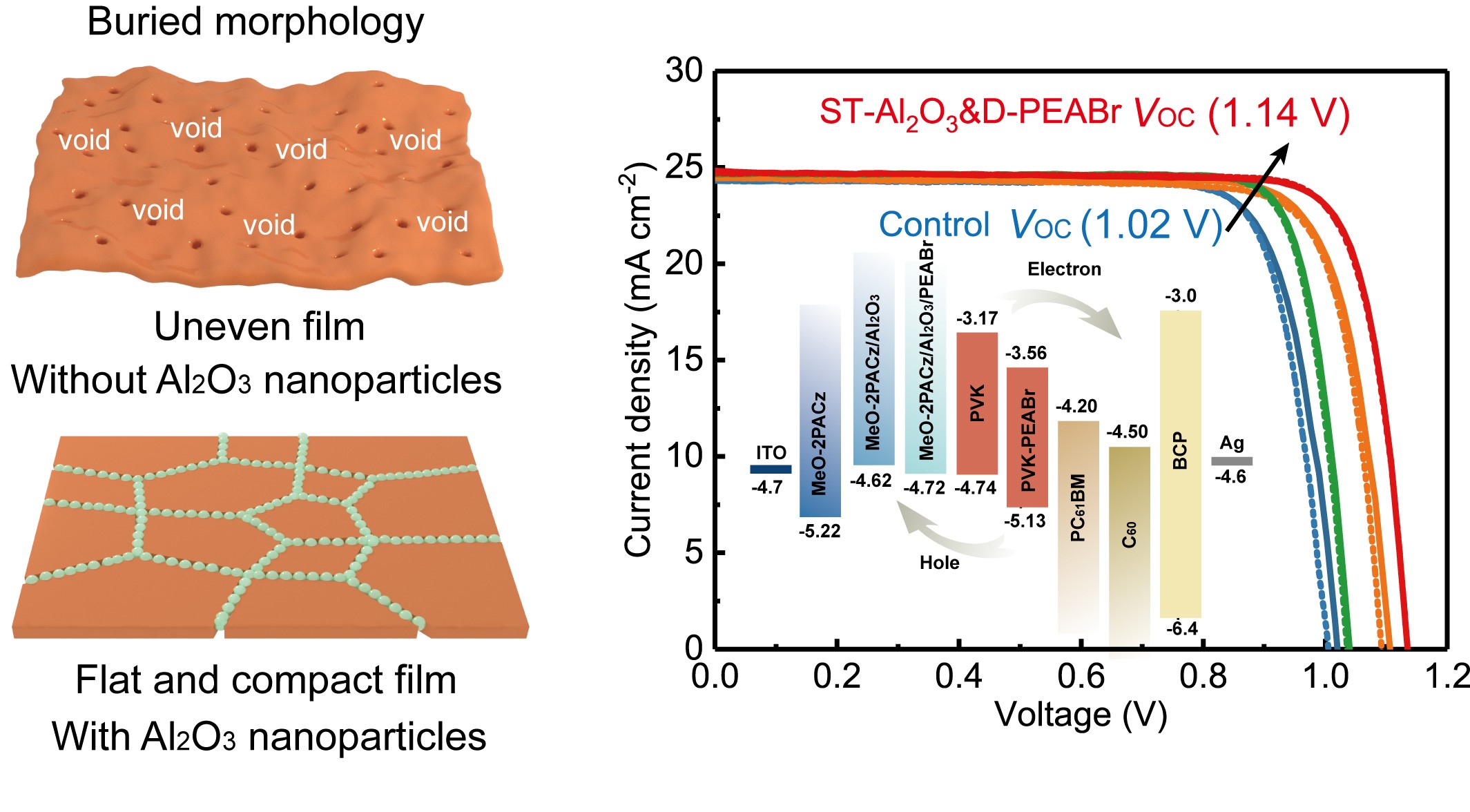

The researchers proposed an omnibearing strategy for the inverted perovskite solar cells to reduce the defect densities at the buried interface of perovskite film, as well as the top interface employing Al2O3 nanoparticles and ammonium salt PEABr. The Al2O3 nanoparticles are imbedded into the buried interface, which enlarges grain size and fills the voids and grain boundaries of perovskite, leading to compact morphology and reducing dangling bonds and defects (Fig. 1). The suppressed trap-assisted recombination, better energy alignment, and decreased J–V hysteresis in modified device with Al2O3 nanoparticles and PEABr contribute to a significant increase in VOC and stability. The dual modification provides a universal method to reduce interfacial defects, revealing a promising prospect in developing high-performance perovskite solar cells and modules.

Their research findings, entitled “Buried Interface Dielectric Layer Engineering for Highly Efficient and Stable Inverted Perovskite Solar Cells and Modules”, have been published in Advanced Science.

Figure 1. Al2O3 nanoparticle passivation perovskite buried interface diagram and the performance comparison diagram of the upper and lower interface passivation device.

Dr. Huan Li from the School of MEE at SUSTech is the first author of this paper. Assistant Professor Longbin Qiu is the corresponding author, and SUSTech is the first affiliation.

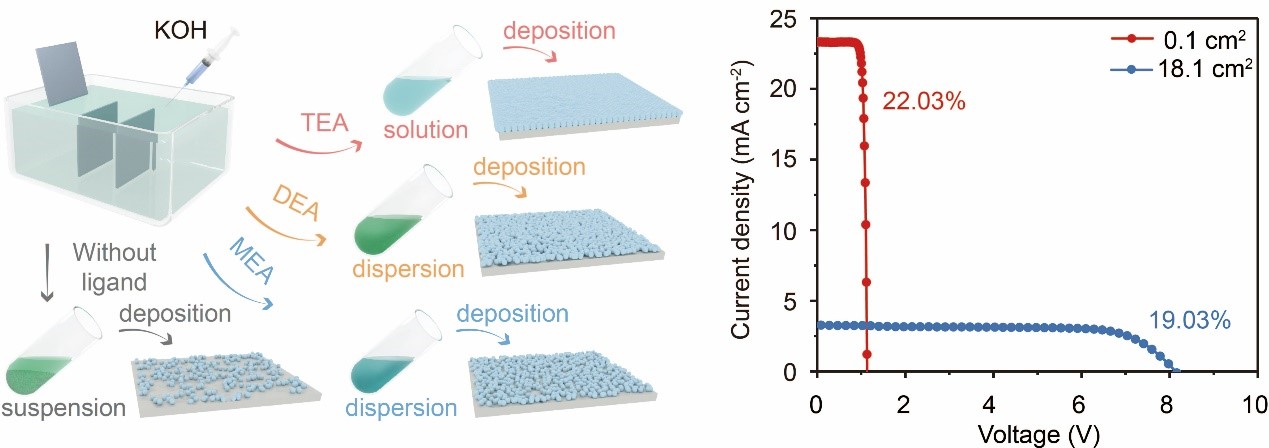

In their next work, the researchers developed a highly efficient inverted perovskite solar cells and large area modules by designing a low-temperature, scalable and uniform chemical bath deposition NiOX thin films, which was obtained by amino-alcohol ligands based controllable Ni2+ release and deposition (Fig. 2). This study paves an efficient, low-temperature, and scalable chemical bath deposition route for large-area NiOX thin films for the scalable fabrication of highly efficient perovskite solar modules.

Their research findings, entitled “Low-Temperature Chemical Bath Deposition of Conformal and Compact NiOX for Scalable and Efficient Perovskite Solar Modules”, have been published in Small.

Figure 2. Deposition model of NiOX thin films deposited in the chemical bath under different ligands and solution of non-uniform deposition of thin films.

Ph.D. student Sibo Li from the School of MEE at SUSTech is the first author of this paper. Assistant Professor Longbin Qiu is the corresponding author, and SUSTech is the first affiliation.

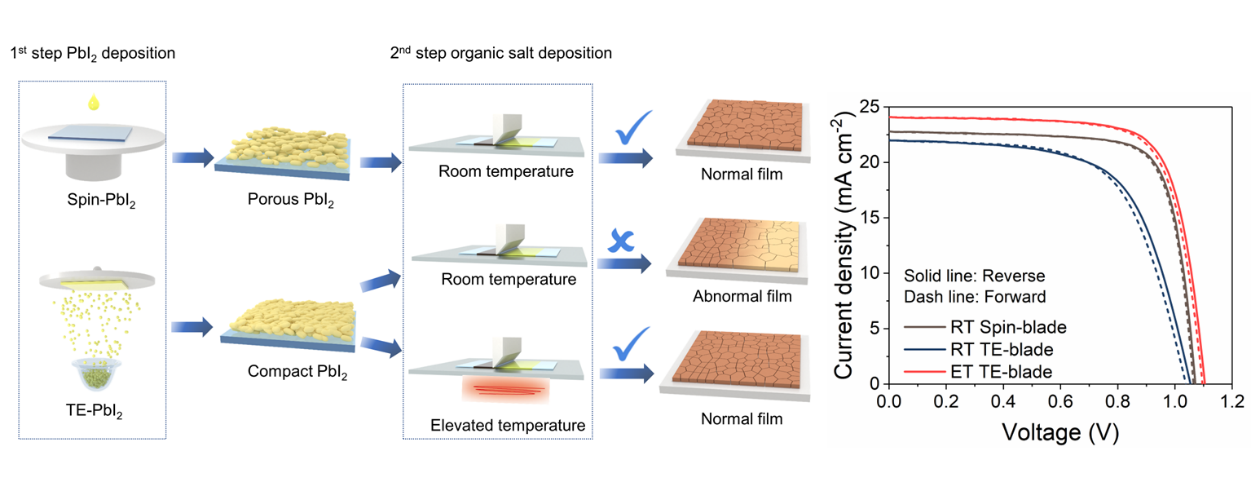

The researchers combined a moderately elevated temperature for coating organic salt on compact thermal evaporated PbI2. They avoided the unwanted 2D-structures and showed the preferred features of suitable evaporation of solvent, effective interdiffusion, and completed conversion for efficient perovskite solar cells, which is potential for large area and conformal coating (Fig. 3). These results suggest that two-step thermal evaporation and blade coating method offer a feasible way for the industrial production of perovskite solar cells in the future.

Their research findings, entitled “Controllable Blading Interdiffusion of Formamidinium Iodide on Thermal Evaporated Scalable and Conformal Lead Iodide for Efficient Perovskite Solar Cells”, have been published in the Journal of Alloys and Compounds.

Figure 3. Schematic diagram of the process of preparing perovskite film by two-step method and device efficiency diagram of different scraping processes.

Postgraduate student Jun Fang from the School of MEE at SUSTech is the first author of this paper. Assistant Professor Longbin Qiu is the corresponding author, and SUSTech is the first affiliation.

In their final work, the researchers achieved perovskite-organic tandem solar cells with minimized open-circuit voltage loss and suppressed phase segregation for wide-bandgap perovskite front cells. A buried interfacial dielectric layer structure and a simplified metal-free interconnecting layer of ambipolar SnOX contributed to the reduced interfacial defect states and an efficiency of 22.31% for the tandem solar cells. The simplified interconnecting layer that does not involve a metal layer is a potential strategy for scalable and flexible perovskite-based tandem solar cells.

The research findings, entitled “Phase Segregation and Voltage Loss Mitigated Highly Efficient Perovskite-Organic Tandem Solar Cells with a Simple Ambipolar SnOX Interconnecting Layer”, have been published in Advanced Functional Materials.

Figure 4. Device performance for the perovskite–organic tandem solar cells.

Ph.D. student Guanshui Xie from the School of MEE at SUSTech is the first author of this paper. Assistant Professor Longbin Qiu is the corresponding author, and SUSTech is the first affiliation.

These works were supported by the National Natural Science Foundation of China (NSFC), Guangdong Provincial Science and Technology Program, Guangdong Grants, Shenzhen Science and Technology Innovation Program, and the Research Startup Grant by the Shenzhen Municipal Government and SUSTech.

Paper links (In order of appearance above):

Advanced Science: https://doi.org/10.1002/advs.202300586

Small: https://doi.org/10.1002/smll.202301110

Journal of Alloys and Compounds: https://doi.org/10.1016/j.jallcom.2023.170255

Advanced Functional Materials: https://doi.org/10.1002/adfm.202308794

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By