Thermal expansion is a fundamental characteristic of matter and plays an important role in the service environments of various devices. However, large differences in the coefficient of thermal expansion (CTE) between metallic and non-metallic materials may lead to large thermal mismatch stress, fatigue, and even failure of engineering systems consisting of metallic and non-metallic components. Thus, tuning the CTEs of metallic materials to large negative and positive values are demanded in many applications to compensate and match the large CTEs of non-metallic materials.

Associate Professor Fuzeng Ren’s research group from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently collaborated with Professor Qingping Sun’s research group from the Hong Kong University of Science and Technology (HKUST) to make important research progress in the field of thermal expansion of shape memory alloys.

Their research work, entitled “Engineered colossal linear thermal expansion in nanocrystalline NiTi micropillars by stress”, has been published in Acta Materialia, a top journal in the field of metallic materials.

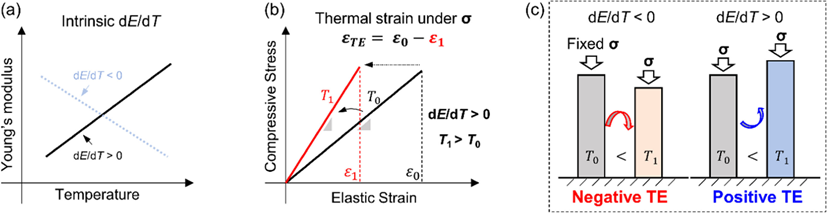

Figure 1. The basic idea to tune CTEs of ferroelastic materials by applying uniaxial compressive stress. (a) The positive and negative temperature dependence of Young’s modulus of the high-symmetry (austenite) and low-symmetry (martensite) phases in ferroelastic materials. (b) The elastic strain variation with temperature under a constant uniaxial stress. (c) The schematic diagram of the negative thermal expansion (NTE) and positive thermal expansion (PTE) under compressive stress due to modulus change.

In this study, the researchers reported a colossal linear thermal expansion in single-phase nanocrystalline NiTi ferroelastic alloy under uniaxial compressive stress (Fig. 1). By microscale isothermal severe plastic deformation, they fabricated fully austenitic and martensitic NiTi nanocrystalline micropillars that respectively possess high yield stresses of 2.65 GPa and 2.23 GPa, and strong negative and positive temperature dependence of Young′s modulus (dE/dT).

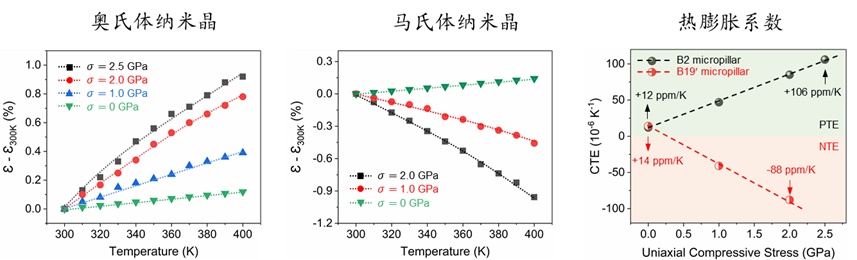

They demonstrated that due to the large dE/dT, the coefficient of linear thermal expansion (CTE) of the austenitic and martensitic NiTi micropillars can be tailored to very large values by applying compressive stress (Fig. 2). The tailored CTEs are approximately ten times larger than the typical value of metallic materials. Their work provides a mechanical route to obtain colossal positive and negative thermal expansion in single-phase nanostructured ferroelastic alloys at the microscale.

Figure 2. Tailored large axial positive and negative thermal expansions of the B2 and B19′ NC micropillars by uniaxial compressive stress. Strain vs temperature curves under different uniaxial compressive states.

Kangjie Chu, a SUSTech Presidential Postdoctoral Fellow of Prof. Fuzeng Ren’s research group, is the first author of this paper. Prof. Fuzeng Ren and Dr. Qiao Li, a visiting scholar at HKUST, are the co-corresponding authors. Other collaborators include Prof. Qingping Sun of HKUST; SUSTech is the first communication unit.

This work was supported by the National Natural Science Foundation of China (NSFC), Hong Kong Research Grant Council, and the Shenzhen Science and Technology Program.

Paper link: https://doi.org/10.1016/j.actamat.2023.119442

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By