In today’s society, smart mobile devices are increasingly impacting our lives, with many of these devices powered by lithium-ion batteries. Most modules in these devices require a 3.3V power supply, making 3.3V voltage a typical target output voltage for the battery’s power management integrated circuit (PMIC). However, as shown in Figure 1(a), the output voltage of a lithium-ion battery varies with its charge level. Consequently, a non-inverting Buck-Boost converter becomes a good choice.

Conventional Buck-Boost converters require two power transistors to operate simultaneously, leading to large conduction and switching losses. Moreover, they have a large inductor current, resulting in substantial conduction losses. Some previous work reduced losses by employing multi-mode Buck-Boost converters. However, they experienced significant overshoot or undershoot voltage issues during mode transitions.

To address these challenges, Professor Chenchang Zhan’s research group from the School of Microelectronics at the Southern University of Science and Technology (SUSTech), in collaboration with Professor Yan Lu’s research group from the Institute of Microelectronics at the University of Macau (UM), recently achieved significant progress in the field of DC-DC converters with a proposed Buck-Boost hybrid converter with a peak efficiency of 97.6%. This work introduces a non-inverting Buck-Boost hybrid converter with three operation modes (3M-BBHC) to reduce the number of main switch transistors and lower inductor currents for improved efficiency. It achieved smooth mode transitions by using a dynamic slope signal.

Their research work, entitled “A Battery-Input Three-Mode Buck-Boost Hybrid DC-DC Converter with 97.6% Peak Efficiency”, has been published in the IEEE Journal of Solid-State Circuits (JSSC), a top-tier journal in the field of integrated circuit design.

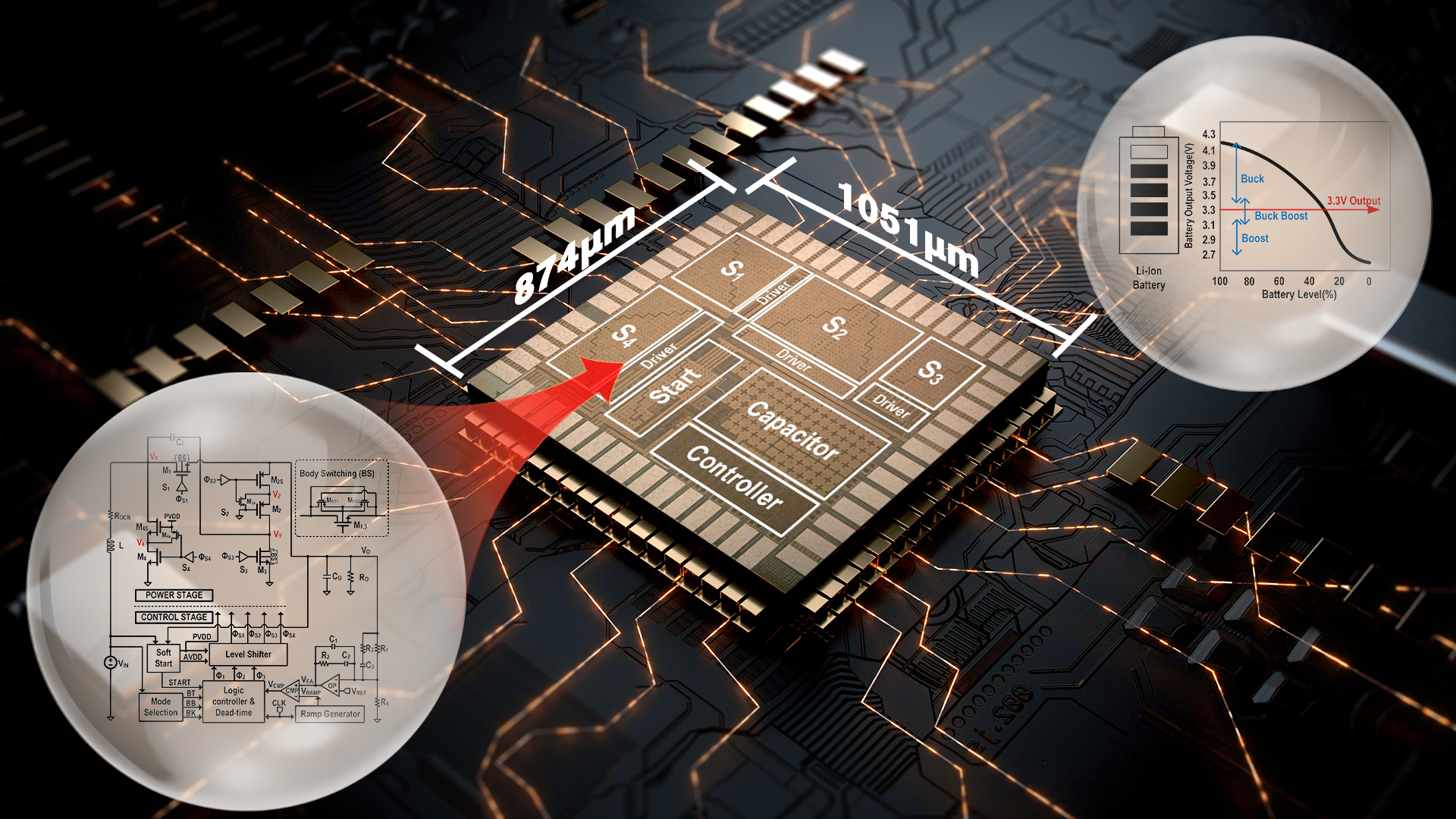

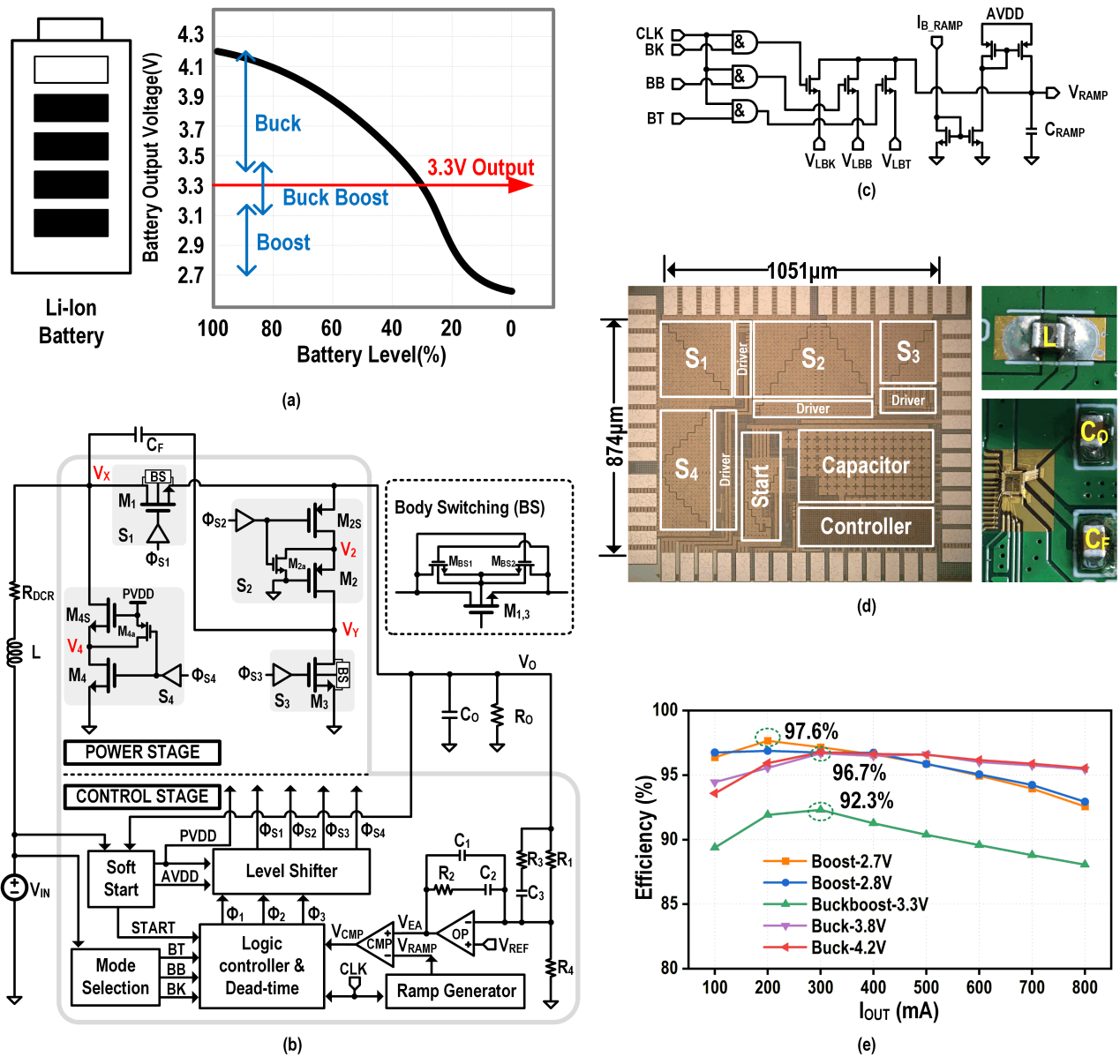

Figure 1. (a) Variation of lithium-ion battery output voltage with battery capacity. (b) System architecture of the proposed 3M-BBHC. (c) Dynamic ramp generation circuit. (d) Photograph of the chip. (e) The measured efficiency at different input voltages.

As shown in Figure 1(b), this work presents a non-inverting Buck-Boost hybrid converter with three modes (3M-BBHC). It comprises a control module, a power module, and off-chip components such as an inductor, a flying capacitor, and an output capacitor. To minimize chip area and parasitic capacitance, only 3.3V devices are used in all circuit modules. The power module consists of four switches, labeled as S1, S2, S3, and S4. At the bottom of Figure 2, the control circuit includes modules for ramp signal generation, logic control, mode selection, soft start, dead-time generation, and level-shifter. The 3M-BBHC allows smooth transitions between Buck, Boost, and Buck-Boost modes. It adds a flying capacitor (CF) while maintaining four power switches, reducing conduction and switching losses. By placing the inductor at the input, the 3M-BBHC achieves smaller electromagnetic interference (EMI) while maintaining continuous input current. Furthermore, in Buck mode, the inductor current is always lower than the output current, reducing the conduction loss of the inductor’s DC resistance (DCR).

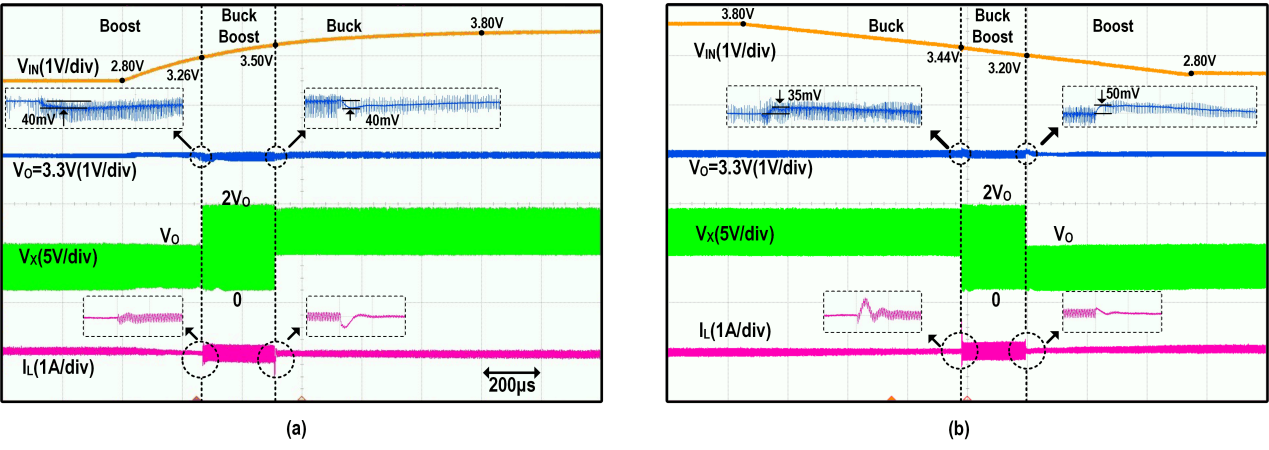

Figure 2. Measured line transient responses among different operation modes. (a) From boost to buck–boost and buck mode. (b) From buck to buck–boost and boost mode.

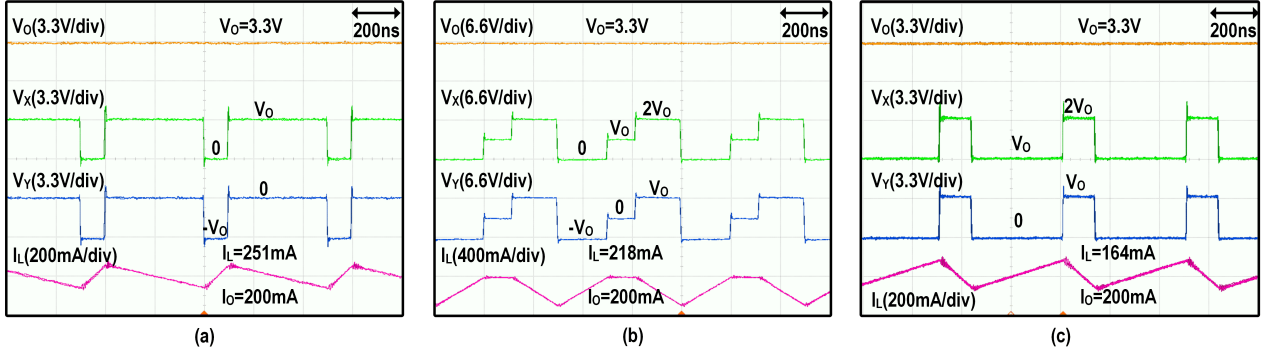

Figure 3. Measured steady-state waveforms at 200-mA output current for different operation modes. (a) Boost mode with 2.7-V VIN. (b) Buck–boost mode with 3.3-V VIN. (c) Buck mode with 4.2-V VIN.

To improve mode-switching performance, a dynamic ramp generation circuit was introduced, as depicted in Figure 1(c). Figure 2 shows measured transient response results during mode transitions as the input voltage varies. It is evident that the 3M-BBHC achieves smooth mode transitions. Figure 3 displays measured steady-state waveforms for the three operational modes. Figures 1(d) and 1(e), respectively, show photographs of the chip and test efficiency at different input voltages. The research achieved an impressive peak efficiency of 97.6%.

Shuangxing Zhao, a joint Ph.D. student of SUSTech and UM, is the first author of this paper. Profs. Chenchang Zhan and Yan Lu are co-corresponding authors, and SUSTech is the first affiliated unit.

This work was partly supported by the National Natural Science Foundation of China (NSFC), Shenzhen Science and Technology Innovation Commission (SZSTI), Nanshan District Science and Technology Innovation Bureau, and the Macao Science and Technology Development Fund.

Paper link: https://ieeexplore.ieee.org/document/10281380

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By