The ever-evolving advancements in high-performance computing, mobile communications, artificial intelligence, and automotive electronics have led to a growing demand for electronic products that boast both high performance and integration capabilities. As mobile and satellite communication technologies continue to evolve, the requirements for communication frequency bands have become increasingly stringent.

Low dielectric constant microwave dielectric ceramic materials are the ideal choice for high-frequency applications. Not only do they minimize communication signal transmission delays, but they also reduce parasitic capacitance between wiring and conductive structures to the maximum extent. Additionally, dielectric loss, which quantifies the electromagnetic energy absorbed and dissipated as heat within a material, is a critical parameter. Materials with low dielectric loss, indicating high-quality factors (Qf), are ideal for high-performance and high-power applications.

To adapt to the rapid development of multifunctional integrated wearable wireless communication devices and meet the demands of low-temperature co-fired ceramics (LTCC) technology, the emerging trend in ceramic material development necessitates compatibility with semiconductors, polymers, and metals in co-sintering. This requires ceramic materials to have a lower sintering temperature. Therefore, preparing low dielectric constant microwave dielectric ceramic materials that can be sintered at low temperatures while maintaining a high-quality factor is of paramount importance for the development of the next generation of high-performance electronic devices.

Professor Hong Wang’s research team from the Department of Materials Science and Engineering (MSE) at the Southern University of Science and Technology (SUSTech) has recently achieved remarkable progress in the study of low-temperature sintering of microwave dielectric ceramic materials.

Their findings have been published in the prestigious Journal of the American Ceramics Society, under the title of “Crystal Structure and Phase Formation of MgO-MoO3 Based Ceramics with Ultralow Dielectric Loss: A Comprehensive Study”.

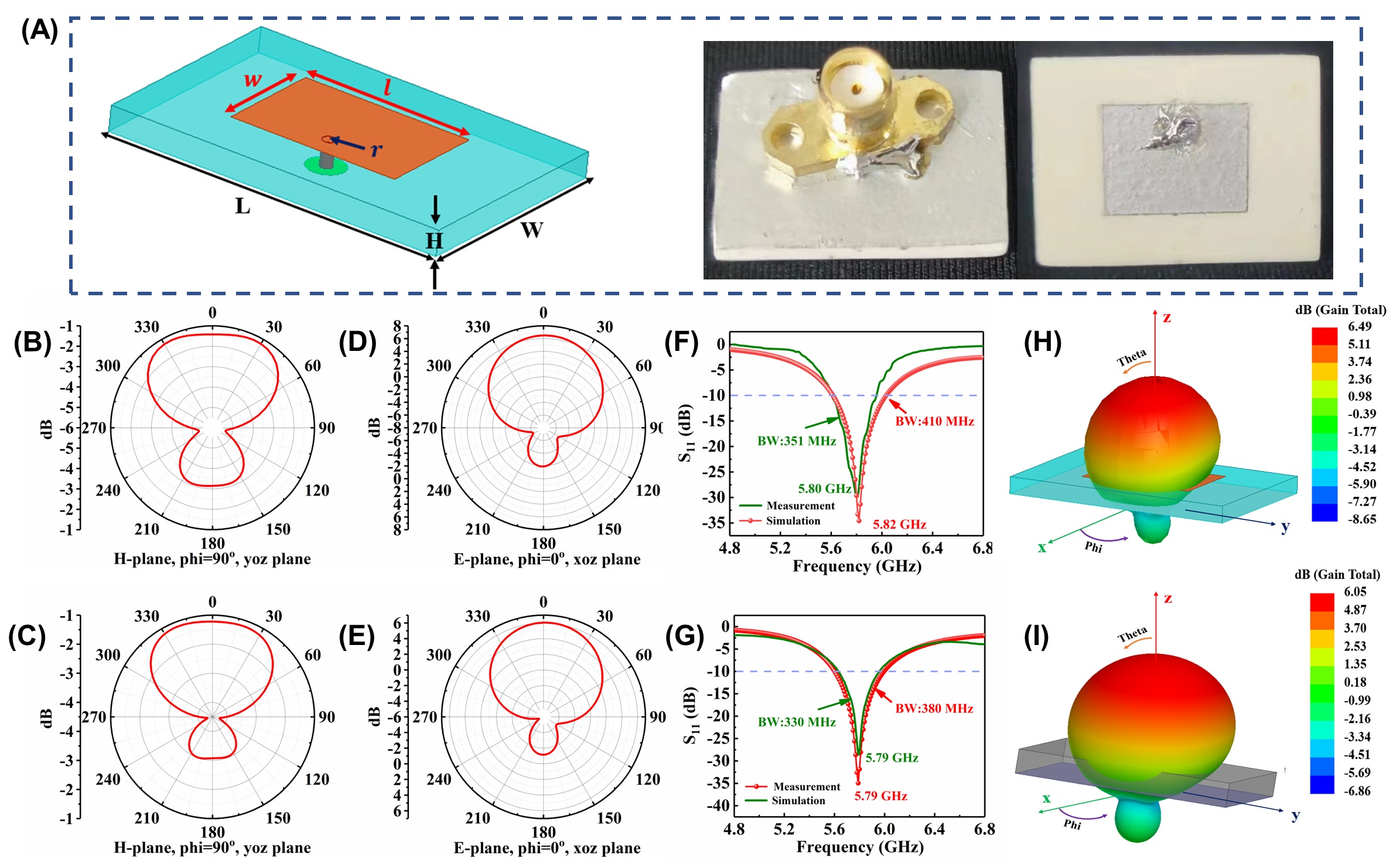

This research systematically delves into the MgO-MoO3 binary system, providing a comprehensive exploration of the phase composition, crystal structure, sintering performance, and microwave properties of compounds within this system. Notably, ceramics from this system can be sintered within a temperature range of 685°C to 900°C and exhibit outstanding microwave dielectric properties. The dielectric constants range from 5.41 to 6.89, with quality factors spanning from 100,000 to 130,000 GHz, and frequency temperature coefficients ranging from -40 ppm/°C to -70 ppm/°C. Furthermore, the team used ceramics from this system as substrates to design and fabricate high-performance microstrip patch antennas, demonstrating the practical potential of these ceramics in microwave devices.

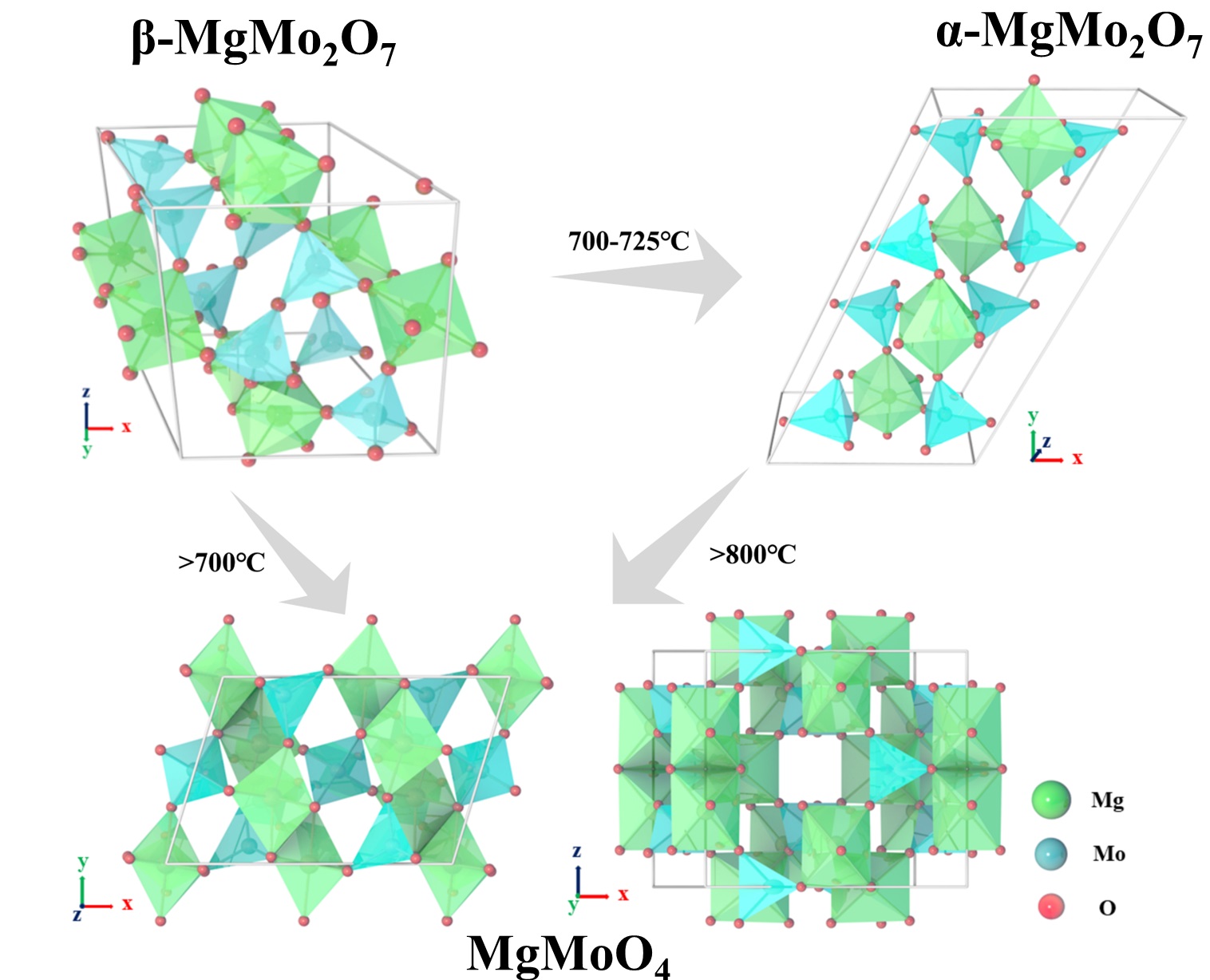

One crucial aspect of understanding microwave dielectric properties in ceramics is structural characterization. In this study, the researchers used a combination of powder diffraction methods along with software tools like Match, Endeavour, and GSAS to determine the crystal structure of β-MgMo2O7 for the first time. They also utilized X-ray diffraction (XRD), thermal analysis (TG), and energy-dispersive spectroscopy (EDS) to reveal the phase transition processes within the MgO-MoO3 system.

Figure 1. Crystal structures and phase transition mechanism of β-MgMo2O7, α-MgMo2O7, and MgMoO4

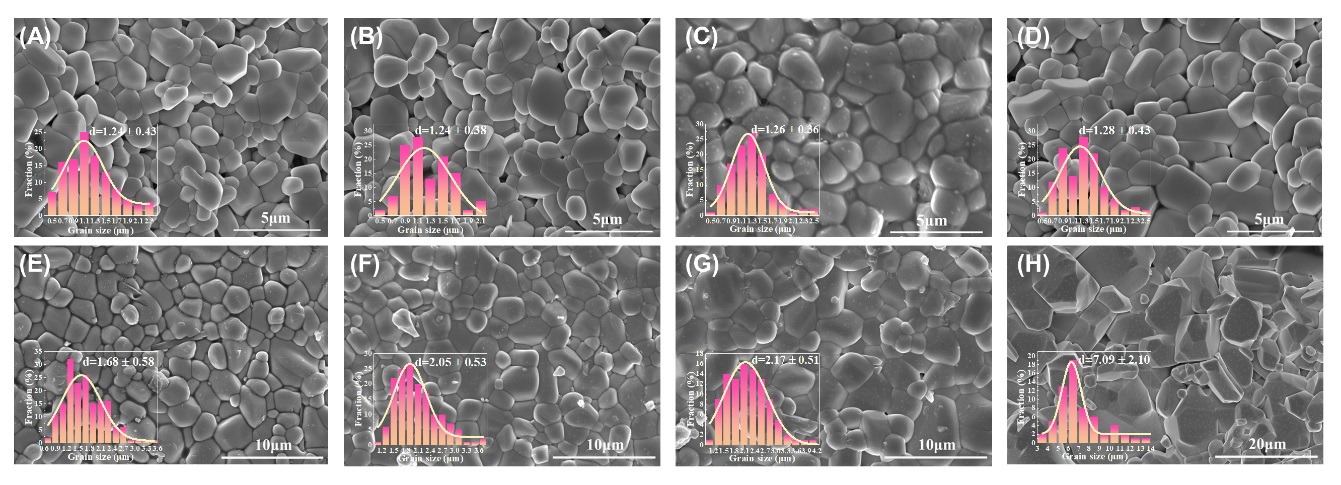

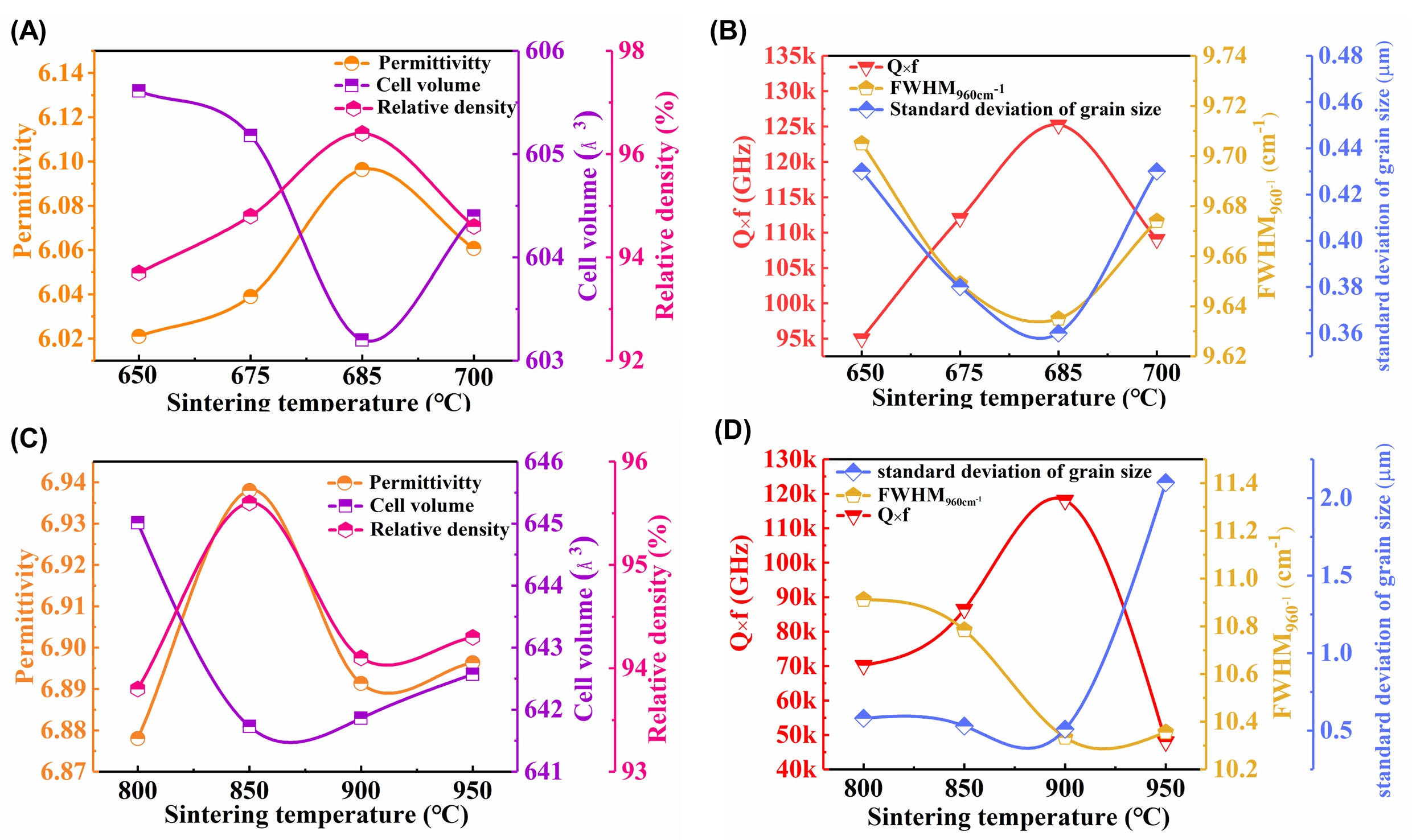

Scanning electron microscope (SEM) images of ceramic sample cross-sections vividly show that the ceramics densified during the sintering process, with a marked reduction in pore density as the sintering temperature increased. Meanwhile, at different sintering temperatures, the ceramics displayed distinct microstructures, such as grain size and uniformity. They meticulously discussed the influence of ceramic density, microstructure, and other factors on microwave dielectric performance, providing a thorough analysis of the performance-structure relationship.

Figure 2. The microstructures and grain size distribution of β-MgMo2O7 ceramics sintered at (A) 650℃; (B) 675℃; (C) 685℃; (D) 700℃; and MgMoO4 ceramics sintered at (E) 800℃; (F) 850℃; (G) 900℃; (H) 950℃

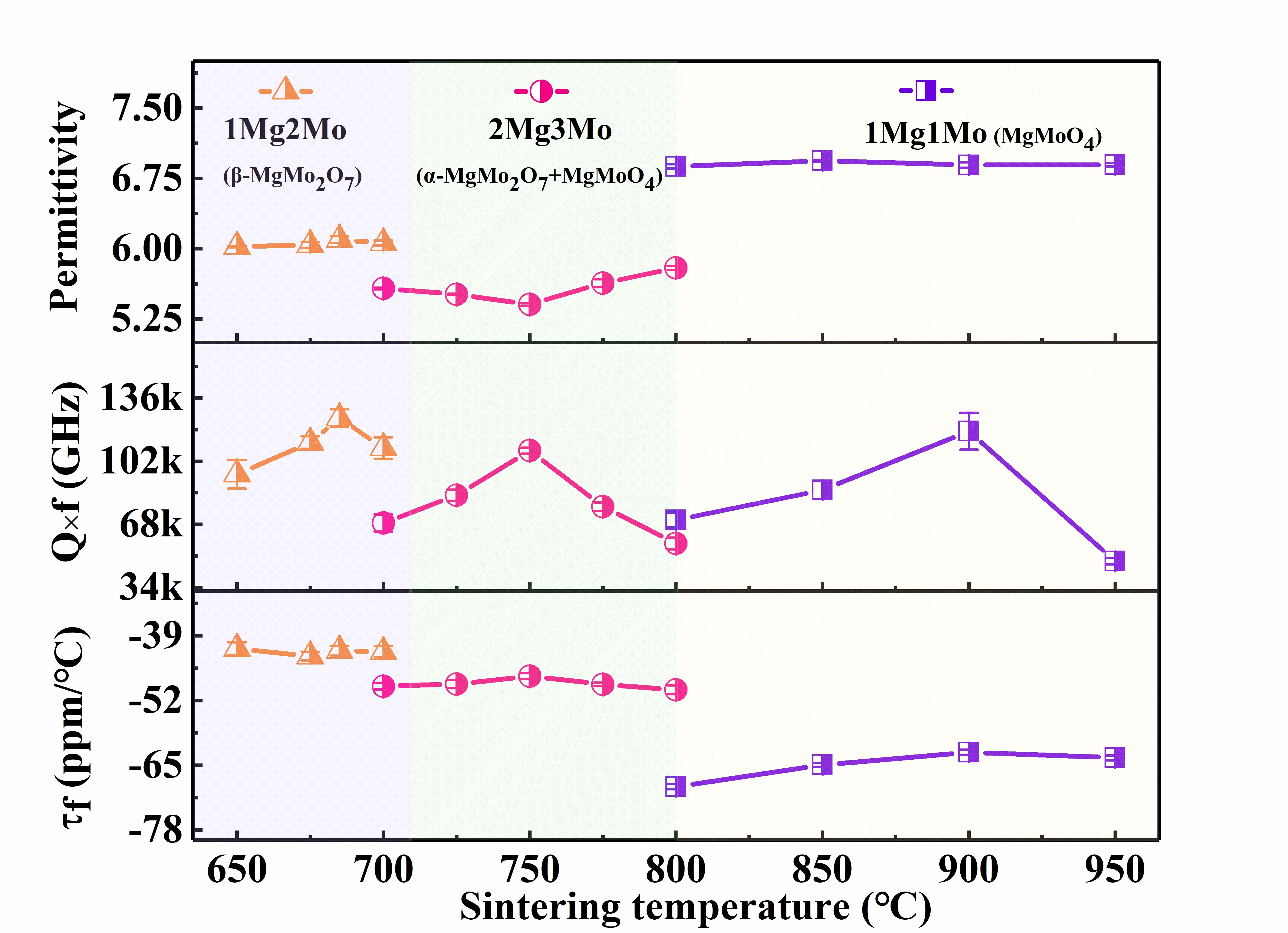

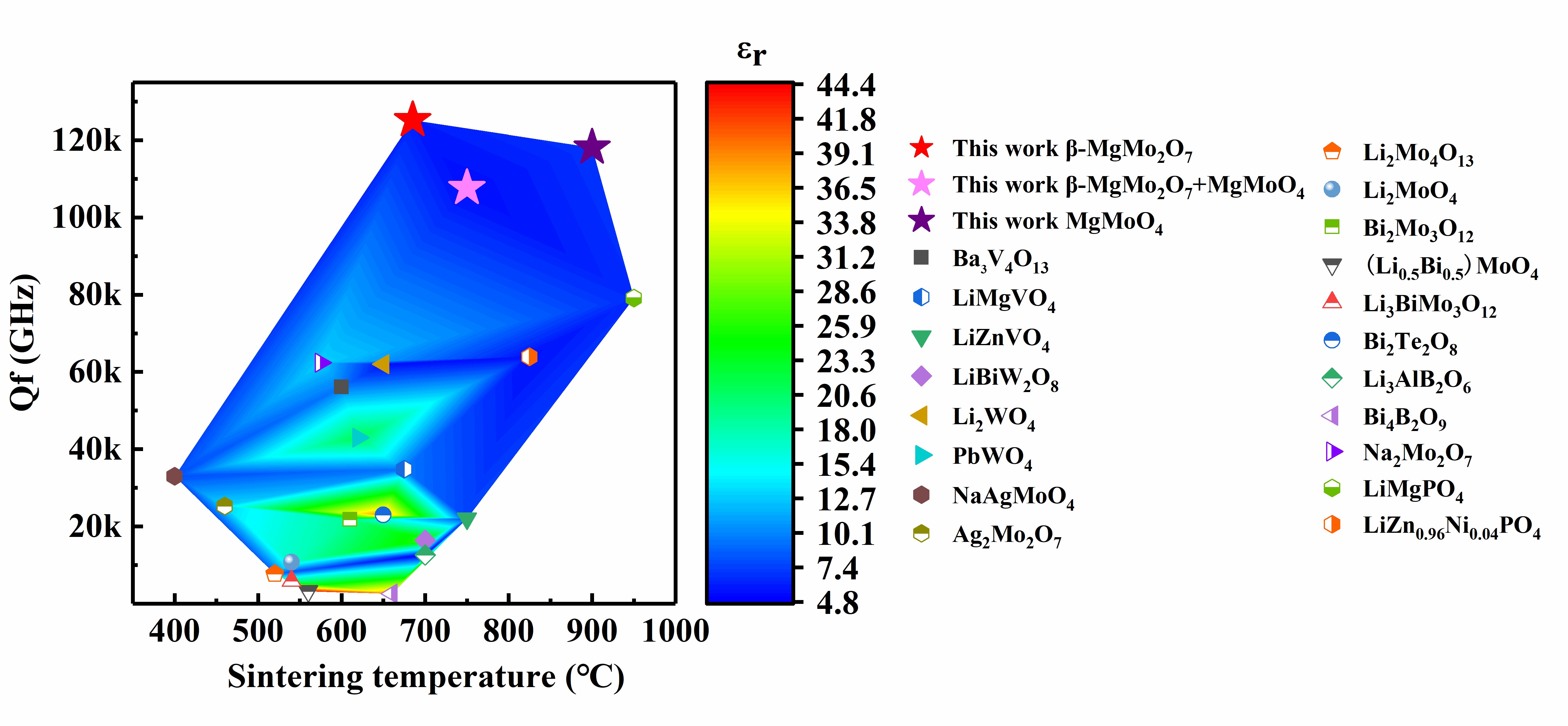

The ceramics from the MgO-MoO3 system as reported in this paper exhibit exceptional microwave dielectric properties. Specifically, β-MgMo2O7 can achieve densification at a low sintering temperature of 685°C, with a Qf value of 125,230 GHz, εr value of 6.09, and τf value of -42 ppm/°C. When sintered at 900°C, MgMoO4 demonstrates a Qf value of 118,110 GHz, εr value of 6.89, and τf value of -62.4 ppm/°C. The composite ceramics of MgMo2O7-MgMoO4, sintered at 750°C, exhibit a Qf value of 107,650 GHz, εr value of 5.41, and τf value of -47.1 ppm/°C.

Compared to other typical low-temperature sintered microwave dielectric ceramics, the ceramics from the MgO-MoO3 system hold a significant advantage in terms of sintering temperature and microwave performance. The low sintering temperatures of β-MgMo2O7, MgMoO4, and MgMo2O7-MgMoO4 ceramics are highly advantageous for practical applications, as they allow for the manufacturing of electronic devices at lower temperatures, maximizing energy efficiency, improving manufacturing efficiency, and satisfying the requirements of LTCC technology. Moreover, these ceramics display outstanding microwave properties, characterized by extraordinarily high Qf values, signifying minimal dielectric loss and low dielectric constants. These properties are of paramount importance for the development of electronic devices such as antennas.

Figure 3. Microwave dielectric properties of MgO-MoO3 system ceramics

Figure 4. Factors influencing the microwave dielectric properties of β-MgMo2O7 (A, B) and MgMoO4 (C, D) ceramics

Figure 5. Comparative chart of optimal sintering temperatures and microwave dielectric properties of ceramics prepared in this study as reported in the literature

Microstrip patch antennas, due to their cost-effectiveness, small size, and ease of manufacture, are widely used in wireless communication. The researchers utilized β-MgMo2O7 and MgMoO4 ceramics as substrate materials to design and fabricate two types of microstrip patch antennas. Both antennas exhibited excellent performance, with S11 values below -30 dB and gains exceeding 6 dB at 5.8 GHz. The low-temperature sintered microwave dielectric ceramics developed in this study based on the MgO-MoO3 system hold the potential to meet the urgent demand for low dielectric constant and low-loss substrate materials in high-frequency wireless communication technology.

Figure 6. Simulation and testing performance of microstrip patch antennas with β-MgMo2O7 (B-H) and MgMoO4 (C-I)

Xiaoyu Li, a doctoral student from the Department of MSE at SUSTech, is the first author of this paper. Professor Hong Wang is the corresponding author. Other members of Professor Hong Wang’s research team, including Hongye Wang, Xinwei Xu, Naichao Chen, Biao Guo, Jin Cheng, and Xianqiang Chen, made significant contributions to this research, with SUSTech being the primary affiliation on the paper.

This research was supported by the Guangdong Provincial Department of Science and Technology and the Shenzhen Municipal Science and Technology Innovation Committee.

Paper link: http://doi.org/10.1111/jace.19500

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By