Sweat, as an attractive biofluid containing numerous molecular biomarkers, including electrolytes, metabolites, amino acids, and hormones, can be analyzed using a variety of bioelectronics. Textile bioelectronics that allows comfortable epidermal contact holds great promise in noninvasive biosensing. However, their applications are limited mainly due to the large intrinsic electrical resistance and low compatibility for electronics integration.

Polymer-assisted metal deposition (PAMD), a low-cost and high-throughput technique, has become a practical chemical process for fabricating conductive textiles due to its superior stability and conductivity (metallic cloth fabricated with PAMD shows typical conductivity with the same order of magnitude as the bulk metal). The remarkable flexibility and mechanical stability of conductive patterns fabricated by PAMD provided a new perspective for textile sensing bioelectronics.

Assistant Professor Yuanjing Lin’s research group from the School of Microelectronics at the Southern University of Science and Technology (SUSTech) and Chair Professor Zijian Zheng’s research group from the Department of Applied Biology and Chemical Technology at the Hong Kong Polytechnic University (PolyU) have recently made advances in the field of textile bioelectronic for wireless epidermal biosensing.

Their research work, entitled “A Monolithically Integrated in-textile Wristband for Wireless Epidermal Biosensing”, has been published in Science Advances, a top multidisciplinary journal publishing impactful research papers and reviews in any area of science, in both disciplinary-specific and broad, interdisciplinary areas.

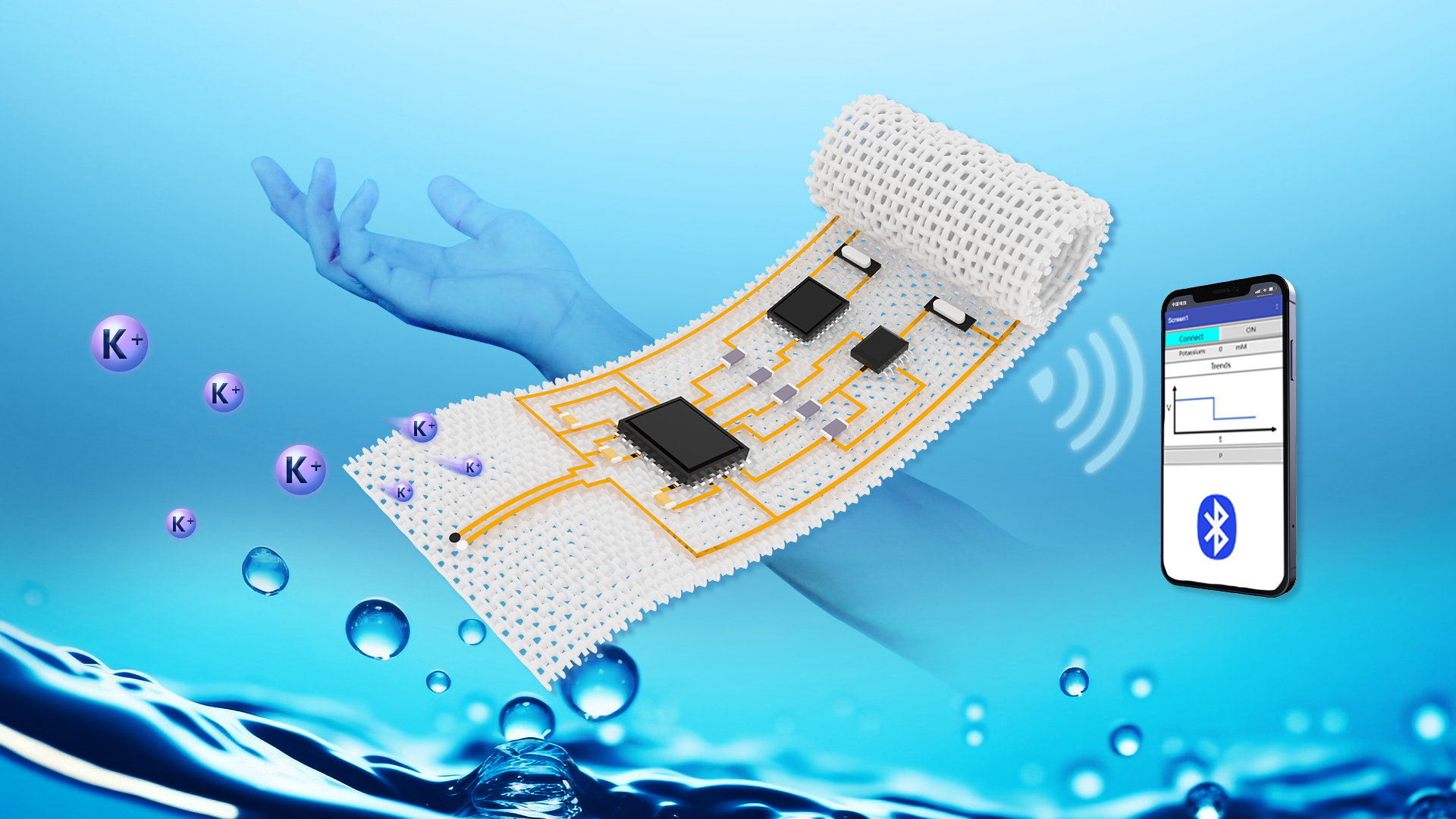

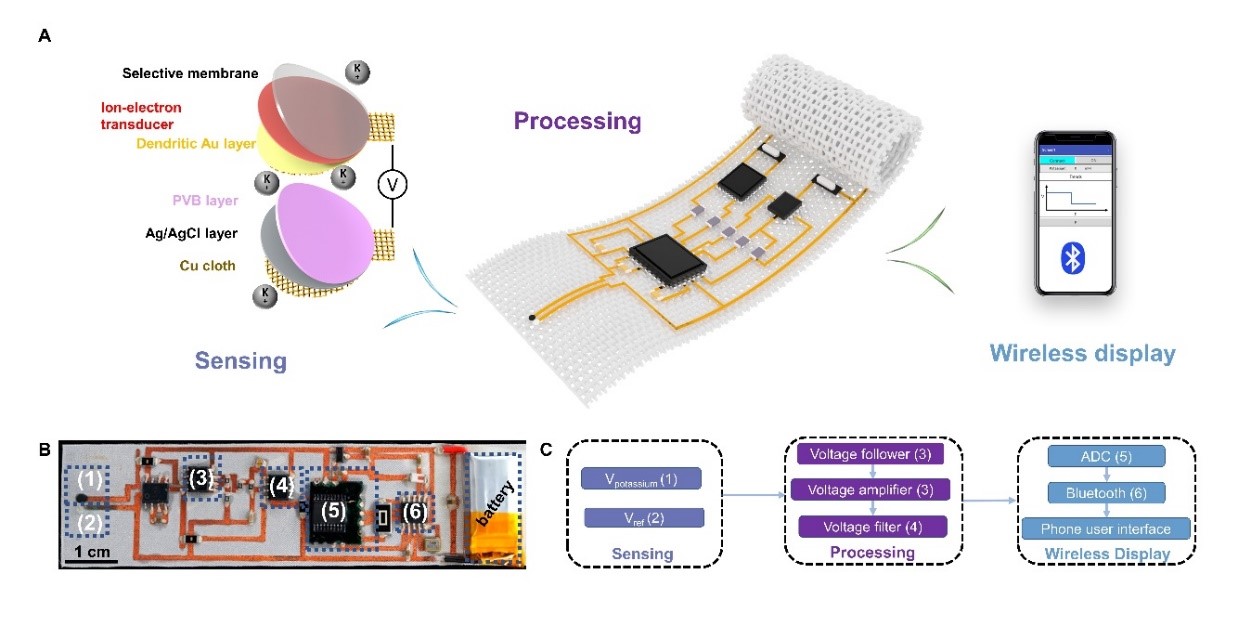

The researchers report for the first time an integrated wristband that consists of multifunctional modules in a single piece of textile to realize wireless epidermal biosensing (Fig. 1). Double-sided photolithography and PAMD allows the precise reproduction of well-designed patterns by imitating the traditional Printed Circuit Board (PCB) manufacturing process.

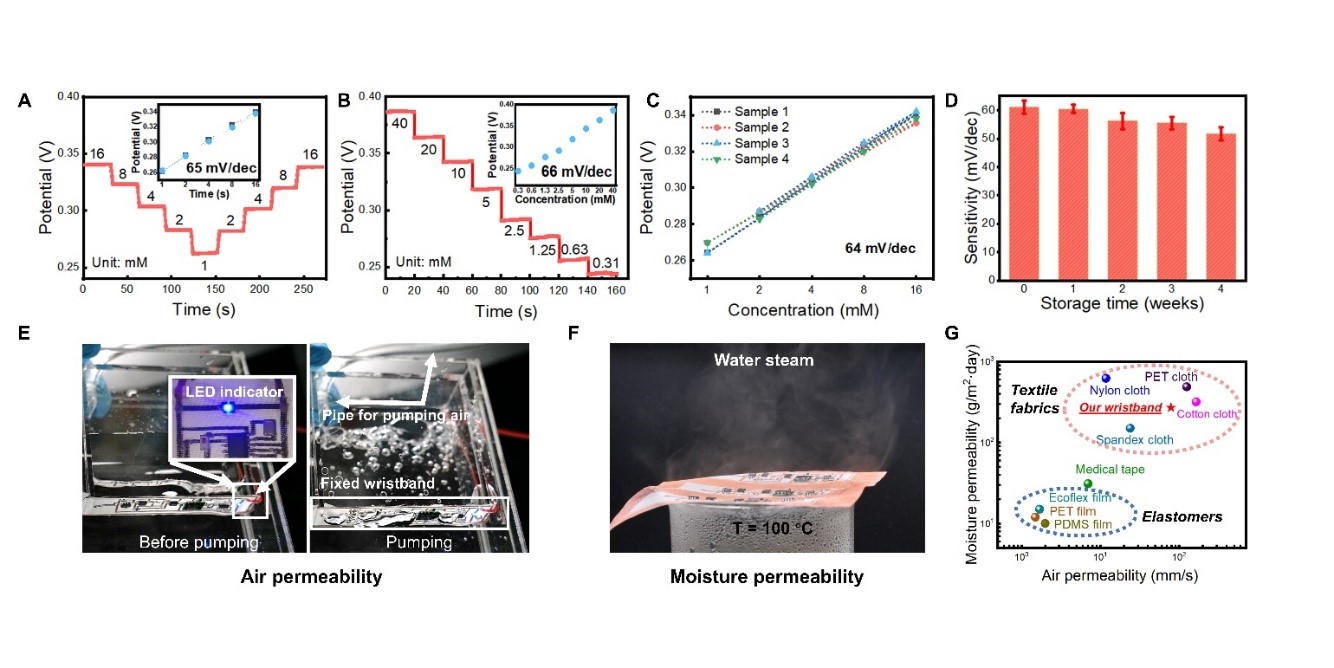

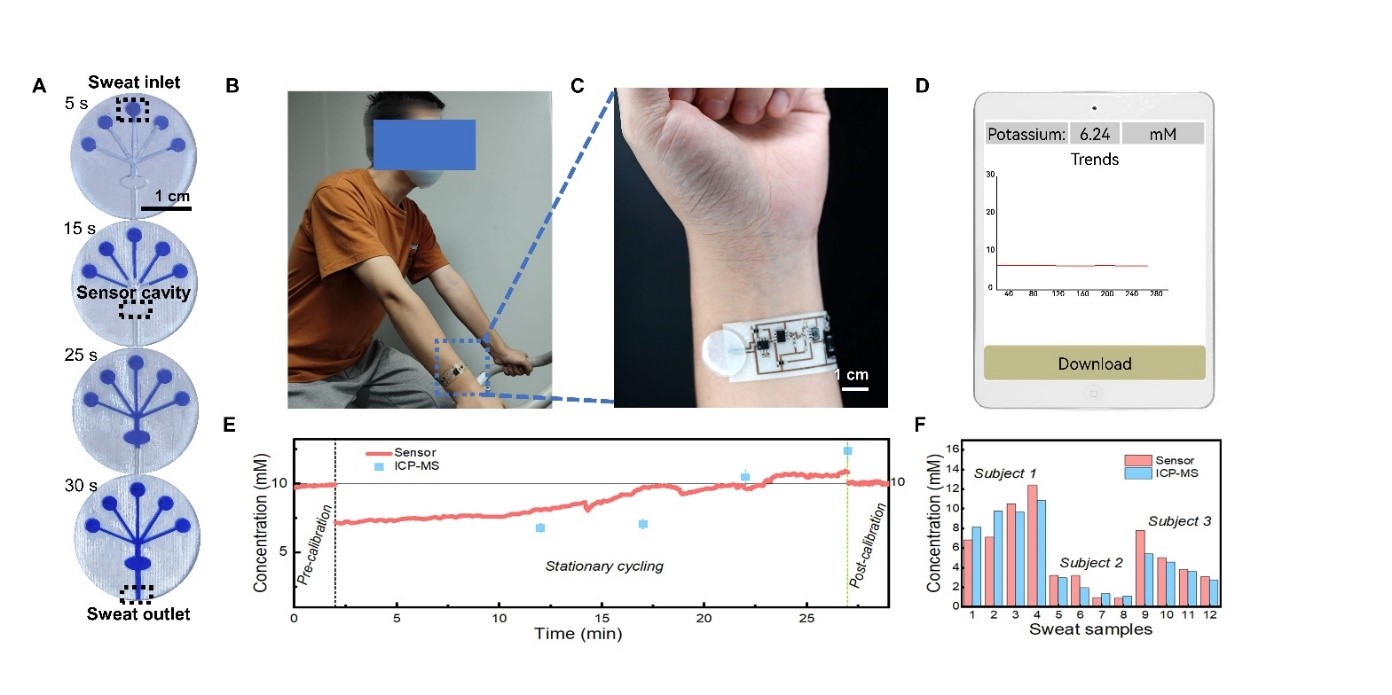

The in-textile metallic patterning and reliable interconnect encapsulation contribute to the excellent electrical conductivity, mechanical robustness, and waterproofness that are competitive with conventional flexible devices. Moreover, the well-maintained porous textile architectures deliver air permeability of 79 mm s-1 and moisture permeability of 270 g m-2 day-1, which are more than one order of magnitude higher than medical tapes, thus ensuring superior wearing comfort (Fig. 2). The integrated in-textile wristband performed continuous sweat potassium monitoring in the range of 0.3-40 mM with long-term stability, demonstrating its great potential for wearable fitness monitoring and point-of-care testing (Fig. 3).

Figure 1. (A) Schematic of textile wristband for wireless sweat K+ analysis. (B) Photograph and schematic illustration of the flexible patch (2.5×9 cm). (C) The logical flow of the systematic design. (Components 1 and 2 are the working electrode and reference electrode, respectively, for electrochemical sweat sensing. Components 3 and 4 are the voltage follower, amplifier, and filter for data processing. Components 5 and 6 are the analog-to-digital converter (ADC) and Bluetooth module, respectively, for wireless signal display).

Figure 2. (A) Repeatability of OCP responses of K+ sensor. The inset of (A) shows the corresponding calibration plots of the sensor. (B) The limit of detection (LOD) of the in-textile sensor. The inset of (B) shows the corresponding sensitivity. (C) Reproducibility. (D) Long-term stability. The error bars represent the RSD of the evaluated sensitivity from three samples. (E) Photographs for air permeability test on bare PET cloth and waterproof sensing system with illuminated LED indicator. (F) Water vapor test of the as-fabricated biosensing wristband. (G) Air/moisture permeability of the as-fabricated biosensing wristband and the comparison with those of pure elastomers and textile fabrics. Elastomers: PET, PDMS, and Ecoflex film. Textile fabrics: PET, nylon, cotton, and Spandex cloth. Fig. 4. Performance evaluation of as-fabricated in-textile K+ sensor.

Figure 3. (A) Verification for the microfluidic channel for artificial sweat collection in a flow velocity of 10 μL/min. (B) Photograph showing in situ sweat monitoring with the in-textile wristband during exercising. (C) Photograph of wristband mounted on the arm. (D) Custom-designed mobile application for real-time and continuous K+ sensing. (E) Representative real-time sweat potassium levels during stationary cycling. (F) Comparison of the extracted K+ concentrations by the sweat analysis wristband and ICP-MS.

Xiaohao Ma, a joint Ph.D. student of SUSTech and PolyU, is the first author of this paper. Chair Professor Zijian Zheng and Assistant Professor Yuanjing Lin are the co-corresponding authors.

This work was supported by the National Natural Science Foundation of China (NSFC), Fundamental and Applied Research Grant of Guangdong Province, Shenzhen Stable Support Plan Program for Higher Education Institutions Research Program, RGC Senior Research Fellow Scheme, and PolyU.

Paper link: https://www.science.org/doi/pdf/10.1126/sciadv.adj2763

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By