Friction and wear are pivotal factors that impose constraints on the performance and lifespan of mechanical components in relative motion. Achieving reduced friction and wear in metallic components under dry sliding conditions has long been a central pursuit for researchers in the fields of materials science and tribology.

In most cases, metals and alloys exhibit elevated coefficients of friction under dry sliding conditions, typically ranging between 0.6 and 1.2. According to traditional wear theories, the wear resistance of metal materials is closely related to their hardness. Refining grains to the nanoscale can enhance the wear resistance of alloys. However, the strain-hardening capability of nanocrystalline alloys is limited. During sliding wear, it frequently triggers strain localization and plastic instability, resulting in surface roughening and microcrack formation, ultimately increasing friction and wear.

Associate Professor Fuzeng Ren’s research group from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently made important research progress in understanding the plastic deformation mechanism of single-phase alloys during sliding wear and provided new insights for designing self-adaptive, wear-resistant alloys.

Their research work, entitled “Significant reduction in friction and wear of an ultrafine-grained single-phase FeCoNi alloy through the formation of nanolaminated structure”, has been published in Acta Materialia, a top journal in the field of metallic materials.

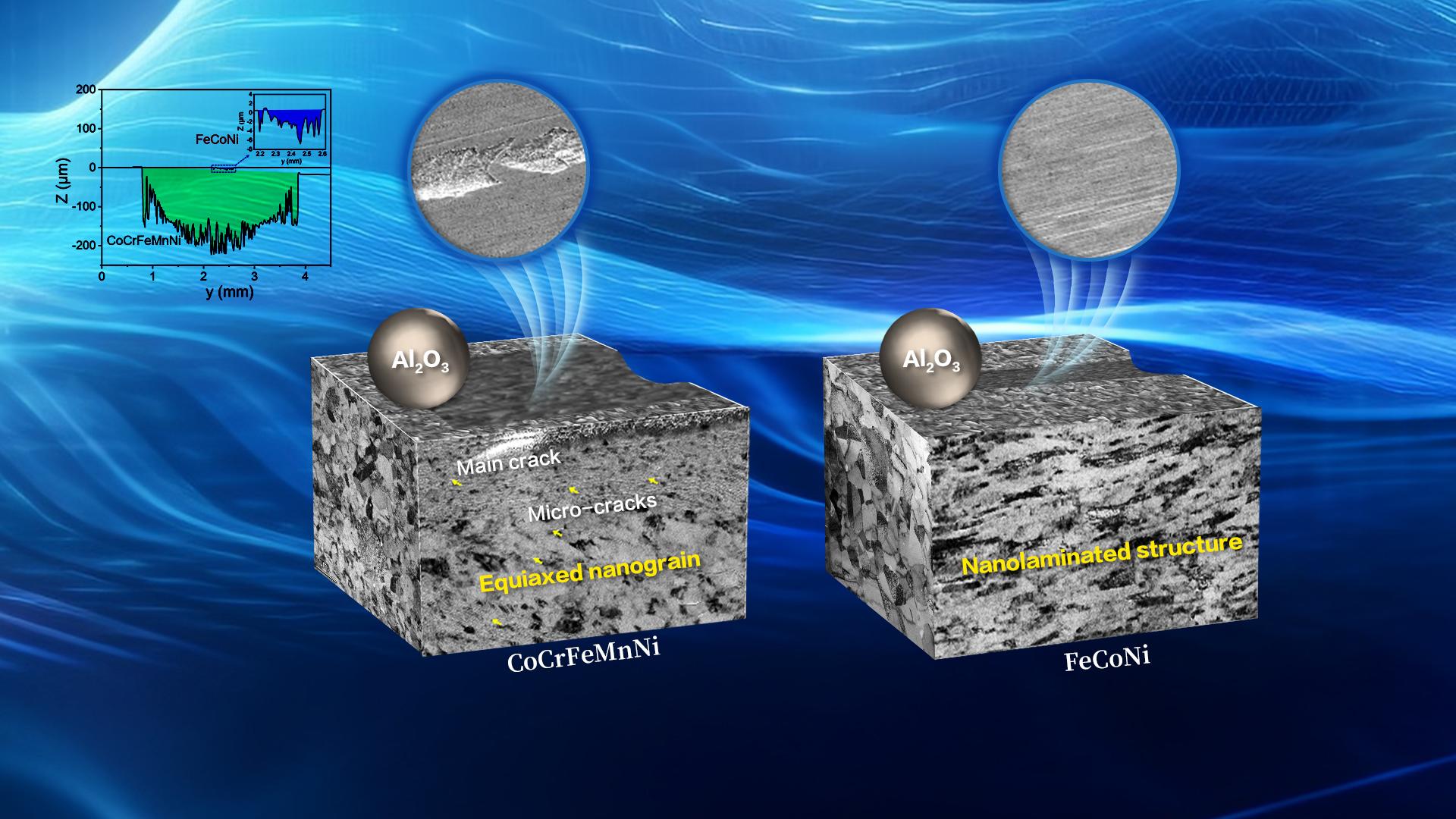

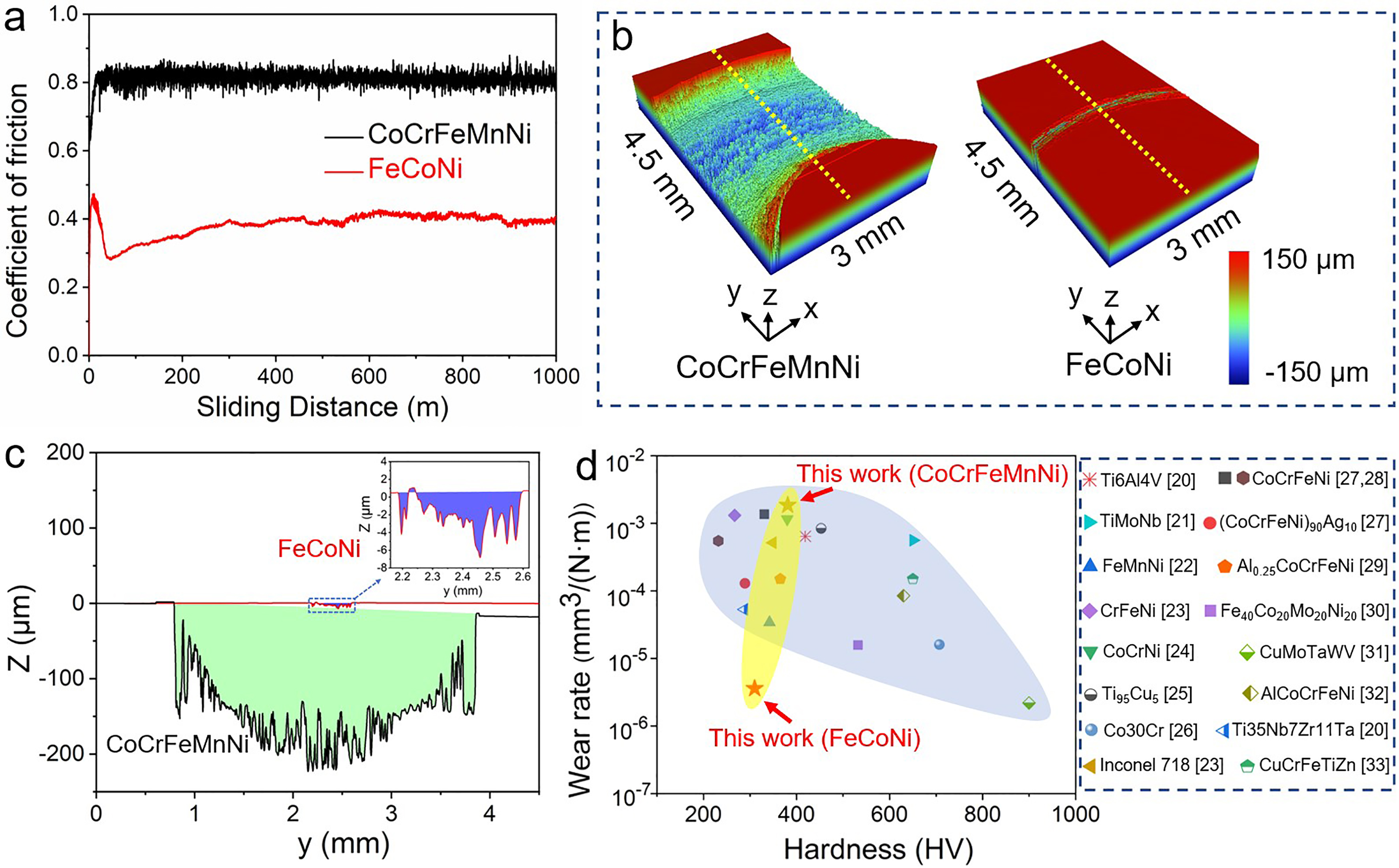

In this study, the researchers embarked on an investigation by selecting ultrafine-grained single-phase CoCrFeMnNi and FeCoNi with different stacking fault energies as our model systems to explore the fundamental formation mechanism of the subsurface gradient microstructures and their impact on tribological behavior. The results showed that despite having a similar initial microstructure and even a 20% lower hardness, the FeCoNi alloy exhibited a remarkable 52% reduction in coefficient of friction, and, more notably, a wear rate three orders of magnitude lower than that of CoCrFeMnNi (Figure 1).

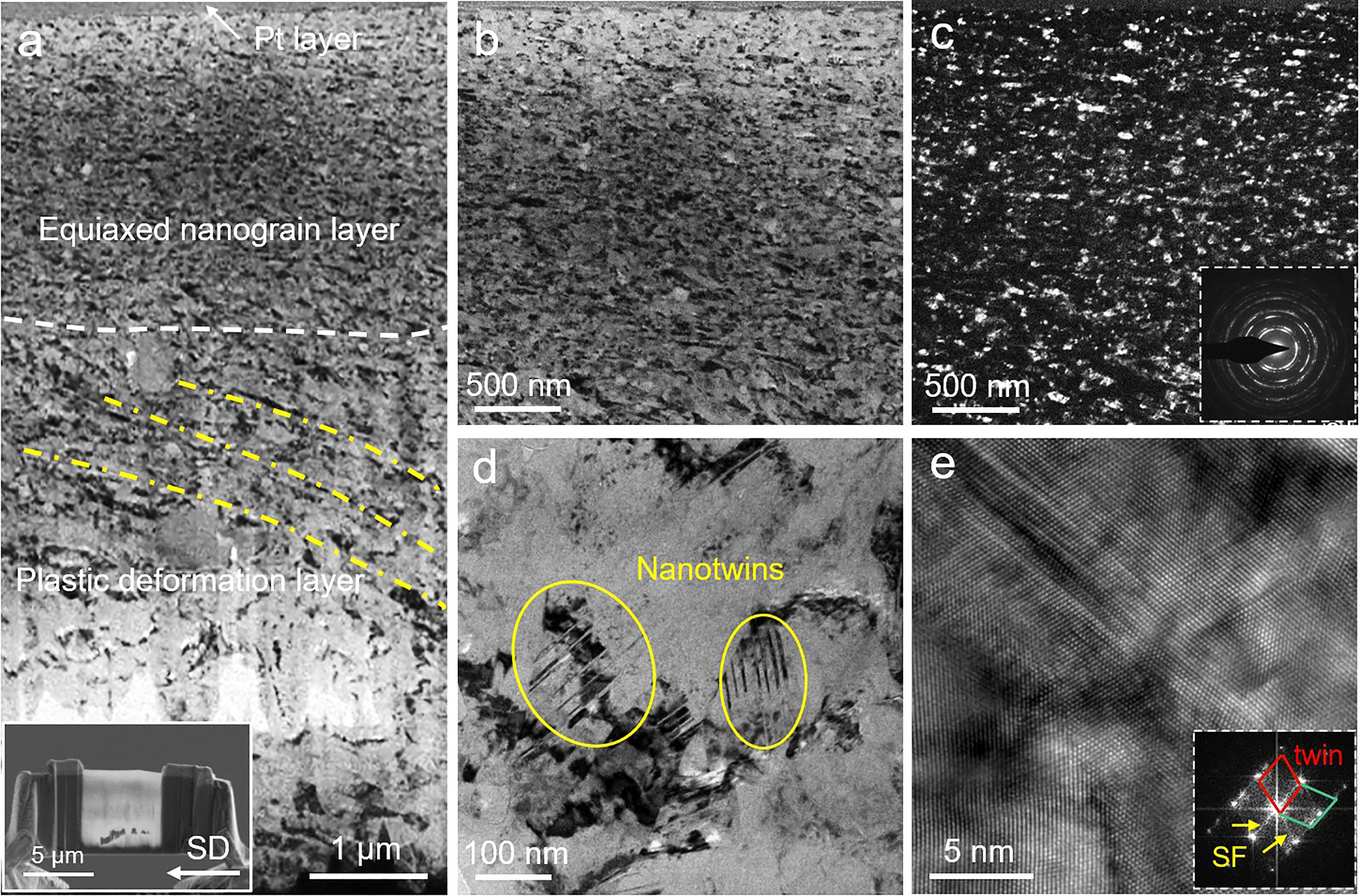

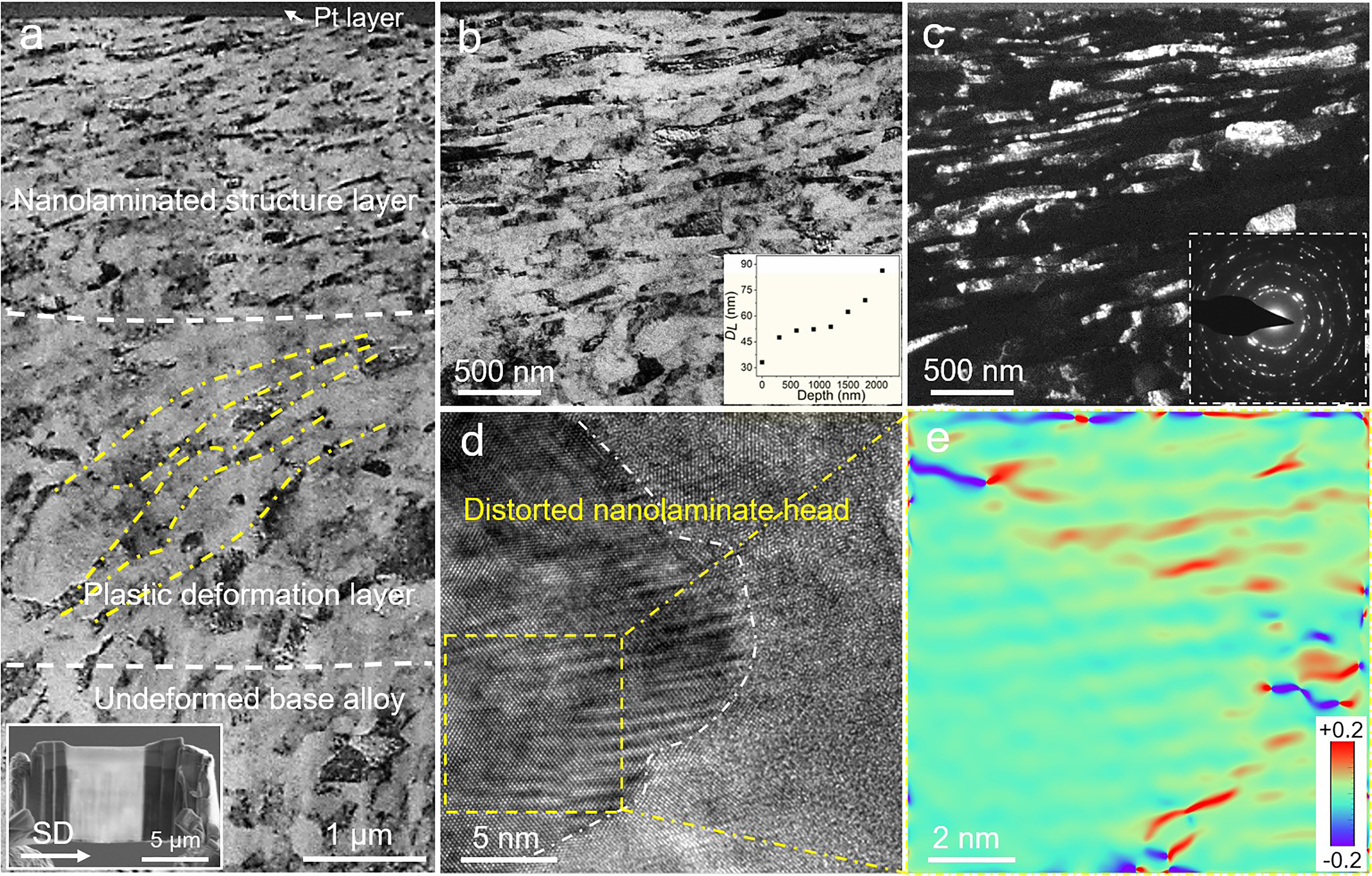

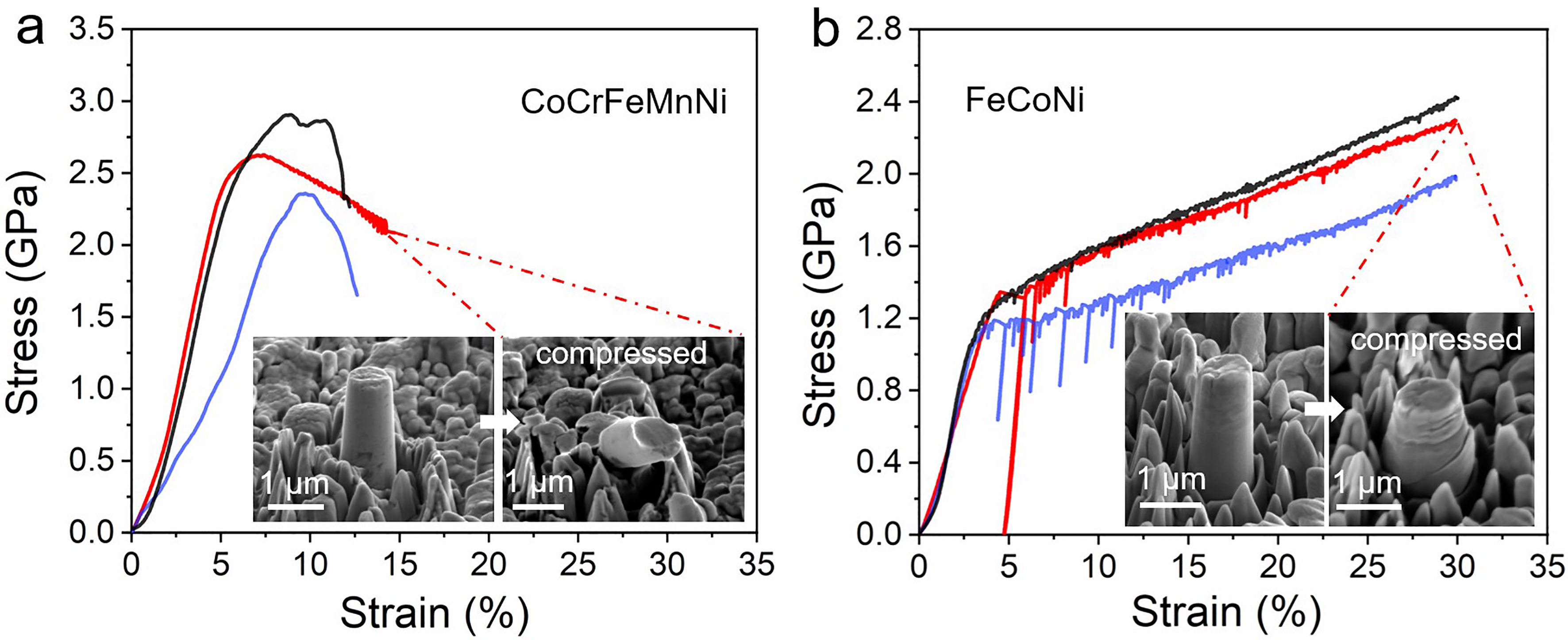

Microstructural analysis revealed that the substantial difference in the friction and wear behavior was attributed to the different subsurface deformation structures of the alloys during sliding wear. In the case of CoCrFeMnNi, the original ultrafine grains were gradually refined into equiaxed nanograins through nanotwin-assisted dynamic recrystallization (Figure 2). In contrast, plastic strain induced by sliding refined the microstructure of FeCoNi alloy into a nanolaminated structure (Figure 3). Micro-pillar compression test (Figure 4) showed that the nanolaminated structure formed in the FeCoNi alloy during sliding exhibited excellent plastic deformation and strain-hardening ability, promoting crack blunting and inhibiting crack propagation. However, the equiaxed nanograins layer formed in the CoCrFeMnNi alloy, despite its high compressive strength, exhibited catastrophic failure behavior after yielding, leading to the overall delamination of the nanograin layer during repetitive sliding.

Figure 1. (a) Coefficients of friction as a function of sliding distance for CoCrFeMnNi and FeCoNi MPEAs. (b) 3D surface profile of the wear tracks. (c) 2D cross-sectional depth profiles of the wear tracks. (d) Comparison of wear rates versus hardness for different alloys.

Figure 2. Sliding wear-induced cross-sectional subsurface microstructure of CoCrFeMnNi. (a) Bright-field TEM image with the inset showing the full view of the TEM lamella. (b) High-magnification bright-field TEM image of the equiaxed nanograin layer. (c) Dark-field TEM image. (d) High-magnification bright-field TEM image of the plastic deformation layer. (e) A high-resolution TEM image of the nanotwins.

Figure 3. Sliding wear-induced cross-sectional subsurface microstructure of FeCoNi. (a) Bright-field TEM image with the inset showing the full view of the TEM lamella. (b) High-magnification bright-field TEM image of the nanolaminated structure. (c) Dark-field TEM image. (d & e) High-resolution TEM image of the nanolaminate head and its corresponding GPA strain map.

Figure 4. Mechanical behavior of the sliding wear-induced equiaxed nanograin layer in CoCrFeMnNi (a) and nanolaminated structure layer in FeCoNi (b).

Ph.D. students Lu Yang and Chengxia Wei from the Department of Materials Science and Engineering at SUSTech are the co-first authors of this paper. Associate Professor Fuzeng Ren is the corresponding author, and SUSTech is the first affiliated unit.

This research was supported by the National Natural Science Foundation of China (NSFC).

Paper link: https://doi.org/10.1016/j.actamat.2023.119526

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By