Lithium-ion batteries are the energy storage devices in many applications, such as smartphones and electric vehicles. In practical scenarios, batteries may operate at extreme rates and/or temperatures, leading to early degradation and safety concerns. Understanding real-world battery degradation is critical to improving the life, safety, and reliability of batteries, relying on the development of advanced battery sensing approaches. Various techniques using different signals have been reported in the literature, e.g., temperature, pressure, electrochemistry, acoustics, and optics. However, most existing methods are complicated, intrusive, and/or qualitative, and thus inappropriate for the application in commercial batteries and practical scenarios.

Led by Assistant Professor Yuqiang Zeng from the School of Microelectronics at the Southern University of Science and Technology (SUSTech), researchers have reported a new battery sensing technique that opens the door to the quantitative evaluation of battery degradation using simple non-embedded thermal-wave sensors.

Their work, entitled “Nonintrusive thermal-wave sensor for operando quantification of degradation in commercial batteries”, has been published in Nature Communications.

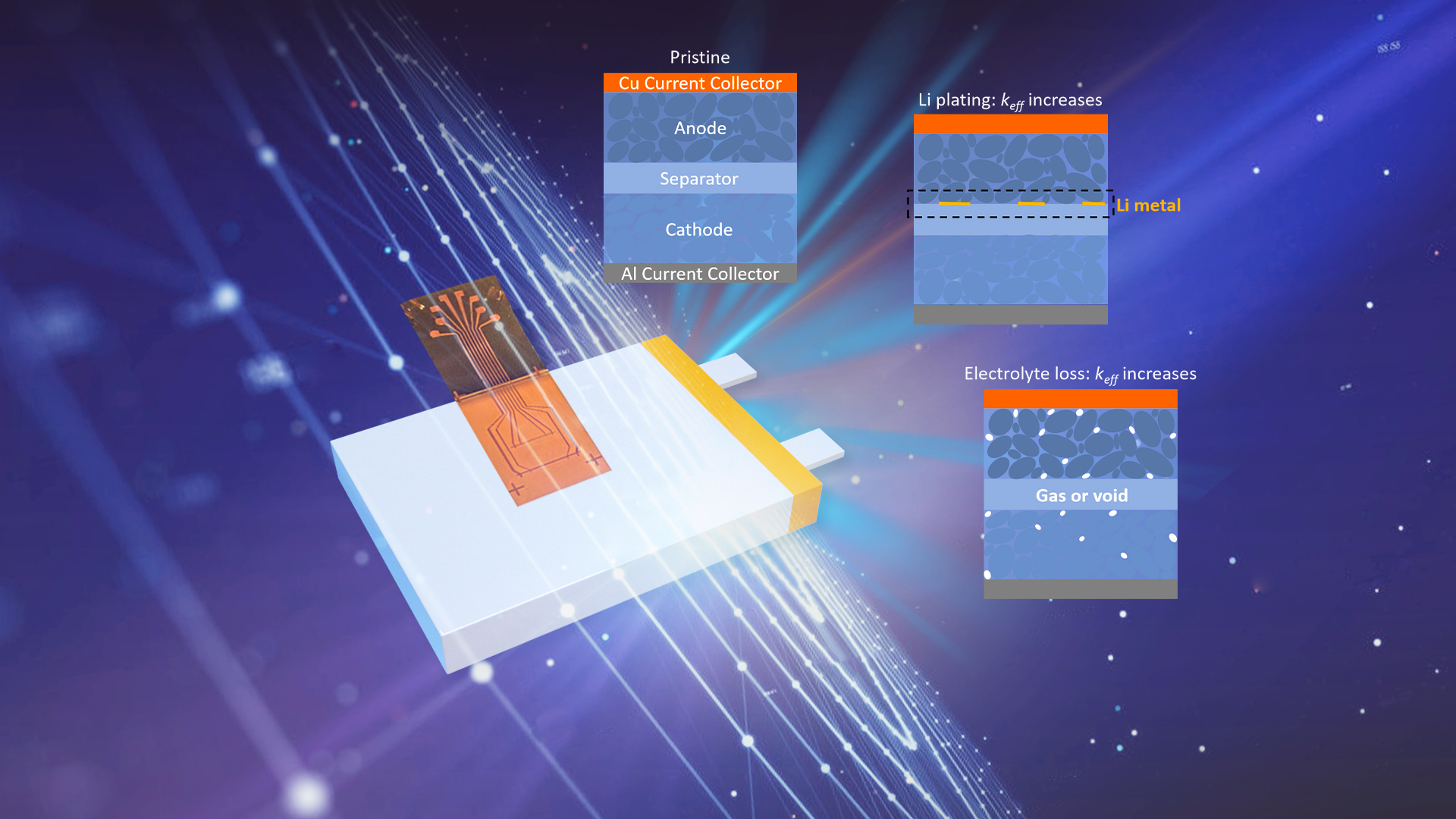

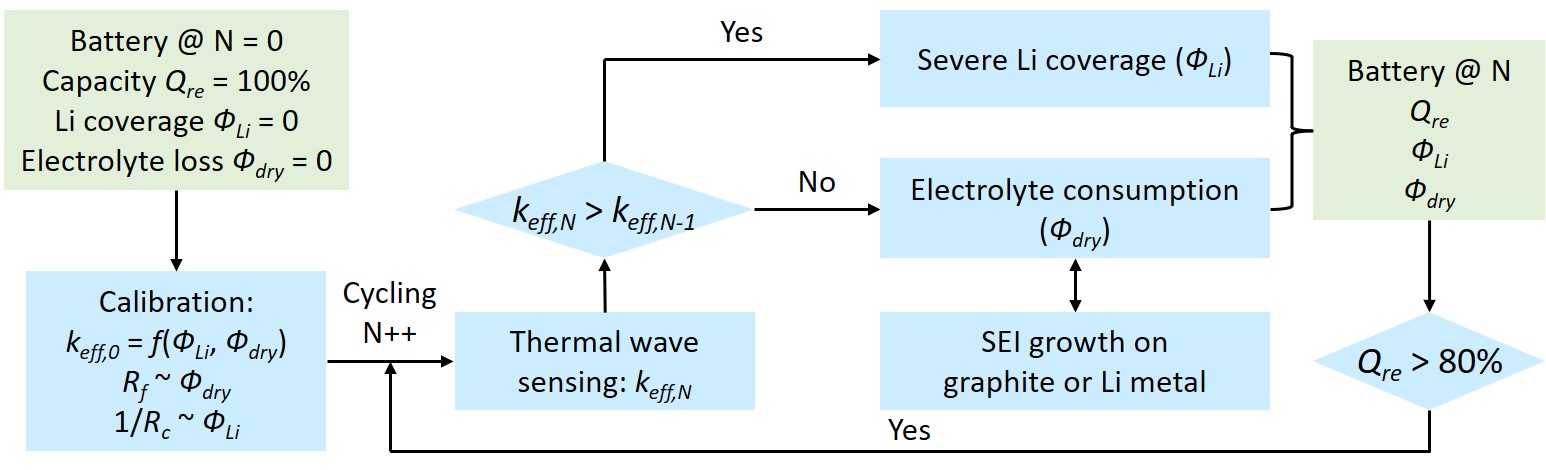

Figure 1. Concept of non-embedded thermal-wave sensors for monitoring battery degradation

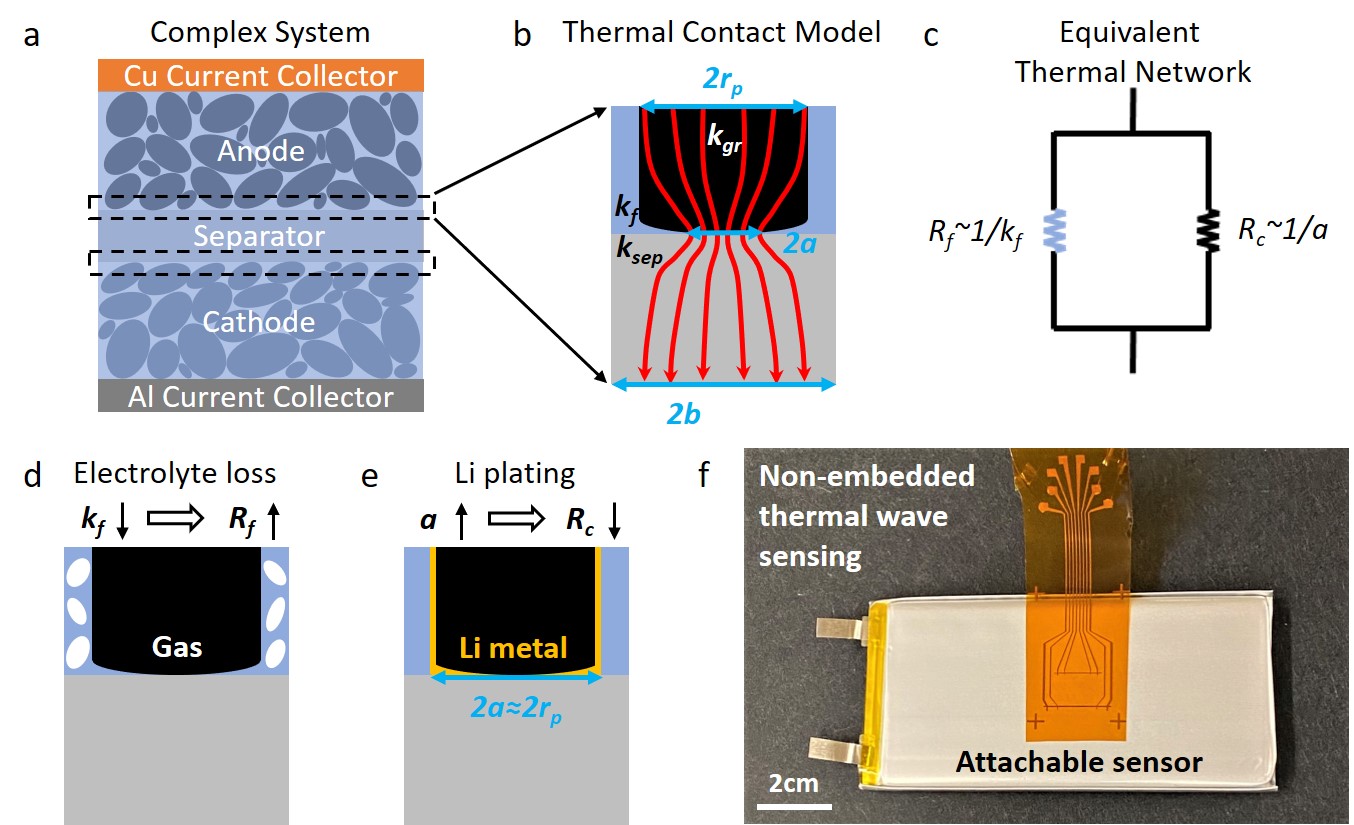

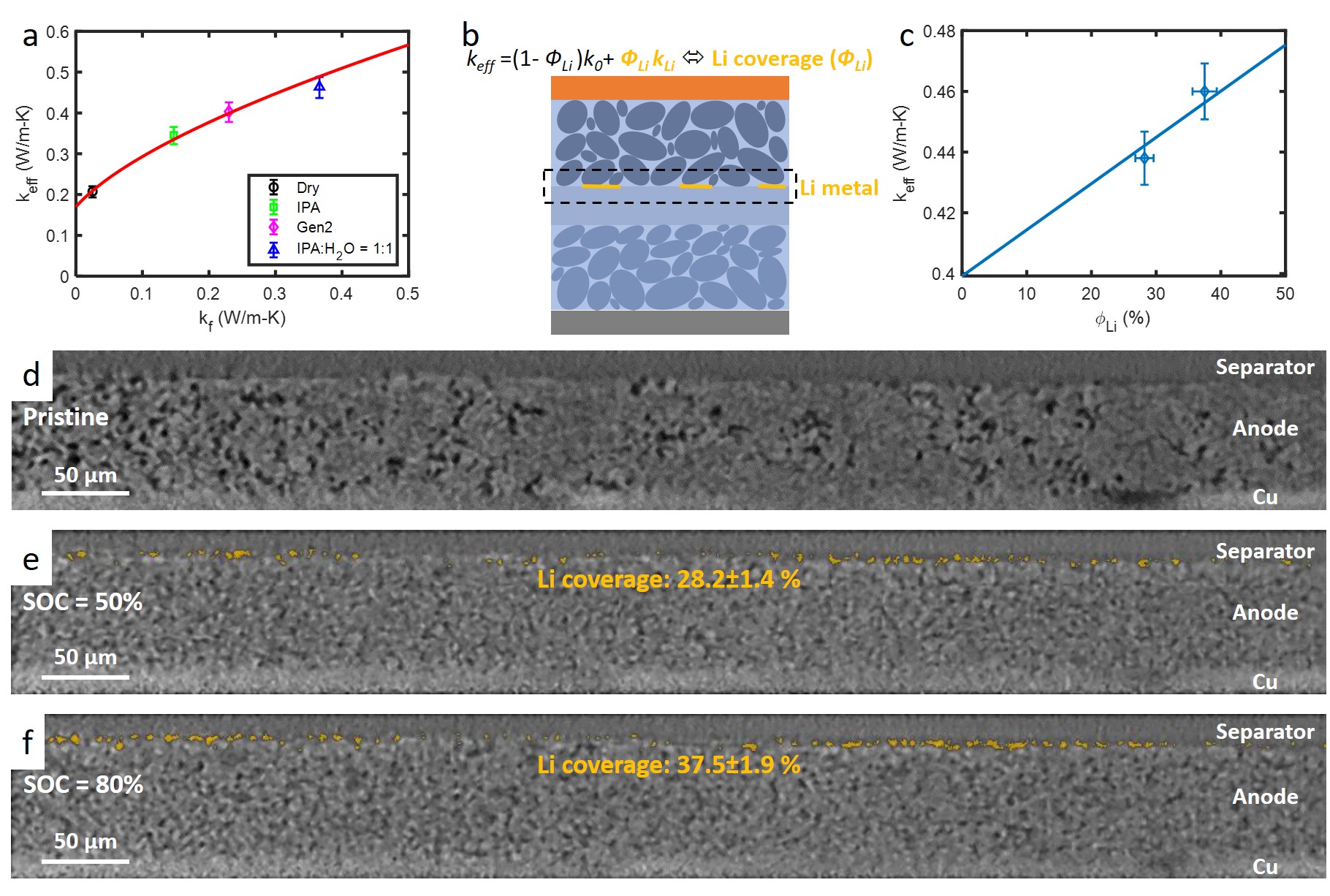

Essentially, battery sensing relies on the type of signals used for detection. In this study, the researchers leverage the strong dependence of battery thermal conductivity (keff) on battery-structure changes. Based on their model (Fig. 1), the two main battery degradation mechanisms, lithium plating and solid-electrolyte interphase (SEI) growth, have an opposite effect on the battery’s thermal conductivity. The plated lithium reduces the thermal contact resistance between the separator and electrode and thus increases the keff, while the consumption of electrolyte due to SEI growth reduces the keff. The accuracy of this model was validated with a series of calibration experiments using different fluids and X-ray tomography (Fig. 2).

Figure 2. Calibration of effective battery thermal conductivity vs degradation sources

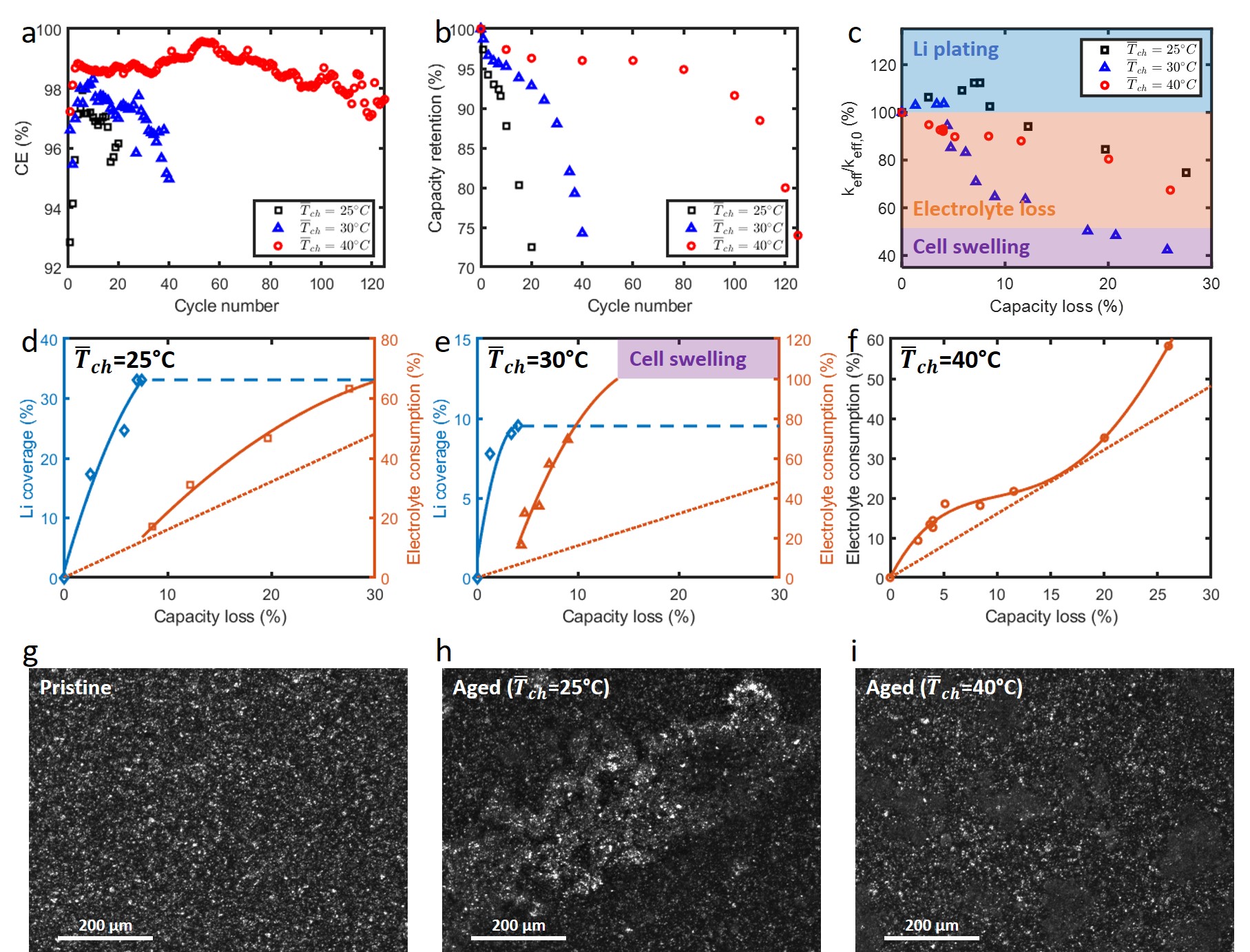

With the calibrated relationship, the researchers developed a measurement scheme for nonintrusive quantitative assessment of battery degradation (Fig. 3), which can be done using an attachable thermal-wave sensor. As a proof of concept, the evolution of battery degradation during fast charging was monitored using this scheme (Fig. 4). They quantitatively distinguished the amount of lithium plating and electrolyte consumption associated with the side reactions on the graphite anode and deposited lithium, as verified using post-mortem characterizations. In summary, the developed approach is simple, non-embedded, and quantitative, which makes it useful in monitoring the degradation in commercial batteries.

Figure 3. Process flow for the data collection and analysis

Figure 4. Quantifying battery degradation during fast charging as a proof of concept

Assistant Professor Yuqiang Zeng is the first author of this paper, and the School of Microelectronics at SUSTech is the first affiliated unit.

Paper link: https://www.nature.com/articles/s41467-023-43808-9

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo BySchool of Microelectronics