Dielectric capacitors are one of the most used electronic components in electronic equipment. Among the many types of capacitor components, dielectric polymer film capacitors comprise ∼50 percent of the global high-voltage capacitor market because polymer dielectrics possess a series of intrinsic advantages, including extremely high breakdown strength, wide frequency range, mechanical flexibility, robust charging–discharging cyclability, and good self-healing.

In recent years, with the development of power systems and pulse power equipment to integration and miniaturization, polymer film capacitors have been driven to the rapid development of high voltage, high temperature, long life, large current, and small volume as product characteristics. Therefore, developing dielectric polymers with high working temperatures (≥150 ℃) and large energy storage densities is critical.

Chair Professor Hong Wang’s research team from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently made a breakthrough in the field of all-organic high-temperature dielectric energy storage materials.

Their work, entitled “Scalable Polyimide Copolymer with Ultrahigh High-Temperature Capacitive Performance Enabled by Modular Molecular Design”, has been published in the academic journal Advanced Energy Materials.

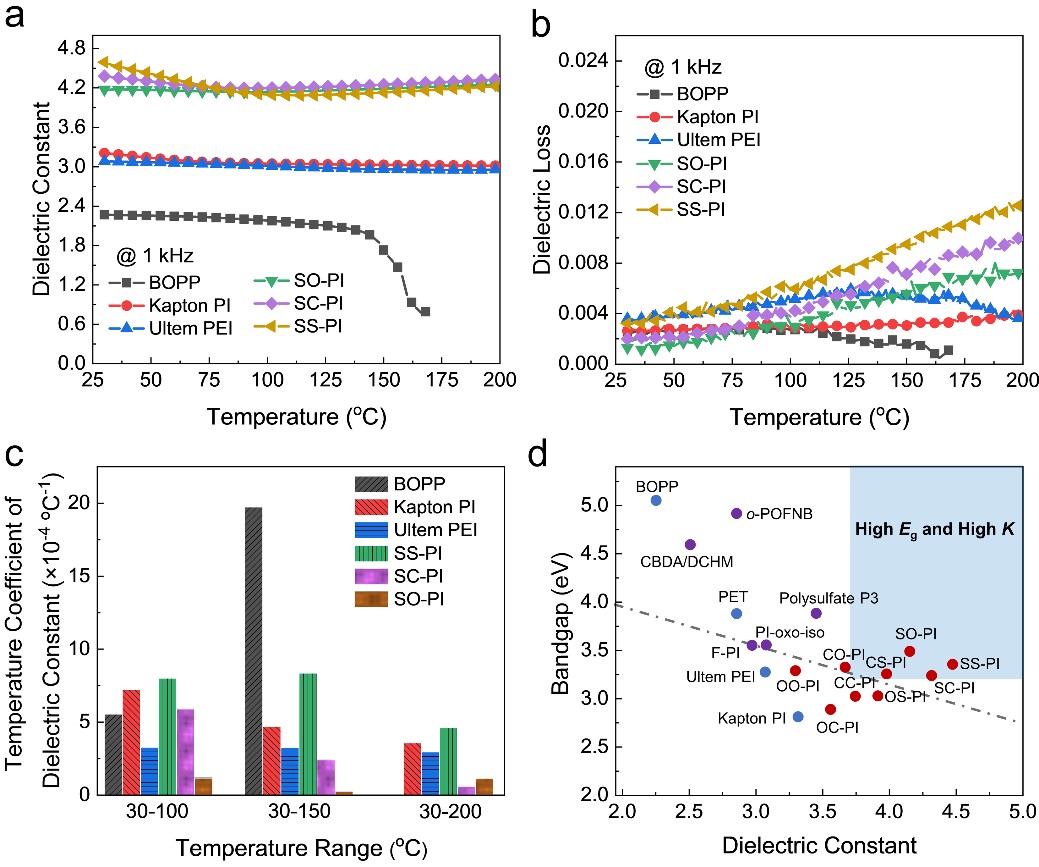

A large permittivity (εr) and a high breakdown strength (Eb) together contribute to a high energy density (Ue), which is beneficial for the miniaturization and lightweight of the electric power device. Unfortunately, traditional polymers exhibit largely reduced high-temperature energy storage performance, as very few polymers simultaneously possess high εr, high glass transition temperature (Tg), and wide bandgap (Eg), severely limiting their applications towards high-temperature scenarios, as shown in Figure 1a.

Figure 1. Schematic of the design criteria and mutual constraints for high-energy-density energy storage at high temperatures. Synthesis route and screening of aromatic polyimide-derived polymer dielectrics.

To address this problem, Professor Wang’s team developed a molecular engineering strategy to break the long-standing paradox correlation in εr, Tg, and Eg of polymer dielectrics (Figure 1b). Firstly, they utilize a series of commercial monomers containing polar groups (-O-, -C(=O)-, and -SO2-) to modulate the dielectric properties Tg and Eg of polyimide (PI) films. The -SO2– group and flexible -O- decouple the orientation of dipoles with the segmental motion of backbones, thereby minimizing polarization relaxation loss while increasing permittivity and bandgap. Among the synthesized PI films, SO-PI film simultaneously exhibits a high εr of 4.2 (RT, 1 kHz), large Eg of 3.4 eV, and high Tg of 311.2 oC. Moreover, compared to SS-PI and SC-PI, SO-PI film has lower dielectric loss and weaker frequency and/or temperature dependence of the dielectric properties.

Figure 2. Dielectric properties of SO-PI, SC-PI, and SS-PI film.

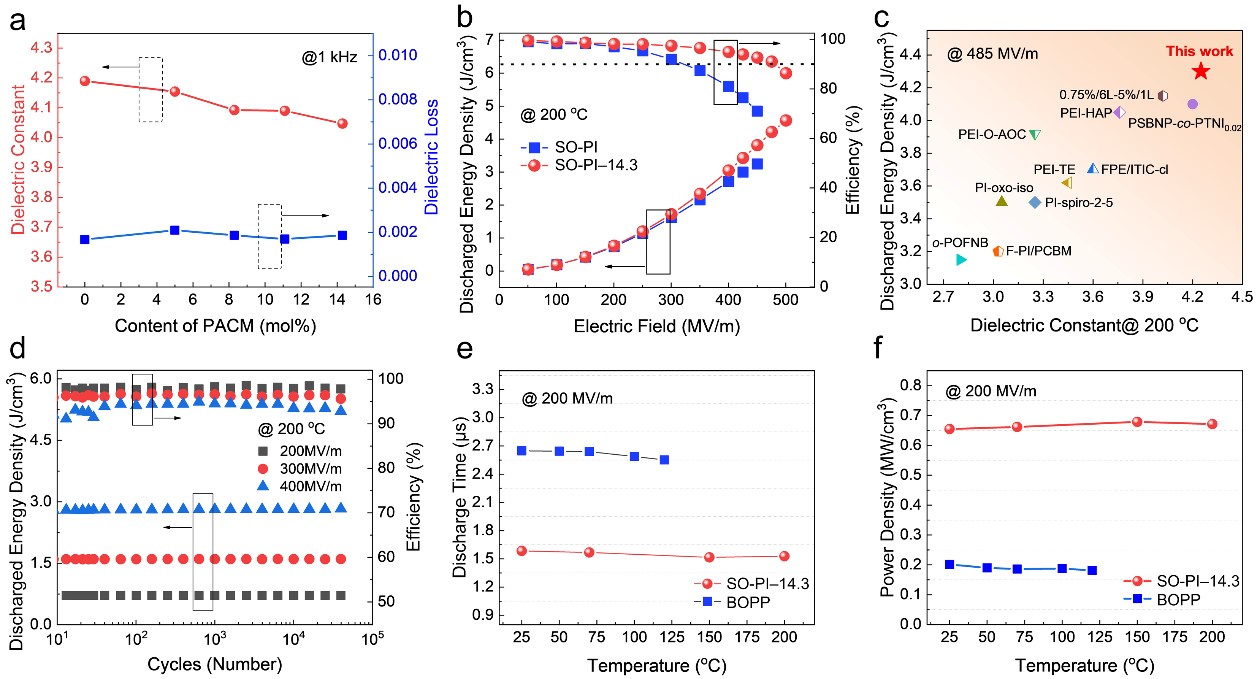

Furthermore, an original semi-alicyclic sulfonyl-containing PI copolymer that exhibits superior high-temperature capacitive performance is prepared by inserting a small amount of non-conjugated alicyclic segments into the backbone of the SO-PI. It was found that non-coplanar alicyclic groups in the backbones reduced π electron delocalization on the conjugated polyimide backbones and effectively inhibited intramolecular and intermolecular charge transfer (CT) interactions. The restriction of alicyclic segments on free electrons can be considered as the charge trapping in the copolymer matrix. The hopping conduction fittings and thermally stimulated depolarization current (TSDC) data further suggest that introducing the alicyclic segments into the backbone of the SO-PI molecular increases the energy barrier between adjacent sites for the charge hopping and brings extra carrier trap sites in the resultant copolymer film.

Figure 3. Synthesis process, electrostatic potential distribution, leakage current, thermal stimulation depolarization current, and breakdown strength of copolymer films.

The SO-PI–14.3 copolymer film delivers a highest Ue of 4.30 J cm-3 with a η of >90% at 485 MV m-1 and 200 oC, 153% and 437% higher than the pristine SO-PI and commercial PEI film. It is observed that the SO-PI–14.3 copolymer film can be continuously charge-discharged for 50000 cycles and deliver an Ue of 3.04 J cm-3 with a η of ~95% even at 200 oC and 400 MV m-1. The SO-PI–14.3 copolymer film also exhibits a faster discharge time of 1.53 µs and a higher power density of 0.67 MW cm-3 at 200 oC and 200 MV m-1, compared to 2.55 µs and 0.19 MW cm-3 of the BOPP at 70 oC, respectively. The power density is about 3.5 times higher than that of BOPP at 70 oC under the same electric field. The copolymer films are synthesized using conventional commercial monomers, and their preparation process is compatible with the industrial production line of current commercial polymer films and has the potential to be applied in high-temperature environments of electric vehicles, power electronics, and other systems.

Figure 4. Dielectric properties and high-temperature capacitive performance of copolymer films.

Jiufeng Dong, a postdoctoral fellow at SUSTech, is the first author of this paper. Li Li, a postdoctoral fellow at SUSTech, is the co-first author. Professors Hong Wang and Qing Wang are the corresponding authors.

This research was supported by the National Key Research & Development Program, National Natural Science Foundation of China (NSFC), and the China Postdoctoral Science Foundation funded project.

Paper link: https://doi.org/10.1002/aenm.202303732

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Materials Science and Engineering