4D printing is an innovative manufacturing technology that has evolved from 3D printing, integrating smart materials and mechanical design into the printing process. Under external stimuli such as light, heat, electric, and magnetic fields, 4D-printed structures can undergo changes in shape or functionality over time, offering vast potential applications in fields such as aerospace and biomedical. Currently, materials suitable for 4D printing are primarily limited to smart soft materials such as hydrogels, shape memory polymers, and liquid crystal elastomers. Due to the extremely weak deformability of ceramics, 4D printing of ceramics is still a great challenge.

Professor Qi Ge from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) recently collaborated with Associate Professor Chao Yuan from Xi’an Jiaotong University to make substantial progress in the field of 4D printing ceramics. The team reported a feasible and efficient manufacturing and design approach to realize direct 4D printing of ceramics, opening up a new avenue for ceramic structure design and application in a broad range of engineering fields.

Their work, entitled “Direct 4D printing of ceramics driven by hydrogel dehydration”, has been published in Nature Communications.

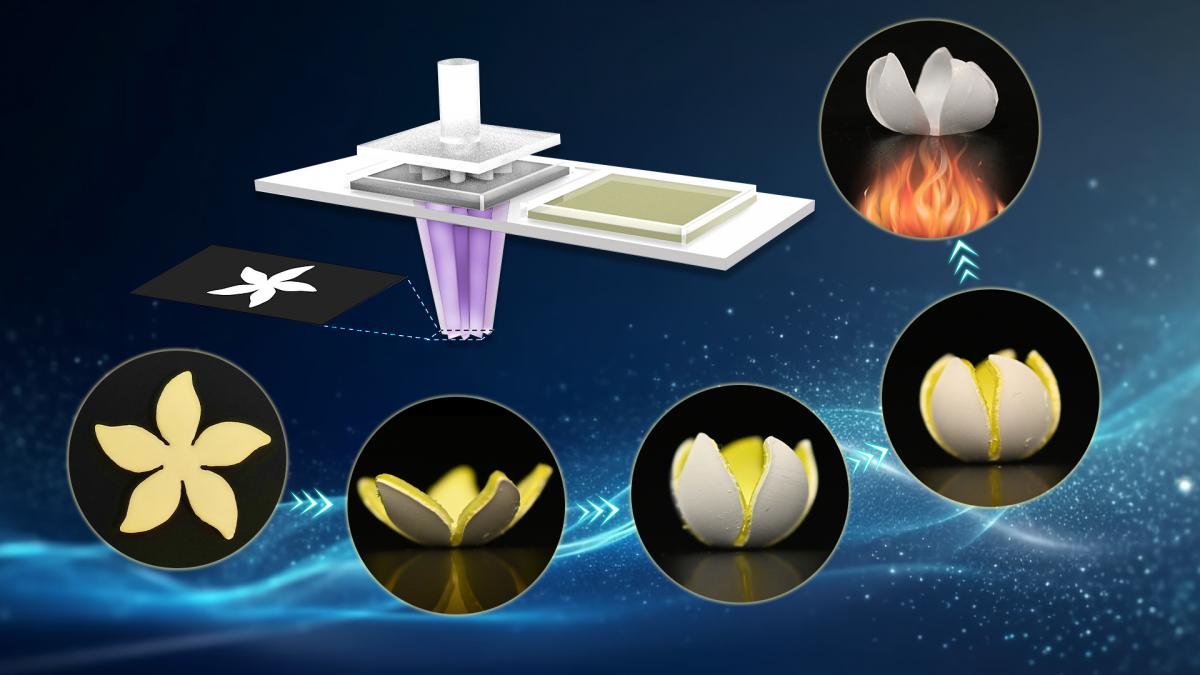

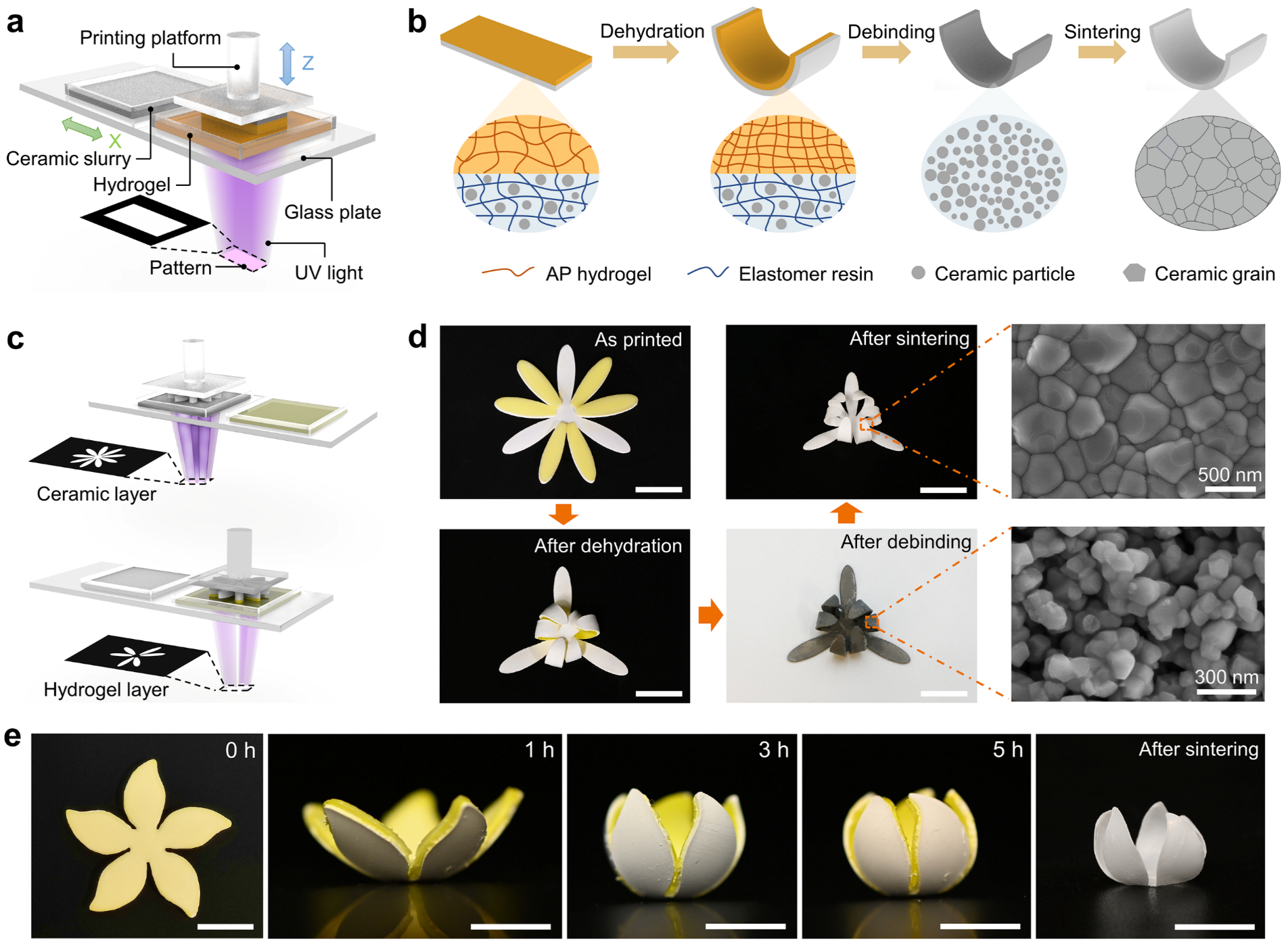

The researchers proposed an approach for 4D printing ceramics driven by hydrogel dehydration. They developed photocurable ceramic elastomer slurry and acrylic acid hydrogel precursors for DLP printing. The printed ceramic elastomer green body is highly stretchable and capable of withstanding a tensile strain of up to 700%. The hydrogel serves as driving material, which exhibits a significant dehydration-induced volumetric shrinkage of 65% along with a 40 times increase in modulus. As shown in Figure 1, multimaterial DLP 3D printing technology is used to create patterned hydrogel-ceramic laminates where the hydrogel and ceramic elastomer layers form strong interfacial bonding. The flat patterned laminates evolve into complex 3D structures driven by hydrogel dehydration. After debinding and sintering at high temperatures, the evolved 3D structures turn into pure ceramic structures.

Figure 1. General process of direct 4D printing ceramics

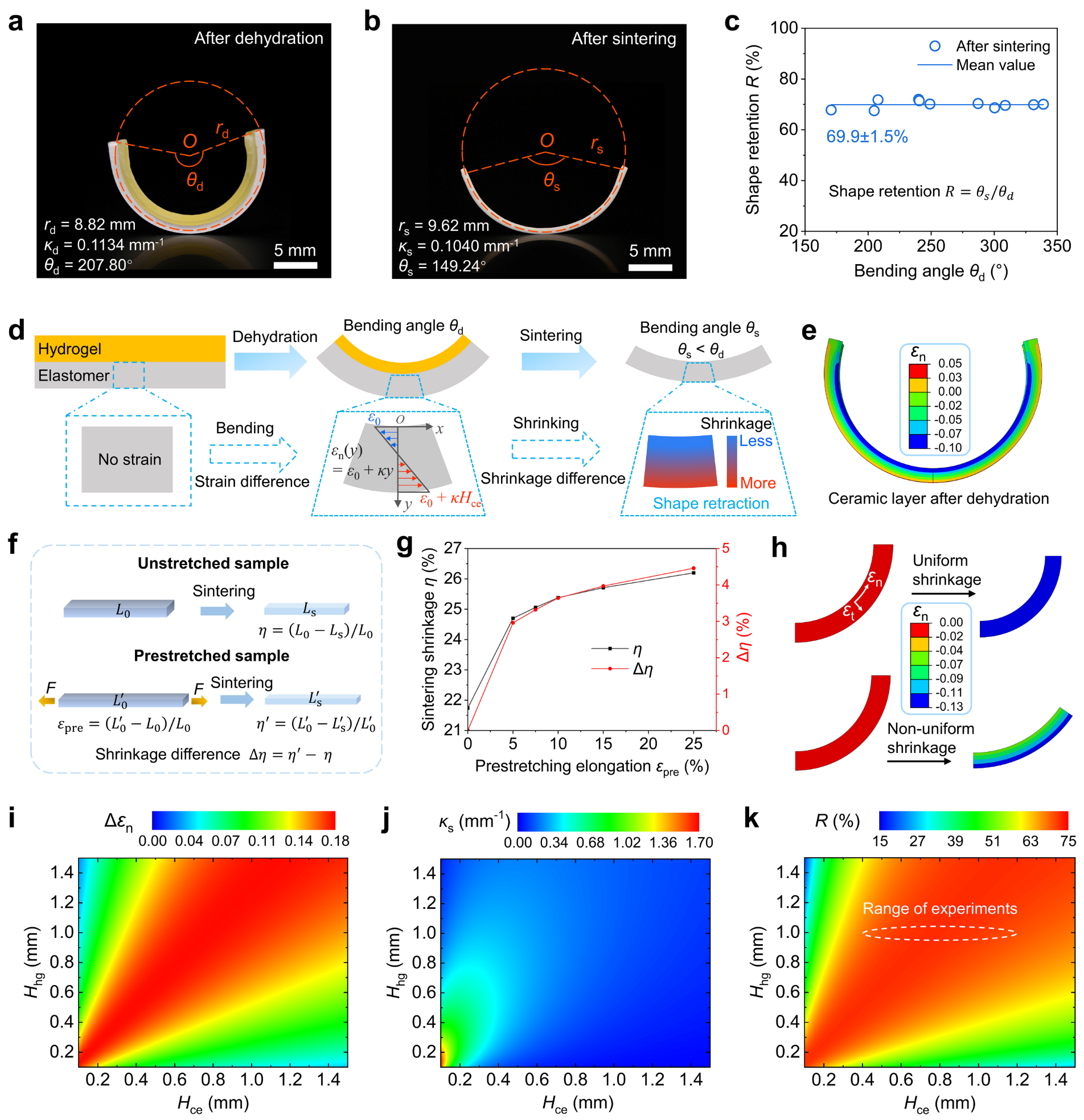

The bending angle (or curvature) of the part retracts after sintering (Figure 2). Through experimental investigations and finite element simulations, the shape retraction phenomenon can be attributed to the non-uniform shrinkage in the thickness direction of the laminate during sintering. Considering both the hydrogel dehydration-induced deformation and sintering-induced shape retraction, the research team established a theoretical model to calculate the final curvature. The design map generated using the theoretical model quantitatively presents the mapping relationship between structural deformation and structural parameters, providing effective guidance for the design of hydrogel-ceramic laminates.

Figure 2. Sintering-induced shape retraction and theoretical model predictions of final curvatures

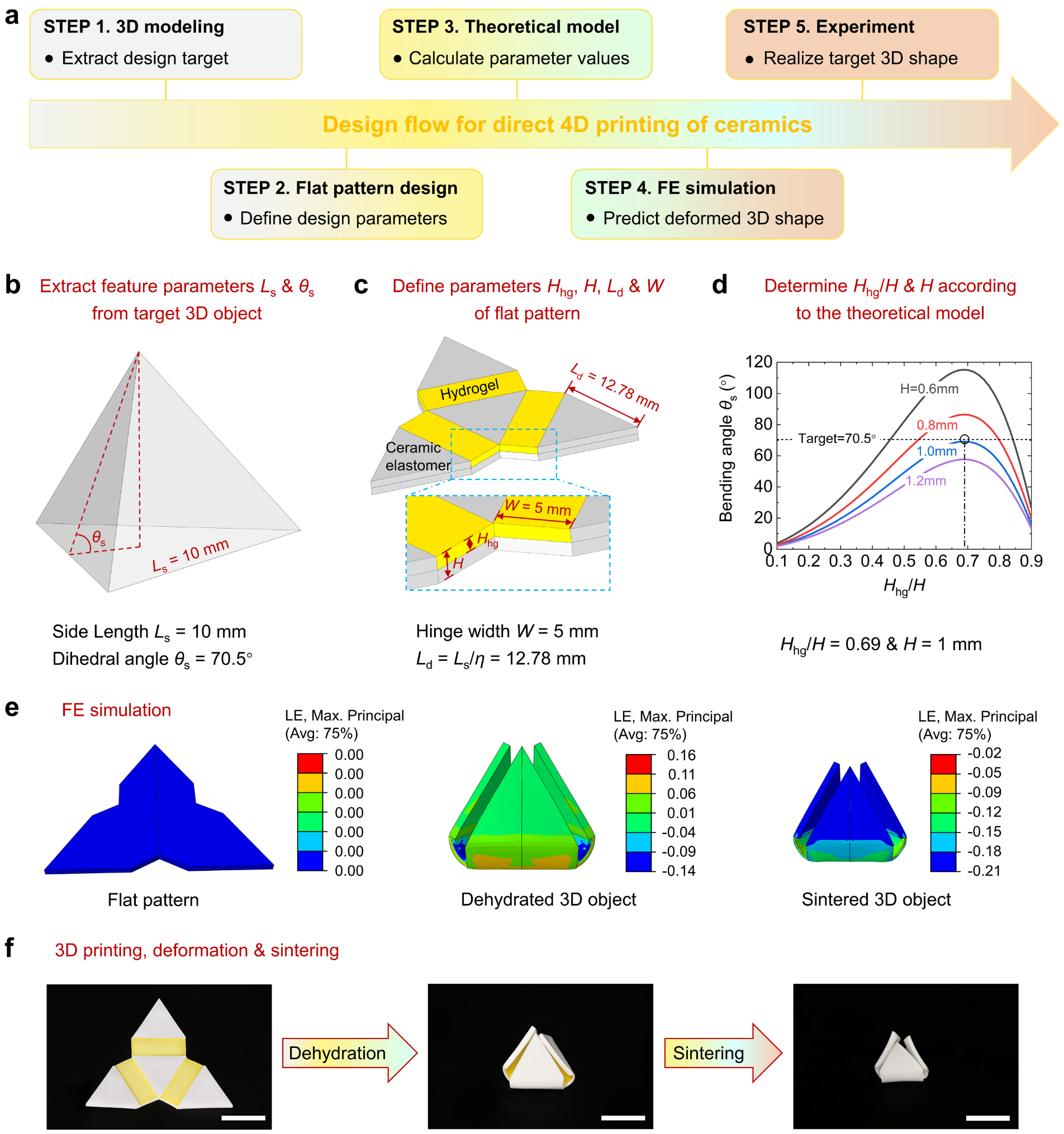

Figure 3 presents a design flow for direct 4D printing of ceramics, which includes five steps: 3D modeling, flat pattern design, theoretical model calculation, FE simulation, and experiment. A thin-walled regular tetrahedron is taken as an example to illustrate the detailed design and manufacturing process of 4D printing ceramics.

Figure 3. Design flow for direct 4D printing of ceramics

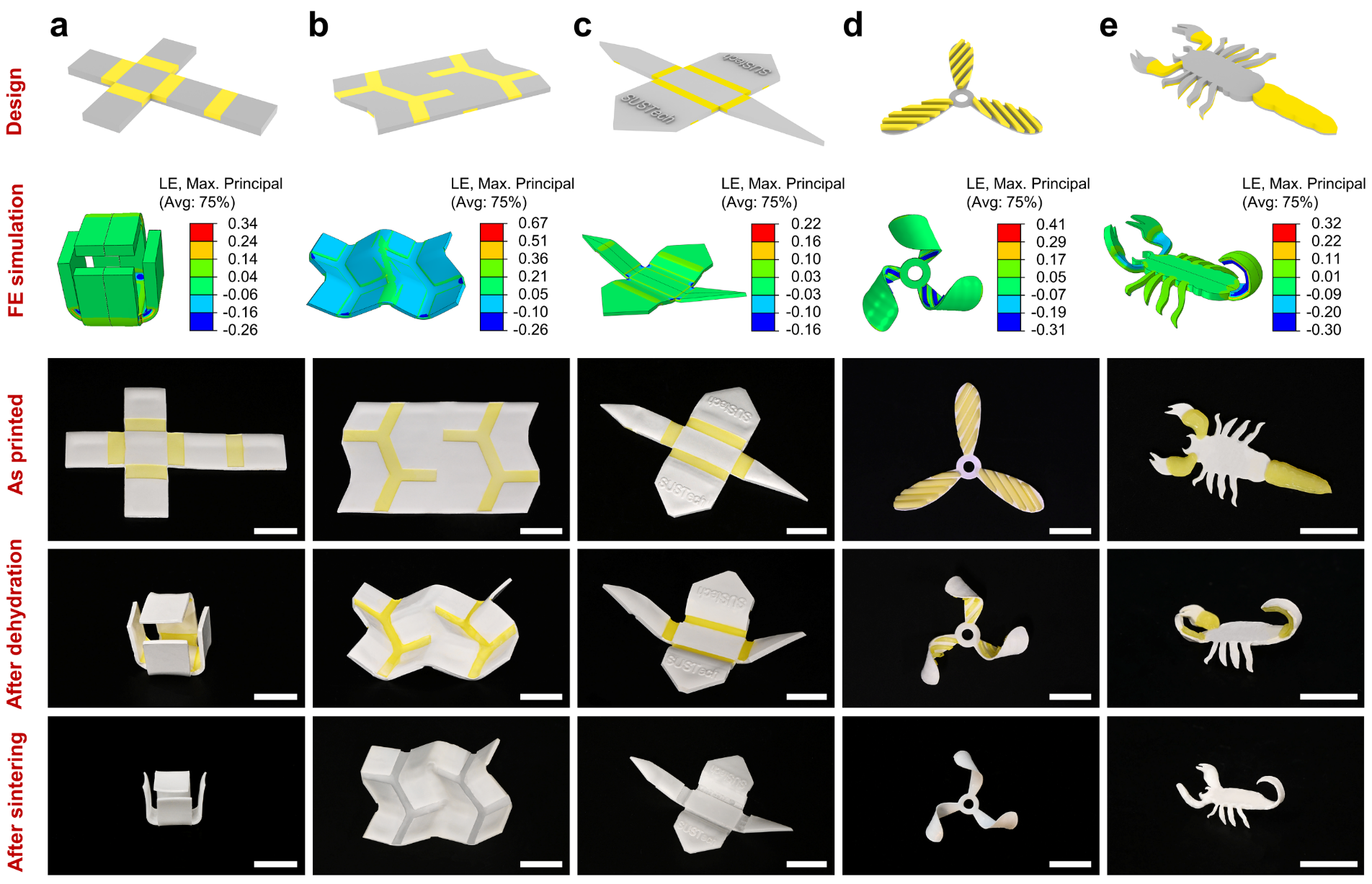

Through deploying the hydrogel ceramic laminates at different positions in the flat pattern via multimaterial DLP 3D printing technology, a wide variety of complex shape configurations can be realized (Figure 4). Compared with mold-assisted reshaping and manual folding, the hydrogel dehydration-driven direct 4D printing enables simpler and more efficient manufacturing of complex 3D ceramic objects.

Figure 4. 4D printing of complex ceramic structures

Research Assistant Professor Rong Wang and doctoral candidate Jianxiang Cheng from the Department of Mechanical and Energy Engineering at SUSTech, and Associate Professor Chao Yuan, are the co-first authors of the paper. Associate Professor Chao Yuan and Professor Qi Ge are the co-corresponding authors, and SUSTech is the first unit of this research article.

This research was funded by the National Natural Science Foundation of China (NSFC), Key Talent Recruitment Program of Guangdong Province, and the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link: https://www.nature.com/articles/s41467-024-45039-y

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Mechanical and Energy Engineering