Ionogels are promising material candidates for ionotronics due to their excellent ionic conductivity, stretchability, and thermal stability. Digital light processing (DLP) 3D printing technology has superior manufacturing accuracy, low processing costs, and great advantages in manufacturing high-precision ionogel microstructures. However, it is challenging to develop 3D printable ionogels with both excellent electrical and mechanical properties.

To solve the above problems, Professor Qi Ge’s research team from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has developed a UV-curable ionogel with bicontinuous nanostructures to achieve high conductivity without sacrificing its printability and mechanical properties.

Their related achievements, entitled “Highly Conductive and Stretchable Nanostructured Ionogels for 3D Printing Capacitive Sensors with Superior Performance”, have been published in Nature Communications, an internationally renowned comprehensive journal.

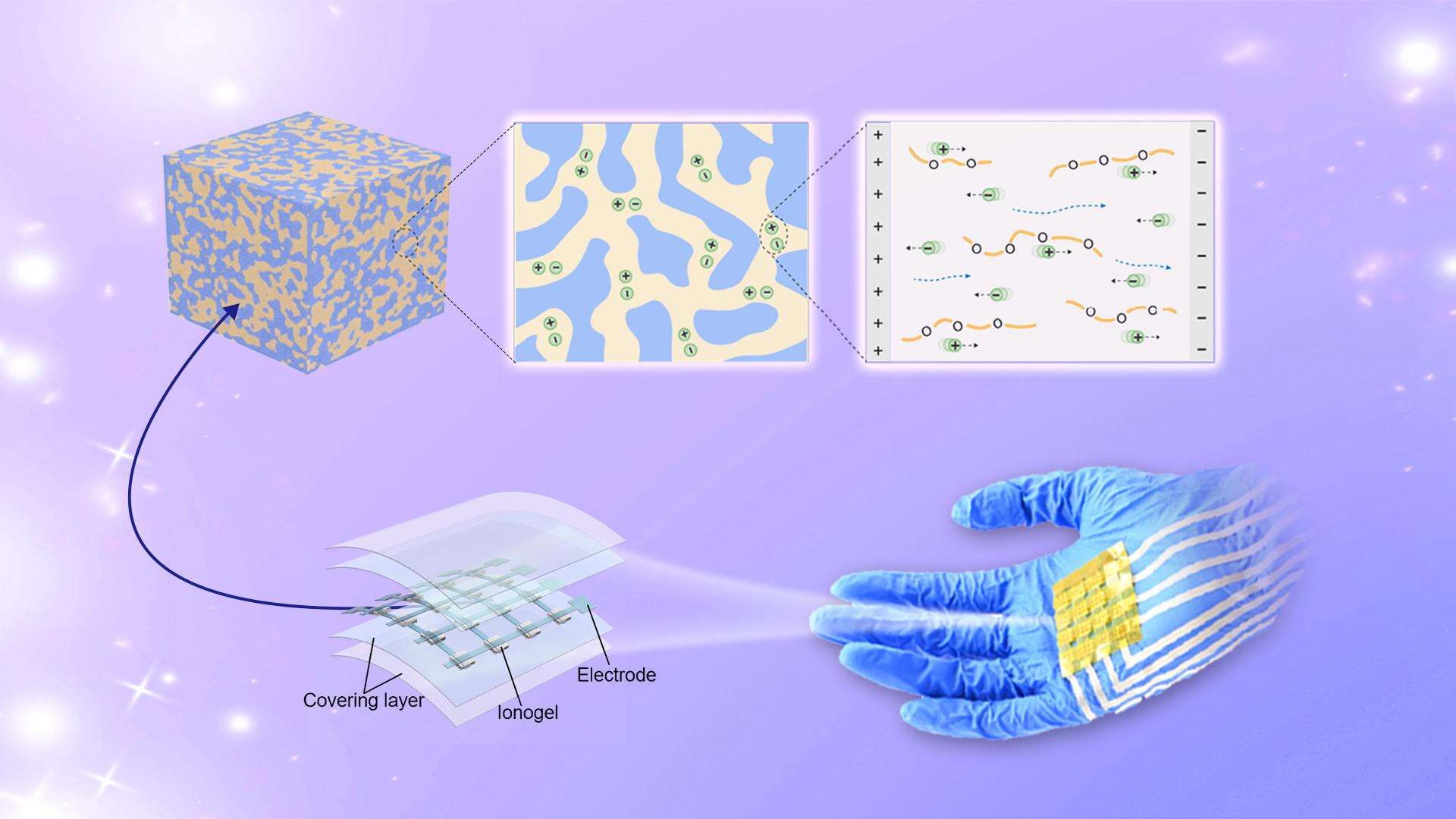

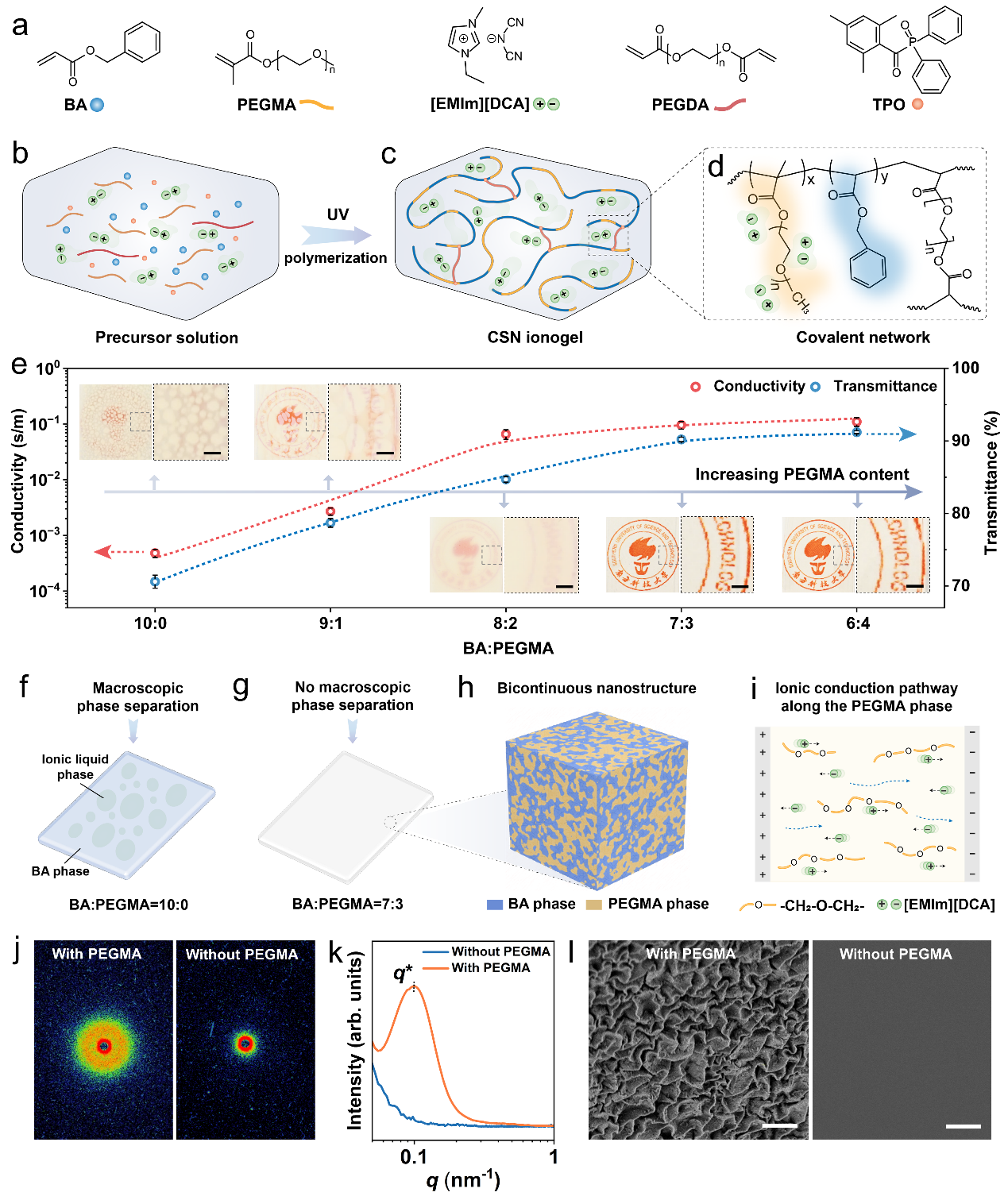

The team proposed a photopolymerization-induced microphase separation strategy to prepare bicontinuous ionogels. These ionogels comprise conducting nanochannels intertwined with a cross-linked polymeric framework (Figure 1). The bicontinous structure provides an ordered and continuous channel for ion transport. This approach endows ionogels with high conductivity without sacrificing the printability and mechanical properties. The developed ionogels exhibit high ionic conductivity (over 3 S·m-1), high stretchability (over 1500%), low degree of hysteresis (0.4% at 50% strain), and wide-temperature-range thermostability (-72 ~ 250 ℃).

Figure 1. Synthesis and characterizations of bicontinuous nanostructured ionogels

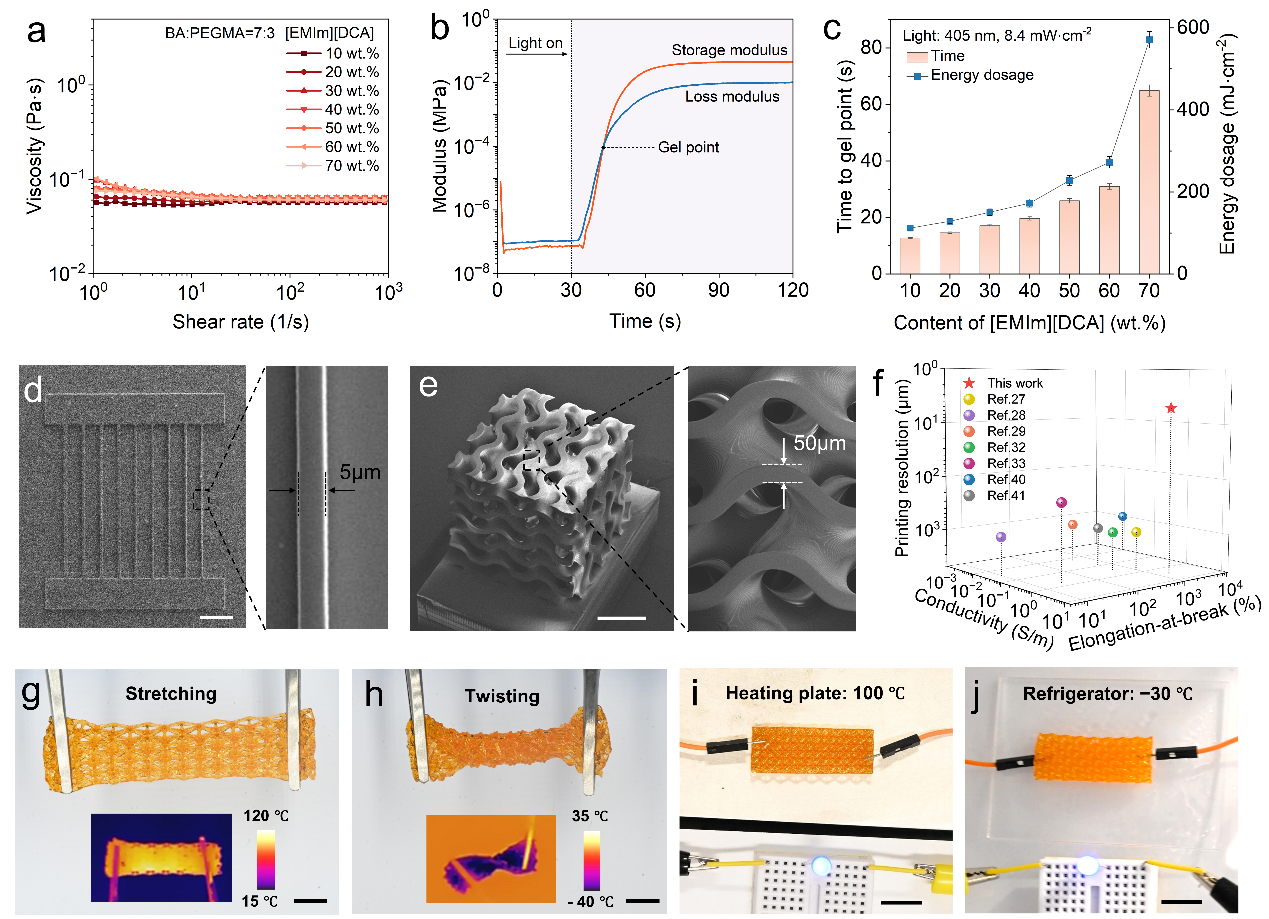

Owing to low viscosity and high photo-reactivity, the bicontinuous nanostructured ionogels are highly suitable for DLP 3D printing to print highly complex geometries with high resolution (Figure 2a-f). Furthermore, the 3D printed structures with the ionogel exhibit high deformability and high conductivity in a wide temperature range. As shown in Figures 2g and 2h, the 3D printed Octet truss structure is highly deformable at both 100 ℃ and -30 ℃. The high conductivity of the Octet truss structure is maintained at both high (100 ℃ in Figure 2i) and low temperatures (-30 ℃ in Figure 2j).

Figure 2. 3D printing of bicontinuous nanostructured ionogels

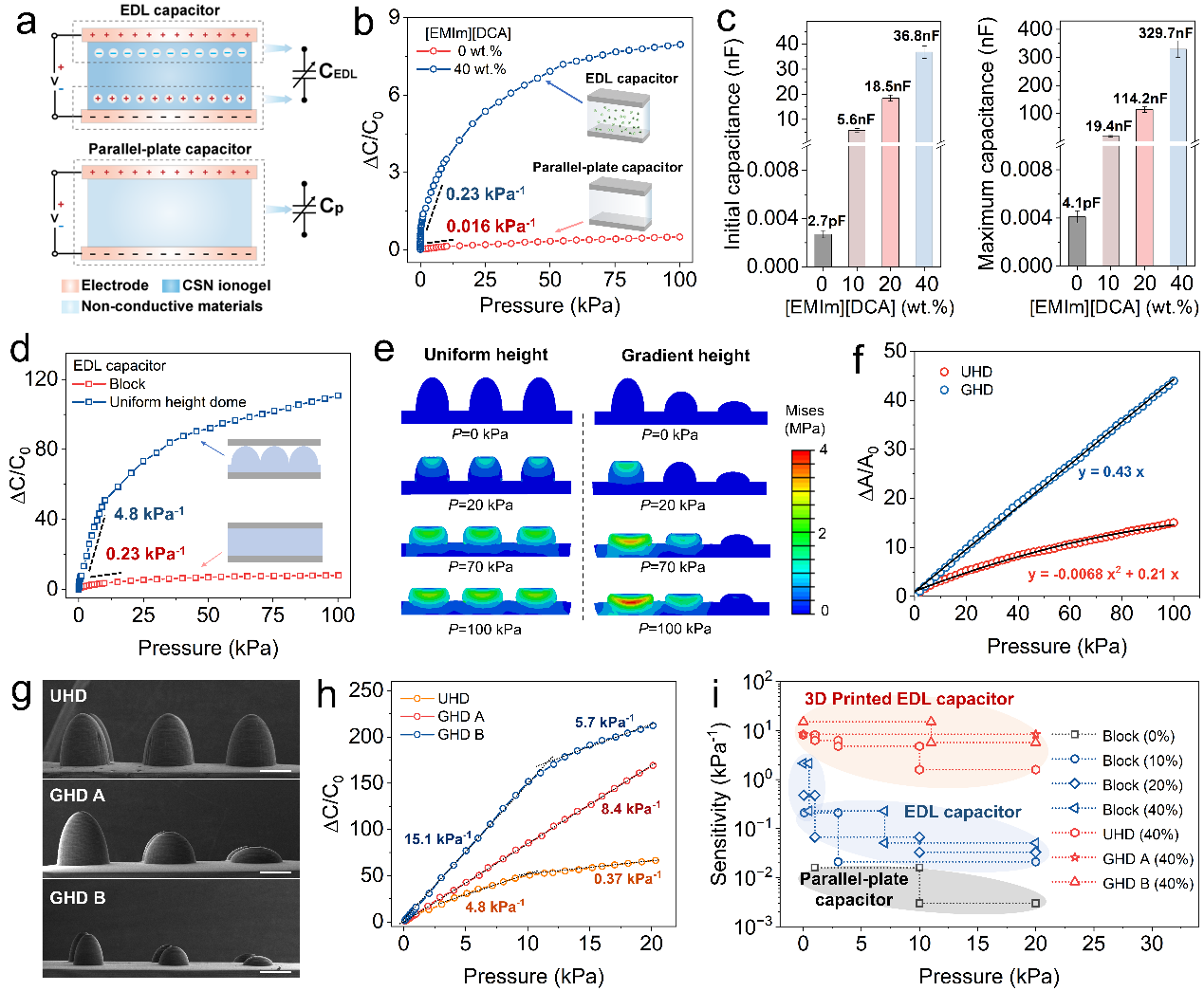

The high printability of the bicontinuous nanostructured ionogels allows the fabrication of intricate geometries, which can be used to further enhance the capacitance of the EDL capacitive sensors by changing the contacting process between CSN ionogel layer and metal-based electrodes. The researchers printed a hemispherical structure with gradient height for the EDL capacitive sensor, which can significantly boost the sensitivity while simultaneously broadening the pressure-responding linearity (Figure 3).

Figure 3. Design and the sensing mechanism of the 3D printed capacitive sensor based on bicontinuous nanostructured ionogels

The 3D printed EDL capacitive sensors have superior sensing performances such as high sensitivity, high linearity, fast dynamic response, excellent cyclic stability, and wide operating temperature range. The printed sensors were integrated into a robotic gripper that can sense grasping signals in a wide temperature range from -30 °C to 150 °C, and collect different combinations of signals while grasping various objects (Figure 4a-f). Furthermore, a pressure sensor array composed of 4 × 4 printed sensors was fabricated for real-time high-resolution pressure mapping (Figure 4g-n).

Figure 4. Robotic hand-sensor integration and multiplex sensing arrays

Ph.D. student Xiangnan He from the Department of Mechanical and Energy Engineering is the first author of this paper. Professor Qi Ge is the corresponding author.

This research was supported by the National Natural Science Foundation of China (NSFC), Key Talent Recruitment Program of Guangdong Province, and the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link: https://www.nature.com/articles/s41467-024-50797-w

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Mechanical and Energy Engineering