In buildings, the overreliance on air conditioning to achieve comfortable indoor temperatures results in significant power consumption and corresponding greenhouse gas emissions. As a viable technology to economize building energy consumption, the installation of smart windows that can block solar radiation and regulate indoor temperature is very important for the construction of zero-energy buildings. However, existing smart windows mainly change their optical properties through light, thermal, and electrical stimuli to achieve privacy protection as well as light and temperature regulation in confined spaces. Inevitably, this requires additional energy consumption from external stimulus signals to maintain their optical adjustment performance.

In contrast, mechanically responsive smart windows can adjust their optical properties simply by changing shape, attracting the attention of researchers due to their simpler, more cost-effective, and quicker response. Despite this advantage, achieving selective modulation of visible and near-infrared spectral transmittance to adapt to varying weather conditions and personal preferences remains a challenge. Therefore, the development of smart windows that can effectively and selectively block different wavelengths of solar radiation is of great significance both theoretically and in practice.

Chair Professor Shu-Hong Yu from the Departments of Chemistry and Materials Science and Engineering (MSE) and Assistant Professor Jin-Long Wang from the Department of MSE at the Southern University of Science and Technology (SUSTech) have recently developed a simple layer-by-layer assembly method to create large-area, mechanically responsive films for smart windows. These innovative smart windows can modulate visible (VIS) and near-infrared (NIR) light by adjusting their transparency in response to mechanical changes, such as stretching.

Their work, entitled “Bio-inspired Mechanically Responsive Smart Windows for Visible and Near-infrared Multiwavelength Spectral Modulation”, has been published in Advanced Materials.

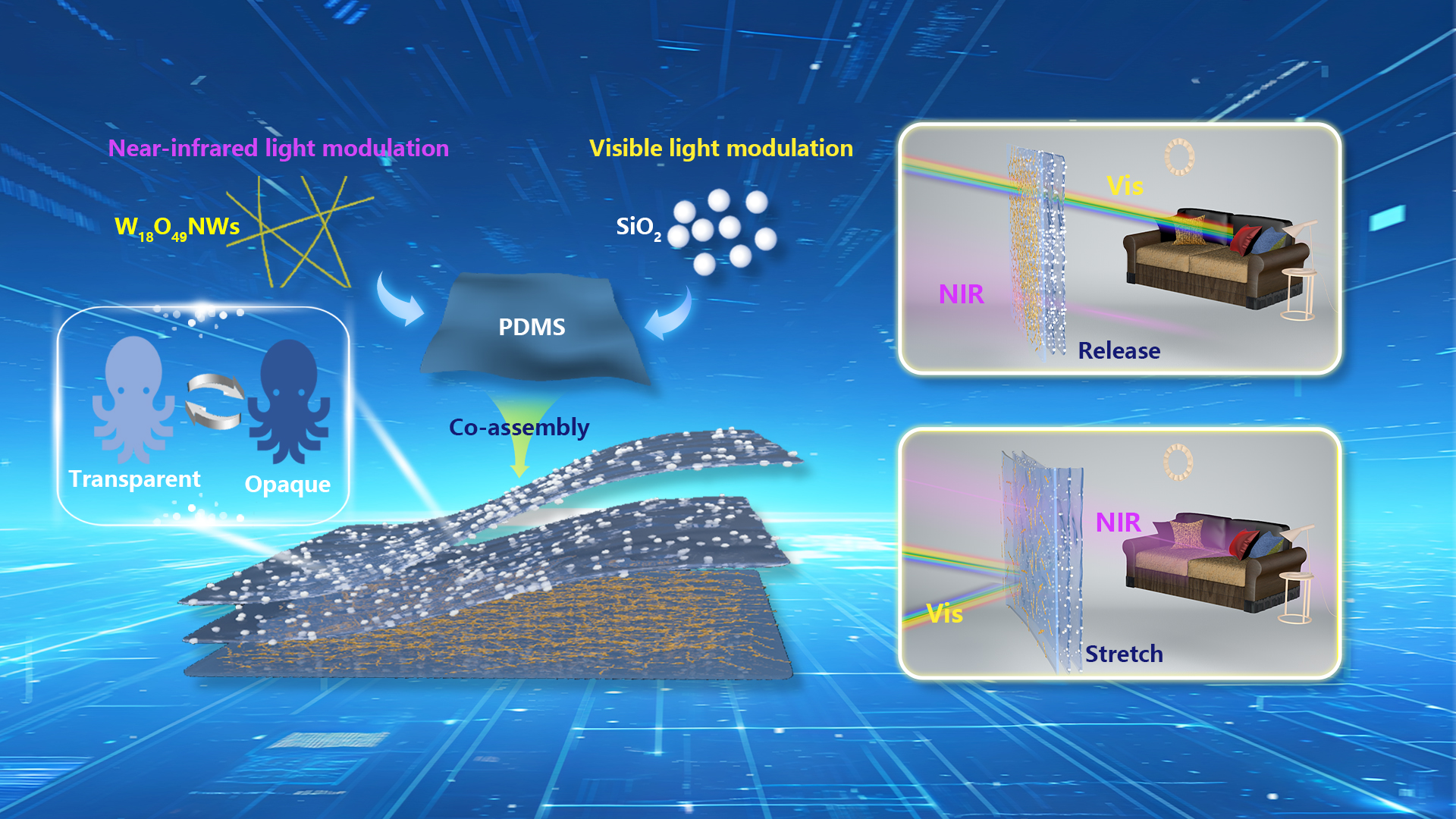

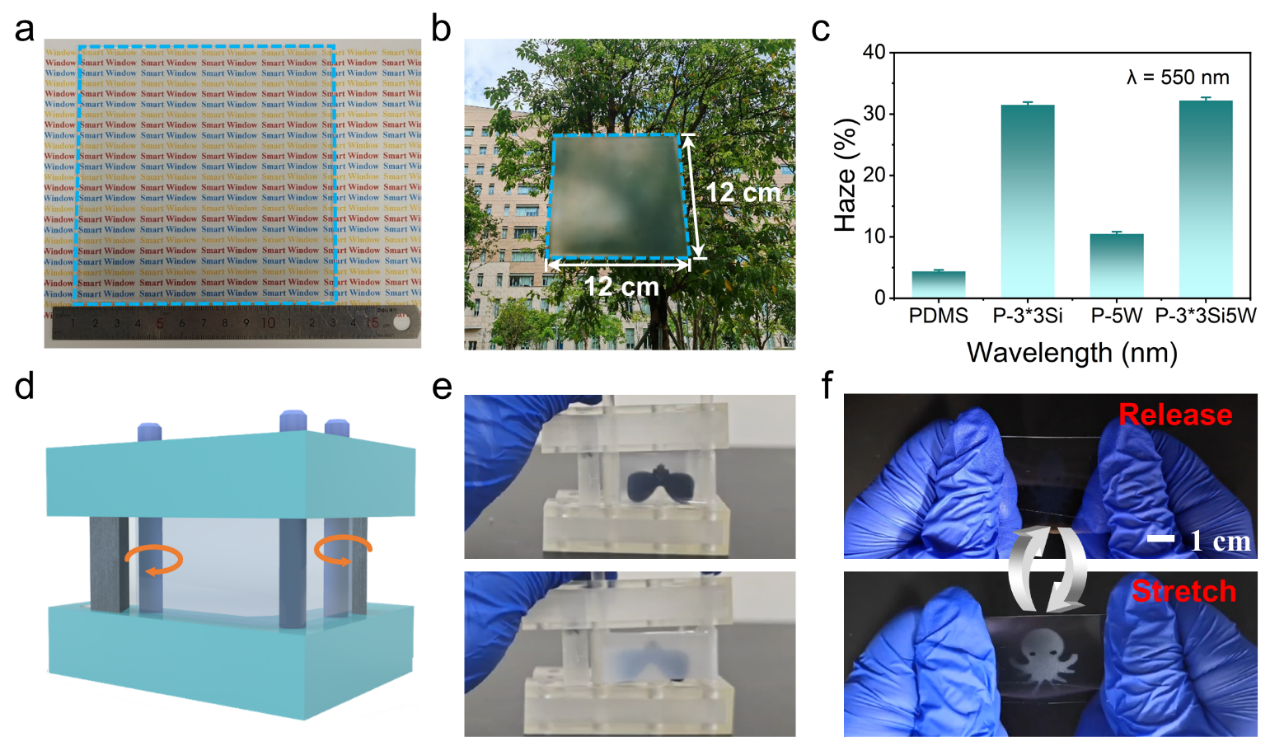

Inspired by the transparency effect of natural marine organisms like jellyfish and octopus, which blend into their surroundings due to similar refractive indices, the research team selected two materials—W18O49 NWs and SiO2 nanoparticles (NPs)—with close refractive indices but different light-blocking properties. These materials were combined into a flexible film using a layer-by-layer assembly process to create a mechanically responsive smart window (Figure 1a).

By adjusting the amounts of these materials in the composite film, they developed a window that changes how it interacts with visible and near-infrared light when stretched. In the released state, the whole window can transmit VIS light and isolate NIR light (Figure 1b); in the stretched state, the window partially isolates VIS light and transmits NIR light (Figure 1c). This dynamic response allows the smart window to actively adjust its shading performance and temperature control-based mechanical changes, making it useful for regulating indoor light and heat efficiently.

Figure 1. Schematic of fabrication and modulation mechanism of mechanochromic smart windows

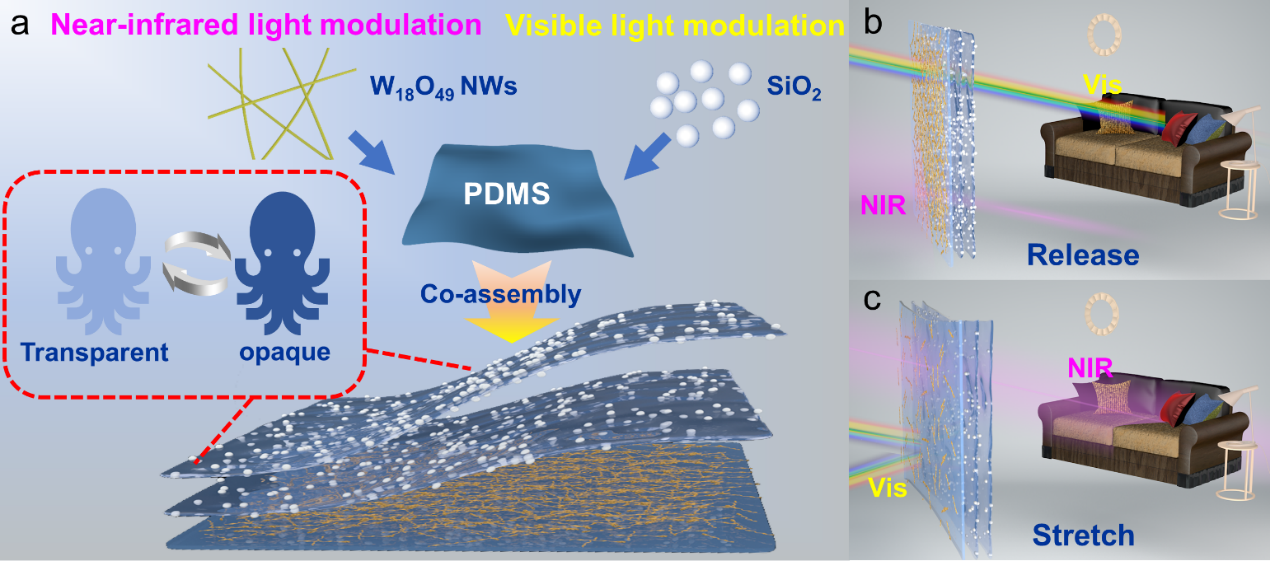

The researchers illustrated how the films adjust their VIS and NIR light (Figure 2). In the assembly, the SiO2 NPs are fully embedded in the PDMS matrix in the released state, allowing a high level of VIS light to pass through due to their close refractive index (1.43 for PDMS and 1.46 for SiO2). When the film is stretched, folds and voids form between the PDMS and SiO2 NPs, creating air pockets with a refractive index of 1.0, which is much lower. This causes the film’s optical properties to change.

When stretched by 50%, the VIS light transmission of the film decreases significantly from 89.2% to 46.8%, showing a modulation rate of up to 42.4% at 𝜆 = 550 nm. For NIR light, W18O49 nanowires (NWs) within the film absorb a lot of NIR light when the film is released. However, when stretched, W18O49 NWs show a plate-like fracture in the PDMS, forming many cracks, allowing more NIR light to pass through. By varying the amount of W18O49 NWs from 3 to 9 mL, the NIR modulation can be modulated from 6.5% to 18.4% during stretching, while the VIS light remains largely unaffected.

Figure 2. Modulation mechanism of P-Si and P-W smart windows

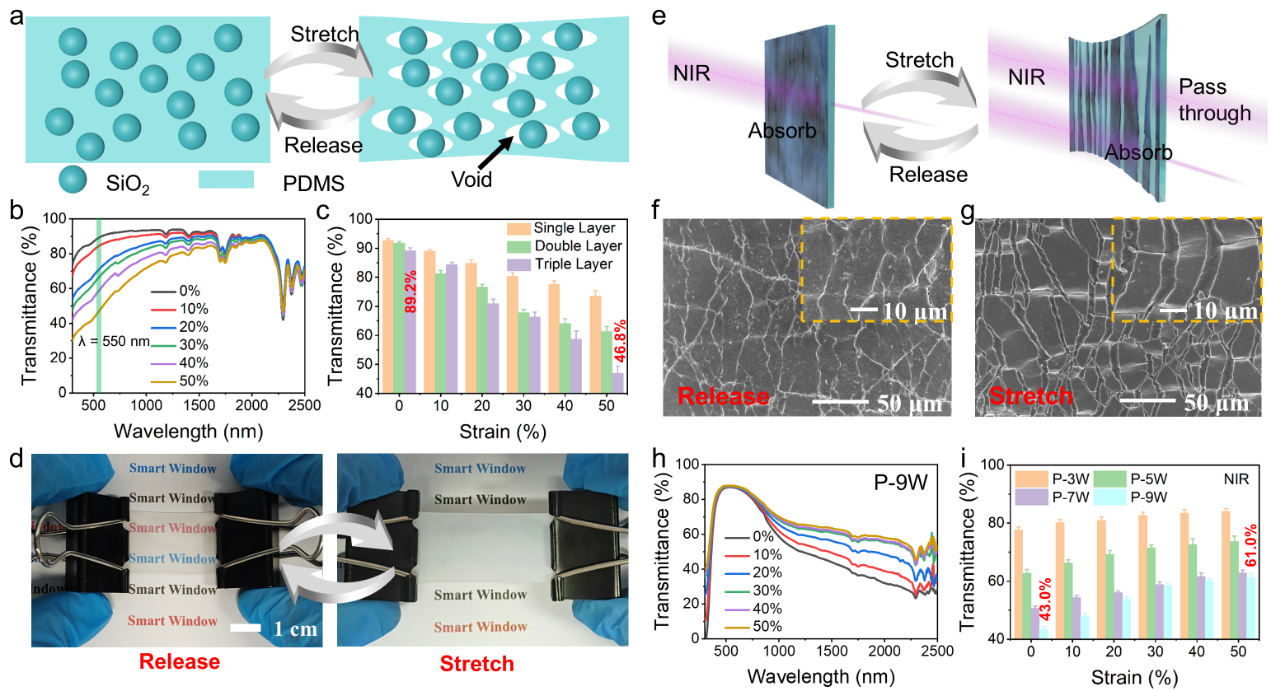

The team selected a typical composite film assembled with three layers of 3 mL SiO2 NPs and 5mL W18O49 NWs (P-3*3Si5W) for mechanical testing due to its high sensitivity in modulating visible and near-infrared light. The film demonstrated impressive durability, with the NIR modulation rate remaining almost unchanged after 100,000 stretching cycles. The VIS modulation rate decreased slightly from 40.6% to 37.7%, maintaining a VIS modulation rate of 92.9% at a wavelength of 550 nm. When the P-3*3Si5W film was stretched by 50% for ten days, its transmittance remained stable and returned to its initial transmittance after release, showing excellent mechanical and optical stability.

Figure 3. Characterization of P-SiW films

A mechanically corresponding smart window size of 12 × 12 cm2 was prepared using a simple layer-by-layer assembly method. The P-3*3Si5W composite film allows a high amount of VIS transmittance and haze, ensuring heat entry from outside sunlight while protecting privacy. A model was made to simulate the real application to realize the change of the spectral transmittance of the film by rotating the column to change the strain of the film. This composite film also has potential uses in display and security applications.

Figure 4. Application of P-SiW film

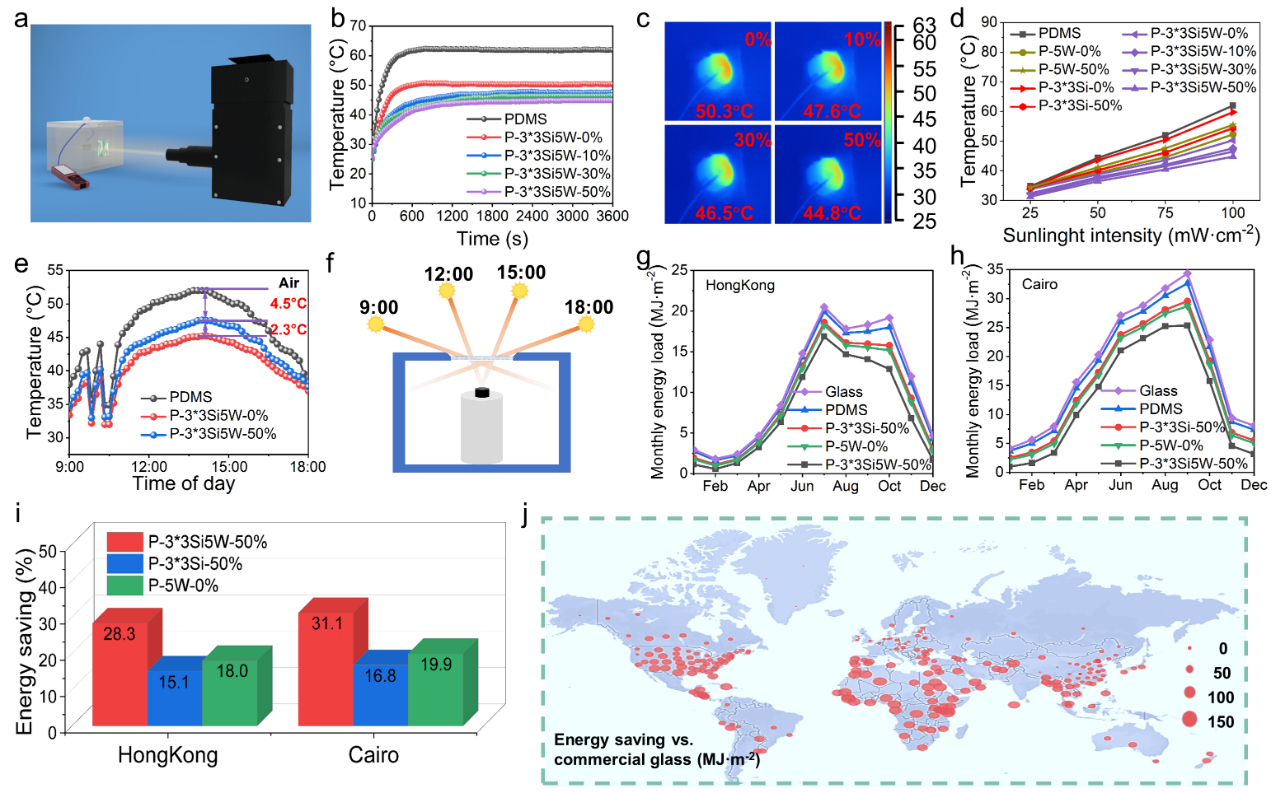

The research team evaluated the smart window’s energy-saving performance by testing its cooling effect. They used a xenon lamp to simulate sunlight and measured how much the smart window could reduce the temperature of a blackbody in a model chamber. The P-3*3Si5W window, when stretched to 50%, reduced the blackbody’s temperature in the model chamber by 17.2°C compared to a standard PDMS window. They also conducted outdoor tests on chambers covered with PDMS, P-3*3Si5W-0%, and P-3*3Si5W-50% films, measuring both the blackbody and air temperatures inside.

The stretched P-3*3Si5W film showed significantly cooler blackbody and air temperatures, 21.3°C and 6.9°C lower, respectively, compared to the PDMS window. Further simulations of building power consumption indicated that P-3*3Si5W smart windows could save more energy during hot months compared to traditional glass windows across various climates.

Figure 5. Actual cooling performance and energy-saving simulation of mechanochromic smart windows

In summary, a generic and feasible layer-by-layer assembly method was proposed to construct mechanochromic film-based smart windows that adjust to light. These films are more energy efficient than traditional electrochromic smart windows because they do not require a continuous power supply. Unlike thermochromic windows, these smart windows can actively adjust to a person’s preferences. By changing the amounts of specific materials in the film, the windows can regulate VIS and NIR light simultaneously, making them adaptable to different environments. The films also demonstrated excellent mechanical and optical cycling stability, making them practical for real-world use. This work is suitable for large-scale production, paving the way for commercial mechanochromic smart windows that help save energy in buildings.

Professor Shu-Hong Yu and Assistant Professor Jin-Long Wang are the co-corresponding authors of the paper, with SUSTech serving as the first and corresponding institution.

This work was supported by the Shenzhen Science and Technology Program, Start-Up Fund of SUSTech, New Cornerstone Science Foundation, National Key Research and Development Program of China, and the National Natural Science Foundation of China (NSFC).

Paper link: https://doi.org/10.1002/adma.202408192

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Materials Science and Engineering