The quest for sustainable energy sources has never been more critical. As our global population grows, so does our demand for electricity. Photovoltaic (PV) technology, which directly converts sunlight into electricity, stands at the forefront of this energy revolution and holds significant promise for combating climate change and achieving Carbon Neutrality. Among the myriad PV technologies, perovskite solar cells (PSCs) have emerged as a beacon of hope, promising breakthroughs that could reshape our energy landscape.

Perovskites exhibit a remarkable property – their bandgap can be fine-tuned by adjusting their chemical composition. This versatility allows researchers to optimize PSCs for specific solar spectrum, enhancing overall efficiency. Unlike traditional silicon-based solar cells, which require high-temperature processing, perovskites can be fabricated from solution-based precursors. This simplicity reduces manufacturing costs and opens doors to scalable production. All these merits make perovskite solar cells not only promising in terms of performance but also in terms of scalability and economic viability.

While PSCs have made impressive strides, their efficiency still lags behind the Shockley-Queisser (S-Q) limit – the theoretical maximum efficiency for a single-junction solar cell. Scientists grapple with charge recombination, nonradiative losses, and defects. Moreover, the long-term stability of PSCs remains a formidable challenge, as these materials are susceptible to degradation under environmental conditions such as humidity, light, and heat. The quest for durable, moisture and heat-resistant PSCs continues.

A research team led by Professor Aung Ko Ko Kyaw from the Department of Electronic and Electrical Engineering (EEE), along with Professor Guangfu Luo from the Department of Materials Science and Engineering (MSE) at the Southern University of Science and Technology (SUSTech), has pushed the boundaries of perovskite solar cell technology. Their innovations promise to bridge the efficiency gap, enhance stability, and propel toward a cleaner, brighter future.

Their work, entitled “Uniform Molecular Adsorption Energy-Driven Homogeneous Crystallization and Dual-Interface Modification for High Efficiency and Thermal Stability in Inverted Perovskite Solar Cells”, has been published in a top-tier journal Advanced Functional Materials.

Their research introduces a novel dual-interface modification strategy that significantly boosts both the efficiency and thermal stability of the PSCs. By strategically modifying the interfaces above and below the mixed-cation and halide perovskite (Cs0.05FA0.85MA0.10Pb(I0.93Br0.07)3) film, the researchers have achieved a remarkable synergy that not only passivates the perovskite layers but also fosters homogenous crystallization and reduces residual stress, leading to unprecedented performance.

The team’s innovative approach involves the use of 5-Aminopyridine- 2-Carboxylic Acid (APC) as a bottom interface layer between the hole-transporting layer, poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine](PTAA), and the perovskite. This crucial layer passivates the buried contact and mitigates the lattice mismatch issue, setting the stage for improved device performance. Simultaneously, an ammonium salt, 2-thiopheneethylammonium chloride (TEACl), is applied as a top interfacial layer between the C60 electron-transporting layer and the perovskite. This top layer not only passivates the surface and grain boundaries but also optimizes the energy level alignment, minimizing the interface-driven energy loss and enhancing overall efficiency.

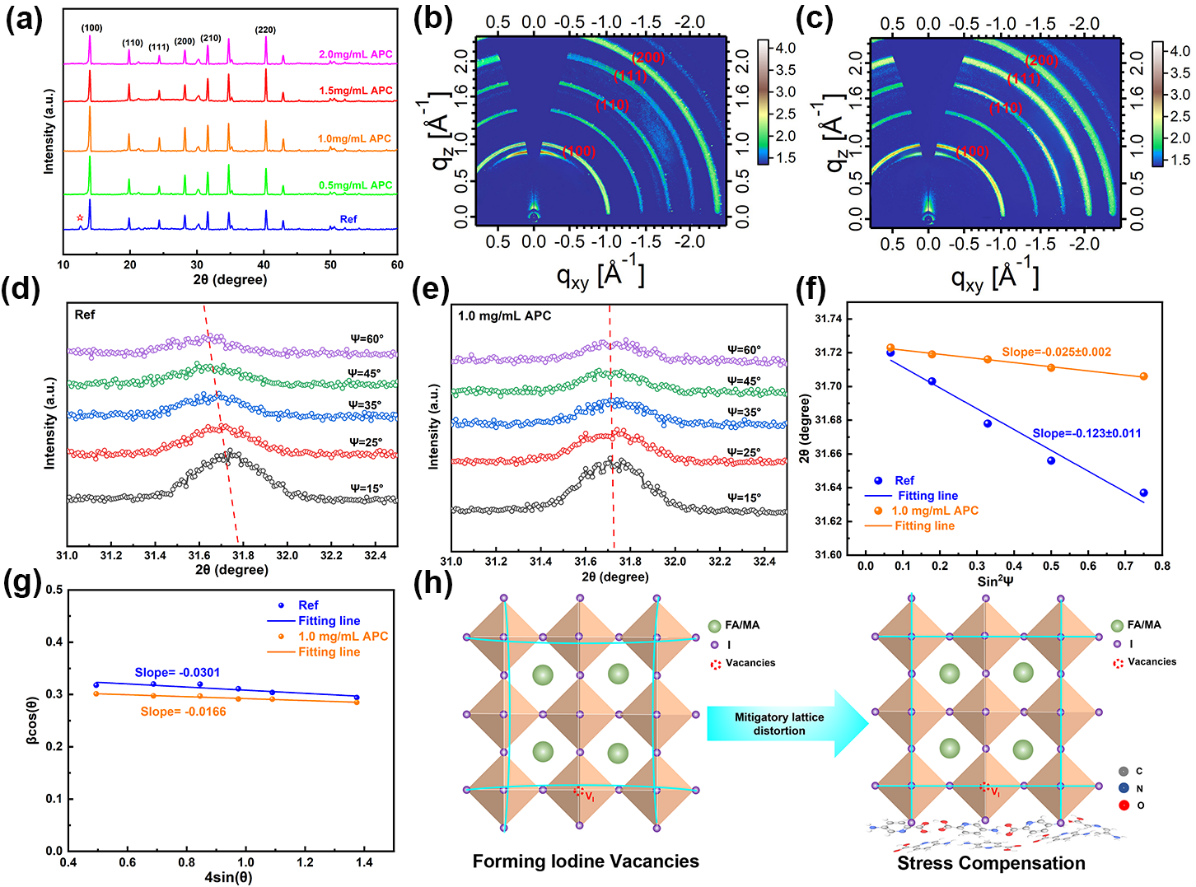

Figure 1. a) XRD patterns and 2D-GIWAXS patterns of b) reference, c) APC-modified (1.0 mg mL−1) perovskite films; d,e) GIXRD patterns and f) residual stress distribution (2𝜃 data as a function of sin2Ψ) of corresponding perovskite films; g) Williamson–Hall plots obtained from XRD patterns of the corresponding perovskite films; h) Schematic diagram of filling iodine vacancy (Vi) and mitigating lattice distortion.

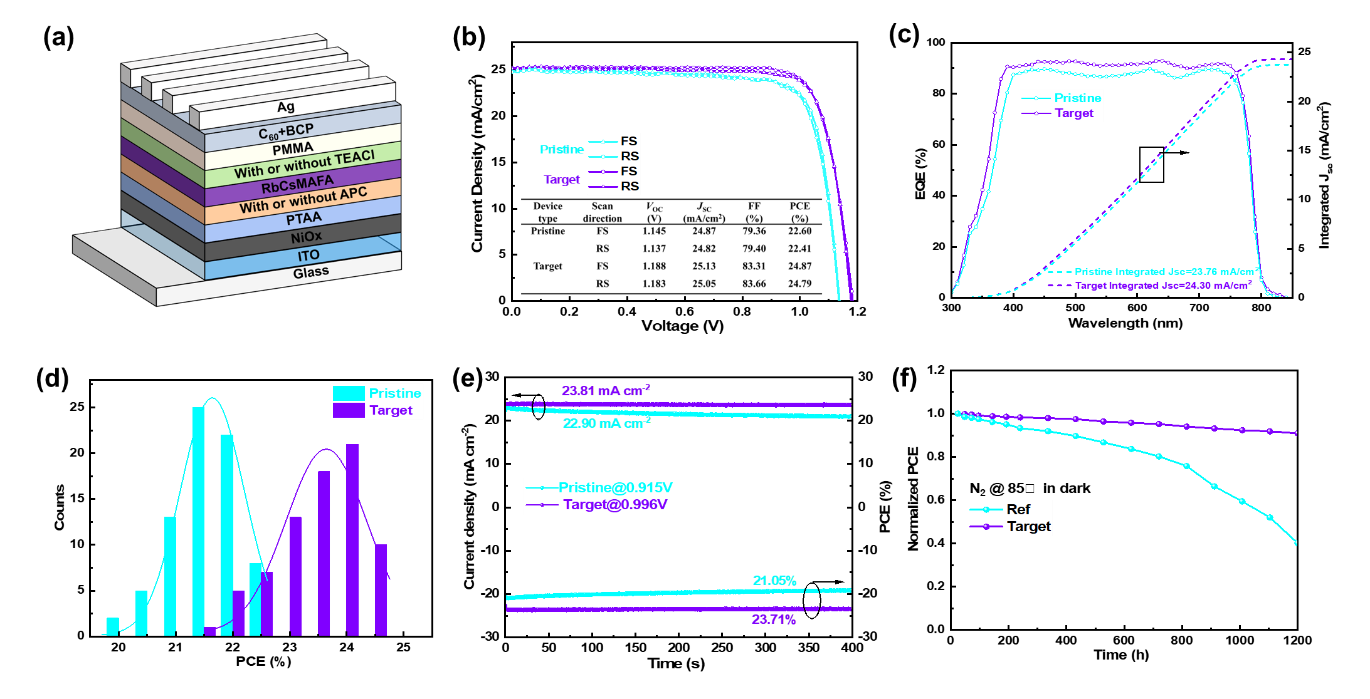

With this dual interface modification strategy, the research team achieved a champion power conversion efficiency (PCE) of 24.87% for the inverted PSCs built on a NiOx/PTAA bilayer HTL. Even more impressively, the unencapsulated devices exhibited remarkable thermal stability, maintaining 90% of their initial PCE after 1200 hours of aging at 85°C. The temperature-dependent conductivity measurements and the Nernst-Einstein relation manifest that the dual interface-modified perovskite film has a higher ion migration active energy (Ea), inhibiting the ion migration and mitigating thermal degradation. These findings demonstrate the significant impact of their strategy on improving both efficiency and stability, critical factors for the commercialization of perovskite solar technology.

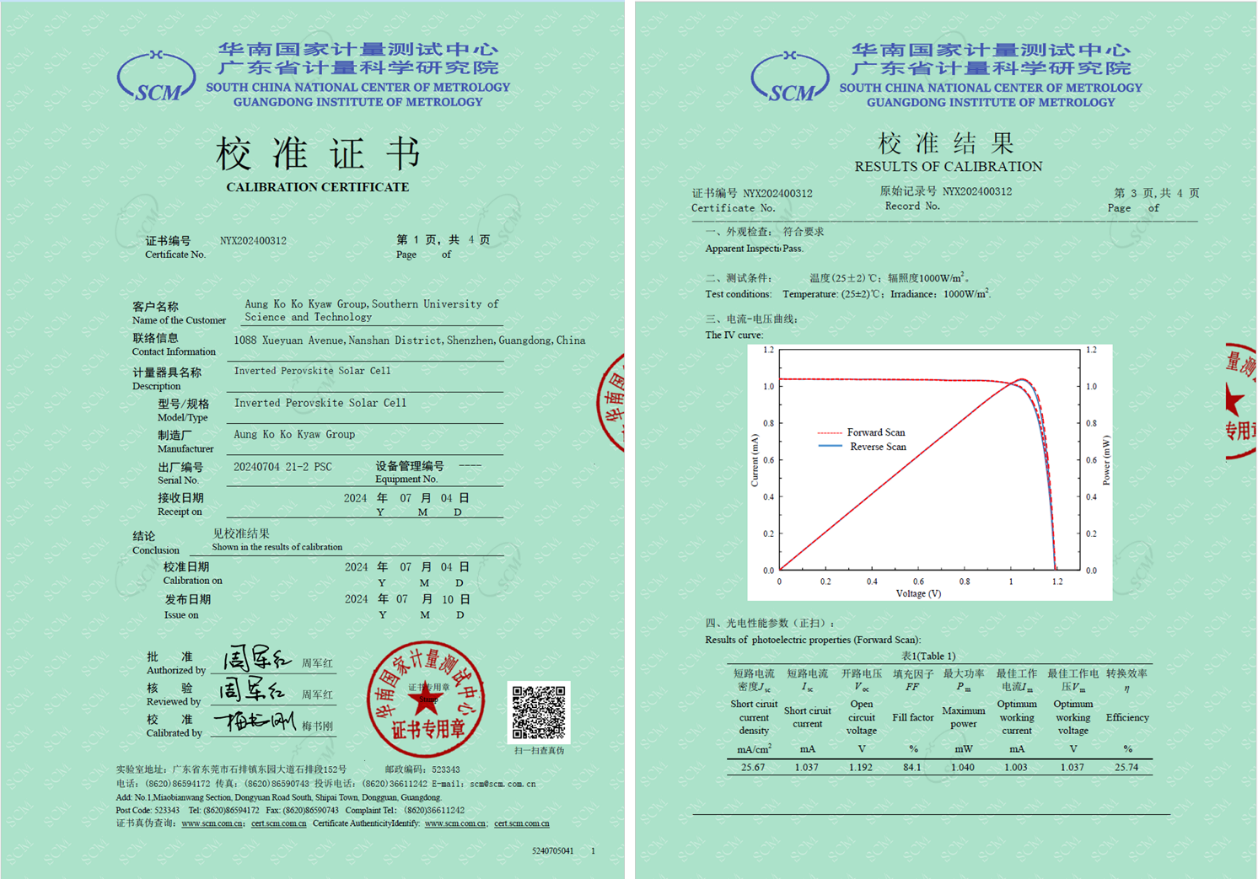

Through further device optimization, they recently achieved a certified PCE of 25.74%, independently certified by the Guangdong Institute of Metrology.

Figure 2. a) Device structure; b) J–V curves of the best-performing devices for pristine and target conditions. Inset shows the detailed parameters of PSCs; c) EQE spectra and the corresponding integrated JSC; d) Histograms of PCE distribution among 75 devices; e) Steady-state photocurrent and output PCE at the maximum power point; Long-term stability test for the unencapsulated corresponding devices under thermal stress of 85 °C.

Figure 3. Certificate of the PSC with PCE of 25.74%.

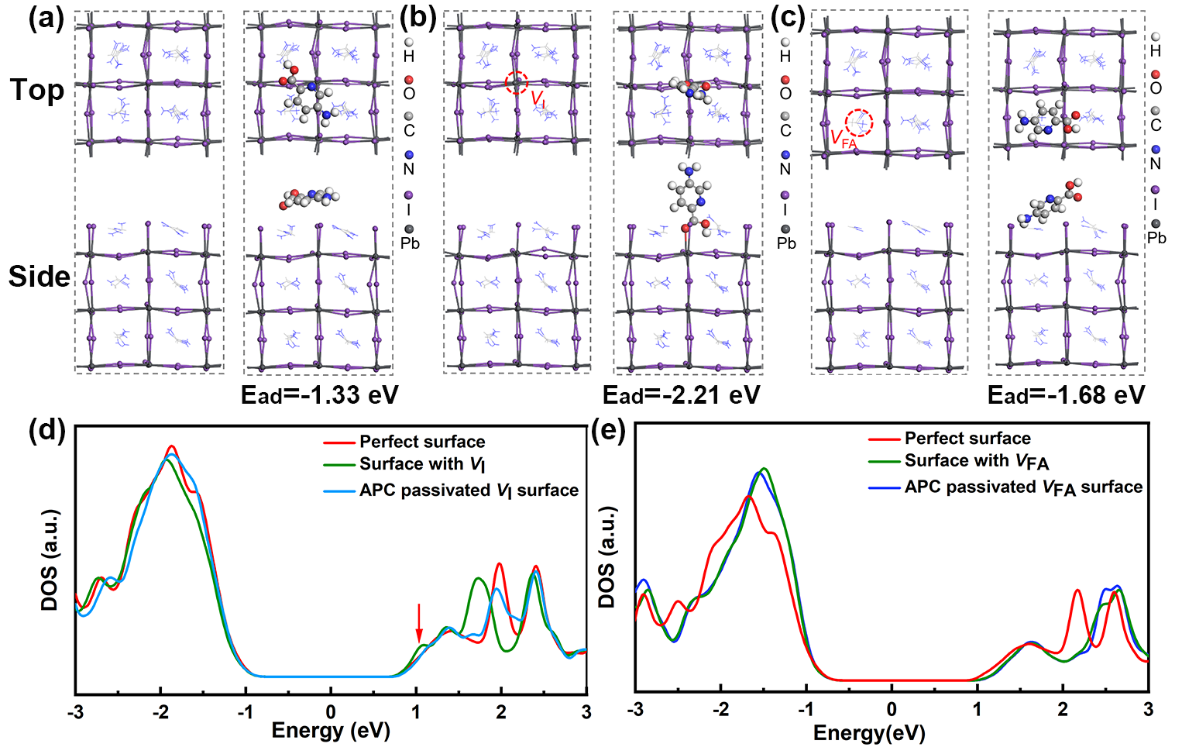

Adding depth to their experimental achievements, they provide a theoretical framework using density functional theory (DFT) analysis to explain the preferential orientation of APC molecules during the adsorption process and its pivotal role in passivation. The study reveals that the horizontal orientation of the APC molecule is energetically favourable, enabling homogenous crystallization of perovskite film without residual stress. Additionally, APC tends to insert its carboxyl functional group into the iodine vacancy, thereby eliminating the shallow defect states. The flat configuration of APC also binds strongly with the perovskite surface, exhibiting higher adsorption energy than that between the irregular-shaped PTAA and perovskite surface.

Figure 4. Structures of a) perfect FAI-terminated perovskite surface, b) FAI-terminated perovskite surface with Vi, and c) FAI-terminated perovskite surface with VFA before and after adsorption of APC. The adsorption energy of APC on each surface is labeled at the bottom; d) Density of state (DOS) of the top two layers for perfect perovskite surface, the surface with Vi, and APC-passivated Vi surface. The arrow indicates a defect state in the surface with Vi; e) DOS of the top two layers for the surface with VFA and APC-passivated VFA surface.

In summary, this research provides a novel dual-interface modification strategy for effective passivation and elimination of residual stress, as well as a theoretical framework for understanding the interaction between perovskite surface and molecular passivator. As the world continues to seek sustainable energy solutions, this work of the research team stands as a beacon of progress, paving the way for a future where clean, efficient, and affordable solar energy is within reach.

Xiaowei Xu, a Ph.D. student from Aung Ko Ko Kyaw’s group at SUSTech, is the first author of the paper. Professor Aung Ko Ko Kyaw and Professor Guangfu Luo are the co-corresponding authors. Other contributors to this work include Professor Baomin Xu from the Department of MSE of SUSTech, Professor Erjun Zhou from the National Center for Nanoscience and Technology, and Professor Gongqiang Li from Taizhou University. SUSTech is the sole corresponding unit of the paper.

This work was supported by the Natural Science Foundation of China, Shenzhen Science and Technology Innovation Commission, and the Guangdong Provincial Key Laboratory of Computational Science and Material Design. The researchers also acknowledge the Core Research Facilities and the Center for Computational Science and Engineering of SUSTech for their technical support in material characterization and computation.

Paper Link: https://onlinelibrary.wiley.com/doi/10.1002/adfm.202408512

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Electronic and Electrical Engineering