Quantum-dot light-emitting diodes (QLEDs) are regarded as promising devices for next-generation displays due to their advantages of high color saturation, tunable emission, and low-cost fabrication. However, their conventional sub-100 nm thickness limits uniform substrate coverage, causing short circuits and reduced device yields. These problems significantly degrade the efficiency and stability of QLEDs.

Professor Shuming Chen’s research group from the Department of Electronic and Electrical Engineering at the Southern University of Science and Technology (SUSTech) has recently made significant progress in developing high-performance QLEDs. Their innovation involves using a novel water treatment technique for the ZnMgO electron transport layer (ETL), which notably reduces defects and dramatically improves its electrical conductivity. This approach enables the realization of micrometer-thick and shelf-stable QLEDs. These findings were published in Science Advances and Advanced Materials.

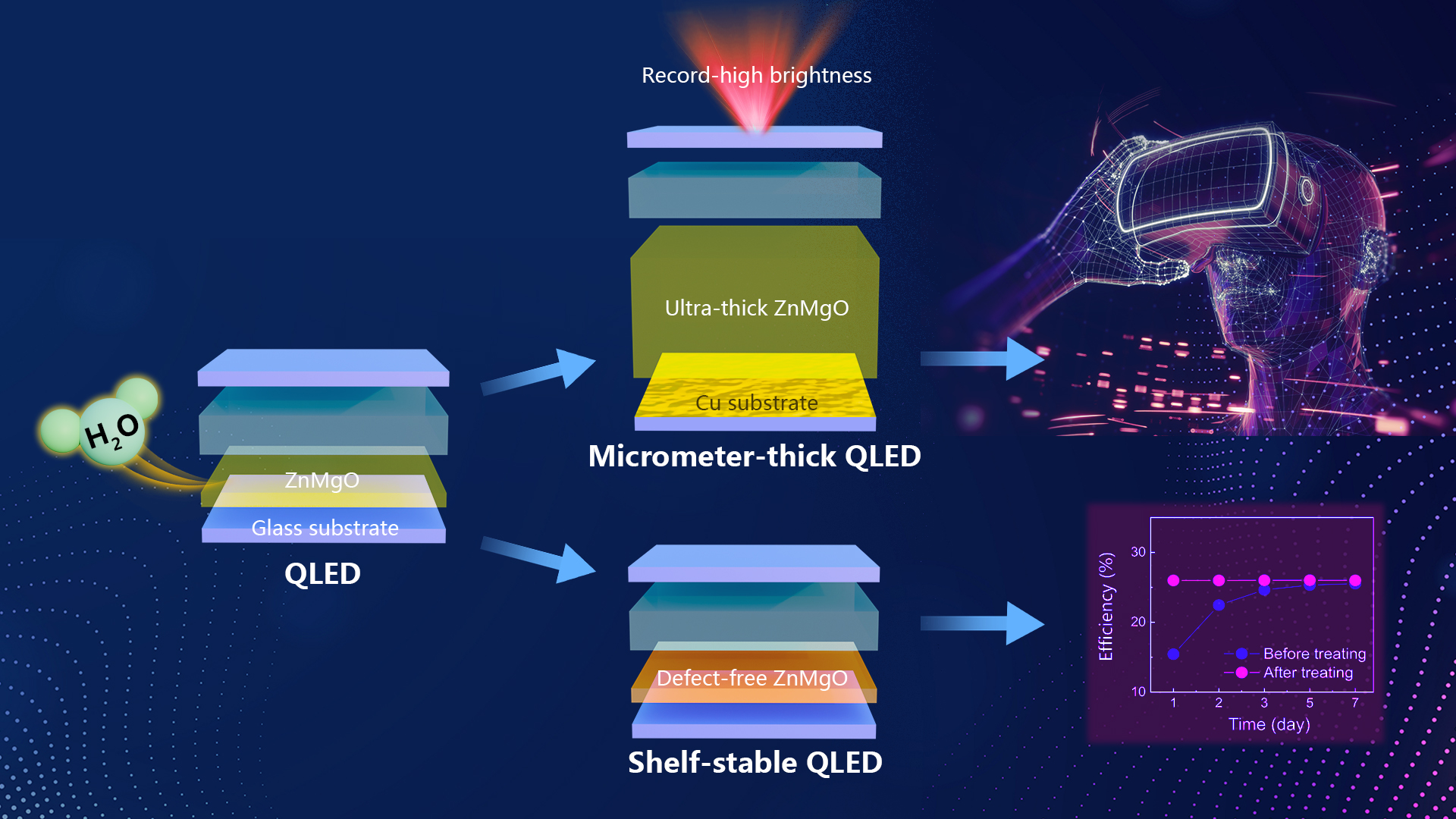

To overcome this, the group introduced micrometer-scale-thick QLEDs by enhancing the ZnMgO through vapor-phase water treatment. This innovative method greatly increases carrier density, facilitating efficient, trap-free electron transport and enabling a substantial increase in the layer thickness to one micrometer—more than ten times thicker than conventional devices. The µm-thick c-ZnMgO-based QLEDs achieve exceptional performance, including low turn-on voltage, high external quantum efficiency (EQE) of 31.2%, extended lifetime, and record-high brightness of 3,941,000 cd m⁻².

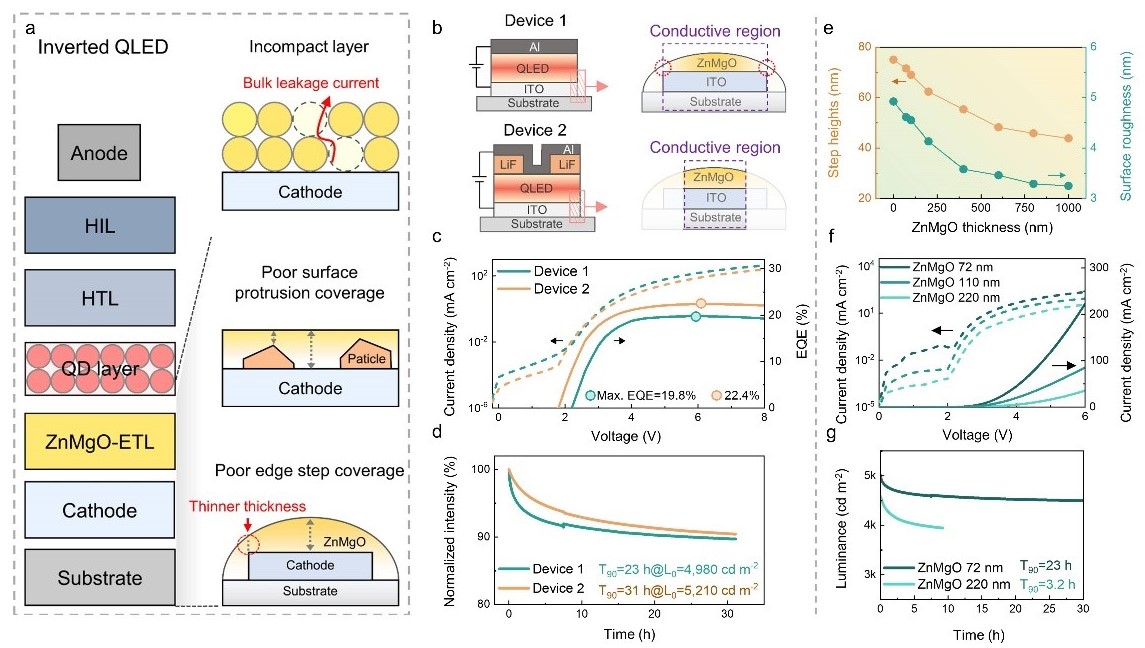

Figure 1. The necessity of µm-thick electron transport layer

A typical inverted QLED structure features an ETL approximately 72 nm thick to facilitate efficient charge transport (Figure 1). However, such thin layers are prone to forming short-circuit paths. Device 1, which lacks a LiF insulating layer over substrate steps, exhibits significantly increased current density, higher leakage current, and notably reduced lifetime compared to Device 2, which incorporates LiF coverage (Figure 1b). These findings indicate that nanoscale ETLs fail to uniformly cover substrate steps, causing uneven current distribution and increased leakage current. Nevertheless, simply increasing the ZnMgO layer thickness results in drastically reduced current and accelerated device degradation (Figure 1g). Therefore, enhancing the conductivity of ZnMgO is essential to realize micrometer-scale QLEDs.

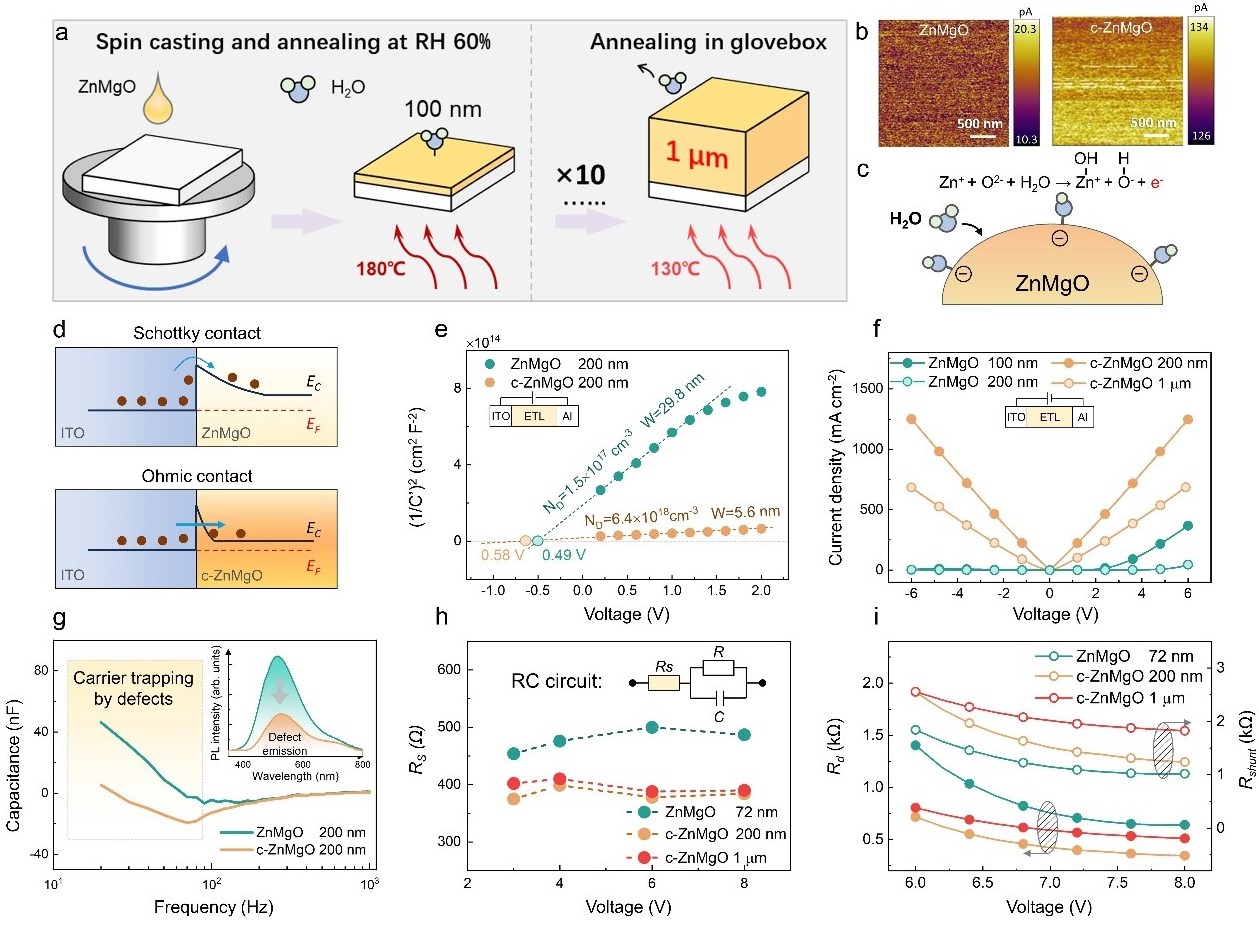

Figure 2. Solution-processed µm-thick c-ZnMgO with enhanced conductivity

This study implemented an innovative vapor-phase water treatment process to significantly enhance the conductivity of ZnMgO thin films. Specifically, a 100-nm-thick ZnMgO film is initially spin-coated and then annealed repeatedly at 180℃ under a relative humidity of 60%, ultimately achieving micrometer-scale thickness. Compared to conventional ZnMgO, the electron concentration increases by more than an order of magnitude, reaching approximately 6.4×1018 cm−3. This method provides a critical technological foundation for fabricating ultra-thick QLED devices.

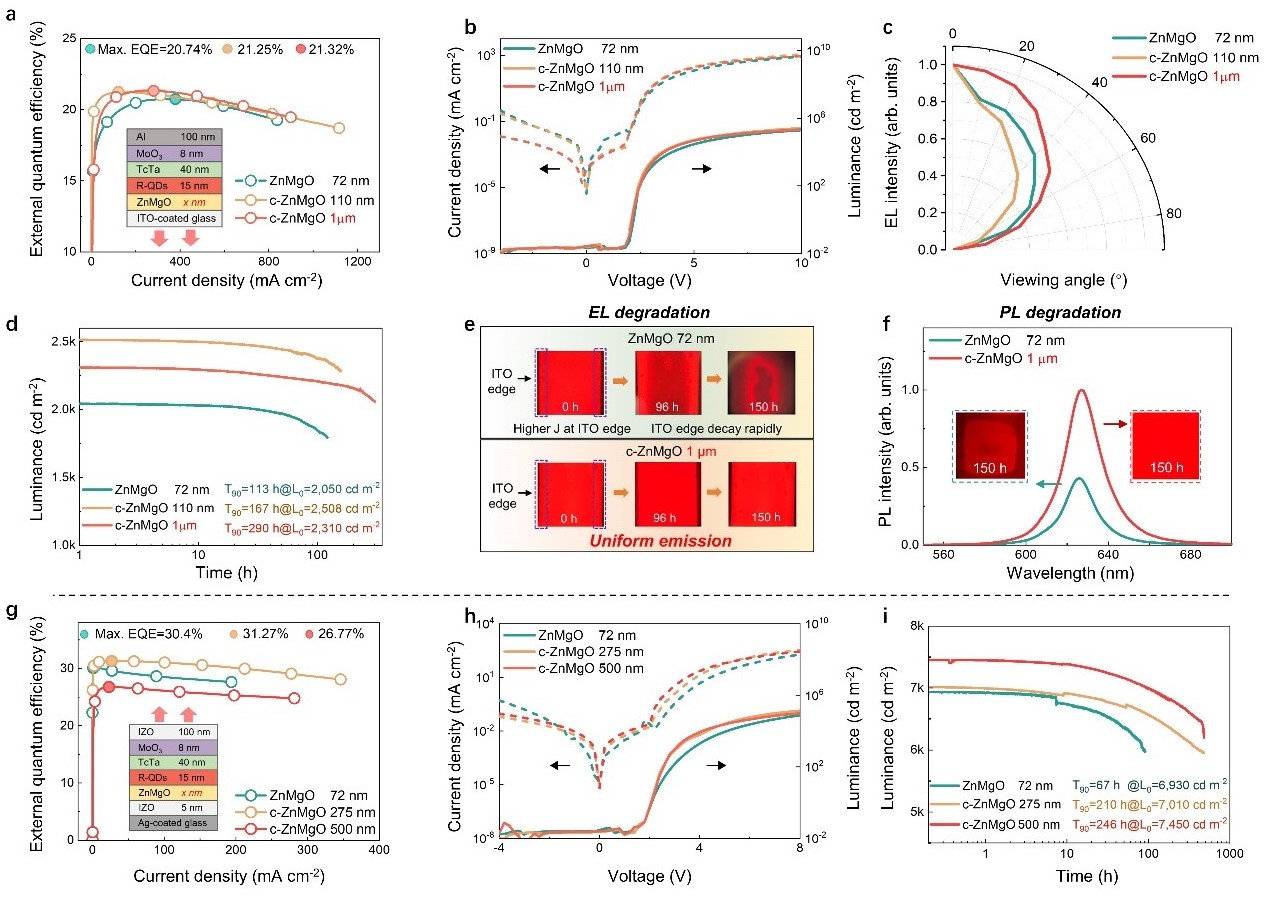

Figure 3. µm-thick QLEDs with enhanced stability and efficiency

The researchers further confirmed that the c-ZnMgO layers significantly enhance the optoelectronic performance and stability of QLEDs. Traditional QLEDs are constrained to thin ZnMgO layers due to their high resistance, limiting the simultaneous achievement of optimal light extraction efficiency and high current densities (Figure 3). In contrast, devices employing 1-µm-thick c-ZnMgO maintain both high current density and high EQE of 21.32%, and demonstrate Lambertian and angle-stable emission characteristics. Moreover, micrometer-thick c-ZnMgO substantially decreases leakage currents, resulting in a nearly threefold improvement in device lifetime.

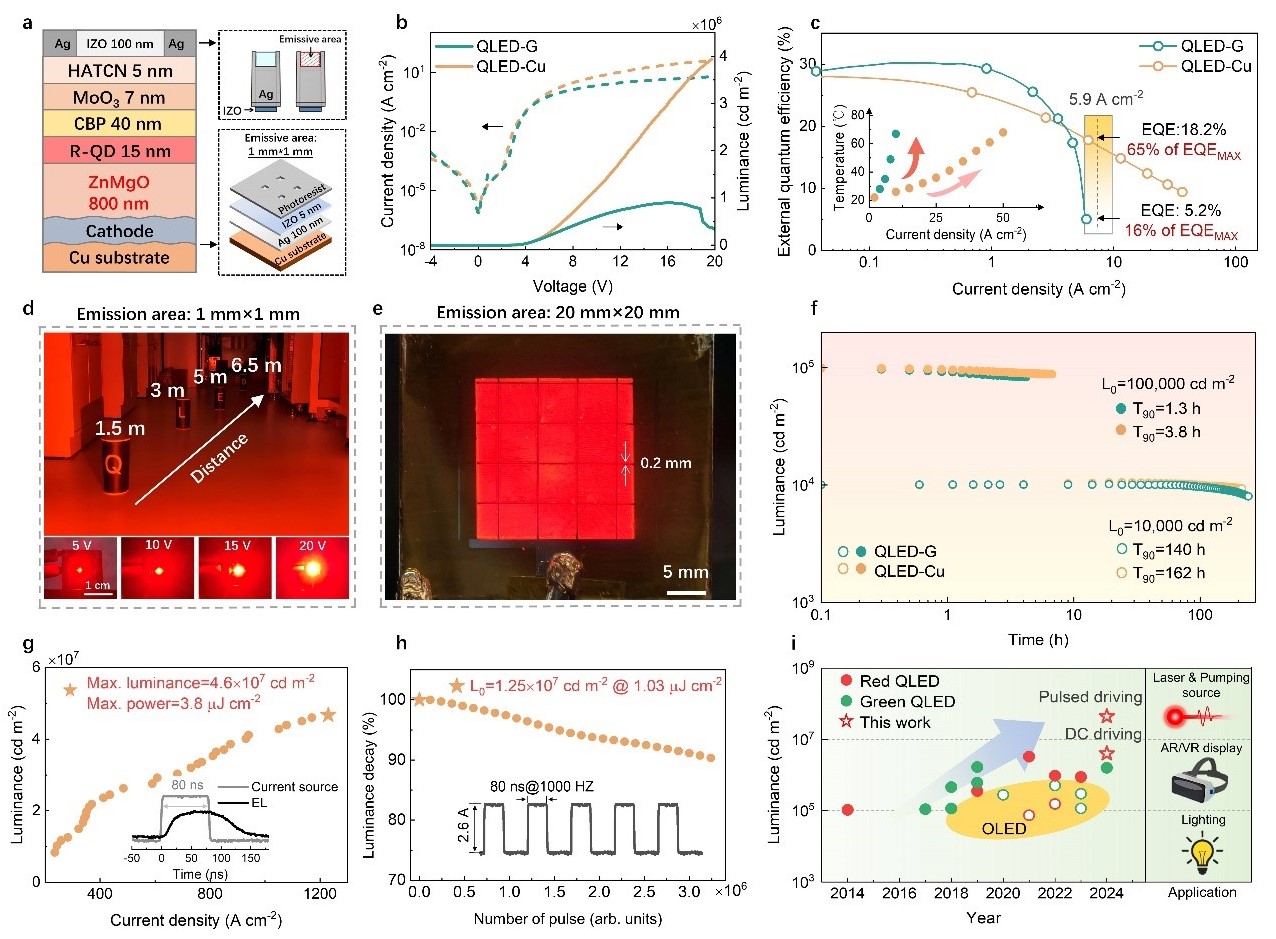

Figure 4. µm-thick QLEDs directly built on heat dissipation Cu substrate

The micrometer-thick c-ZnMgO layers notably broaden substrate compatibility for QLEDs, eliminating the strict requirement for nanometer-scale surface smoothness and enabling direct fabrication on rough copper substrates for the first time. Copper’s exceptional thermal conductivity significantly enhances heat dissipation under high-current operation, substantially reducing efficiency degradation (Figure 4). Consequently, these devices maintain 65% of their peak EQE even at a high current density of 5.9 A/cm², far surpassing the 16% achieved by conventional devices.

This effective thermal management enables a record-high brightness of 3,941,000 cd/m²—11.8 times higher than traditional QLEDs. Additionally, pulse-driven tests yield a remarkable peak brightness of 4.6×10⁷ cd/m², with a stable single-pulse optical output reaching 3.8 µJ/cm². Such exceptional brightness and stability significantly expand the potential applications of QLEDs in AR/VR, high-power lighting, and optical pumping technologies.

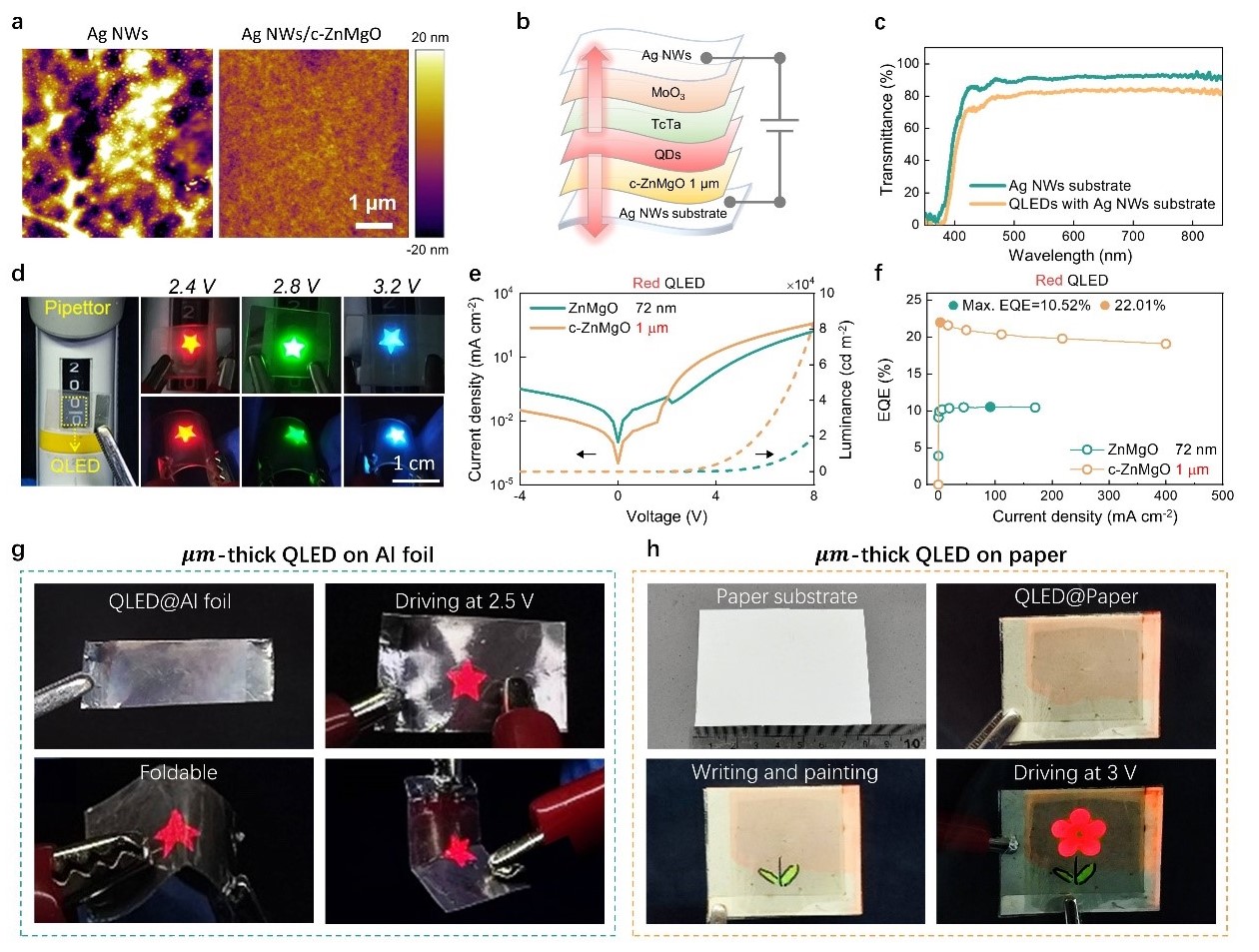

Figure 5. µm-thick QLEDs directly built on Ag NWs coated PETs, Al foils, and printed papers

This study further demonstrates that micrometer-thick c-ZnMgO efficiently accommodates rough substrates. By directly coating a 1 µm c-ZnMgO layer onto silver nanowires, significant reductions in surface roughness enabled the fabrication of fully transparent, flexible QLEDs exhibiting a high transmittance of 81.2% and an EQE of 22.01%, greatly surpassing traditional devices (10.52%). Similarly, QLEDs fabricated on rough substrates such as aluminum foil and paper also achieved nearly 20% EQE, highlighting promising applications in low-cost, flexible, writable, and stretchable displays.

Movie 1. The demo of QLED based on paper substrate

The work introduces a novel vapor-phase water treatment method to significantly increase electron concentration and suppress trap states in ZnMgO, successfully achieving highly conductive, micrometer-scale c-ZnMgO layers. Remarkably, QLEDs with these 1 µm thick ETLs demonstrated an EQE as high as 31.2% and exceptional stability, substantially surpassing conventional devices. The micrometer-thick film effectively covers rough substrates, enabling direct device integration onto copper, silver nanowires, aluminum foil, and paper substrates, thus facilitating flexible, transparent, and stretchable applications. Notably, QLEDs fabricated on copper substrates reached record brightness (3,941,000 cd/m²) and a lifetime exceeding 11,000 hours, establishing new performance benchmarks and accelerating QLED adoption for high-brightness displays and optical pumping applications.

This paper, titled “Micrometer-scale-thick quantum-dot LEDs with notably enhanced stability and ultra-high brightness”, has been published in Science Advances.

Doctoral student Zinan Chen at SUSTech is the first author of the paper, with Professor Shuming Chen serving as the corresponding author.

QLEDs often exhibit an unusual “positive aging” behavior, characterized by gradual improvements in device efficiency and brightness after days of storage. This phenomenon introduces randomness and unpredictability to device performance, severely undermining reproducibility in large-scale manufacturing—a critical bottleneck for QLED industrialization.

To address this critical industry challenge, Professor Chen’s group investigated the underlying mechanisms of positive aging and identified water-driven defect passivation in ZnMgO as the chemical driving force. Building upon this insight, they innovatively proposed a liquid-phase water treatment combined with post-annealing to effectively passivate ZnMgO defects, fundamentally eliminating positive aging. Their research showed that ZnMgO reacts with encapsulation adhesive (acidic resin), generating moisture that slowly diffuses and passivates ZnMgO defects, thus causing gradual efficiency and brightness enhancement during storage.

They employed liquid-phase water treatment followed by annealing to achieve defect passivation, resulting in devices exhibiting high initial performance—55.2 lm/W efficacy and 26% EQE, representing 2.04-fold and 1.67-fold improvements, respectively, over untreated devices. Moreover, device performance remained stable after storage, completely removing the positive aging effect. This work not only identifies water as the chemical driving force behind positive aging but also provides a viable approach toward producing high-performance, stable QLEDs.

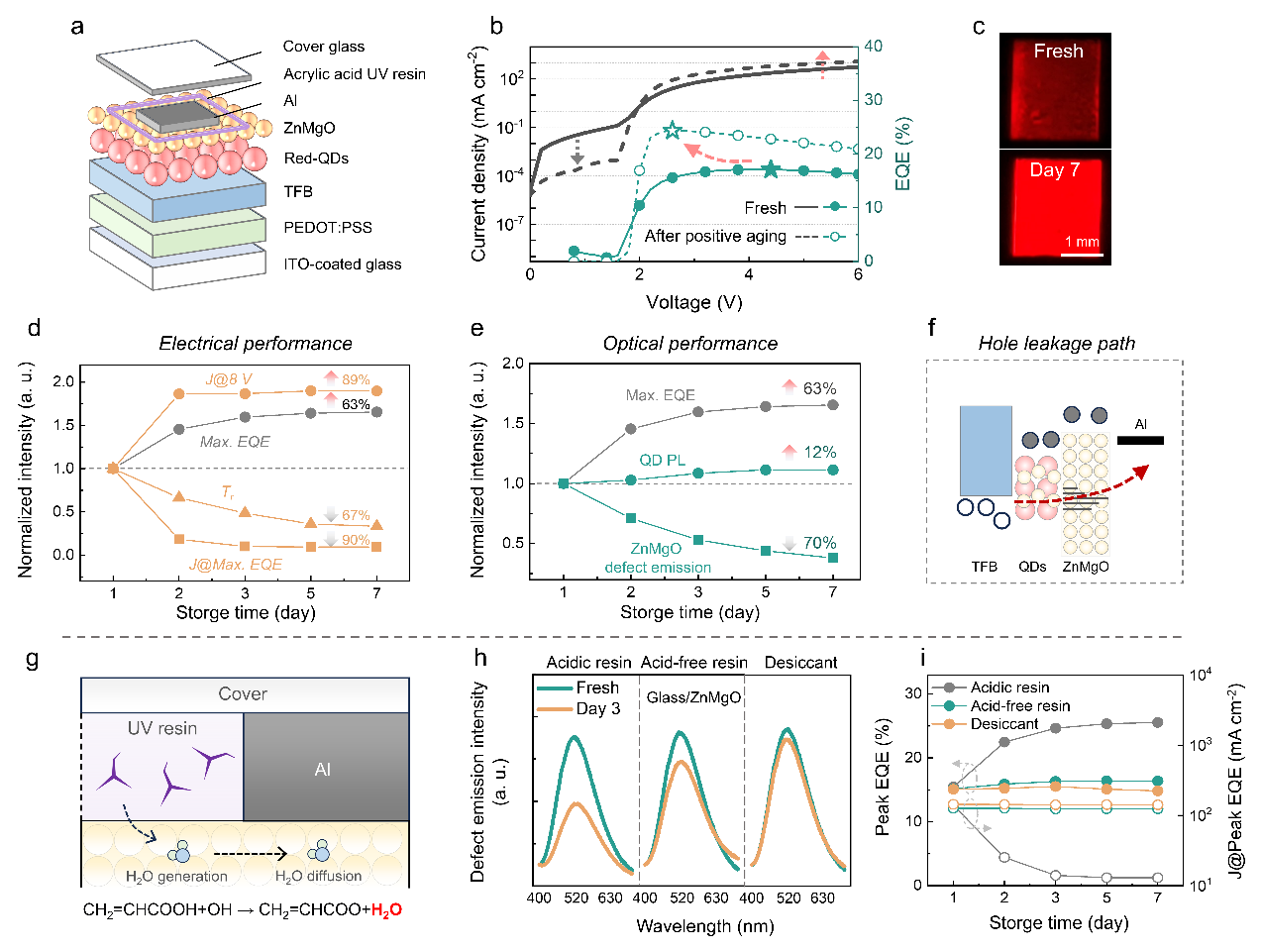

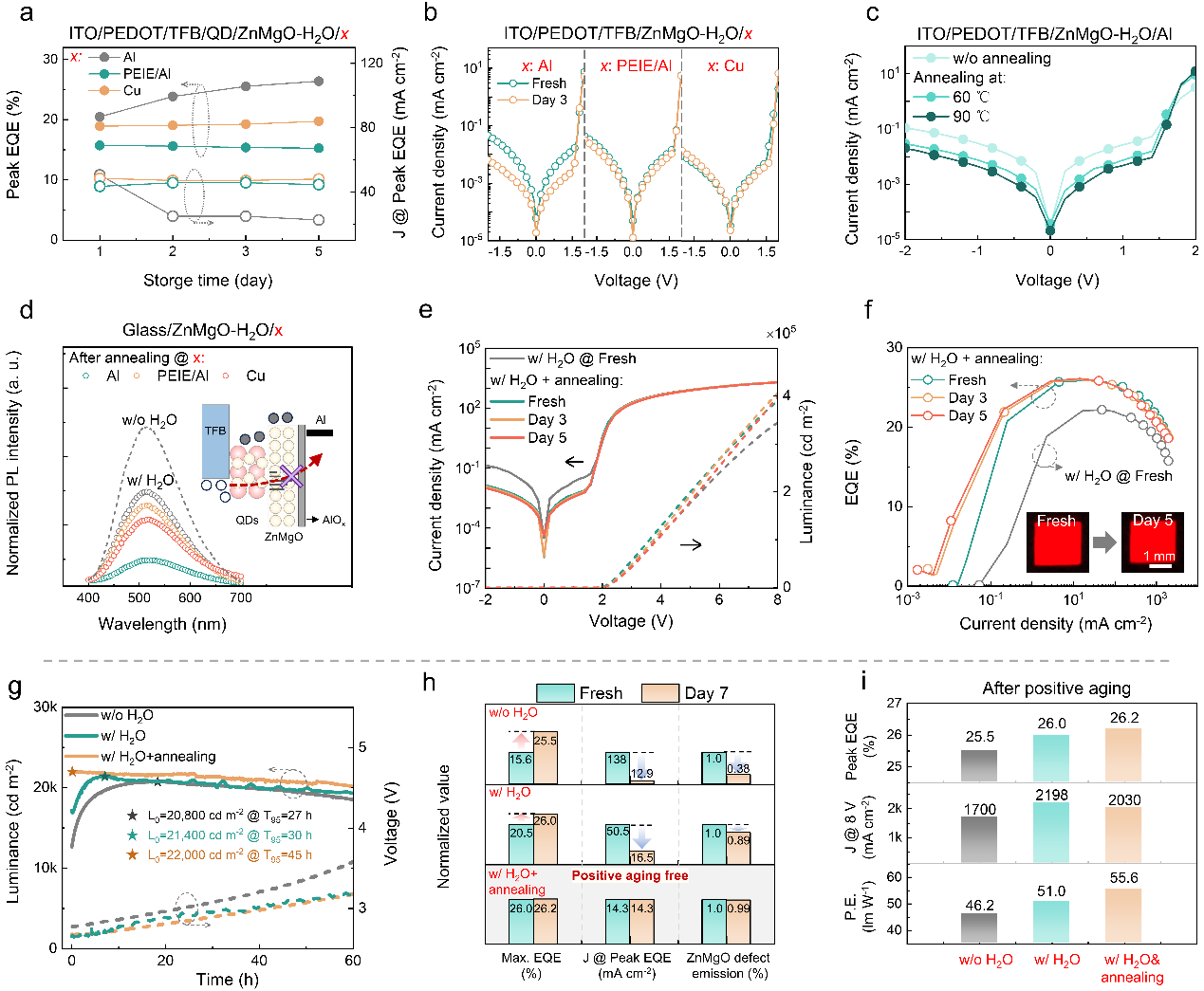

Figure 6. Deciphering the origin of positive aging

The mechanism underlying the positive aging effect observed in QLEDs is investigated through changes in device performance over time (Figure 6). In a typical QLED device with a standard structure, initial performance exhibits high leakage current and low charge recombination efficiency. However, after seven days, the device exhibits reduced leakage current and increased EQE (from 15.6% to 25.5%). Historically, this “positive aging” phenomenon was attributed to complex interactions between ZnMgO and acidic resins, yet the precise mechanism remained unclear.

Through comparative experiments, this study demonstrates that positive aging is not directly driven by the acidic resin itself. Instead, it results from water generated from reactions between the resin and hydroxyl groups on the ZnMgO surface. These water molecules chemically adsorb onto the ZnMgO surface, effectively passivating defects, enhancing conductivity, and increasing recombination efficiency, ultimately leading to substantially improved device performance. This insight fundamentally revises traditional views regarding positive aging, highlighting the crucial role of moisture in defect passivation and providing essential theoretical and technological pathways toward highly efficient and stable QLED devices.

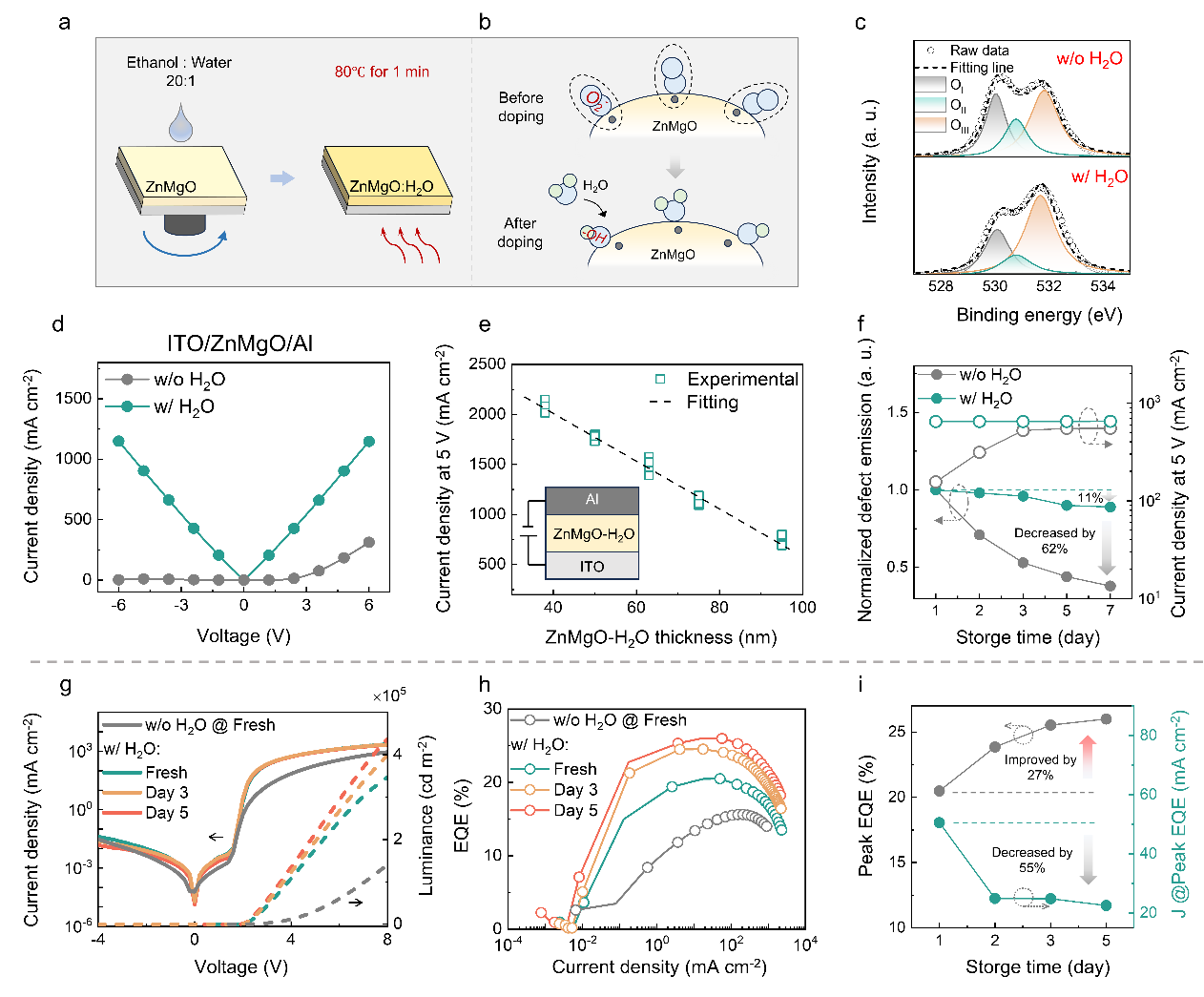

Figure 7. In-situ liquid-phase water treatment on ZnMgO

To rapidly passivate ZnMgO defects, the group developed a simple and controllable liquid-phase water treatment method. This involves spin-coating an ethanol-water mixture onto the ZnMgO surface, followed by a brief annealing step at 80°C for one minute to promote chemical adsorption of water molecules (Figure 7). This treatment suppresses oxygen adsorption sites, releases free electrons, and enhances ZnMgO conductivity.

QLED devices treated with this method demonstrated improved initial performance, achieving an EQE of 20.5% along with reduced leakage current and enhanced charge recombination efficiency. However, despite stabilized ZnMgO characteristics, devices still exhibited a mild degree of positive aging after five days of storage, indicating additional involvement from reactions at the ZnMgO/Al metal interface. Future research efforts will thus focus on interface engineering to fully suppress the positive aging phenomenon.

Figure 8. High performance and positive aging-free QLEDs enabled by water treatment and post-annealing

To investigate the influence of the ZnMgO/Al metal interface on the positive aging phenomenon in QLEDs, the researchers fabricated devices featuring various interfaces (Figure 8). The findings indicate that reactions between ZnMgO and Al effectively reduce hole leakage current and enhance efficiency, thus identifying this interface interaction as a fundamental cause of positive aging. Defect-related emission analysis further revealed that water treatment alone primarily suppresses shallow-level defects in ZnMgO, whereas deep-level defects persist and require additional passivation through annealing combined with highly reactive metals (such as the Al electrode).

By employing a synergistic strategy of water treatment followed by post-annealing, devices directly exhibited high efficiency (EQE up to 26%), significantly reducing leakage currents. Moreover, treated devices demonstrated extended lifetimes, consistent driving voltages, and excellent reproducibility.

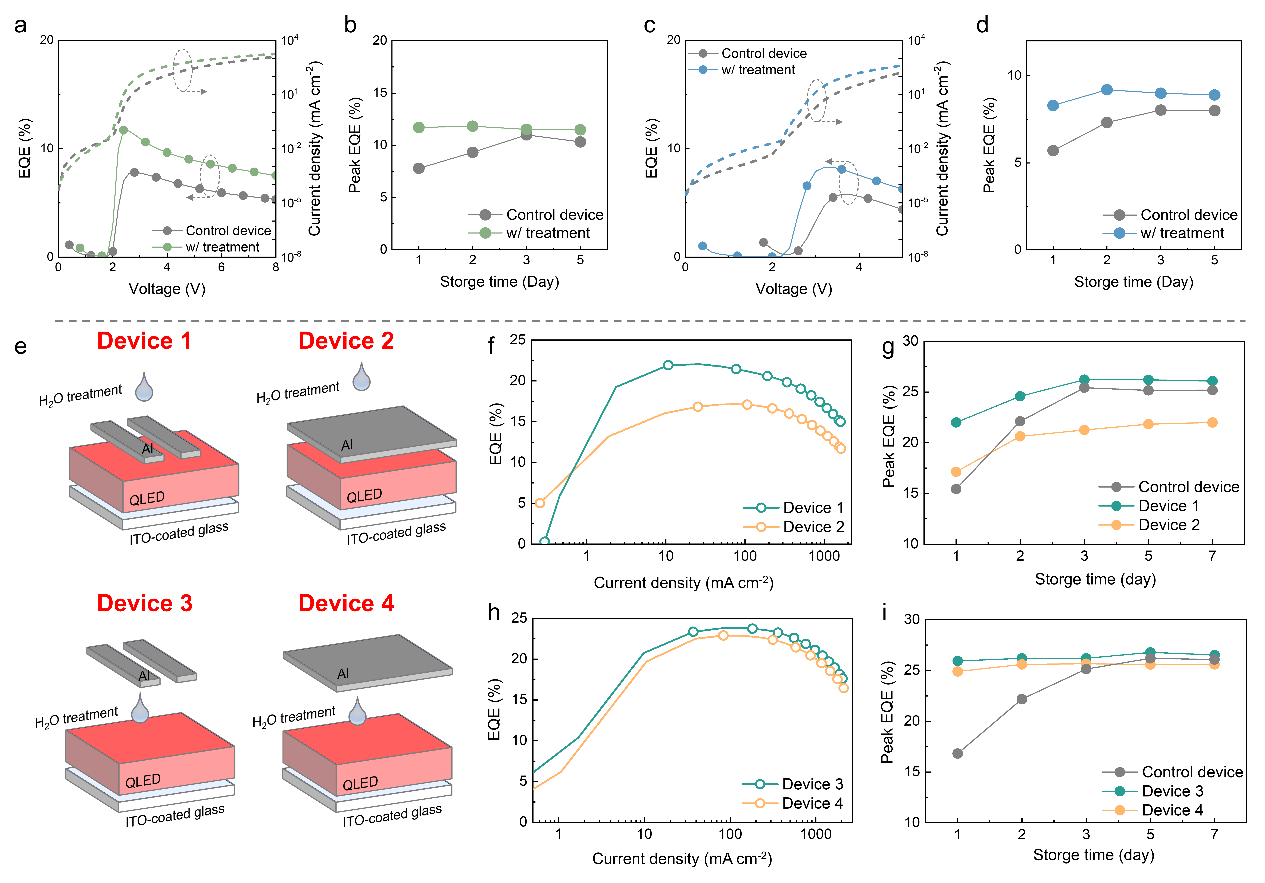

Figure 9. The versatility of water treatment method

The liquid-phase water treatment combined with the post-annealing strategy presented above was also successfully extended to green and blue QLEDs. Treated devices consistently demonstrated higher current densities and EQEs, along with stable electroluminescent performance over time, completely eliminating the positive aging phenomenon (Figure 9). The group further evaluated the practicality of various treatment methods. When water treatment was applied after Al electrode deposition, only partially exposed stripe electrodes (Device 1) allowed water penetration into the ZnMgO layer, effectively enhancing performance. In contrast, fully covered electrodes (Device 2) impeded water infiltration, resulting in limited defect passivation. Conversely, when water treatment was conducted prior to Al electrode deposition, both stripe and fully covered electrodes (Devices 3 and 4) exhibited high efficiency and stable, aging-free characteristics. These findings highlight the broad applicability of the proposed liquid-phase water treatment.

Although positive aging can temporarily enhance QLED performance, its inherently slow, random, and uncontrollable characteristics often lead to performance instability, posing substantial barriers to industrialization. To overcome this challenge, the researchers effectively passivated ZnMgO defects and significantly reduced leakage current through water treatment and post-annealing. As a result, treated QLEDs exhibited high performance (26.0% EQE, 55.2 lm/W) without requiring storage, thereby eliminating positive aging and providing critical technical support for industrial-scale QLED production.

This paper, titled “Eliminating Positive Aging in Quantum Dot Light‐Emitting Diodes by H₂O‐Treatment”, has been published in Advanced Materials.

Zinan Chen is the first author and Professor Shuming Chen is the corresponding author.

Paper links (In order of appearance above):

Science Advances: https://www.science.org/doi/10.1126/sciadv.ads7770

Advanced Materials: https://doi.org/10.1002/adma.202503477

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yilin ZHOU

Photo ByDepartment of Electronic and Electrical Engineering