Organic-inorganic hybrid perovskite materials have emerged as a game-changer in solar energy technology, thanks to their excellent photoelectric conversion efficiency and tunable bandgap properties. Unlike traditional silicon-based solar cells, perovskite solar cells (PSCs) can be manufactured using cost-effective solution processing, making them ideal for large-scale production. Despite their promise, PSCs still face challenges in reaching their full theoretical potential, hindered by issues like charge recombination, non-radiative losses, and material defects at critical interfaces.

To overcome these limitations, researchers have turned to self-assembled monolayers (SAMs) to improve interface contact and boost power conversion efficiency (PCE), particularly in inverted PSCs (iPSCs). However, conventional SAM-based hole transport layers often suffer from uneven coverage and weak adhesion, leading to perovskite crystal cracking and ion migration—key factors that degrade device performance and stability.

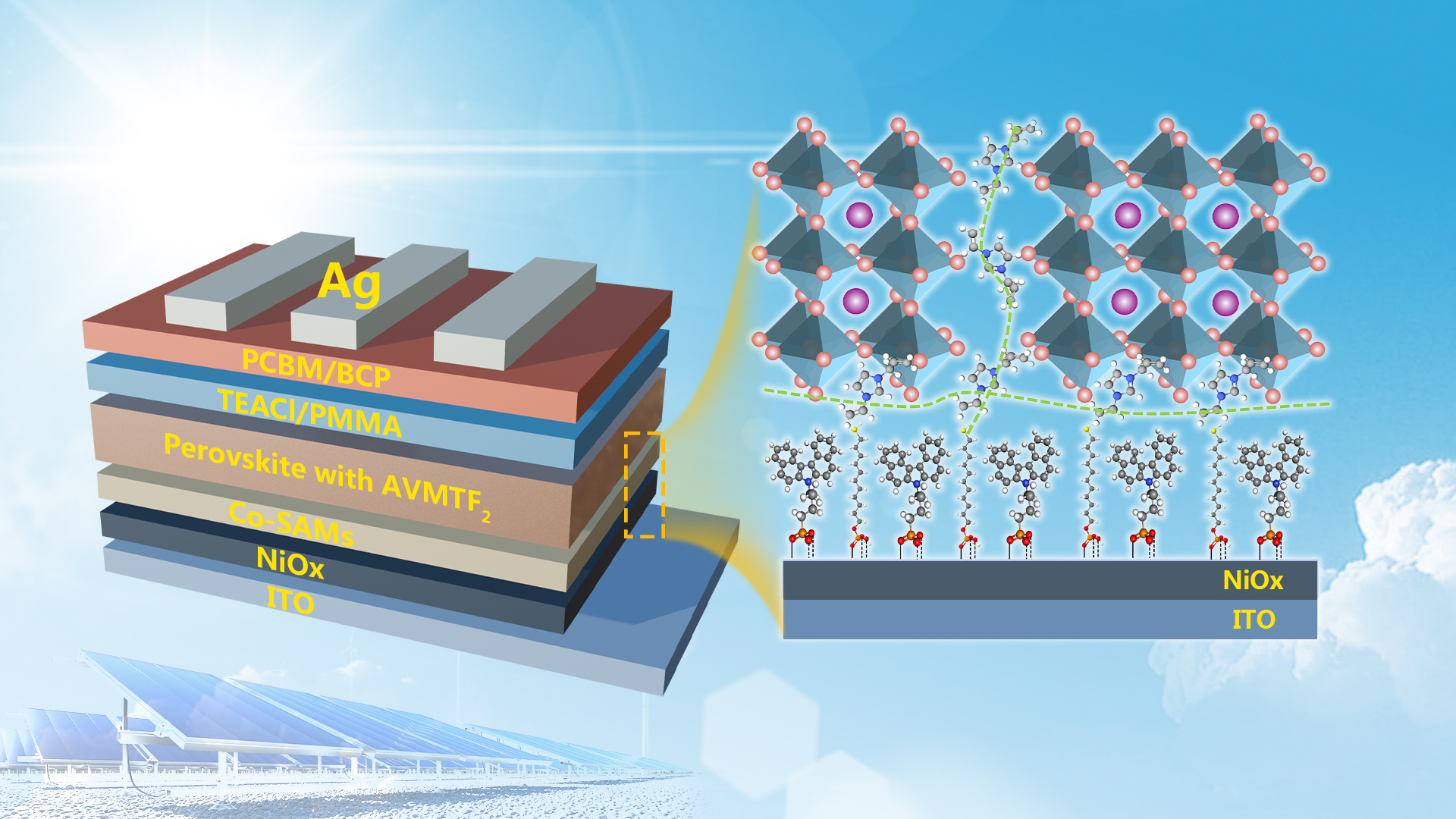

A research team led by Associate Professor Aung Ko Ko Kyaw from the Department of Electronic and Electrical Engineering at the Southern University of Science and Technology (SUSTech) has developed an innovative solution to address these challenges. By employing in-situ polymerization at the interface, they have successfully enhanced both the efficiency and stability of iPSCs. Instead of relying on a single SAM, the team introduced a co-assembly of two SAMs, one of which reacts with ionic monomers in the perovskite precursor solution. This triggers in-situ polymerization, forming a robust POL-AVM polymer layer at the buried interface (Figure 1).

Their study, titled “Adhesively Bridging Co-Self-Assembled Monolayer and Perovskite Via In Situ Polymerization for Enhanced Stability of Inverted Perovskite Solar Cells”, has been published in the leading scientific journal Advanced Materials.

Figure 1. Schematic illustration of in situ interfacial polymerization initiated by co-self-assembled molecules

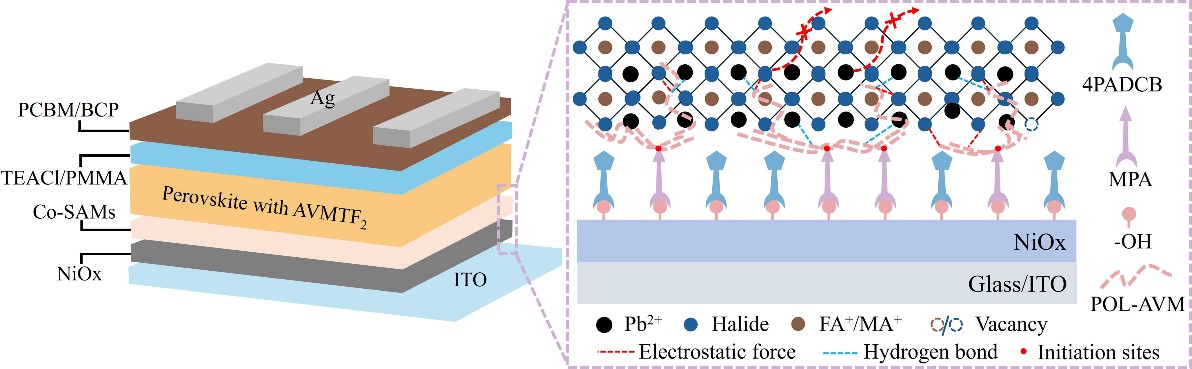

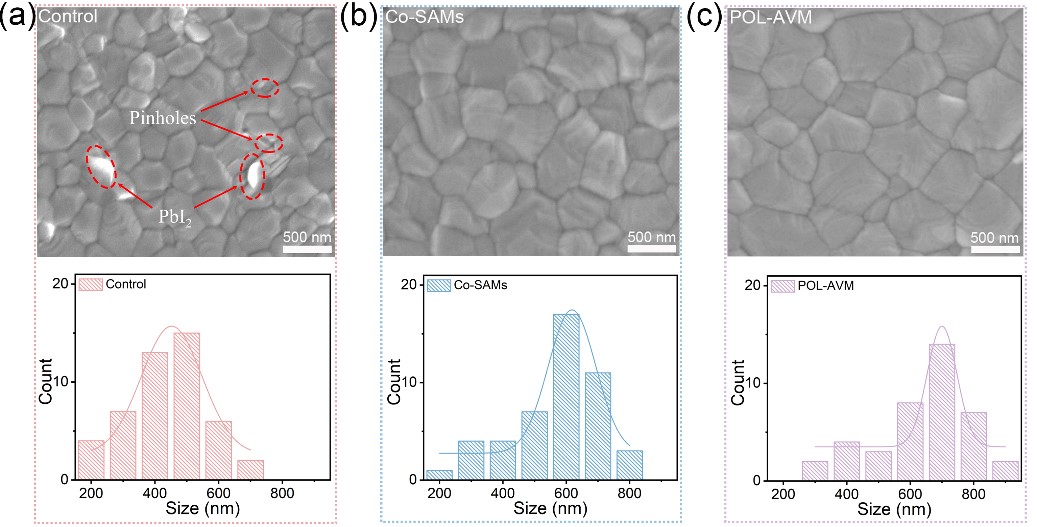

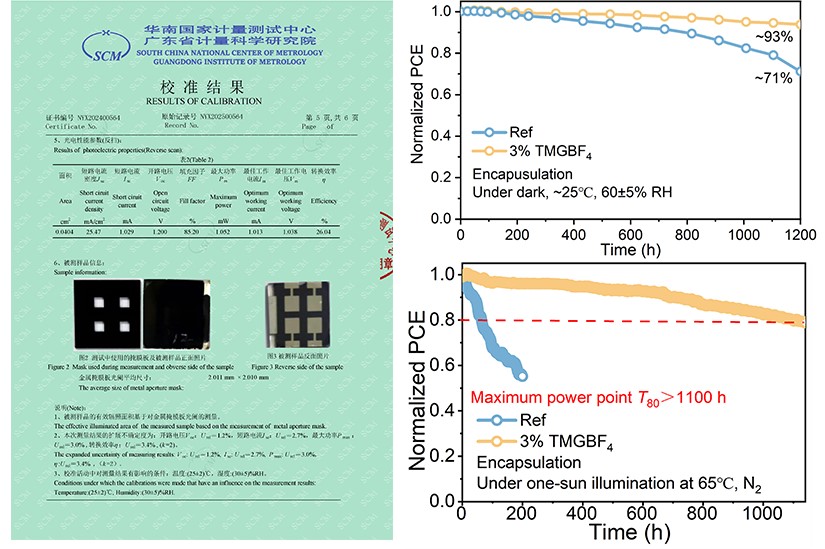

This novel approach improves crystallization by regulating perovskite crystal growth (Figure 2) while strengthening interface adhesion through multiple hydrogen bonds. These bonds effectively anchor organic cations and suppress halide ion migration, creating a “molecular welding” effect (Figure 3). As a result, the optimized iPSCs achieved a champion PCE of 26.25%, with third-party certification confirming a PCE of 26.04%. The devices also demonstrated an open-circuit voltage of 1.2 V and a fill factor of 85.2% (Figure 4).

Figure 2. Perovskite film morphology and grain size distribution

Figure 3. Characterization of interfacial adhesion (nano-scratch and 90° separation of beams)

Beyond efficiency, the devices exhibited exceptional stability. Unencapsulated cells retained 95.6% of their initial PCE after 1,000 hours of continuous illumination under maximum power point tracking (ISOS-L-2I standard). Even under thermal stress at 150°C, the perovskite film remained intact with no pore formation, overcoming organic cation escape—a common degradation mechanism.

Figure 4. The third-party certification report and the stability performance of the device

This synergistic interface engineering strategy—combining co-assembled SAMs and in-situ polymerization—provides a new pathway for developing high-efficiency, long-lasting perovskite solar cells and marks a significant step toward their commercial viability.

Doctoral student Xiaowei Xu from SUSTech is the first author of the paper. Associate Professor Aung Ko Ko Kyaw, Professor Baomin Xu from the Department of Materials Science and Engineering at SUSTech, and Pingping Sun from Hainan University are the corresponding authors.

Paper link: https://onlinelibrary.wiley.com/doi/10.1002/adma.202505745

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yifei REN

Photo ByDepartment of Electronic and Electrical Engineering