Understanding the structure of catalysts under reaction conditions is a topic of considerable concern for scientific researchers across the globe. Developing a better understanding of the atomic and molecular structure of catalysts during reactions will help scientists create more effective catalysts. To date, conventional characterization methods are used to indirectly obtain the structural information of the catalysts, which prevents researchers from determining specific and detailed local features. Given that catalytic reactions take place at the nanoscale or sub-nanoscale level, various in-situ imaging techniques have developed rapidly, with in-situ transmission electron microscopy technology (in-situ TEM technology) being the most typical.

Professor Gu Meng from the Department of Materials Science and Engineering (MSE) at Southern University of Science and Technology (SUSTech) has led his research group to design several experiments that have made full use of in-situ TEM technology to observe dynamic changes in catalytic structures during reactions. The results were published in top academic journals Small and ACS Nano.

The paper that was published in Small was titled “CO Gas Induced Phase Separation in PtPb@Pt Catalyst and Formation of Ultrathin Pb Nanosheets Probed by In Situ Transmission Electron Microscopy.“ The paper sought to study the state of catalysts in the catalytic reaction, as the surface structure of the catalyst is regulated by the influence of gas molecules on the surface energy. Current research is still trying to determine how gas molecules reconstruct the catalyst surface during catalytic reaction, and more are trying to work out how the overall structure changes in the process of catalytic reaction.

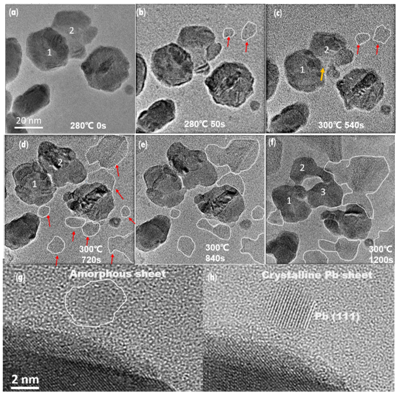

In their paper, the structural and phase changes of platinum lead catalysts (PtPb@Pt core-shell catalysts) in carbon monoxide heavy gas environments were studied, as well as under vacuum conditions, using in-situ TEM technology to observe the impact of the different environments. They found that the nanosheets would grow in size with an increased heat size and shed larger ultrathin flakes, before ultimately combining into larger particles. Studying this using in-situ TEM technology ensured an improved understanding of dynamic evolution process of phase separations.

The research team was able to visualize the layer-by-layer growth of ultrathin Pb-nanosheets and determine their structural properties in different environments. It also provides an insight onto the toxic impact of CO on many catalytic systems, while determining methods for optimizing bimetallic or core-shells catalysts.

Wang Qi was the first author, and Zhao Zhiliang was a contributing author, with Professor Gu Meng as the correspondent author. SUSTech was the correspondent unit. This paper was supported by the National Natural Science Foundation of China, Shenzhen DRC project, and Guangdong Provincial Key Laboratory of Energy Materials for Electric Power. The TEM work was performed at the SUSTech Pico center that receives funding from the Shenzhen government.

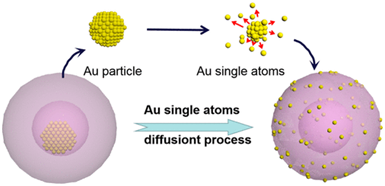

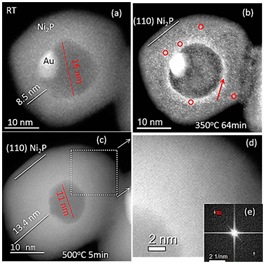

The paper published in ACS Nano was titled “Direct Observation of Yolk–Shell Transforming to Gold Single Atoms and Clusters with Superior Oxygen Evolution Reaction Efficiency.” It aimed to reduce the cost of commercial iridium dioxide (IrO2) as a catalyst for commercial hydrogen production in order to develop clean sustainable energy. At this point in time, oxygen evolution reaction (OER) catalysis is quite slow and the commercial IrO2 catalyst is extremely expensive due to its use of precious metals. Recent research has indicated that a single-atom catalyst is highly efficient for chemical reactions and significantly reduces the use of precious metals.

The research team of Professor Gu Meng found a new method of converting gold nanoparticles into single atoms or clusters through annealing. They observed through in-situ TEM technology that the individual gold (Au) atoms would provide significantly better OER performance compared to commercial IrO2 catalysts. This finding could provide highly levels of selectivity in a wide range of chemical reactions, and is worthy of further research.

Cai Chao and Han Shaobo were the co-first authors. Wang Qi was a contributing author, with Professor Gu Meng as the correspondent author. SUSTech was the correspondent unit. The ACS Nano Paper was supported by the National Natural Science Foundation of China, Development and Reform Commission of Shenzhen Municipality, Shenzhen Peacock Plan, Guangdong Innovative and Entrepreneurial Research Team Program, and Guangdong Provincial Key Laboratory of Energy Materials for Electric Power.

Proofread ByXia Yingying

Photo ByDepartment of Materials Science and Engineering