Organic photovoltaics (OPVs) hold the promise as renewable power sources for portable and wearable electronics, as well as smart wallpapers in buildings because OPVs could be thin, light, and flexible. However, in the practical application scenario of solar cells, the incident angle of sunlight constantly changes with time and cannot remain perpendicular to the stationary flat photovoltaic devices. Traditional solar tracking methods rely on heavy motion mechanisms that often require additional motor and power, which are not suitable for thin-film solar cells.

Professor Weiwei Deng’s group from the Department of Mechanics and Aerospace Engineering (MAE) at the Southern University of Science and Technology (SUSTech) recently published their findings where they put forward a new approach to solar tracking based on kirigami, a variation of origami, the Japanese art of folding paper, by taking the benefits of its paper-like OPVs made on flexible materials.

Their research, entitled “Printed kirigami organic photovoltaics for efficient solar tracking,” was published in Advanced Functional Materials, a top-tier journal reporting breakthrough research in all aspects of materials science, including nanotechnology, chemistry, physics, and biology.

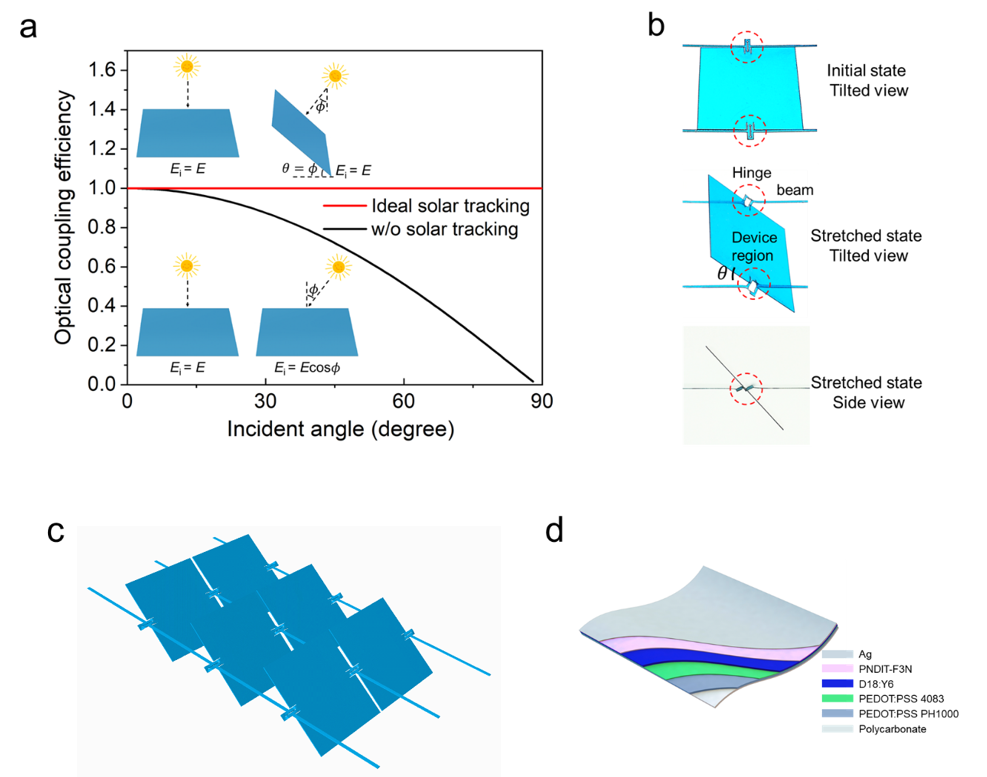

In this study, the researchers proposed a new solar tracking approach based on kirigami by taking the advantage of the paper-like OPVs made on flexible substrates. The kirigami pattern is judicially designed to form three separate regions of beams, hinges, and devices. The stretching force is applied to beams, which cause out-of-plane deformation of the hinges, rotating the device connected to the hinges and maintaining nearly 100% optical coupling efficiency. In this way, the stress only appears on the hinges while the device regions are stress-free.

Figure 1. The principle and structure of solar tracking for flexible kirigami OPVs: (a) The principle of solar tracing to maximize light utilization; (b) Schematic diagram of kirigami; (c) Configuration of kirigami OPV stretching; (d) Flexible OPV device structure.

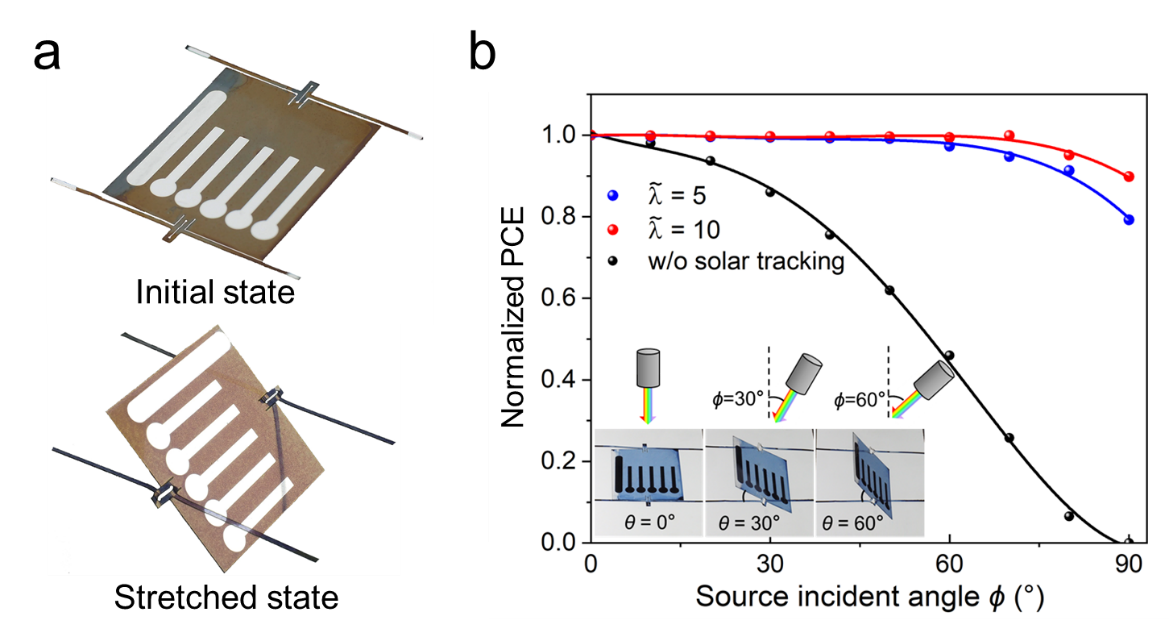

The electrospray method is used to print active layers on the pre-cut kirigami substrates of polycarbonate. Small-area devices (0.043 cm2) printed on the kirigami substrates reach the highest efficiency of 14.15%. The large-area devices (0.62 cm2) demonstrate PCE up to 10.19%. The kirigami OPVs are also mechanically robust, showing no appreciable performance degradation after over 20,000-cycle stretching. The rotating angle and strain are decoupled from the device region between hinges, which provides possibilities to customize the shapes of the device region to achieve other functions such as ventilation and decoration.

Figure 2. Performance of kirigami OPVs (a) The configuration of kirigami in its initial state and stretched state; (b) The normalized PCEs of kirigami OPVs measured by rotating the plane of the devices with the light source simultaneously (i.e., at the solar-tracking state), and the inset showing rotating states at θ = 0, 30, and 60°.

The satisfactory PCEs, the effective solar tracking, and the versatile design possibilities brought by the kirigami are powerful demonstrations of the thin, light, and flexible features of OPVs. The stretchability of the kirigami structure is independent of the functional materials, which will make the kirigami design a versatile strategy and may spawn new research ideas for stretchable electronics.

Yaxing Li, a master’s student from the Dept. of MAE at SUSTech, is the first author of this paper. Research Assoc. Prof. Xinyan Zhao and Prof. Weiwei Deng at SUSTech are the co-corresponding authors. Kai Chang, Boyang Yu, Jingyu Chang, Linna Liu and Bingyang Liu also contributed to this study.

The work was financially supported by the National Natural Science Foundation of China (NSFC) and the Shenzhen Key Laboratory of Soft Mechanics & Smart Manufacturing.

Paper link: https://onlinelibrary.wiley.com/doi/abs/10.1002/adfm.202204004

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By