Alternating current electroluminescent (ACEL) devices are devices that can emit vibrant, luminous light when applying an alternating current. Because of their simple device architecture, promising ability to work under harsh environments and uncomplicated manufacturing processes, these devices have attracted considerable attention in various emerging fields, such as information encryption, smart electronic skins, soft robots, and optical communications.

Despite recent advances in ACEL devices, producing mechanically flexible ACEL devices via customizable methods remains challenging. At present, ACEL devices are commonly fabricated via multi-layer lamination, where an electroluminescent phosphor layer is sandwiched between two stretchable electrodes. The series of steps and expensive utilities (i.e., masks and delicate tools) involved in this technique severely limit its applications in rapid prototyping and customization.

Associate Professor Ji Liu’s research group from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has recently reported a facile and streamlined approach for fabricating electroluminescent devices through multi-materials direct ink writing.

The fabrication scheme and the ink formulation enable the creation of mechanically flexible devices with excellent interfacial robustness, enabling the integration of the electroluminescent devices with soft robots. Using this fabrication scheme, a chameleon-inspired soft robot with self-adaptive background-matching ability was created.

Their study, entitled “Integrated 3D printing of flexible electroluminescent devices and soft robots,” was published in Nature Communications, a multidisciplinary journal covering the natural sciences, including physics, chemistry, earth sciences, medicine, and biology.

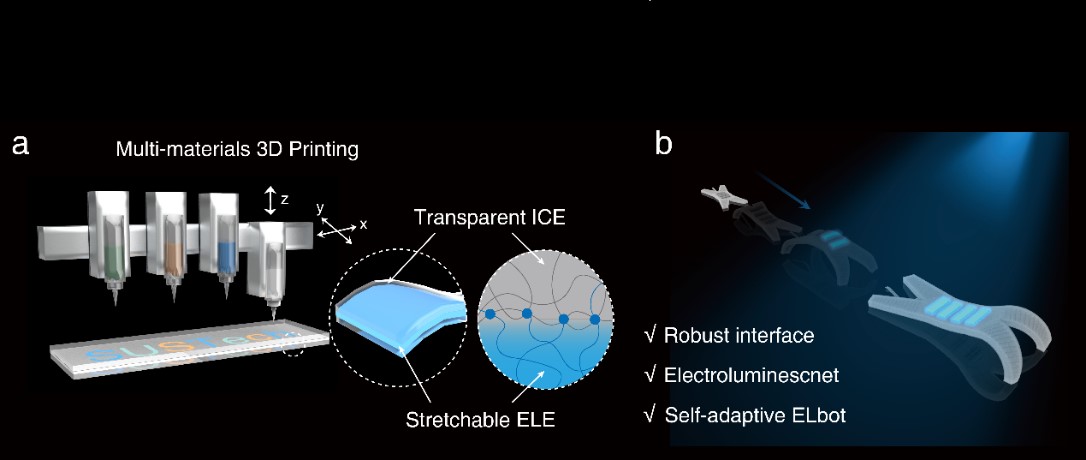

Prof. Liu’s team proposed a streamlined approach to fabricate flexible electroluminescent (EL) devices through multi-material 3D printing (Figure 1a). The devices exhibit excellent robustness and high mechanical flexibility, making them suitable for soft robotic applications. To further demonstrate this potential, the researchers integrated these 3D printed EL devices with a pneumatically-driven soft robot to produce an artificial camouflage that can instantly self-adapt to the environment by displaying matching colors, imitating the color-changing ability of chameleons (Figure 1b). This proposed strategy can be readily extended to create the next generation of soft and complex EL devices.

Figure 1. 3D printing of electroluminescent devices and an integrated fabrication strategy for self-adaptive soft robots

3D printing flexible electroluminescent devices

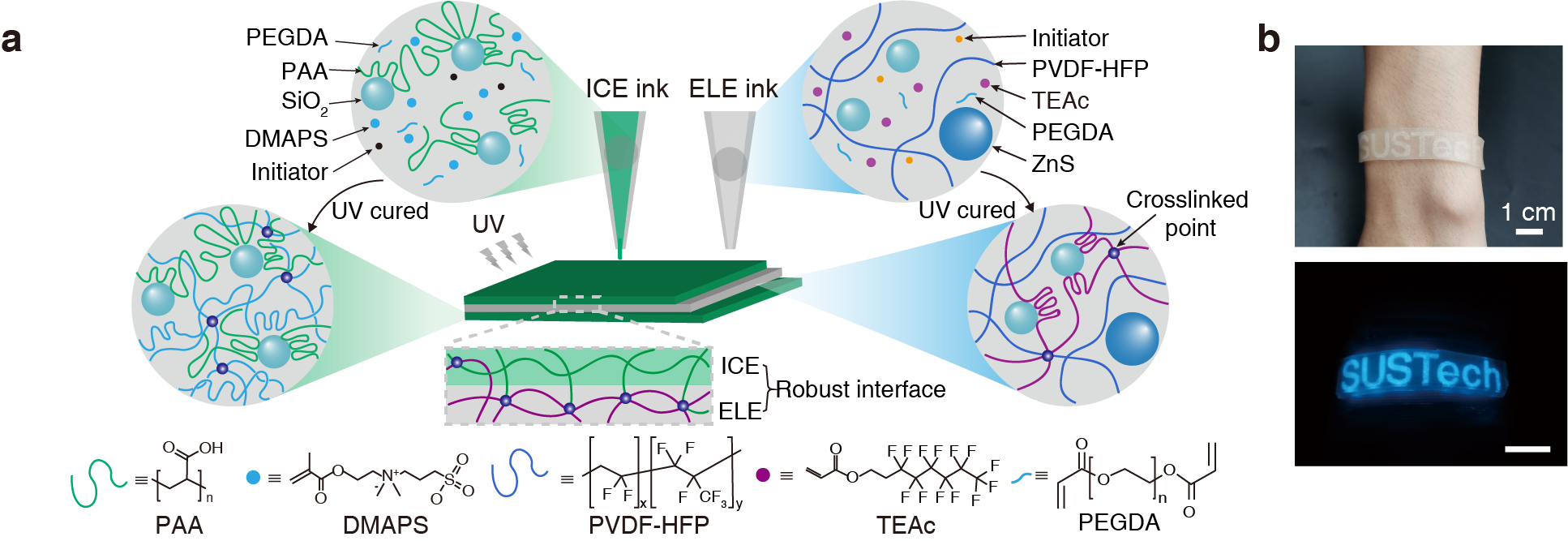

This work utilized multi-material direct ink writing (DIW), a widely used extrusion-based 3D printing technique, to achieve a viable and high-throughput fabrication. This method enables the fabrication of 2D and 3D complex architectures in a layer-by-layer manner. In general, alternating current electroluminescent devices are composed of ion conducting elastomer (ICE), electroluminescent elastomer (ELE), and insulting dielectric elastomer (IDE) layers.

To encompass these components, the researchers formulated various printable and UV curable composite inks (Figure 2a). With the fabrication strategy and the tuned ink formulation, high mechanical compliance of the devices can be achieved, and robust interfacial adhesion is realized between different layers of the devices. The devices can withstand repeated large deformation, such as bending and twisting, without delamination. This fabrication strategy offers scope for customization. As an example, a wearable EL wristband with a customized luminous ‘SUSTech’ logo was created (Figure 2b).

Figure 2. 3D printing flexible electroluminescent devices

Chameleon-inspired camouflages via integrating EL devices with soft robots

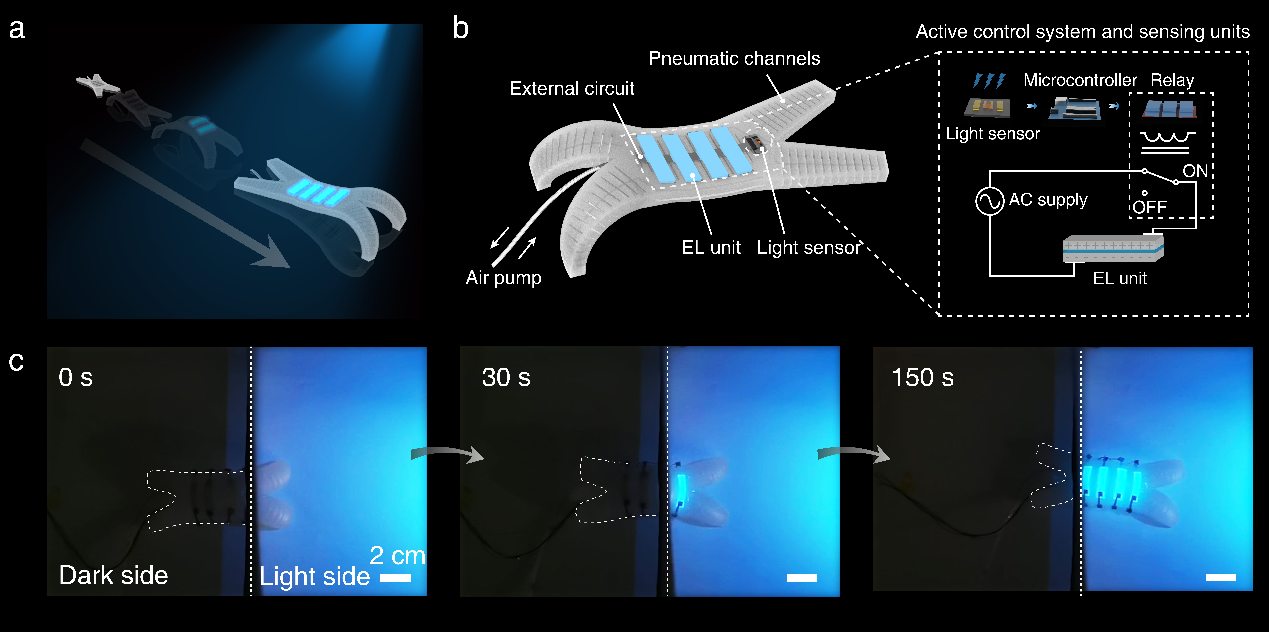

Owing to the flexibility and the interfacial robustness of the 3D printed EL devices, the 3D printed EL devices can be integrated with other soft systems. Prof. Liu’s team integrated the EL devices with a pneumatic soft robot to create self-adaptive background-matching camouflages, inspired by the color-changing ability of nature chameleons (Figure 3a). The EL units were printed on a quadrupedal soft robot, which is powered by pressurized air (Figure 3b).

With the use of a light sensor, the ELbot can retrieve the background color information and spatially change its surface color to match the environment in an autonomous fashion via circuit control (Figures 3b-c). As demonstrated in Figure 3c, when the robot crawled to a blue light environment, the EL devices emitted a blue light and instantly blended into the background environment without any notable delay. Noteworthy, owing to the flexibility and interfacial robustness of the EL devices, the 3D printed EL devices can be conformally attached to the soft robots’ surface even under continuous dynamic deformation.

Figure 3. Control logic and the spatially color-changing ability of the electroluminescent soft robot

Video 1. Spatially color-changing ability of the ELbot when crawling from dark to bright environment

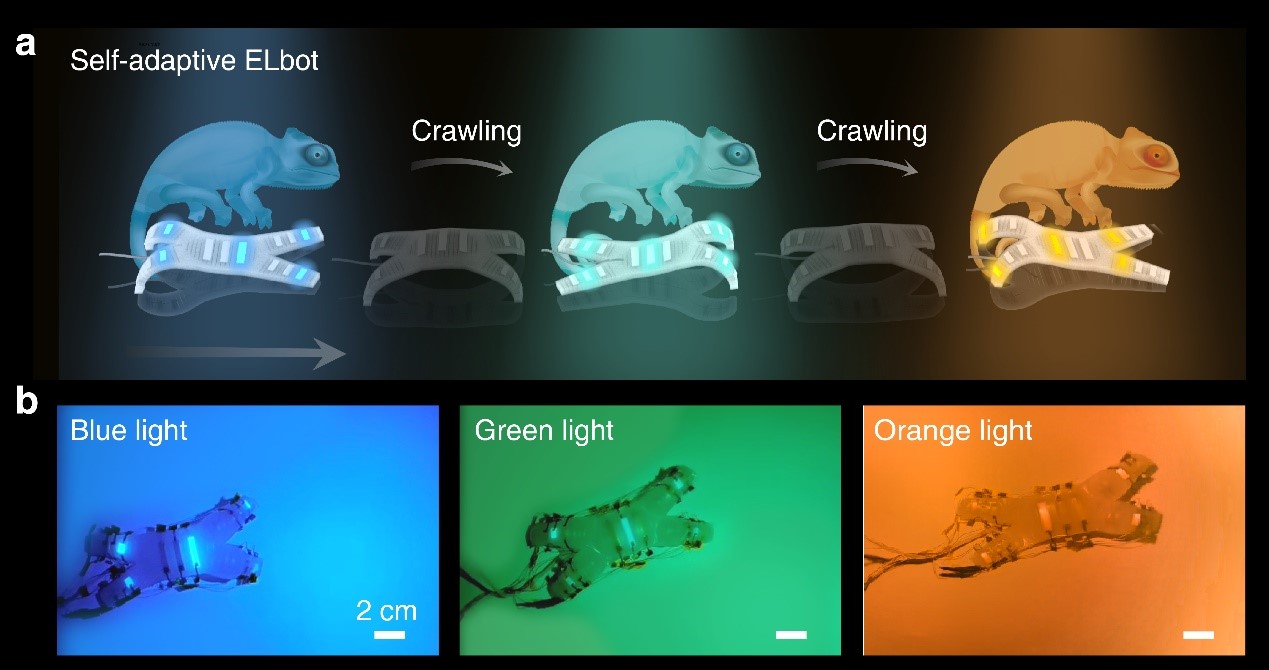

Multiple color-matching within one single device can be achieved via printing different EL devices through multi-material DIW printing. For example, light display and soft robots (Figures 4a) can be endowed with multiple color-matching abilities when encompassing different printable light-emitting EL units in the systems, such as green, blue, and orange. Upon exposure to different light environments or crawling to different light habitats, the corresponding color-emitting units on the system instantly illuminated and emitted similar light colors. This color-matching capability is fast, outrivaling most of the existing artificial camouflages, and enables the potential to recapitulate the innate camouflaging behaviors in living species.

This work suggests a facile strategy that can be used to transform conventional electroluminescent components into soft, stretchable, and customizable EL devices. The proposed strategy opens up new avenues for the next generation of completely soft light-emitting devices, smart displays, and camouflaging systems.

Figure 4. Self-adaptive multiple background color-matching ability of the electroluminescent soft robot

Video 2. Self-adaptive background-matching ability of the ELbot

Pei Zhang, a Ph.D. candidate in Assoc. Prof. Ji Liu’s research group at SUSTech, is the first author of this paper. Prof. Ji Liu is the corresponding author.

This research was supported by the Shenzhen Key Laboratory of Bionic Robots and Intelligent Systems, Guangdong Provincial Key Laboratory of Human Enhancement and Rehabilitation Robots in Ordinary Universities, Natural Science Foundation of Guangdong Province, Basic Research Program of Shenzhen, MechERE Centers at MIT and SUSTech, and Additive Manufacturing Innovation Center at SUSTech. This work was also supported in part by the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link: https://www.nature.com/articles/s41467-022-32126-1

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By