Solar interfacial evaporation using the thermal localization concept offers a flexible and efficient pathway for desalination, steam sterilization, and various other water treatment processes. Several novel materials and device configurations have been reported to enhance the evaporation efficiency of solar interfacial evaporation systems.

Although these studies have provided insights on how to achieve high evaporation performance, it has not yet revealed how to quantitatively assess the optimal materials and devices designed to maximize the device performance. In addition, the understanding of the interplay of the various evaporator layers and their interactions with bulk water and environment, as well as the corresponding understanding of the coupled light absorption, multi-mode heat transfer, and water and vapor transfer mechanisms in the layers and the complete device is important for engineering practical solar evaporators.

Assistant Professor Meng Lin’s research group from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has recently published their research findings which the evaporation interface (location and thickness) is identified to quantify the interplay of optical and transport processes for guiding the rational design of materials and devices.

Their research results, entitled “Understanding Interfacial Properties for Enhanced Solar Evaporation Devices: From Geometrical to Physical Interfaces,” have been published in ACS Energy Letters. The paper was also selected as the supplementary journal cover article of the issue.

Prof. Lin’s team theoretically and experimentally demonstrated that an absorption coefficient of 400 m-1 leads to an optimal efficiency that pins the interfacial location below the top surface of the absorber due to reduced radiation and convection losses to the ambient. They subsequently demonstrated an efficient multi-stage evaporation device with an optimized interface within the transitional region. This device shows an evaporation rate of 5.38 kg m-2 h-1, which is 12% higher than the device operated within the interfacial region.

The light absorber layer in solar interfacial evaporation devices is, in general, considered as a thin layer with high absorptance, leading to the evaporation interfacial overlapped with the absorbing surface. This design is effective in terms of the separation of the evaporation surface from the cold bulk water. However, the direct contact of the hot evaporation surface with the ambient may lead to uncontrolled convection and radiation losses.

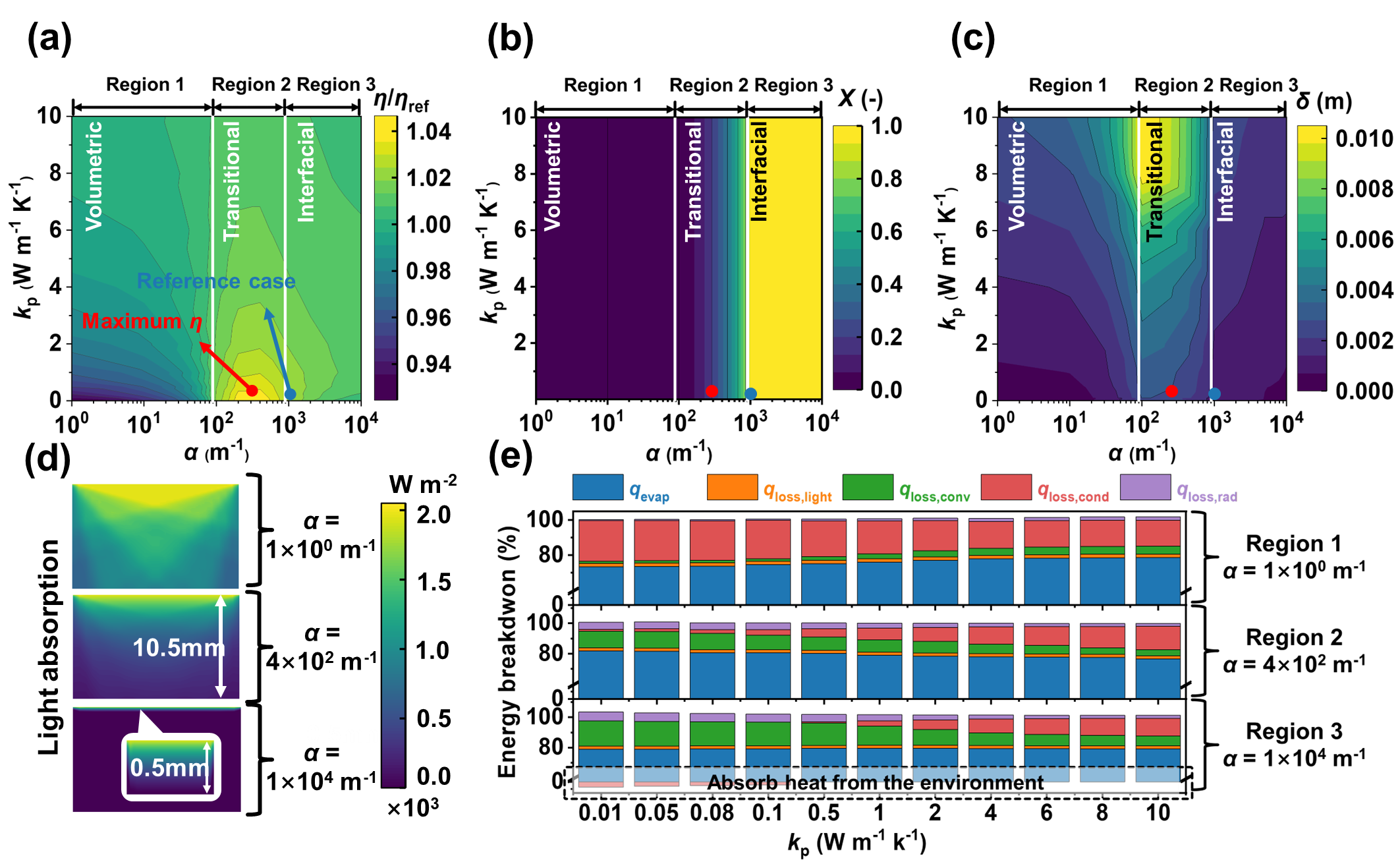

In this study, the researchers defined two additional metrics: ‘Interfacial location (X)’ and ‘Interfacial thickness (δ)’ to quantify the thermal localization effect (Figure 1). The interfacial location is defined as the location of the cross-section with the highest temperature in the system (Tmax). The interfacial thickness is the height of the region in which superheat is larger than 10%. The superheat here refers to the temperature difference between the highest temperature in the system and the far-field ambient temperature.

Figure 1. Schematics of solar interfacial evaporators, including the light absorber, substrate, and bulk water. The interfacial location – X and interfacial thickness – δ, as well as the wicking direction and waterfront – Hwf are represented by white dashed lines or arrows. The detailed energy breakdown, i.e., solar radiation – qin, evaporation – qevap, reflection – qloss,light, radiation – qloss,rad, convection – qloss,conv, and conduction – qloss,cond are denoted by dashed red arrows.

Firstly, a comprehensive 2D physical-based model was developed, accounting for the optical as well as the heat and mass transfer involved within a solar interfacial evaporator and its surrounding environment. The effects of optical and thermodynamic interfaces on evaporation performance were explored by adjusting the absorption coefficient (α) and thermal conductivity (kp), as shown in Figure 2a. Three regions with distinct evaporation behaviors were identified, i.e., Region 1 – Volumetric region; Region 2 – Transitional region; Region 3 – Interfacial region. A typical solar interfacial evaporator generally absorbs the incident light at the upper surface of the system and converts it into heat for evaporation; that is, it works in the interfacial region.

Figure 2. Effects of absorption coefficient and thermal conductivity on evaporation efficiency. (a) Evaporation efficiency (η), (b) interfacial location (X), and (c) interfacial thickness (δ) as a function of absorption coefficient (α) and thermal conductivity (kp) under the reference condition. Three regions are identified: Region 1 – Volumetric region; Region 2 – Transitional region; Region 3 – Interfacial region. The highest η is marked with a red dot. The reference case is marked with a blue dot. (d) The light absorption profile within the solar interfacial evaporator for three selected α in different evaporation regions. (e) The energy breakdown for three evaporation regions as a function of kp. The α is 1 m-1, 400 m-1, and 10,000 m-1 for regions 1, 2, and 3, respectively.

Through their research, they found that the evaporation performance of the device can be further improved by reasonably designing the interface properties of the system and making the system work in the transition evaporation area. In this work, the best-performing design lies in the transitional region (Region 2) with the α = 400 m-1, where the location (X = 0.32) for evaporation was within the evaporator, instead of the top surface, and the interfacial thickness (δ = 0.0027 m) was thin (see Figure 2b, 2c and 2d). Heat loss analysis shows that evaporation in the transitional region can effectively reduce the radiation and convection losses of the system to the environment and maximize the evaporation performance.

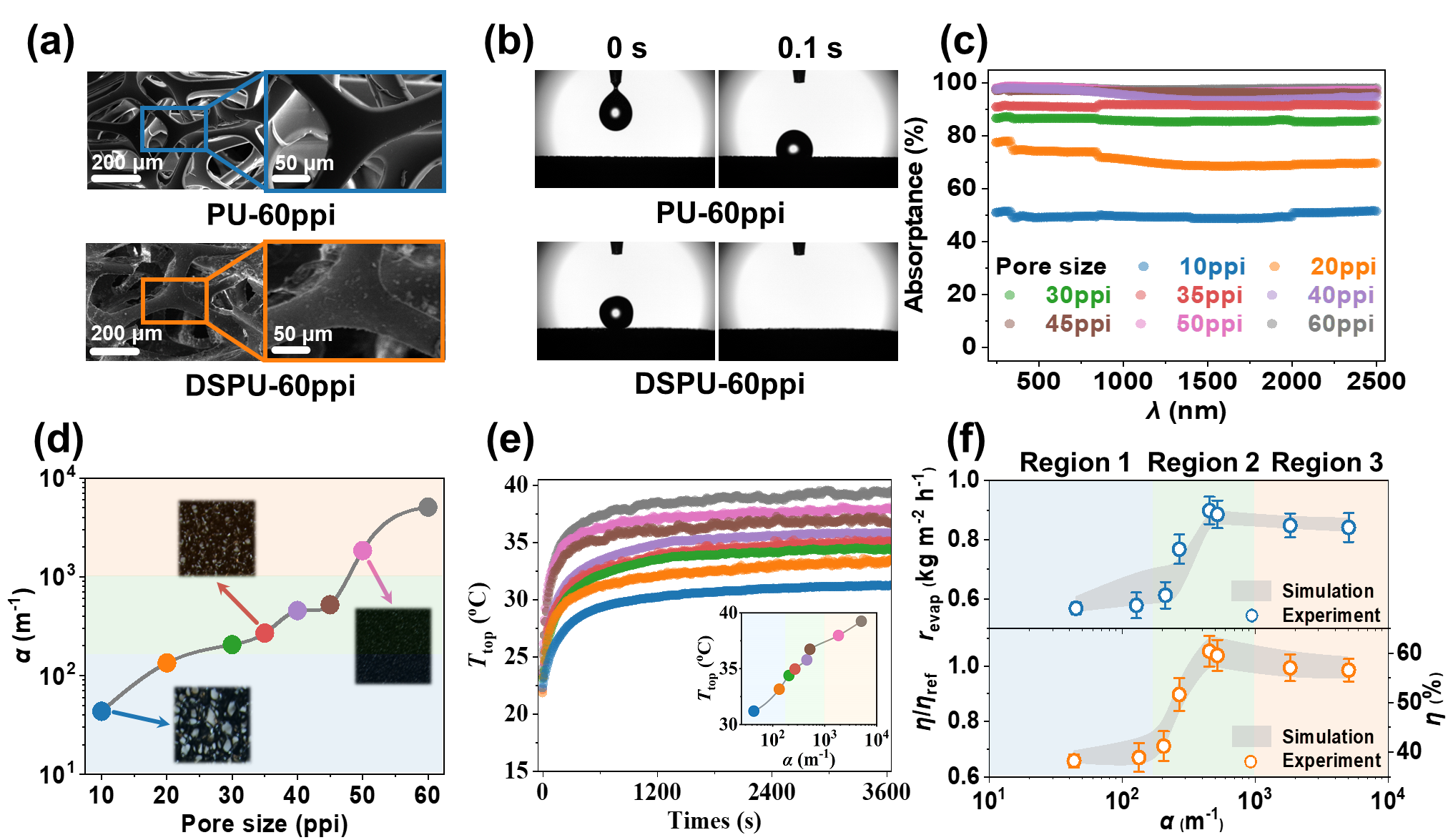

The dopamine solution-polyurethane (DSPU) sponge was obtained by hydrophilic treatment of polyurethane sponge (PU) using dopamine solution for validating the effect of the absorption coefficient on evaporation efficiency (Figure 3). The DSPU was tested by SEM, water contact angle, and absorptivity, and the corresponding absorption coefficient at different pore sizes (PPI) was obtained (Figure 3a – 3d). The evaporation experiment was consistent with the model results, which further verifies the correctness and feasibility of the optimization of interface properties (Figure 3e – 3f).

Figure 3. Validation experiment of the influence of different absorption coefficients on evaporation efficiency.

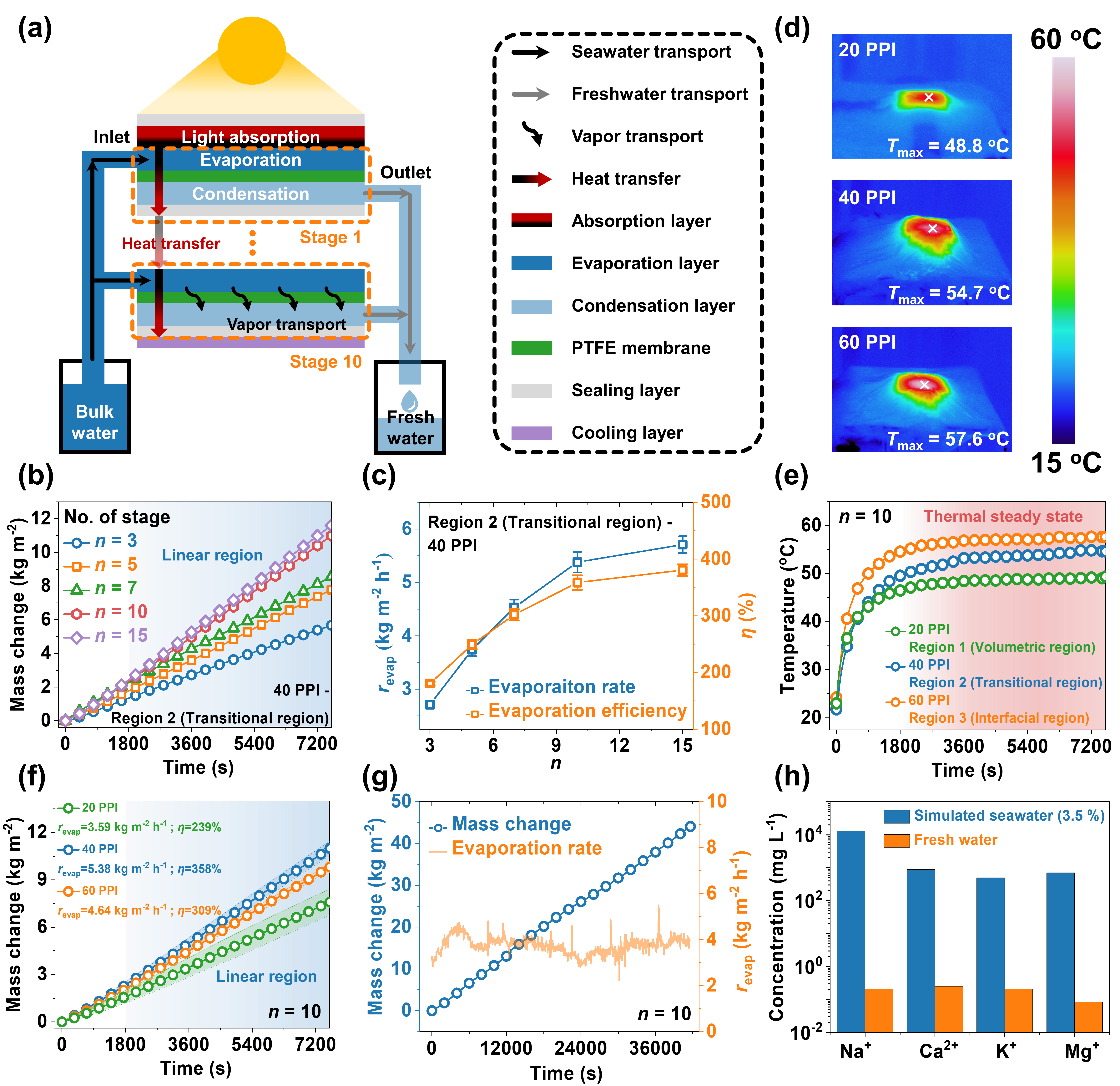

Based on the understanding of the interfacial properties, in this work, Prof. Lin’s team designed a multi-stage solar interface evaporator (MSSIE) device working in the transition region based on the optimization of the interfacial properties, as shown in Figure 4a. The effects of the number of total stages on MSSIE evaporation performance were investigated, and they noticed that 10-stage is an optimal design to balance the efficiency and device complexity (Figure 4b – 4c). The 10-stage MSSIE operating in the transitional region shows an evaporation rate of 5.38 kg m-2 h-1, which is increased by about 12 % compared with the traditionally designed interfacial absorption.

Figure 4. The evaporation performance of the multi-stage solar interface evaporator (MSSIE) device. (a) The schematic diagram of the MSSIE device with low salinity water mode. (b) The mass change of the MSSIE system with different stages (3, 5, 7, 10, 15) under 1 sun condition. (c) The evaporation rate and evaporation efficiency of MSSIE with different stages. (d) The infrared diagram (d) and surface temperature change (e) of the MSSIE device with different PPI (20, 40, 60). The maximum temperature is marked with a white cross. (f) The mass change and the evaporation performance of MSSIE device (n = 10) with different PPI. (g) The mass change and the corresponding evaporation rate of the MSSIE device with simulated seawater. (h) The ion concentrations in raw seawater and the collected fresh water.

In sum, the evaporation interface in terms of its location and evaporation thickness is identified to quantify the interplay of optical and transport processes in a front-side solar interfacial evaporator for guiding the rational design of materials and structures based on a coupled experimental and numerical method. It can be concluded that there is an optimal absorption coefficient to improve the evaporation efficiency, which is about 400 m-1 in this work.

Meanwhile, an efficient multi-stage interface evaporation device was designed based on the optimized interfacial properties as an illustrative case. The evaporation rate achieved 5.38 kg m-2 h-1 with a 10-stage design, which was 12 % higher than the device operated at interfacial region under 1 sun condition. This quantitative analysis enables the rational design of materials and devices for high-performing solar evaporation systems. It offers important guidelines for the rational engineering of various solar evaporators, such as traditional double-layer structures, 3D structures, and multi-stage evaporators.

Shang Liu, a joint doctoral candidate of SUSTech and the Harbin Institute of Technology (HIT), is the first author of this paper. Shiteng Li, a research assistant, is the second author of the paper. Assoc. Prof. Meng Lin is the corresponding author, and SUSTech is the first affiliation.

This work was supported by the National Natural Science Foundation of China (NSFC), Science, Technology and Innovation Commission of Shenzhen Municipality, and Guangdong Basic and Applied Basic Research Foundation.

Paper link: https://doi.org/10.1021/acsenergylett.3c00054

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By