As the preferred material for passive electronic components such as capacitors, substrates, resonators, and filters, microwave dielectric ceramics are widely used in wireless communications, intelligent driving, electric vehicles, aerospace, and satellite communications. On the one hand, in the preparation process, to meet the needs of device miniaturization, microwave dielectric ceramics usually need to be co-fired with metal electrodes such as Ag or Al, which requires that the sintering temperature of microwave dielectric ceramics must be lower than the melting point of metal electrodes. On the other hand, with the rapid development of information technology, the power density of electronic devices has multiplied, which requires higher thermal conductivity of microwave dielectric ceramics.

Against this background, the development of microwave dielectric ceramics with high thermal conductivity, which can be sintered at low temperatures, has important theoretical research and practical application value. However, because ceramics with high thermal conductivity generally have strong chemical bonds, simple lattices, and light atomic characteristics, their sintering temperatures are usually very high. At present, it is difficult to sinter ceramics with high thermal conductivity at low temperatures, and the maximum thermal conductivity does not exceed 15 W m-1 K-1, which is significantly behind conventional high-temperature sintered ceramics.

Professor Hong Wang’s research group from the Department of Materials Science and Engineering (MSE) at the Southern University of Science and Technology (SUSTech) has recently made important progress in the field of microwave dielectric ceramics. Their work has developed microwave dielectric ceramics with ultra-high thermal conductivity at ultra-low sintering temperatures, which provides important technical support and development power for developing high-frequency and high-speed communication circuits.

Their research, entitled “All-Ceramics with Ultrahigh Thermal Conductivity and Superior Dielectric Properties Created at Ultralow. Temperatures”, has been published in Cell Reports Physical Science, an international academic journal from Cell Press publishing cutting-edge research across the physical sciences.

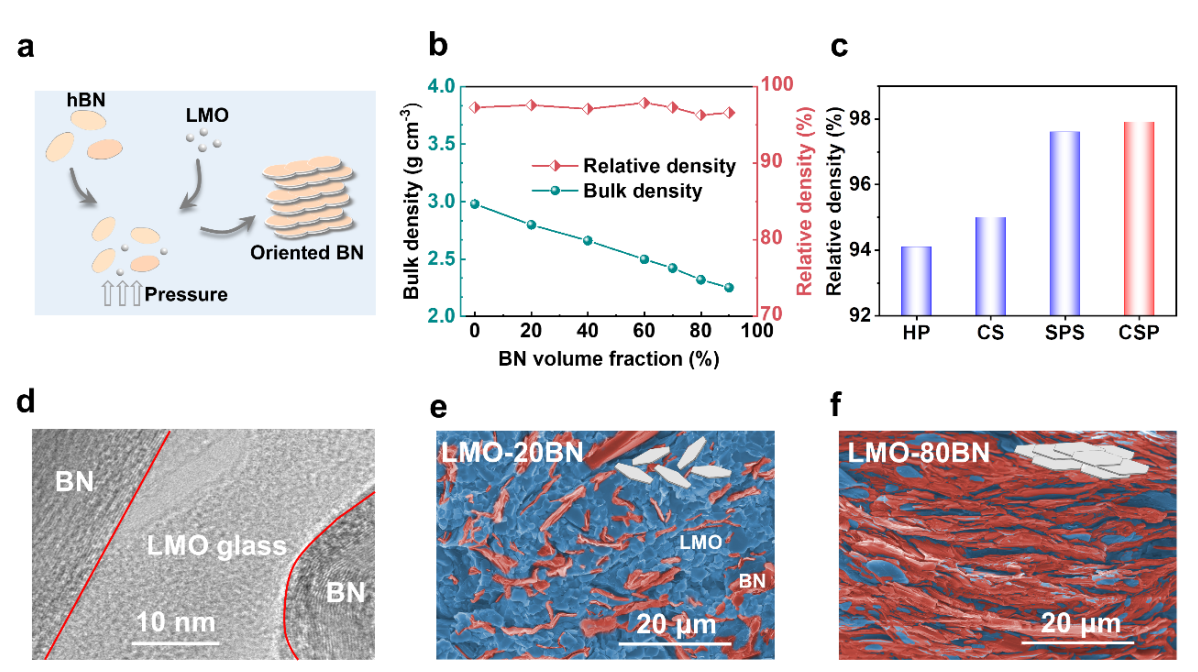

In this work, the research team introduced hexagonal boron nitride sheets with high thermal conductivity, and by adjusting the composition and pressure to form a highly oriented ceramic structure, the ceramic with ultra-high thermal conductivity was prepared at an ultra-low sintering temperature of 150°C. The boron nitride-based ceramics prepared by this process have a high relative density of 97%, which exceeds or matches the boron nitride-based ceramics prepared by other sintering processes, such as plasma sintering, traditional high-temperature sintering, and hot press sintering. The high orientation and high relative density of BN pieces lead to the establishment of efficient phonon transport channels, resulting in a record thermal conductivity of 42 W m-1 K-1, which exceeds all current low sintering temperature ceramics and can even be compared with high-temperature sintered ceramics above 1500°C.

Figure 1. Fabrication and characterization of structures of LMO-BN composites

Figure 2. Thermal conductivity of LMO-BN composites

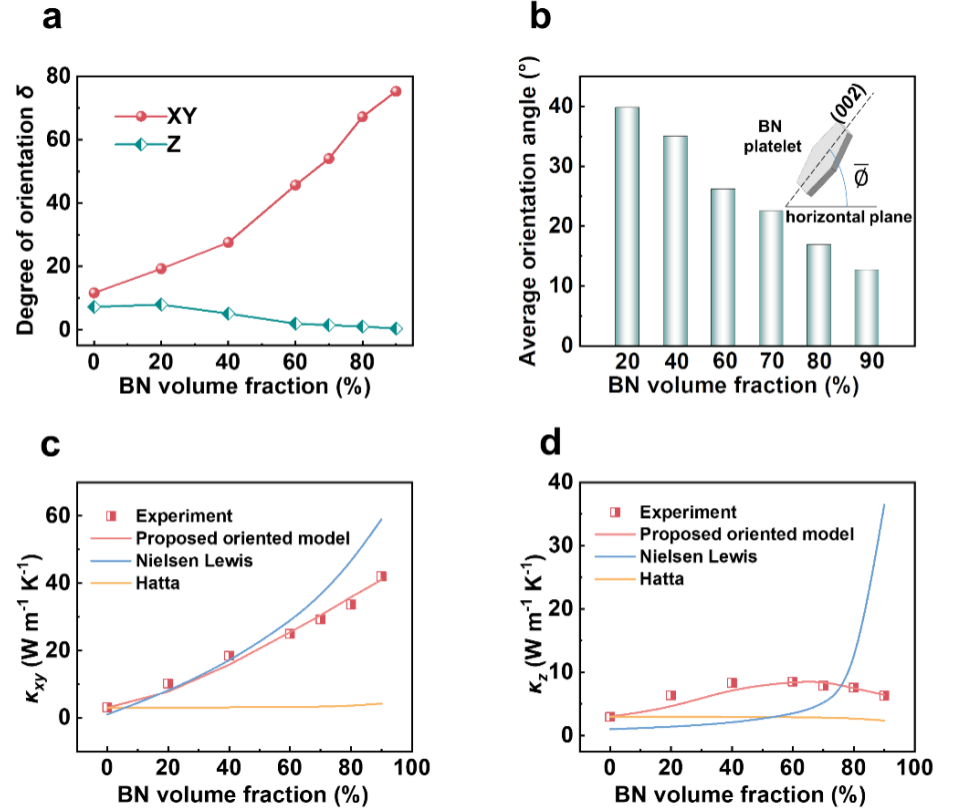

This work explores the internal formation mechanism of high thermal conductivity through the combination of experiment and simulation. The orientation of the boron nitride sheet was found by an electron microscope at a microscopic scale. The orientation degree of boron nitride and the angle between boron nitride and the XY plane were calculated using X-ray diffraction data. In addition, to solve the problem that thermal conductivity cannot be understood by the traditional thermal conductivity model, an oriented thermal conductivity model of composite materials was established. The results of the model are in good agreement with the experimental data, and the intrinsic relationship between orientation structure and thermal conductivity are further explained theoretically.

Figure 3. Orientations of BN and our proposed mixture models of thermal conductivity

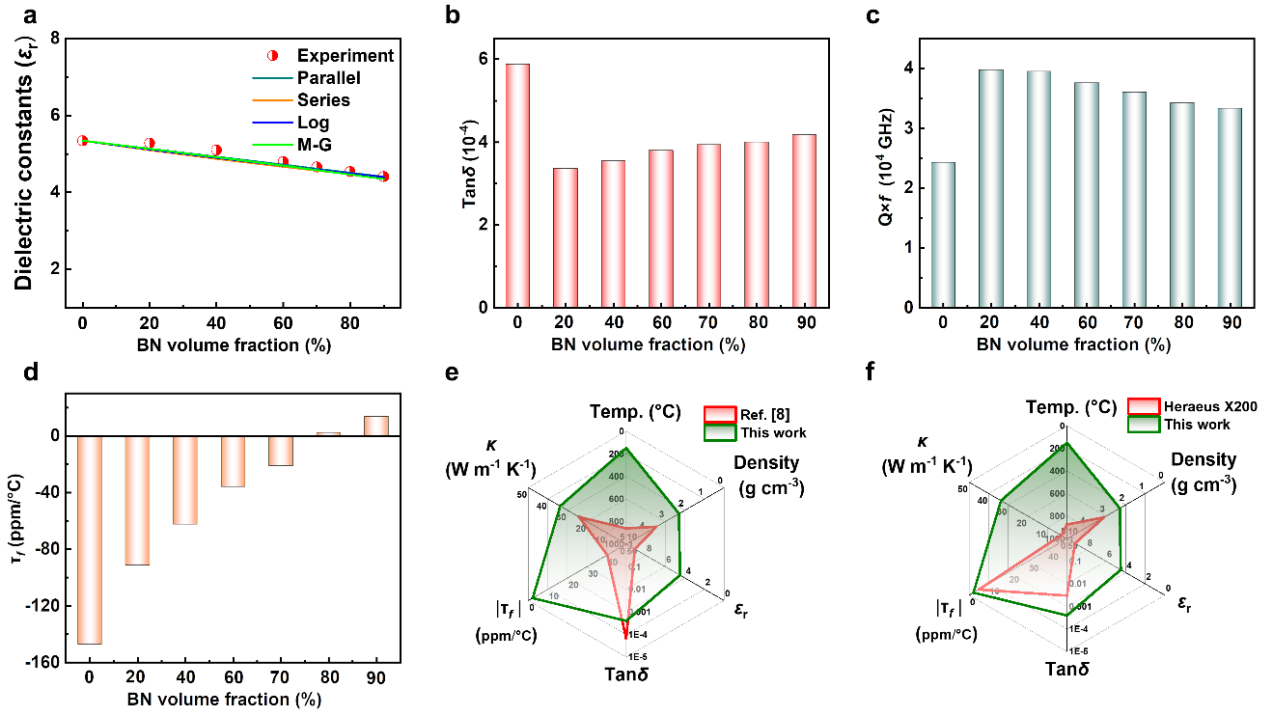

This study not only has high thermal conductivity, but also has excellent microwave performance. Compared with the materials reported in the current representative literature and widely used materials, this work has excellent comprehensive properties, and has broad application prospects in microwave/millimeter wave communication equipment.

Figure 4. The microwave properties of the LMO-BN composites

Naichao Chen, a doctoral student, and Li Li, a postdoctoral fellow, both from the Department of MSE at SUSTech, are the first and co-first authors of the paper, respectively. Professor Hong Wang is the corresponding author, and SUSTech is the only communication unit. Other contributors to this study included Professor Weishu Liu, Research Assistant Professor Xinwei Xu, Ph.D. candidate Jin Cheng, and master’s student Chengyuan Wang.

This work was supported by the Key Research Project of the National Natural Science Foundation (NSFC), National Key Research and Development Program, Key Laboratory Project of Guangdong Province, and the Shenzhen Science and Technology Innovation Commission.

Paper link: https://www.sciencedirect.com/science/article/pii/S2666386424001176

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Materials Science and Engineering