4D printing, as an emerging interdisciplinary frontier research field, has become one of the hot research directions at home and abroad. Shape memory polymers (SMPs) have been widely used in 4D printing due to their relatively high modulus. However, most SMPs used for 4D printing are thermosetting materials. Once the chemical structure is determined, they can only “remember” a permanent shape.

In recent years, some studies have introduced covalent adaptive networks (CAN) into SMPs to achieve multiple reconfigurable permanent shapes. However, the existing dynamic covalent SMPS cannot take into account the shape memory performance, deformation and reconstruction ability, and high-precision printability.

To solve the above problems, Professor Qi Ge’s team from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has made significant progress in the field of reconfigurable 4D printing technology. They have developed a covalent adaptive network shape memory polymer (MRC-SMP) with high mechanical properties that can be used for digital light processing (DLP) high-resolution 3D printing, realizing reconfigurable, large deformation and high-precision 4D printing.

Their related achievements, entitled “Reconfigurable 4D Printing via Mechanically Robust Cooperative Adaptive Network Shape Memory Polymer”, have been published in Science Advances, an internationally renowned comprehensive journal.

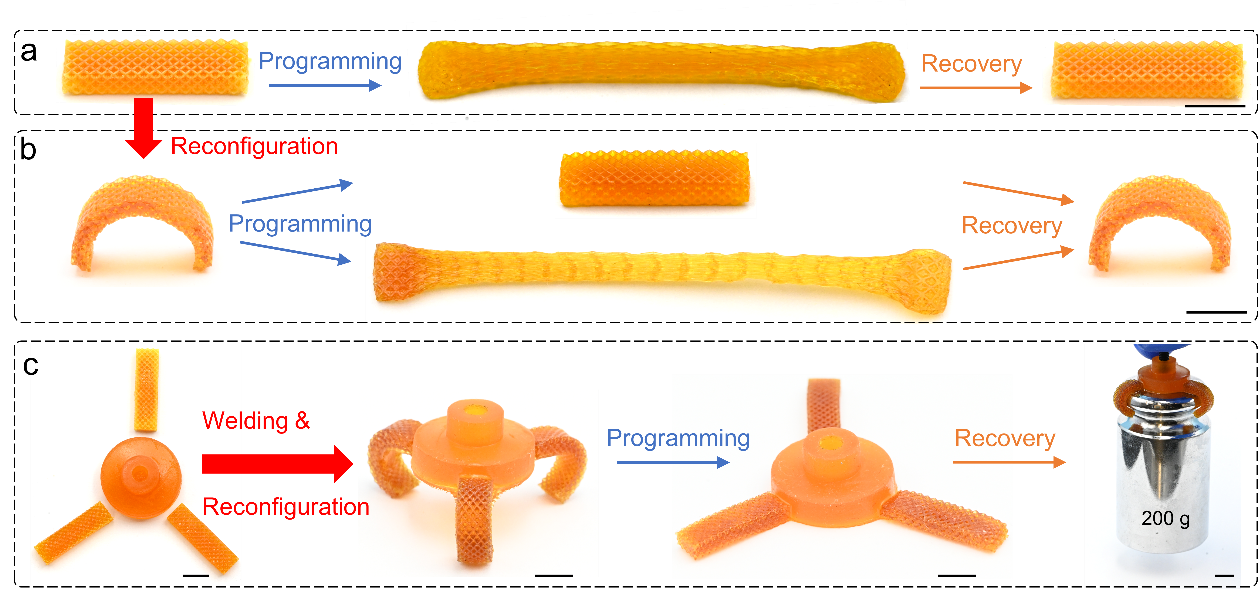

The MRC-SMP lattice structure is printed by a DLP printer to show the large deformation shape memory behavior (Figure 1a). As shown in Figure 1b, the permanent shape reconfiguration of lattice structure caused by transesterification reaction, and the shape configurated MRC-SMP, still possess large deformation performance and shape memory performance. In addition, the covalent adaptive network also endows MRC-SMP with high-strength welding ability. Three high-precision printed MRC-SMP lattice structures and one MRC-SMP connector form a gripping gripper through welding and shape reconfiguration (Figure 1c). The MRC-SMP gripper can be programmed to the unfolded state first, and then restored to the grasping state through shape memory to lift heavy objects.

Figure 1. The reconfigurable, large deformation, and high-resolution 4D printing of MRC-SMP. (a) Large deformation shape memory behavior of high-resolution MRC-SMP lattice structure printed by DLP 3D printer. (b) Shape memory behavior of reconfigured arc-shaped MRC-SMP lattice structure. (c) A shape memory gripper manufactured by welding three 3D printed and reconfigured MRC-SMP lattice structures onto a printed circular connector.

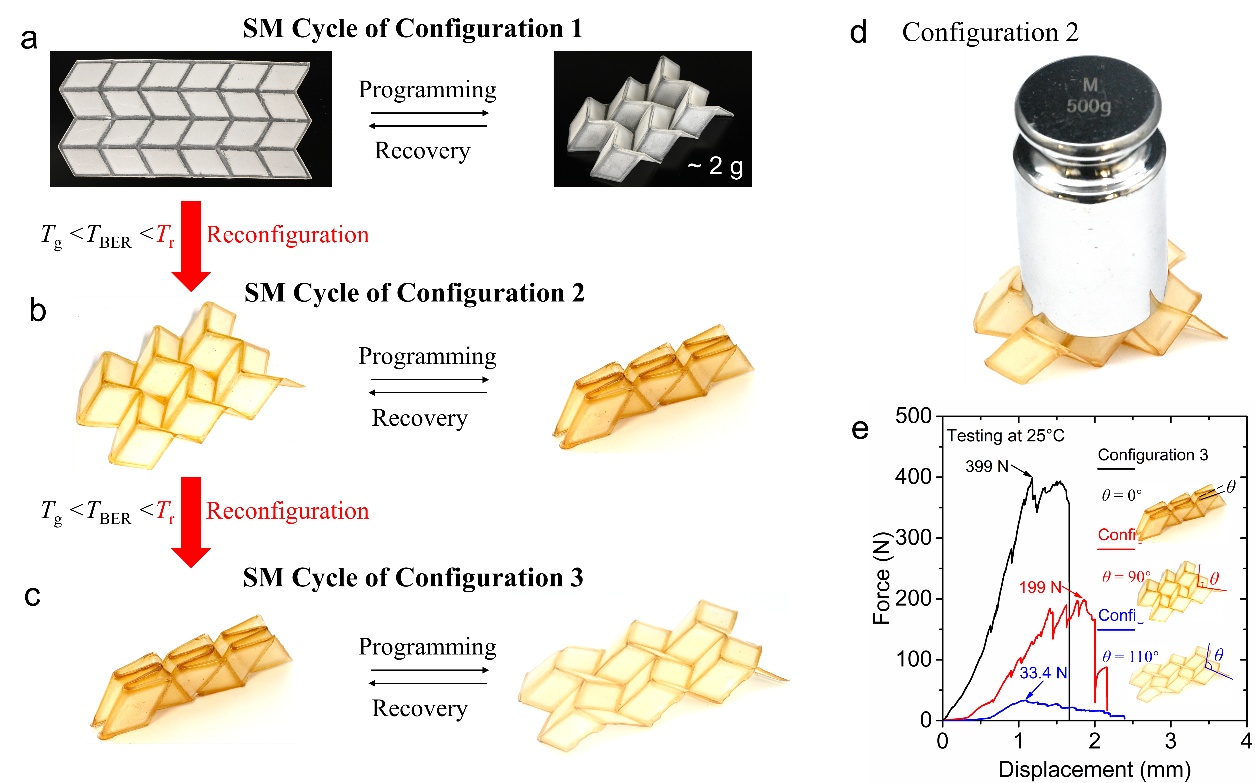

The combination of MRC-SMP reconfigurable performance and multimaterial printing can manufacture three-dimensional shape memory origami structures in any shape, greatly reducing the time required to manufacture complex SMP origami structures. As shown in Figure 2a, the multimaterial origami is made of MRC-SMP as deformable hinges and high-temperature resistant high-strength photocurable resin as rigid board surfaces.

The significant deformability of MRC-SMP allows for quick reconfiguration of a printed origami into multiple SMP origami (Figure 2a-c). The high glass transition temperature of MRC-SMP ensures that the 3D origami structures have high stiffness at room temperature and can support heavy loads (Figure 2d-e).

Figure 2. Multimaterial reconfigurable shape memory origami. (a-b) Multiple shape reconfiguration and shape memory behaviors of reconfigurable shape memory origami. (d) A snapshot of the reconfigurated origami shape 2 carrying heavy objects. (e) Compression tests on different origami shapes at room temperature.

Honggeng Li, Research Assistant Professor of the Department of Mechanical and Energy Engineering at SUSTech, is the first author of the paper. Professor Qi Ge is the corresponding author, and SUSTech is the first affiliated unit.

This research was supported by the National Natural Science Foundation of China (NSFC), Pearl River Talent Program of Guangdong Province, Natural Science Foundation of Guangdong Province, and the Shenzhen Science and Technology Innovation Commission.

Paper link: https://www.science.org/doi/10.1126/sciadv.adl4387

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Mechanical and Energy Engineering