The push for sustainable energy solutions has heightened interest in advanced energy storage and conversion technologies, such as flow batteries and fuel cells. However, traditional formic acid fuel cells rely on precious metal catalysts and suffer from low electrochemical efficiency, while flow batteries often experience capacity loss over time. Addressing these issues is crucial for improving the performance and longevity of these systems, which are essential for scalable, long-duration energy storage.

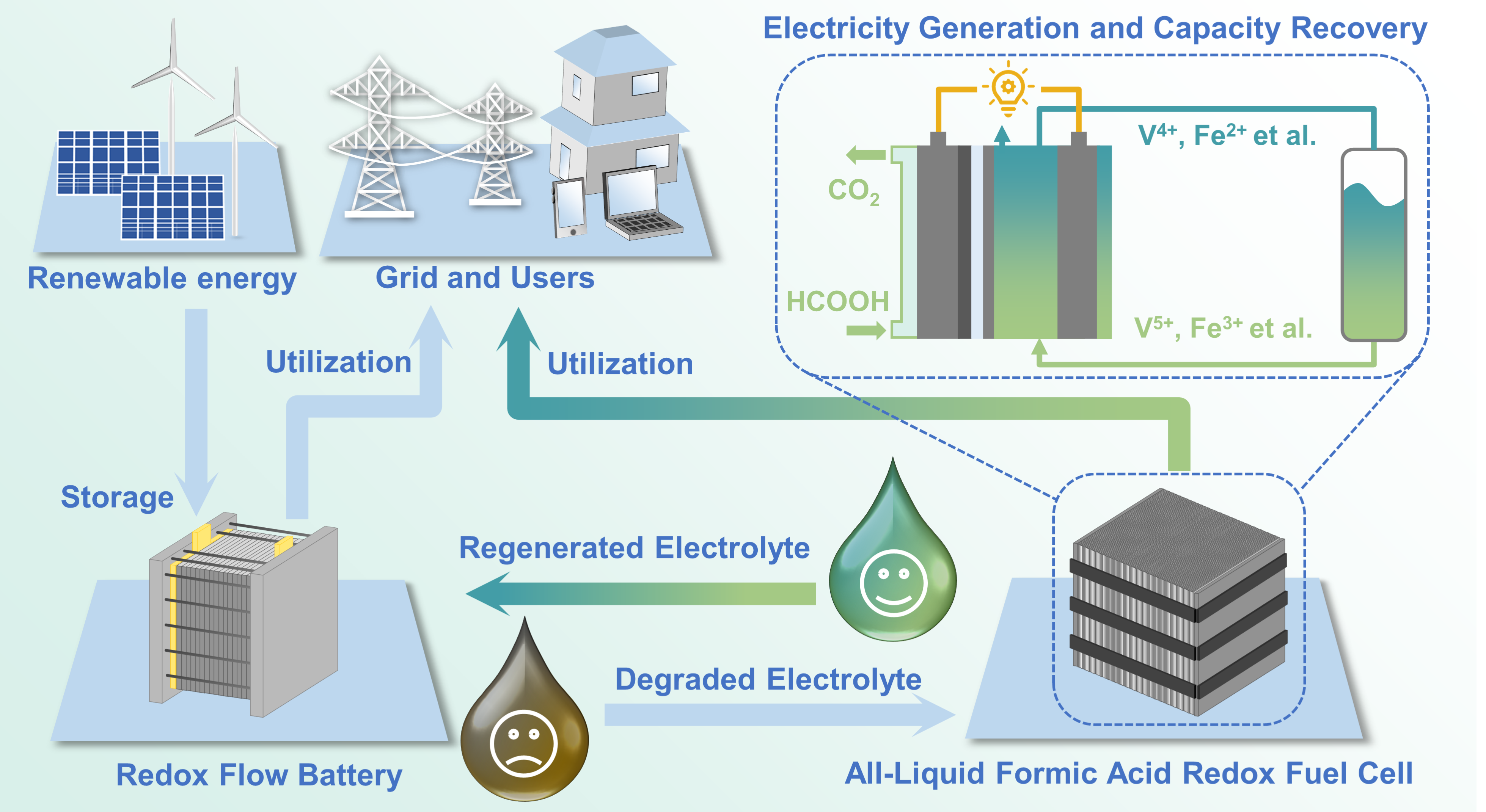

Figure 1. Dual functionality of the all-liquid formic acid redox fuel cell

A research team led by Chair Professor Tianshou Zhao, Associate Professor Lei Wei, and Associate Professor Lin Zeng from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) has developed a novel high-performance all-liquid formic acid redox fuel cell (LFARFC).

Their innovative work breaks through the limitations of traditional fuel cells by using the electrolyte from flow batteries, which undergoes a valence shift, as the anode reactant in the fuel cell, replacing the conventional oxygen reduction reaction (ORR) electrode. This method not only efficiently generates electricity but also reconditions the flow of battery electrolytes, restoring the battery’s capacity and achieving a “turning waste into treasure” effect (Figure 1).

Their related paper, entitled “A Novel High-performance All-liquid Formic Acid Redox Fuel Cell: Simultaneously Generating Electricity and Restoring Capacity of Flow Batteries”, has been published in Energy & Environmental Science (EES).

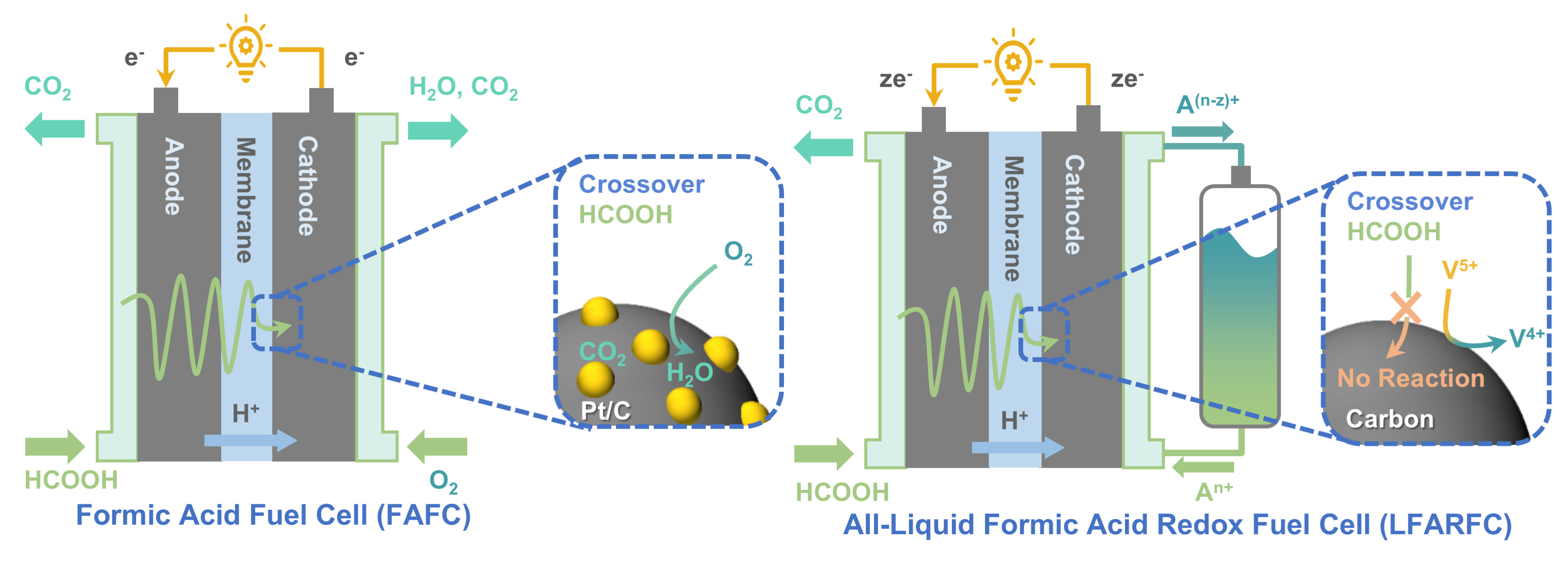

In this study, the team developed the LFARFC to replace the traditional ORR electrode by using an electrolyte containing redox-active substances as the cathode active material in the fuel cell. This approach avoids the use of precious metal catalysts for ORR, effectively addressing the issues of mixed potential and low electrochemical kinetics efficiency on the cathode in formic acid fuel cells.

Figure 2. Comparison between traditional formic acid fuel cells and the novel redox fuel cell

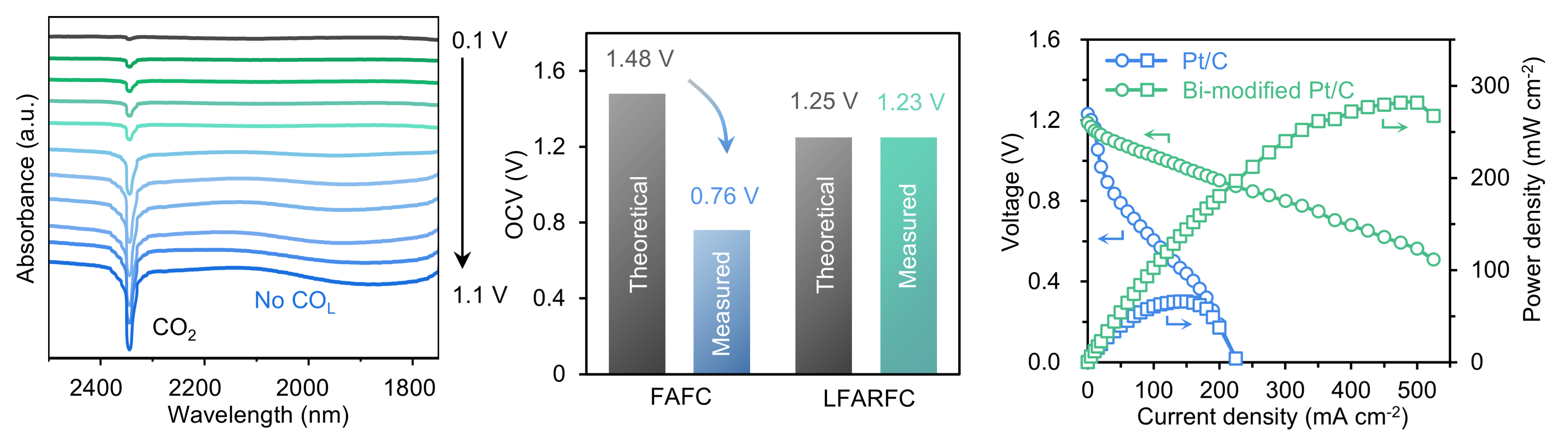

To enhance the power output density, the researchers used a bismuth-modified Pt/C electrocatalyst, which improved the efficiency of the formic acid oxidation reaction and significantly enhanced CO tolerance. On this basis, the LFARFC exhibited excellent performance across several key metrics (Figure 3), with an open-circuit voltage reaching 1.23 V and a peak power density of 281.5 mW/cm². These figures represent an increase of 55.7% and 235.1%, respectively, over traditional formic acid fuel cells.

Figure 3. CO tolerance of the new catalyst and high performance of the LFARFC

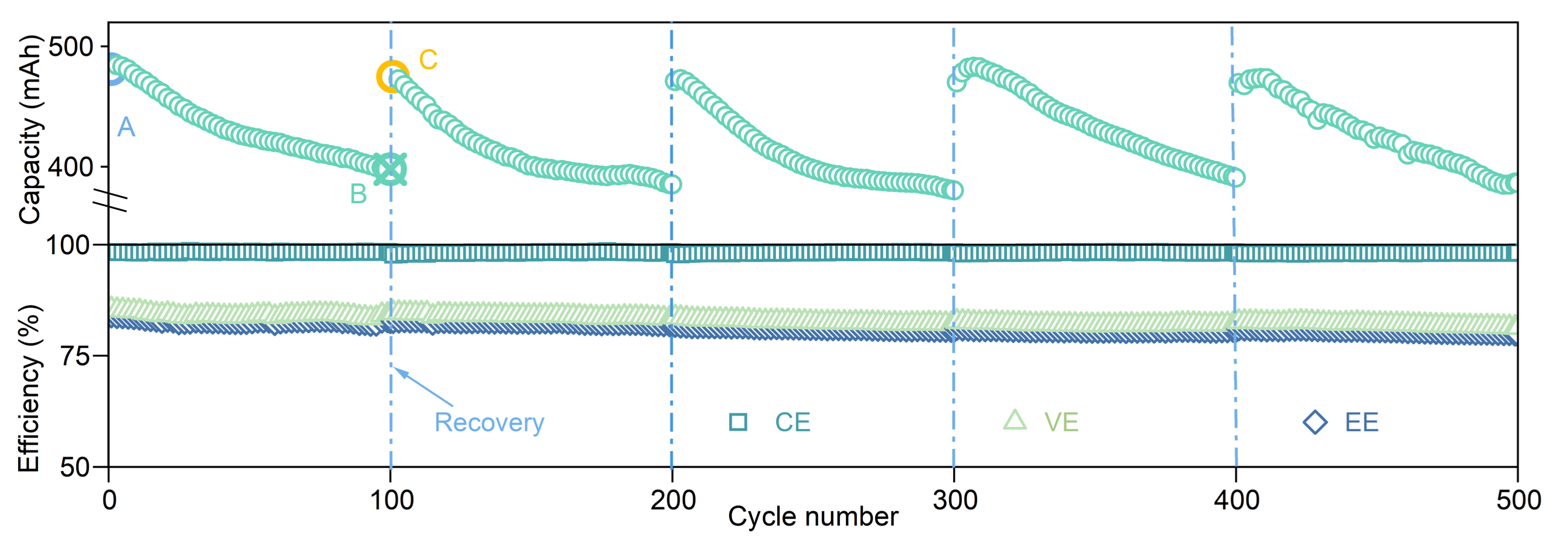

The team explored the practical application of the LFARFC in restoring the capacity of flow batteries. Combined with a vanadium redox flow battery (VRFB), the capacity of the VRFB declined after 100 cycles due to factors such as self-discharge. However, after recharging with LFARFC, the battery capacity was restored to 97.6% of its initial peak level. Even after multiple long cycles, the LFARFC consistently achieved this capacity recovery effect (Figure 4). This result demonstrates that LFARFC can effectively extend the cycle life of flow batteries.

Figure 4. Capacity recovery of VRFB using the LFARFC

This research provides new insights for the design of efficient energy storage and conversion systems. By combining the fuel cell anode with the active substances in flow batteries, the study successfully addresses some inherent issues in formic acid fuel cells while also providing effective technical support for the capacity restoration of flow batteries. This dual-system design shows great potential for future large-scale, long-duration energy storage systems.

Master’s graduate Dongbo Wei, Ph.D. student Lyuming Pan, and visiting scholar Jing Sun are the co-first authors of the paper. Chair Professor Tianshou Zhao, Associate Professor Lei Wei, and Associate Professor Lin Zeng are the co-corresponding authors, and SUSTech is the sole corresponding institution.

This research was supported by the National Key Research and Development Program, National Natural Science Foundation of China (NSFC), Guangdong Provincial Department of Science and Technology, and the Shenzhen Science and Technology Innovation Commission.

Paper link: https://doi.org/10.1039/D4EE02450H

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Mechanical and Energy Engineering