The demand for solar cells has seen researchers explore a wide range of optimization methods for mixed perovskite compositions, with a strong focus on its high-throughput synthesis. However, the high-throughput fabrication of mixed perovskite films with the representative film properties has not been examined by many researchers.

Last month, Professor Xu Baomin from the Department of Materials Science and Engineering (MSE) at Southern University of Science and Technology (SUSTech) led his research group to publish a groundbreaking paper on material genetic engineering. The results were published in top academic journal Advanced Functional Materials (IF=15.62), in a paper titled “Accelerating the Screening of Perovskite Compositions for Photovoltaic Applications through High‐Throughput Inkjet Printing.”

Perovskite-based solar cells based on organometallic halides were introduced in 2009 and was selected by Science as one of the top ten scientific breakthroughs in 2013. The efficiency of perovskite solar cells have increased from 3.8% to 25.2% in just ten years, a dramatic improvement compared to other new concept solar cells. The main challenge with perovskite composition engineering has been determining the optimal preparation of the perovskite film, given the vast number of variables available.

The research team developed a high-throughput inkjet printing method designed for preparing mixed perovskite films that can quickly produce between 30-50 high-quality mixed perovskite films.

The entire inkjet printing process is fully automated and highly repeatable. This greatly accelerates the screening and optimization of perovskite solar cell components and promotes the application of perovskite optoelectronic devices.

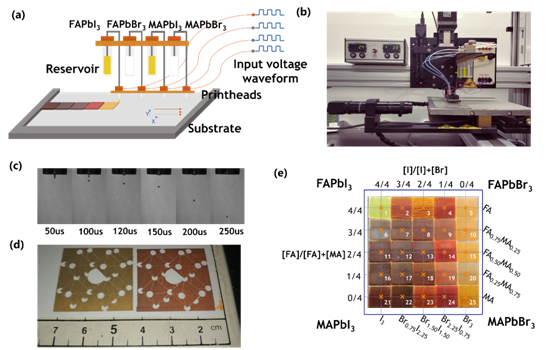

Figure 1. (a) 4-channel mixed printing schematic; (b) inkjet printer physical map; (c) single droplet control map; (d) inkjet-printed perovskite crystal structure; (e) inkjet printing 25 mixed perovskite film.

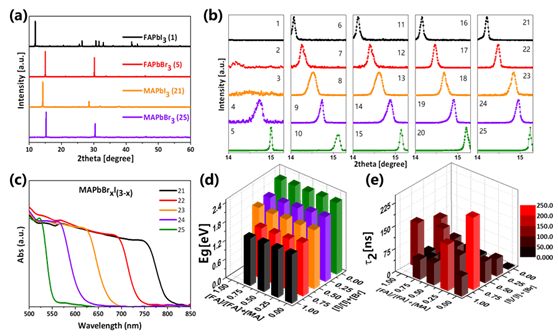

The four nozzles on the printer can each print a different component in sequence. By determining the printing sequence, the perovskite film can be made in different compositions. Software maintains the fully automated printing process, resulting in high-quality printed films that provide different levels of phase change, optical absorption and fluorescence intensity over the life of the film. The performance database can effectively speed up the screening of perovskite photovoltaic components, as shown in Figure 2.

Figure 2. (a) XRD of four single component films; (b) XRD of 25 mixed films; (c) absorption curves for four single component films; (d) optical band gaps for 25 mixed films; (e) Fluorescence lifetime of 25 mixed films.

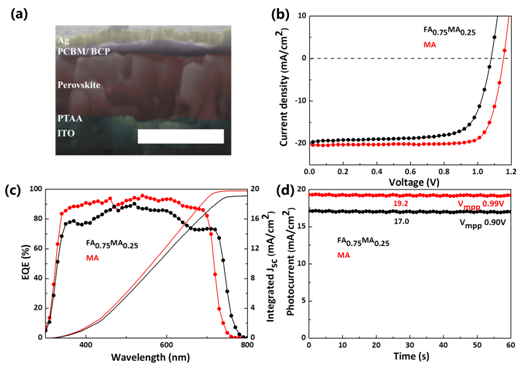

The researchers found that there is a high level of efficiency (19.0%) based on the screened perovskite composition, which has seen smaller dark saturate current density, lower energetic disorder, increased charge transfer efficiency and decreased charge recombination losses. These superior properties highlight the accelerated screening of perovskite composition for photovoltaic applications through the team’s unique high-throughput inkjet printing approach.

Figure 3. (a) SEM cross-section of a perovskite cell; (b); (c) current density-voltage curve for MA and FA0.75MA0.25 devices; (d) MA and FA0.75MA0.25 devices Quantum efficiency; (e) Steady-state output efficiency of MA and FA0.75MA0.25 devices.

Professor Xu Baomin is the correspondent author of the paper. SUSTech is the first completion unit of the work. The first author of this paper is Dr. Shi Chen and Lihua Zhang.

This work was financially supported by the National Key Research and Development Project funding from the Ministry of Science and Technology of China, the Peacock Team Project funding from Shenzhen Science and Technology Innovation Committee, the Fundamental Research Project funding from Shenzhen Science and Technology Innovation Committee, the Guangdong Science and Technology Program, the HK-RGC General Research Funds, and the HK Innovation and Technology Fund. This work was also supported by the Shenzhen Engineering Research and Development Center for Flexible Solar Cells Project funding from Shenzhen Development and Reform Committee.

Paper link:

https://www.onlinelibrary.wiley.com/doi/10.1002/adfm.201905487

Proofread ByDepartment of Materials Science and Engineering

Photo ByDepartment of Materials Science and Engineering, Qiu Yan