Nature builds biological materials from limited ingredients with unparalleled mechanical performances compared to artificial materials by harnessing inherent structures across multi-length scales. In contrast, synthetic material design overwhelmingly focuses on developing new compounds and fails to reproduce the mechanical properties of natural counterparts, such as fatigue resistance.

Recently, Associate Professor Ji Liu from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech), in collaboration with researchers from Massachusetts Institute of Technology (MIT), University College London (UCL), and Ningbo University (NBU), reported a general yet straightforward strategy to engineer conventional hydrogels with a more than 100-fold increase in fatigue thresholds. This paper, entitled “Anisotropically Fatigue-Resistant Hydrogels,” was published in Advanced Materials, a high-profile journal in material science.

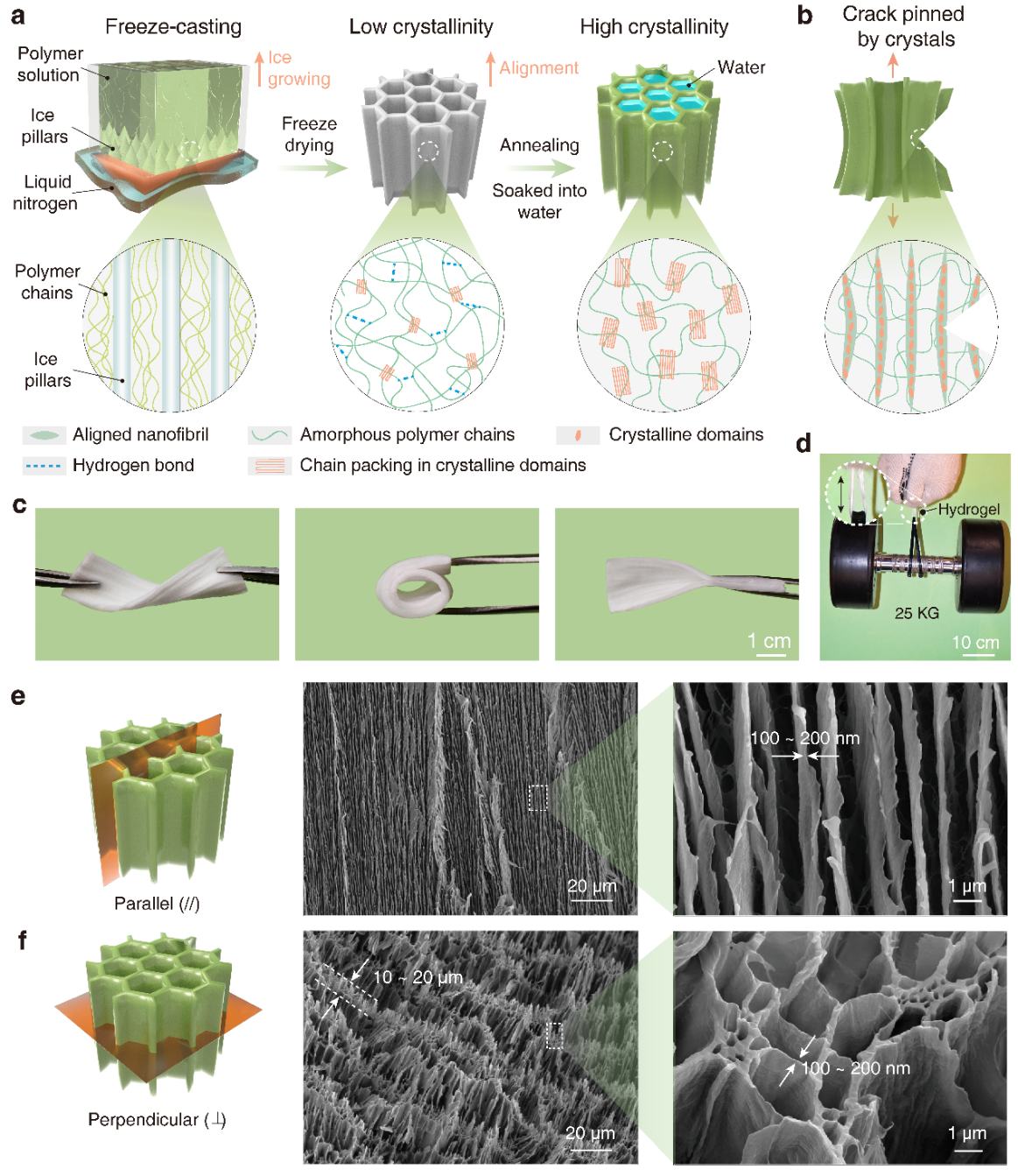

Figure 1. Fabrication of anisotropically fatigue-resistant hydrogels and their multi-lengthscale structures.

Professor Liu and his team engineered the preferentially-aligned micro/nanostructures within a hydrogel material through the ice-templated freeze-casting process, followed by thermal annealing, using polyvinyl alcohol as the exemplary material. As a result, the as-obtained hydrogel possessed a water content as high as 90%, while its fatigue resistance reached as high as 2740 J m-2, much higher than that of the control group (~20 J m-2) with random structure. Similarly, this strategy can be applied to other material systems, including polysaccharides (i.e., alginate, cellulose), proteins (i.e., gelatin), synthetic polymers (i.e., poly (vinyl alcohol)), as well as corresponding polymer composites.

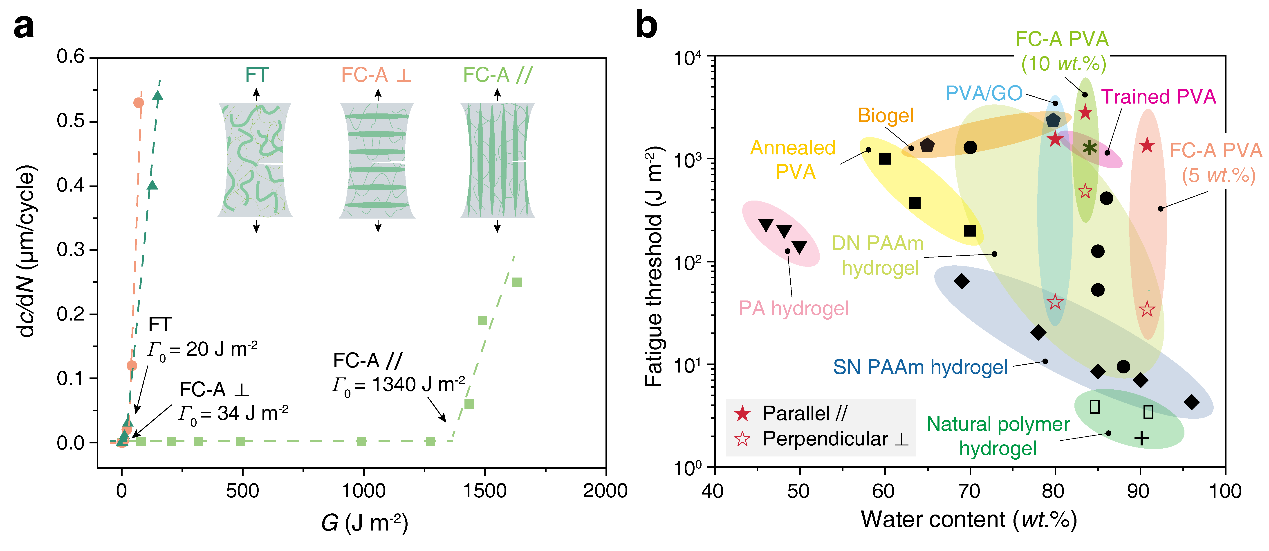

Figure 2. Record-high fatigue resistance and generality of the design rationale.

The capability to engineer conventional hydrogel materials with unprecedented resistance to crack propagation during long-term cyclic loads enables applications such as load-bearing components in underwater robotics.

Video 1. Design model of the underwater robot with fatigue-resistant hydrogel as the load-bearing components.

When the PVA hydrogels are loaded with pre-cut crack, no crack propagation is observed over 1,000,000 stretching-and-contracting cycles at an energy release rate of 1340 J m−2 over 250 h, showing unprecedented fatigue-resistant performance in real application circumstances. On the contrary, the control samples failover 40 h, after 197 630 stretching-and-contracting cycles at an energy release rate of 90 J m−2. This is the first time the fatigue-resistant hydrogel finds real-world application and is evident by over a million-cycle validation.

Video 2. Million-cycle validation of fatigue-resistance on an underwater robot.

This work is led by SUSTech, in collaboration with MIT, UCL, and NBU. Postdoctoral fellow Xiangyu Liang is the first author of this paper, while Professor Ji Liu is the corresponding author. This work is financially supported by the Science, Technology and Innovation Commission of Shenzhen Municipality and the Basic and Applied Basic Research Foundation of Guangdong Province.

Paper link: https://onlinelibrary.wiley.com/doi/full/10.1002/adma.202102011

Proofread ByAdrian Cremin, Yingying XIA

Photo By