Superelastic materials capable of recovering large nonlinear strains are ideal for various applications in morphing structures, reconfigurable systems, and robots. However, making oxide materials superelastic has been a long-standing challenge due to their intrinsic brittleness. The only macroscopically brittle oxide recently discovered to be superelastic is ZrO2-based micropillars or particles, which are realized via austenite-martensite phase transformation. Although ultimate strengths approaching the theoretical limit have been demonstrated in nanoscale samples, long fatigue life is elusive, which is arguably more important for most applications. Poor fatigue life has been a long-standing challenge for oxide ceramics in general.

Recently, Associate Professor Fuzeng Ren and Professor Jiangyu Li from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) demonstrated that the micropillars of typically brittle BaTiO3 (BTO) are not only superelastic but also fatigue-resistant over 1 million cycles without accumulating residual strains or noticeable variation in stress-strain curves over cycles. They collaborated with Dr. Yingwei from Wuhan University (WHU), Professor Jie Wang from Zhejiang University, Professor Peng Gao from Peking University (PKU), Professor Qingping Sun from the Hong Kong University of Science and Technology (HKUST), and Professor Longqing Chen from the Pennsylvania State University (Penn State).

The mechanism lies in the surface tension–modulated 90° domain switching. Their paper, entitled “Superelastic oxide micropillars enabled by surface tension–modulated 90° domain switching with excellent fatigue resistance,” was published in the prestigious journal Proceedings of the National Academy of Sciences of the United States of America (PNAS).

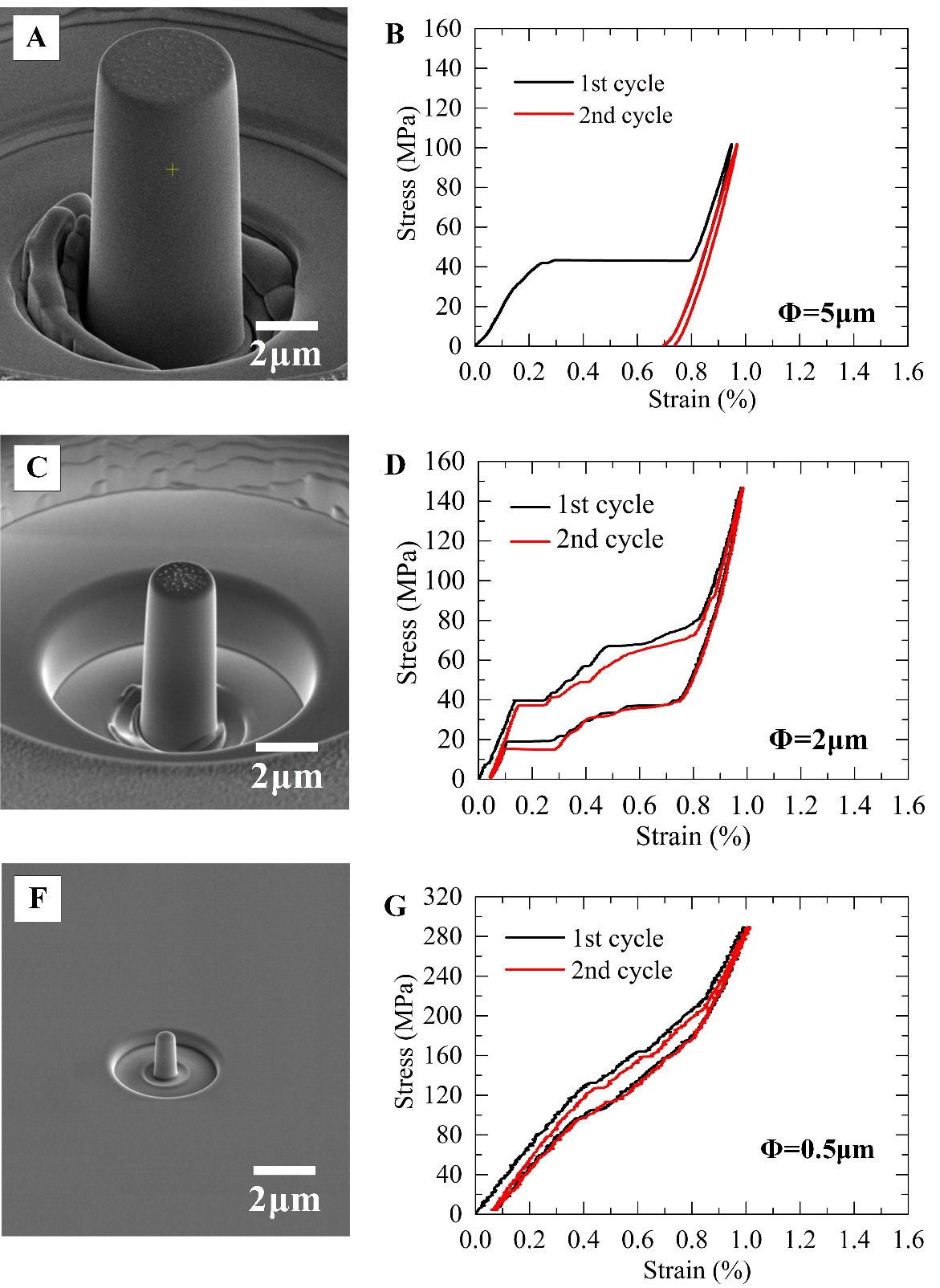

In this work, the authors fabricated single-crystalline BTO micropillars with diameters (Φ) ranging from 0.5 μm to 5 μm from [001]-oriented bulk crystals using focused ion beam (FIB) and examine their mechanical responses. The results showed that for micropillars with relatively large diameters (e.g., 5 μm), the stress-strain curve is similar to that of the bulk crystal. The second cycle of loading and unloading is drastically different from the first one, exhibiting linear elastic behavior since 90° domain switching is already exhausted in the first cycle. However, when the micropillar diameter decreases to 2 μm, superelastic behavior was observed.

When the diameter was further reduced to 0.5 μm, the linear, plateau, and subsequent linear regimes in the loading curve could hardly be differentiated. Only a slight change in slopes could be seen throughout the loading range. After unloading, the large strain of 1.0% was almost completely recovered with a residual strain of 0.06%. The second cycle closely followed the first one, and the behavior was drastically different from that of the bulk crystal.

Figure 1. Superelastic BTO micropillars below a critical size

To understand the large recoverable strain in the BTO micropillars at a small size, the researchers carried out the piezoresponse force microscopy (PFM) mapping and switching experiments, which confirmed that the micropillars are ferroelectric with switchable polarization.

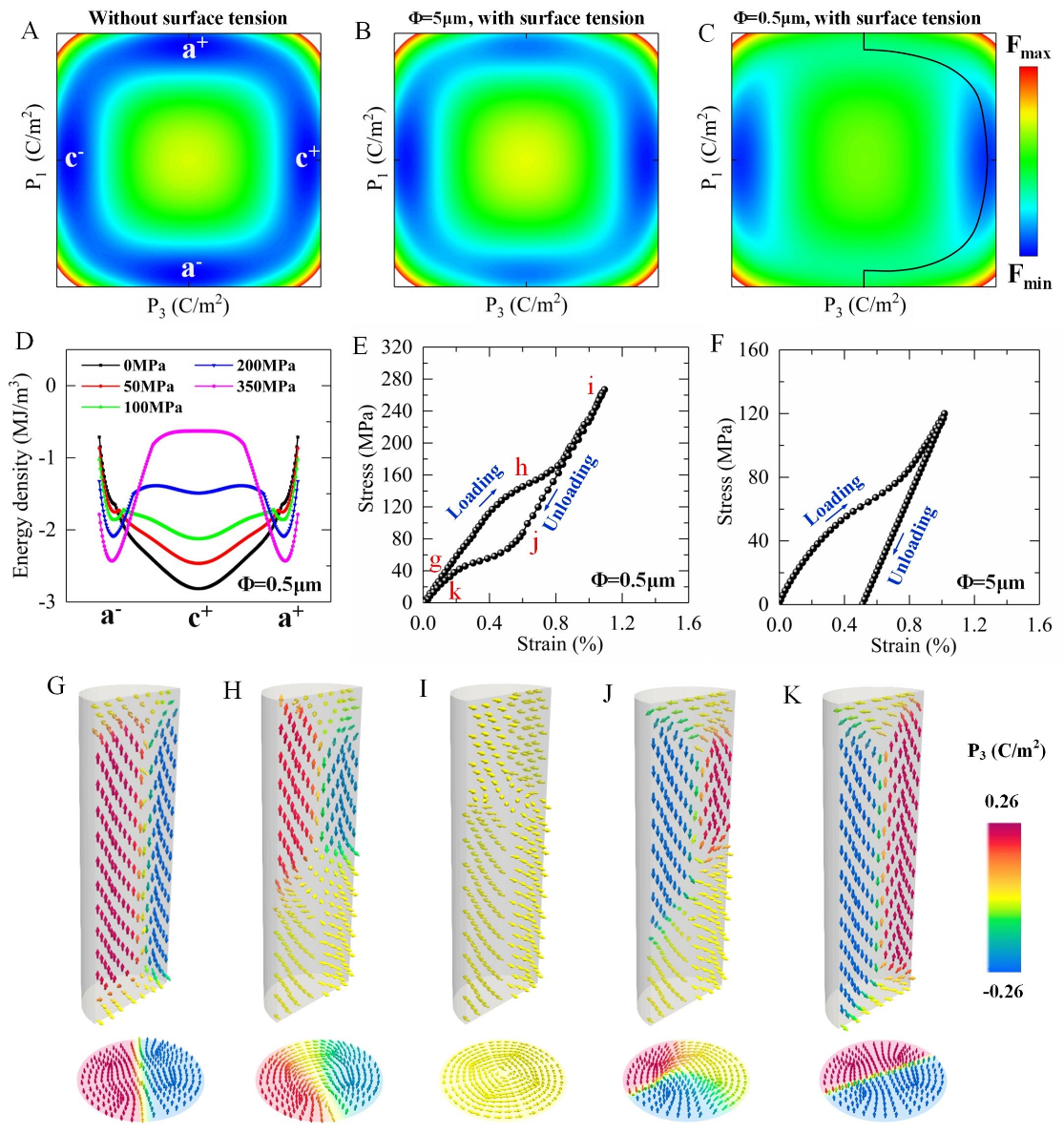

The 90° domain switching process under stress was also captured in situ transmission electron microscopy. Phase-field simulations revealed that the large recoverable strains of BTO micropillars arose from surface tension–modulated 90° domain switching and thus are size-dependent. At the same time, the small energy barrier and ultralow energy dissipation are responsible for their unprecedented cyclic stability among superelastic materials (Figure 2).

Figure 2. Superelasticity via surface tension–modulated ferroelectric switching

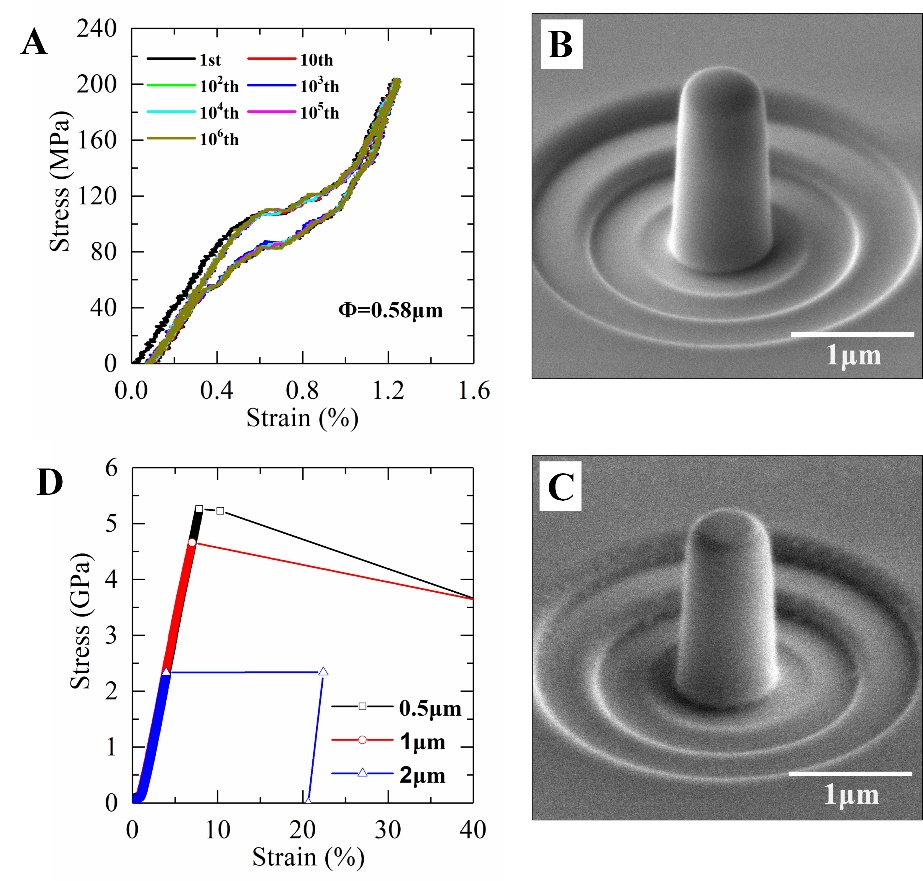

One of the major issues facing oxide micropillars is their poor fatigue life. The group of researchers found that the BTO micropillars, on the other hand, demonstrated remarkable fatigue resistance (Figure 3A). Indeed, after loading and unloading for one million cycles, the stress-strain curves of a micropillar with Φ = 0.58 μm showed no sign of degradation, recovering strains as large as 1.0% under a stress of 203 MPa and with a residual strain as small as 0.08%.

Furthermore, there was negligible variation in the stress-strain curves from the second cycle and on. Micropillars with diameters ≤ of 2 μm showed similar fatigue characteristics, going up to ten thousand cycles without failure. The SEM images of the as-milled 0.58-μm micropillar (Figure 3B) and after one million cycles (Figure 3C) show virtually no difference, with no damages or defects induced by cycling seen, demonstrating its excellent fatigue resistance.

The authors also measured the ultimate compressive strength of BTO micropillars with Φ = 0.5 μm, reaching an ultrahigh strength of 5.3 GPa, which is two orders of magnitude higher than bulk BTO of only 30 MPa. It approaches the theoretical strength of BTO crystal estimated to be 7 GPa based on the shear modulus of 70 GPa.

Figure 3. Fatigue-free BTO micropillars and their ultrahigh strength

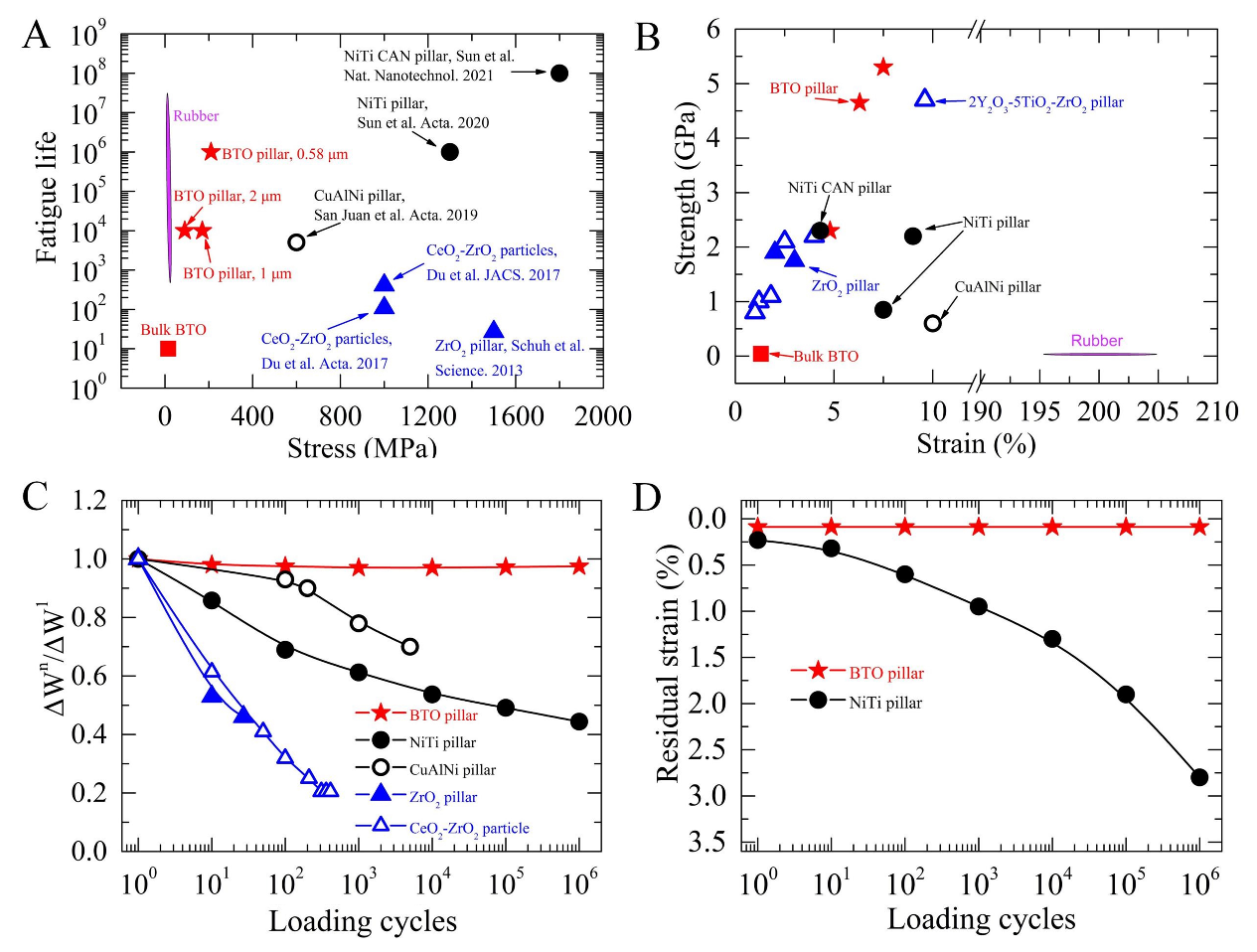

They also compared the fatigue lives and strengths of the BTO micropillars with other superelastic materials. The fatigue lives of BTO micropillars outperform previous zirconia-based micropillars and particles and are on par with NiTi SMA micropillars as well as rubbers (Figure 4A). This is exceptional since bulk BTO is brittle, whereas NiTi, CuAlNi, and rubber all enjoy excellent fatigue lives in bulk forms. The stresses needed to realize superelasticity in BTO micropillars are in the range of 40 to 100 MPa, much smaller than SMA and ZrO2 micropillars, and are only larger than rubber.

Furthermore, the ultimate strength of the BTO micropillar is higher than other materials (Figure 4B), partly responsible for its excellent fatigue life as the necessary stress for superelasticity is much smaller. While other superelastic micropillars suffer from large variations in stress-strain curves during cycling, as measured by the amounts of their normalized energy dissipation (Figure 4C), as well as a continuous accumulation of residual strains over cycling (Figure 4D), BTO micropillars are remarkably stable with negligible variation in stress-strain curves and virtually no accumulation of residual strains.

Figure 4 Comparison of BTO micropillar with other superelastic materials

In summary, the researchers demonstrated excellent superelasticity with remarkable fatigue resistance of BTO micropillars. The surface tension–modulated 90° domain switching uncovered in superelastic BTO micropillars is advantageous over the conventional phase transition mechanism, and it is distinct from freestanding BTO membranes. The same mechanism will likely operate in other ferroelectric materials, such as in PbTiO3, which is expected to generate even larger recoverable strains.

This work presents the very first observation that the size-related surface tension can serve as a restoring force for domain switching, resulting in not only superior superelastic behavior but also fatigue-resistant cyclic performance. Such BTO micropillars could potentially be utilized as dampers in micro-electro-mechanical system (MEMS) devices. Therefore, this work provides understanding to ferroelectrics while demonstrating a promising strategy to realize fatigue-resistant superelasticity in functional oxides.

Dr. Yingwei Li, a visiting scholar of SUSTech from WHU, Kangjie Chu, a Ph.D. student in HKUST, Ph.D. students Chang Liu from Zhejiang University and Jiang Peng from Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences (CAS), are the first-authors of this paper. Dr. Yingwei Li, Professor Jie Wang, Associate Professor Fuzeng Ren, and Professor Jiangyu Li are the co-corresponding authors.

This project was financially supported by the National Key Research and Development Program of China, National Natural Science Foundation of China (NSFC), Guangdong Provincial Key Laboratory Program from the Department of Science and Technology of Guangdong Province, and the Fundamental Research Program of Shenzhen.

Paper link: https://doi.org/10.1073/pnas.2025255118

Proofread ByAdrian Cremin, Yingying XIA

Photo By