Thermoelectric (TE) conversion technology can directly convert thermal energy into electrical energy, and exhibits many advantages, such as no pollution, no noise, and no moving parts. It is an up-and-coming green energy conversion technology. Thermoelectric generators (TEGs) based on this technology are widely used in space exploration and the energy supply of electronic devices in extreme environments. At the same time, with the rapid rise of the Internet of things technology, many sensors need to operate independently and continuously, which provides a new huge potential application scenario for TEGs, but also puts forward more efficient and reliable requirements for TEGs.

In recent years, environmentally friendly Mg3Sb2-based thermoelectric conversion materials (TEcMs) have been rapidly developed in a wide temperature range (room temperature-500 °C). However, the assembly and reliability of Mg3Sb2-based TEGs are still an urgent problem to be solved.

Professor Weishu Liu’s group from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently made new progress in the field of Mg3Sb2-based thermoelectric (TE) devices.

Their related results were published in top journals in the field of metal materials and energy materials, Acta Materialia and Advanced Energy Materials, respectively.

The assembly of TEGs is mainly based on soldering or brazing processes. Most TEcMs have poor solderability due to their semiconducting behavior, so a metallization layer, i.e., thermoelectric interface materials (TEiMs), needs to be introduced to optimize the connection between the TEcMs and the electrodes before device assembly. However, interfacial reaction and diffusion easily occur at the TEiM/TEcM contact interfaces, resulting in a decrease in the interfacial bonding strength (σs) and an increase in the contact resistance (ρc), which causes the deterioration in TEGs output power density (ω) and conversion efficiency (η). This parasitic problem is particularly prominent in high-temperature service environments.

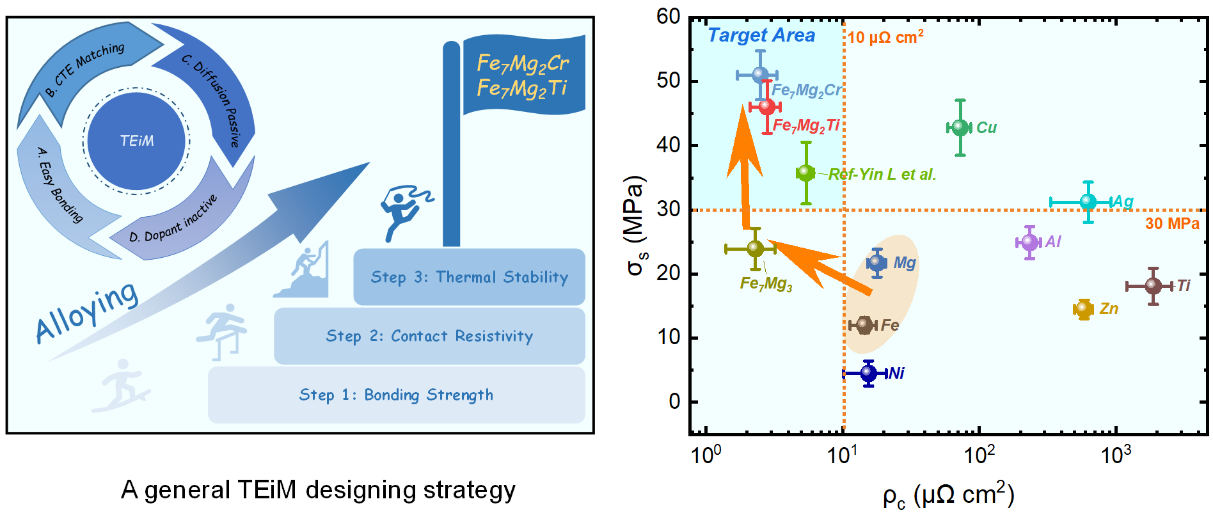

From the perspective of promoting the new Mg3Sb2-based TEcM to the industrial world, it is crucial and urgent to redesign the multifunctional TEiMs and improve the reliability of the TEGs. However, how to select the optimal TEiMs for a specific TEcM has not been systematically studied and discussed in depth. In response to this challenge, the research group designed new Fe7Mg2Cr and Fe7Mg2Ti ternary alloy TEiMs based on the principles of activated sintering, thermal expansion coefficient (CTE) matching, inactive doping, and diffusion passivation.

After 15 days of high-temperature aging treatment at 400 °C, the TEiM/TEcM interface exhibits ρc <10 μΩ cm2 and σs>30 Mpa, which meets the basic requirements and shows good interfacial stability. This general design strategy provides an important reference for specifying TEcM to quickly search for TEiMs and is expected to break through the technical bottleneck of Mg3Sb2-based TEGs in real power generation applications.

These related results were published in Acta Materialia, entitled “A general design strategy for thermoelectric interface materials in n-type Mg3Sb1.5Bi0.5 single leg used in TEG”.

Xinzhi Wu, a doctoral student in Prof. Weishu Liu’s research group, is the first author of this paper. Prof. Weishu Liu is the corresponding author, and SUSTech is the first unit of the paper.

Figure 1. A general strategy for designing TEiMs for Mg3Sb2-based TEcMs

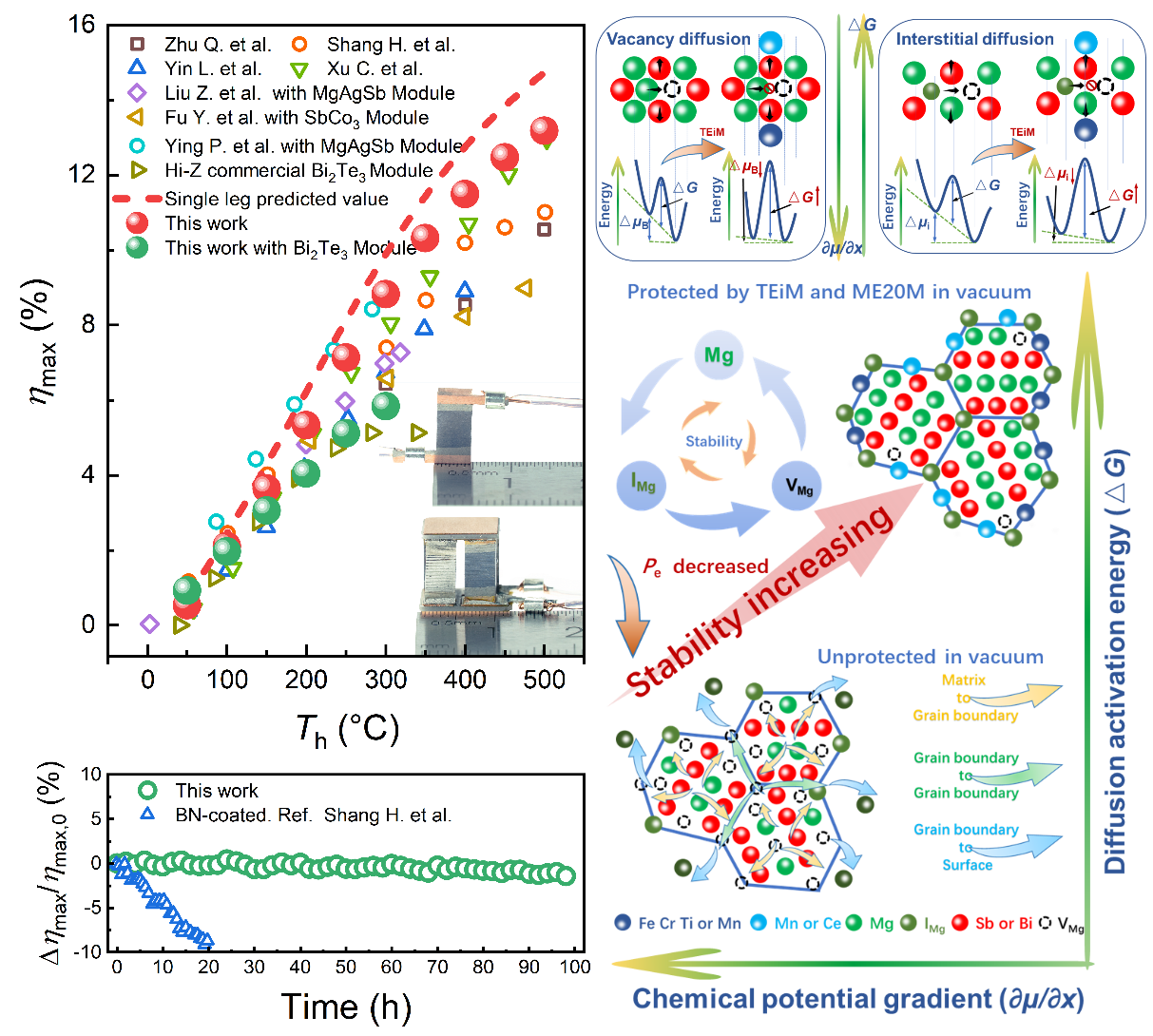

In the previous work, based on the alloy TEiMs design strategy, Prof. Liu’s group improved the interface stability of Mg3Sb2-based TEGs through fast and efficient screening optimized TEiMs. However, a more challenging problem is how to optimize the high-temperature stability of the Mg3Sb2-based TEcM.

Mg3Sb2-based TEcM is prone to Mg loss at high temperatures, which induces Mg vacancies, reduces carrier concentration, and deteriorates the intrinsic TE properties. From the material point of view, strategies such as Mg overcompensation, high-temperature sintering, cation site doping, thermal deformation, and sputtering protective coating can effectively stabilize the Mg vacancy concentration, thereby improving the stability of TEcM. However, there is still a lack of effective methods to synergistically optimize thermal stability from both the device and interface perspectives.

Therefore, the research group designed a 5-element TEiM (FeCrTiMnMg) and a multifunctional Mg alloy (ME20M) protective coating by reducing the interface chemical potential gradient, increasing the diffusion activation energy barrier, and reducing the saturated vapor pressure. This significantly improves the thermal stability of TEGs based on reducing the driving force of diffusion at the surface and interface. The optimized TEGs can obtain a high η of 13% at the hot side temperature (Th) of 500 °C, which is the highest value reported so far for an N-type TE single-leg device. Moreover, the device shows excellent high-temperature stability with performance (ω and η) change < 10% after continuous in-situ testing at 400 °C for 100 h, and Th cycled between 200-400 °C over 200 times.

The researchers also used the in-situ heating transmission electron microscopy technique to visually demonstrate the microstructure evolution of the Mg3Sb2-based TEG interface at high temperatures for the first time, which provides an important reference for the study of the interface service behavior of TE devices.

These results were published in Advanced Energy Materials, entitled “Interface and Surface Engineering Realized High Efficiency of 13% and Improved Thermal Stability in Mg3Sb1.5Bi0.5-based Thermoelectric Generation Devices”.

Xinzhi Wu and Yangjian Lin, a doctoral student from Anhui University, are the co-first authors of this paper. Prof. Weishu Liu and Prof. Binghui Ge are the corresponding authors, and SUSTech Technology is the first unit of the paper.

Figure 2. Boosting conversion efficiency and high-temperature stability of Mg3Sb2-based TEG by interface and surface engineering

These works were supported by the National Key Project of Research and Development Plan, National Natural Science Foundation of China (NSFC), Guangdong Innovative and Entrepreneurial Research Team, and Shenzhen Key Projects of Long-Term Support Plan. The authors also acknowledge the support of the Key Laboratory Program of the Department of Science and Technology of Guangdong Province and the Tencent Foundation through the Xplorer Prize.

Paper links (In order of appearance above):

Acta Materialia: https://doi.org/10.1016/j.actamat.2021.117616

Advanced Energy Materials: https://doi.org/10.1002/aenm.202203039

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By