Additive manufacturing (AM), as a disruptive technique, is having a profound effect on industrial manufacturing processes. It represents a significant trend in advanced manufacturing and forms a primary sector of intelligent manufacturing. The past decade has witnessed a transition of AM from a rapid prototyping technology into a viable industrial production option. However, decision-making for AM and its design is nontrivial due to limited information, large uncertainties, and high-dimensional design spaces. These challenges are inherent to AM and limit the broader adoption of AM for industrial applications.

Recently, there has been a surge of interest in exploring the feasibility of utilizing emerging information technologies, such as cloud computing, data analytics, and artificial intelligence (AI), to solve these challenges. Related attempts ranging from intelligent AM design, equipment, product, and services are generally known as intelligent additive manufacturing and design (IAMD).

Assistant Professor Yi Xiong’s research team from the School of System Design and Intelligent Manufacturing (SDIM) at the Southern University of Science and Technology (SUSTech) has recently made new progress in the field of intelligent additive manufacturing and design.

Their results have been published in Additive Manufacturing, Journal of Manufacturing Systems, and Advanced Engineering Informatics.

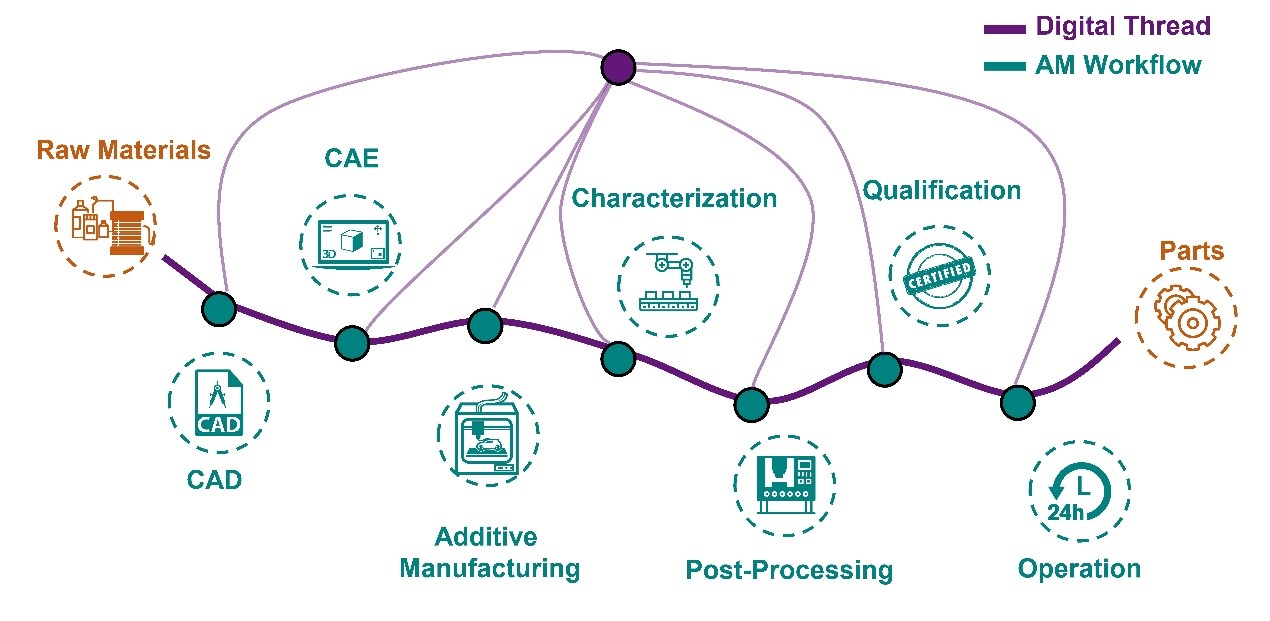

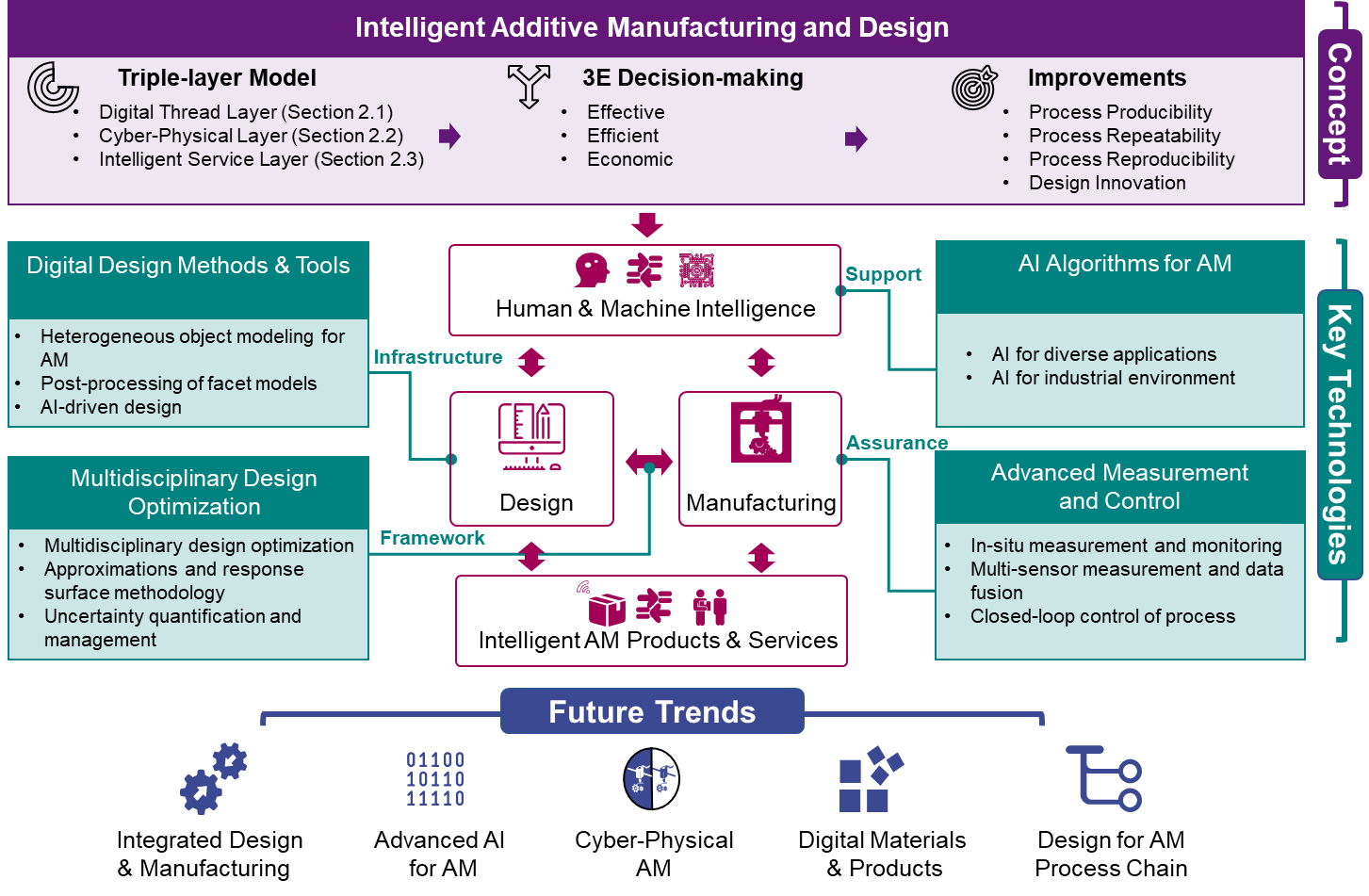

To build a roadmap for this emerging research field, the research team defines the concept of IAMD as follows: it aims to maximize the value of AM by fully utilizing its design freedom in terms of materials, structures, and processes through interactions with cyber-physical systems based on both human and machine intelligence. Also, a triple-layer model is provided for reference, including digital thread, cyber-physical, and intelligent service layers. Moreover, scientific and engineering challenges raised during the studies and implementations of IAMD are discussed with potential solutions.

Multidisciplinary design optimization, as a key technology to link design and manufacturing, is discussed for the first time. The future perspective on IAMD towards the directions are also outlined, including integrated design and manufacturing, cyber-physical AM, advanced artificial intelligence for AM, digital materials and products, as well as design for the AM process chain.

This study, entitled “Intelligent additive manufacturing and design: state of the art and future perspectives,” was published in Additive Manufacturing.

Figure 1. Research framework for studies on intelligent additive manufacturing and design

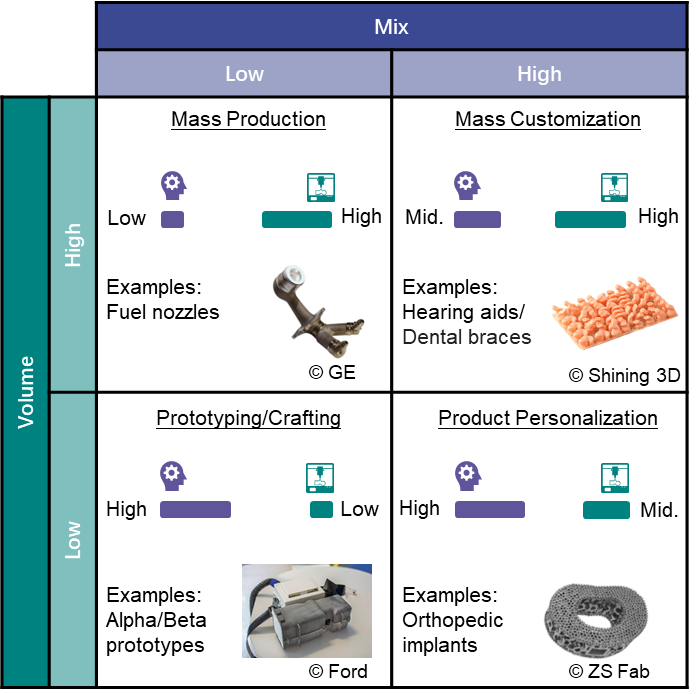

Prof. Xiong’s team also utilizes the human-cyber-physical systems (HCPS) framework to gain better insight and build a clear understanding of the diverse and complex relationships between humans and machines for collaborative activities in additive manufacturing. HMC-AM is an emerging and specific research topic in the field of human-centric intelligent manufacturing. Human-machine collaborations in AM are divided into two types, active-supportive and active-active, and into three classes based on the purposes, i.e., human augmentation, AM intelligentization, and human-machine co-creation.

This study, entitled “Human-machine collaborative additive manufacturing,” was published in the Journal of Manufacturing Systems.

Figure 2. Typical application scenarios for AM productions that need human-machine collaborations

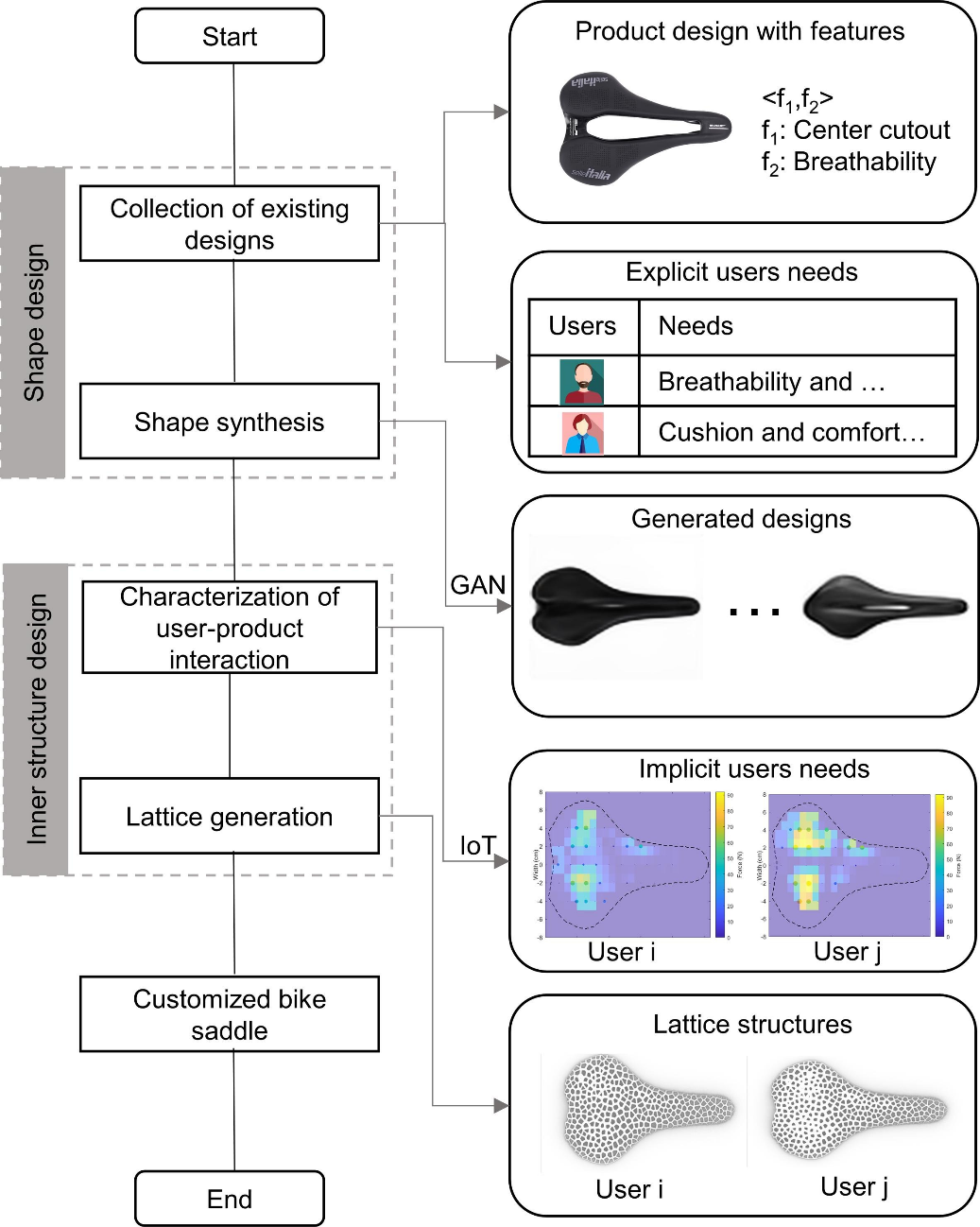

Intelligent additive manufacturing and design hold great promises for satisfying the increased demands of mass customization. To this end, the research team established a data-driven generative design approach for boosting design efficiency and improving customer satisfaction. The proposed approach transformed the design paradigm from designer-centric into computational-based by leveraging the data acquired from the product-, customer-, and service-ends via intelligent design automation.

This study, entitled “Data-driven generative design for mass customization: A case study,” was published in Advanced Engineering Informatics.

Figure 3. A bike saddle development procedure based on the data-driven generative design framework proposed

Asst. Prof. Yi Xiong is the corresponding author for these series of papers. Zhouminju Jiang, a master’s student from Prof. Xiong’s group, is the first author of the third journal paper. Prof. Yunlong Tang from Monash University, Prof. David Rosen from the Agency for Science, Technology and Research (A*STAR), Prof. Qi Zhou from Huazhong University of Science and Technology, Profs. Yongsheng Ma and Fred Han from SUSTech, and Prof. Samyeon Kim from Jeonju University also contributed to these work.

The above research works were supported by the National Natural Science Foundation of China (NSFC), National Key Research and Development Program of China, Natural Science Foundation of Guangdong Province, and Technology and Innovation Commission of Shenzhen Municipality.

Paper links (In order of appearance above):

Additive Manufacturing: https://doi.org/10.1016/j.addma.2022.103139

Journal of Manufacturing Systems: https://doi.org/10.1016/j.jmsy.2022.12.004

Advanced Engineering Informatics: https://doi.org/10.1016/j.aei.2022.101786

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By