The team led by Prof. Qiang Zhu from the Department of Mechanical and Energy Engineering of the Southern University of Science and Technology (SUSTech) will focus on the basic theories and application technology research of metal material 3D printing including aluminum alloys, nickel-based alloys, die steel and titanium alloys, relying on the “Shenzhen Key Laboratory of Additive Manufacturing of High Performance Materials” and the team’s long-term research background in theories of metal solidification, precision forming and numerical simulation of the solidification process as well as other fields.

Researching and Developing Low-Cost and High-Efficiency Metal Manufacturing Technology by Focusing on Market Demands

The current metal 3D printing technology mainly adopts lasers or electron beams and other high-energy beams as the energy source. The energy density is high and can be extremely subtly focused, allowing to achieve rapid precision molding of high melting point metals. However, printing equipment with high-energy beams as the heating source is complex and expensive, and is currently only applicable to aerospace, medical treatment and other high value-added applications. Meanwhile, the powder materials required for the metal 3D printing is limited and expensive, which is also the main reason for its high technological cost. In order to meet the urgent needs of high-efficiency and low-cost rapid manufacturing of metal parts in the industrial fields of aviation, medical treatment, automobile, molding, and so on, it is urgent to carry out technological research on the additive manufacturing of high-efficiency and low-cost complex metal parts.

Qiang Zhu’s team is committed to the development of a multiphase melt direct writing technology for alloys and composites based on the conventional heating method (non-high energy beams). The core of the technology is to combine the advantages of free manufacturing by 3D printing and non-Newtonian flow characteristics, so as to achieve the direct writing through the control over its rheological behavior. The process flow of this method is simple, and only the traditional heating method can meet the needs of the molding process. Meanwhile, the raw materials used are diverse and cheaper. The overall technological cost is significantly reduced compared to 3D printing technology through lasers/electron beams. In addition, the solidification shrinkage in the process is reduced, which is more conducive to the control over the holes, micro-cracks and also residual stress in the solidification process.

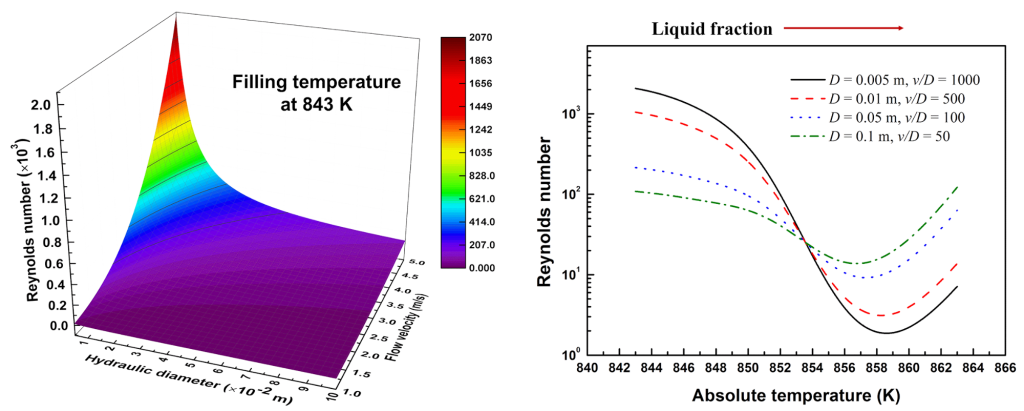

Currently, Qiang Zhu’s team has established an apparent viscosity model describing its macroscopic rheological properties for the mixed system, and the shear time effect was introduced into the model for the first time. The related work is published on Acta Materialia (Acta Mater., 2017, 124, 410). The team has also established a criterion for describing the micro-flow stability of the micro-rheological behavior of the fluid, which had revealed the correlation between the flow stability and the particle volume fraction and shear condition (Fig. 1). The related work is published in the same issue of Acta Materialia (Acta Mater., 2017, 124, 446). The above research results are an important theoretical basis for the metal flow control in the process of metal direct writing, playing an important guiding role on simulation and process optimization. At present, this method is mainly applicable to aluminum-silicon cast alloy. Qiang Zhu’s team will focus on researching the direct writing technology for ultra-high strength aluminum alloys, titanium alloys and composites.

Fig.1 Effects of Liquid Fraction and Shear Conditions on the Average Reynolds Numbers of Liquid-solid Mixed Aluminium Melt

Metal 3D Printing Process To Achieve Complex Pipeline Design

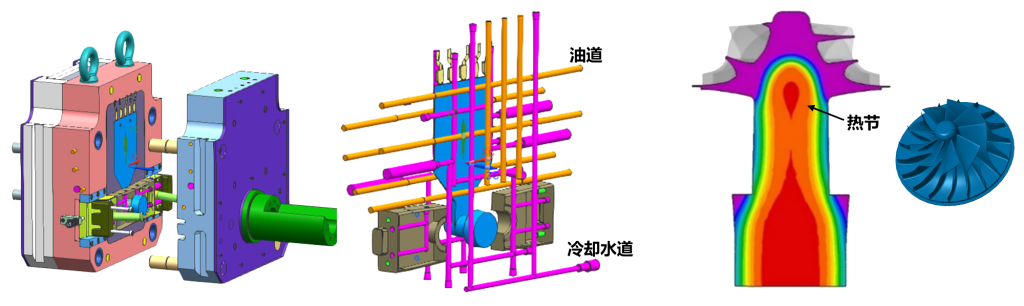

For the traditional molds, such as the injection molding industry (a method of producing industrial products) and the die casting industry (metal casting process), the cooling channel is achieved through machining. A linear internal network is generated through cross drilling, and the flow rate and direction are adjusted through the built-in fluid plug. Taking the die casting process as an example, the temperature of the mold cavity will undergo a complex thermal cycle throughout the process. The heating oil channel and the cooling water channels can precisely control the mold temperature, so that the mold will achieve the ideal thermal equilibrium state. In this way, it improves the progressive solidification conditions of the die castings, improves the internal quality and surface quality of the die castings, stabilizes the dimensional accuracy of the die castings, improve the efficiency of the die casting production, reduces the heat strain force of the die and prolongs its service life. However, the traditional mold for oil and water channels are straight pipes, as is shown in Fig. 2. Therefore, it is difficult to control the temperature according to product appearance, especially for the spare parts with complex designs. The solidification process tends to cause hot spots, which eventually leads to shrinkage cavities or thermal cracks and other defects in the castings.

Fig. 2 Diagram of Arrangement of Traditional Die-casting Mold Cooling Water Channels

With the benefits of free molding by metal 3D printing technology, we can overcome the limitations of the cross-drilling method on the design of the oil ducts and water channels in the die-casting molds. Based on the thermal balance system analysis on the die-casting mold, we can design complex cooling water channels more suitable for the structure of castings, so that they have smooth corners, faster flow and more controllable cooling efficiency. Qiang Zhu’s team will focus on researching the design of shape follow-up cooling channels and 3D printing technology for the mold core by virtue of their rich experience in the field of metal die casting, especially their in-depth understanding of the progressive solidification control in the die casting process and mold thermal balance system.

Improving Aeronautical Parts Manufacturing Industry by Exploring 3D Printing Technology for High-Temperature Alloys

Aeronautical product manufacturing is the most high-end technology in the manufacturing industry, and to a large extent represents a country’s manufacturing level and comprehensive national strength. The aviation industry has a huge market potential in the future. To this end, the governments are investing an enormous sum of money in the aviation industry, so as to promote the continuous upgrading of aeronautical products. The demand for the continuously reduced manufacturing cycle and the increasing complexity of the parts puts pressure on the traditional manufacturing technologies to meet the requirements for efficient upgrading of the aviation technology, especially direct manufacturing capacity in the high-temperature complex structural parts. Therefore, 3D printing technology becomes the most powerful way to solve the technical bottleneck. Compared to the traditional manufacturing methods, the metal 3D printing technology has significant advantages in improving the design freedom and manufacturing flexibility, and has played an increasingly important role in the field of aerospace spare parts.

However, only a very few superalloys (such as In718) can be reliably applied to the 3D printing technology. Most of the superalloys tend to crack seriously during the 3D printing. The superalloys are generally of poor weldability. Meanwhile, some highly-alloyed alloys undergo serious micro-segregation as 3D printing always generates high thermal stress, and the cracks are very likely to occur in the heat affected zone of the substrate and expand along the grain boundary due to the epitaxial growth characteristics of the printing texture. Therefore, Qiang Zhu’s team is cooperating with the international advanced research team to carry out relevant research on the crack sensitivity improvement of superalloys during the 3D printing process. Inspired by the traditional alloy casting process, the team will adopt CALPHAD method (Phase Diagram Calculation Method) to build the database of alloy thermodynamics and dynamics, and regulate and control the solidification behavior of the alloy in real time during the printing by means of component optimization and addition of nucleating agents.

Proofread By

Photo ByDepartment of Mechanical and Energy Engineering