Traditional artificial composites are achieved by high-temperature sintering, which is energy-consuming and has a limited scope of application. In contrast, natural composites (e.g., bones, shellfish, etc.) are developed in a relatively mild, humid environment through the regulation of biological enzymes to achieve a multi-scale hierarchical structure with a much higher mechanical behaviour than various synthetic composites.

Associate Professor Ji Liu’s team from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech), in collaboration with researchers from Massachusetts Institute of Technology (MIT), and Nanjing Tech University (Nanjing Tech), recently published an article in which they integrate 3D printed hydrogel architectures with enzyme-induced biomineralization.

Their work, entitled “Bioinspired 3D Printing of Functional Materials by Harnessing Enzyme-Induced Biomineralization,” was published in Advanced Functional Materials. They combined hydrogel 3D printing and enzyme-induced biomineralization to construct functional materials with extreme mechanical behavior, enabling the transformation of 3D printed soft hydrogel materials (modulus of 125 kPa) to rigid composite composites (modulus of 150 MPa).

The researchers developed a series of enzyme-carrying hydrogel inks with shear thinning and stress-yielding properties to achieve 3D printing of various types of fine hydrogel structures. Meanwhile, under the induction of alkaline phosphatase (ALP), calcium glycerophosphate (CaGP) hydrolysis was deposited inside the hydrogel, and the fraction of minerals can reach as high as 50%, leading to composites with Young’s modulus up to 150 MPa (Figure 1, Video 1).

Figure 1. 3D printing and enzyme-catalyzed mineralization of the composite hydrogels with extreme mechanical behaviors

Video 1. Preparation process of 3D printed mineralized hydrogels

Combined with embedded printing, the team realized 3D printing manufacturing of single ink/multiple inks with various self-supporting structures (Figure 2, Video 2), free from the influence of gravity and the restriction of layer-by-layer stacking mode. Self-supporting structures produced through conventional embedded 3D printing will collapse rapidly after the support material is removed. In this study, CaGP was added to the Pluronic (PEO-PPO-PEO) support bath to promote in situ mineralization of 3D printed structure. For the first time, a stable three-dimensional self-supporting structure can still be obtained when the support bath is removed.

Figure 2. Embedded 3D printing and enzyme-induced biomineralization are utilized to fabricate spatially self-supporting structures

Video 2. Embedded printing 3D structure process

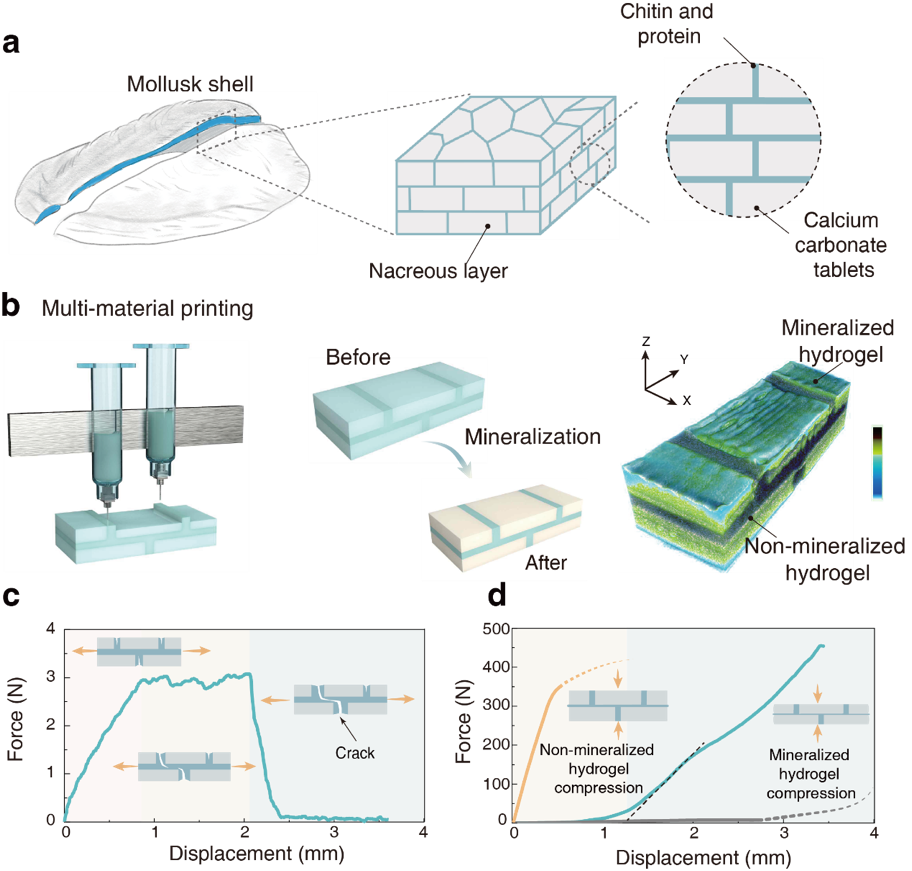

A vast array of invertebrate and vertebrate animals adapt tessellation geometries with periodic soft and hard elements, allowing for a built-in safety mechanism. Therefore, both compressive and tensile loads are well managed. Inspired by such structures, Prof. Liu’s team achieved selective distribution of alkaline phosphatase through multi-material 3D printing, which in turn led to mosaic geometry materials with regioselective mineralization (Figure 3).

These structures exhibit mechanical behavior that has not been found in conventional homogeneous structures, such as tensile-compression asymmetry. The soft component during tension provides large deformation under small stresses, while the hard material undergoes greater loading during compression, offering new possibilities for the preparation of various types of biomimetic structural metamaterials.

Figure 3. Periodic structure in animal shells, mosaic structures fabricated by multi-material 3D printing technology, and asymmetric mechanical behavior of tensile compression

This work was led by SUSTech, in collaboration with MIT and Nanjing Tech. Guangda Chen, a master’s student at SUSTech, and Liang Xiangyu, a postdoctoral fellow at SUSTech, are the co-first authors of this paper. Prof. Ji Liu is the corresponding author.

This study was supported by the Shenzhen Key Laboratory of Bionic Robots and Intelligent Systems, Guangdong Provincial Key Laboratory of Human Enhancement and Rehabilitation Robots in Ordinary Universities, Guangdong Natural Science Foundation-Regional Joint Fund Project (Youth Fund), Additive Manufacturing Innovation Center at SUSTech, Shenzhen Outstanding Scientific and Technological Innovation Talents Project, and the President’s Outstanding Postdoctoral Project of SUSTech.

Paper link: https://onlinelibrary.wiley.com/doi/10.1002/adfm.202113262

Prof. Ji Liu’s profile page: https://faculty.sustech.edu.cn/liuj9/en/

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By