Sliding wear is a key factor that limits the lifetime of metallic components for a wide range of functional and structural applications. Thus, developing wear-resistant bulk alloys or coatings with exceptional wear resistance is in great demand for ensuring the reliability, durability, and efficiency of metallic contacts in harsh environments.

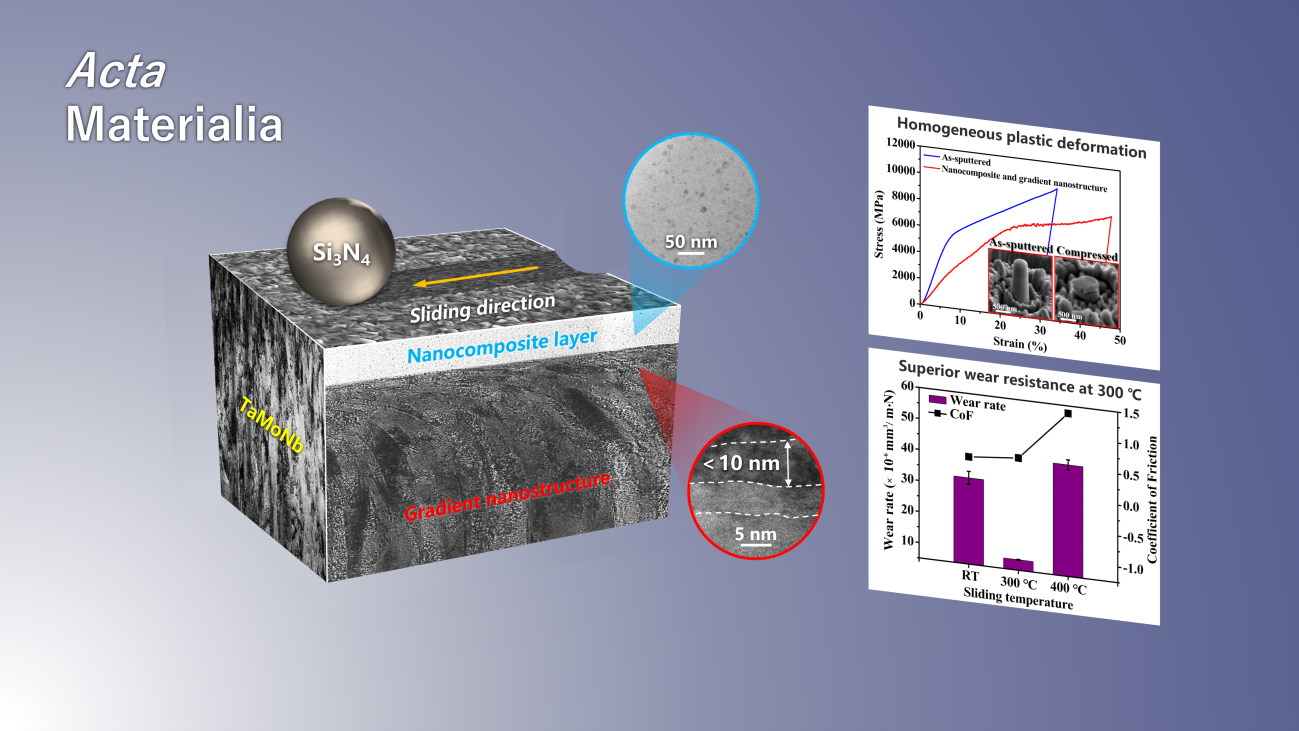

Associate Professor Fuzeng Ren’s research group from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has recently achieved new advances in the field of superior wear-resistant alloy film. They proposed a strategy to achieve superior wear resistance via in-situ formation of an amorphous-crystalline nanocomposite surface layer and gradient nanostructure during wear at an elevated temperature.

Their research work, entitled “Superior wear resistance in a TaMoNb compositionally complex alloy film via in-situ formation of the amorphous-crystalline nanocomposite layer and gradient nanostructure,” was published in Acta Materialia, a top journal in the field of metallic material.

Compositionally complex alloys (CCAs) composed of high-melting point elements have been shown to exhibit notable strengths owing to their intrinsic solid solution strengthening and sluggish diffusion, which lead to lessened thermal softening and grain coarsening. Furthermore, grain refinement has also been used to strengthen and further enhance the wear resistance of CCAs. However, it should be noted that homogenous plastic deformation through the multiplication and motion of dislocations is severely inhibited in homogenous nanograins, resulting in mechanical instability and strain localization (roughening, delaminating, and cracking), and thus the deterioration of wear resistance.

In contrast, the strength-ductility dilemma can also be reconciled by introducing gradient nanostructure or amorphous-crystalline nanocomposites, owing to the particular cooperative effects of strain/stress partitioning between different domains. It has been demonstrated to achieve plastic co-deformation, suppress strain localization, and improve the tribological performance of metallic components with reduced coefficients of friction (CoFs) and wear loss.

Analogous to the top-down approach via severe plastic deformation, cyclic sliding wear-induced gradient strain along the depth direction also triggers the formation of gradient nanostructured worn subsurfaces. In addition, sliding wear at elevated temperatures potentially promotes the oxidation reactions that form the oxide amorphous-crystalline nanocomposite surface in a metallic alloy. Therefore, this work proposed a strategy to achieve superior wear resistance via in-situ formation of an amorphous-crystalline nanocomposite surface layer and gradient nanostructure during wear at an elevated temperature.

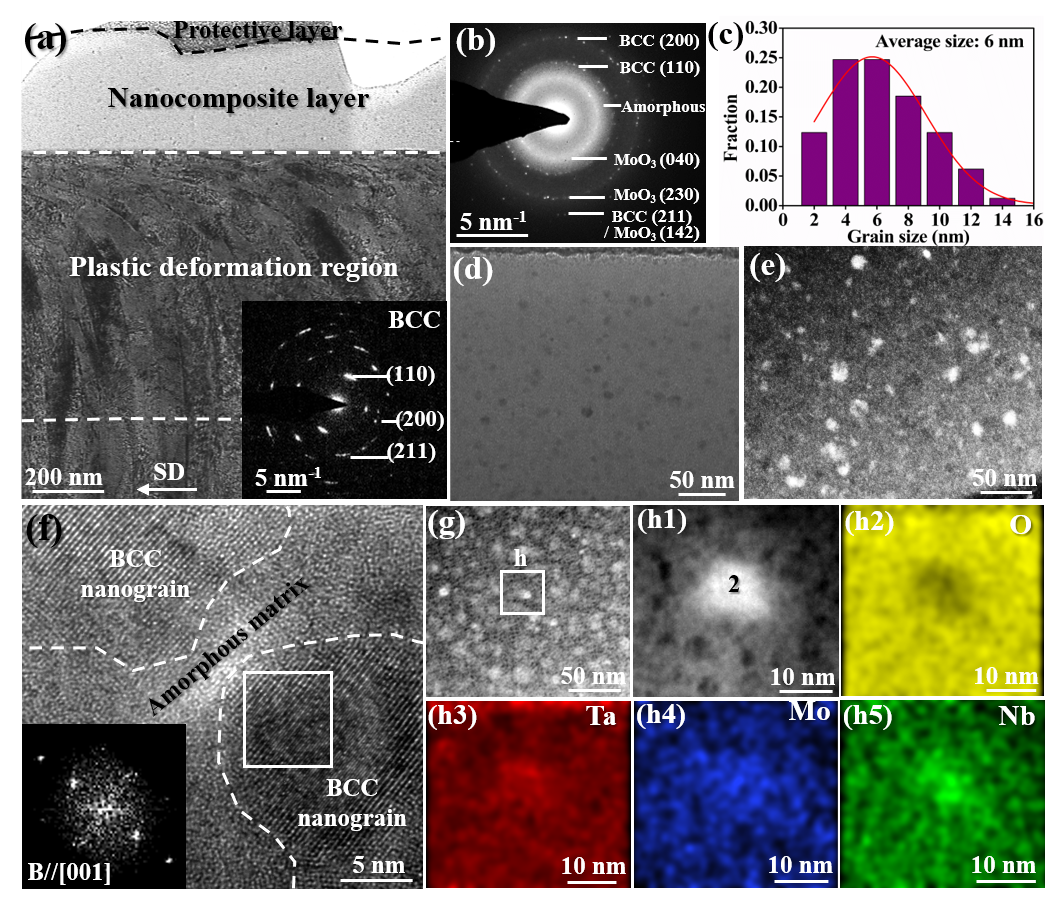

Figure 1. ND-SD cross-sectional TEM characterizations of the TaMoNb film after dry sliding against the Si3N4 ball at 300 °C. (a) A bright-field TEM image showing cross-sectional microstructure below the sliding surface, with the inset showing the SAED pattern of the plastic deformation region. (b) SAED pattern of the nanocomposite layer. (c) Grain size distribution of the nanograins in the nanocomposite layer. (d) and (e) are high-magnification bright- and dark-field TEM images of the nanocomposite layer, respectively. (f) A high-resolution TEM image showing the nanograins surrounded by the amorphous matrix in the nanocomposite layer. The inset is the FFT pattern of the selected region. (g) A HAADF-STEM image of the nanocomposite layer. (h) A high-magnification HAADF-STEM image of the selected area in (g), and the corresponding EDS elemental maps.

As a proof of concept, a body-centered cubic (BCC) nanostructured TaMoNb CCA film was used as the model system. The film was fabricated by magnetron co-sputtering. Then, the ball-on-disk dry sliding tests were performed at various temperatures (RT, 300 °C, and 400 °C). Finally, the chemical composition and cross-sectional microstructure below the sliding surface were examined, and the self-adaptive wear-resistant mechanism of the film at elevated temperatures was finally uncovered.

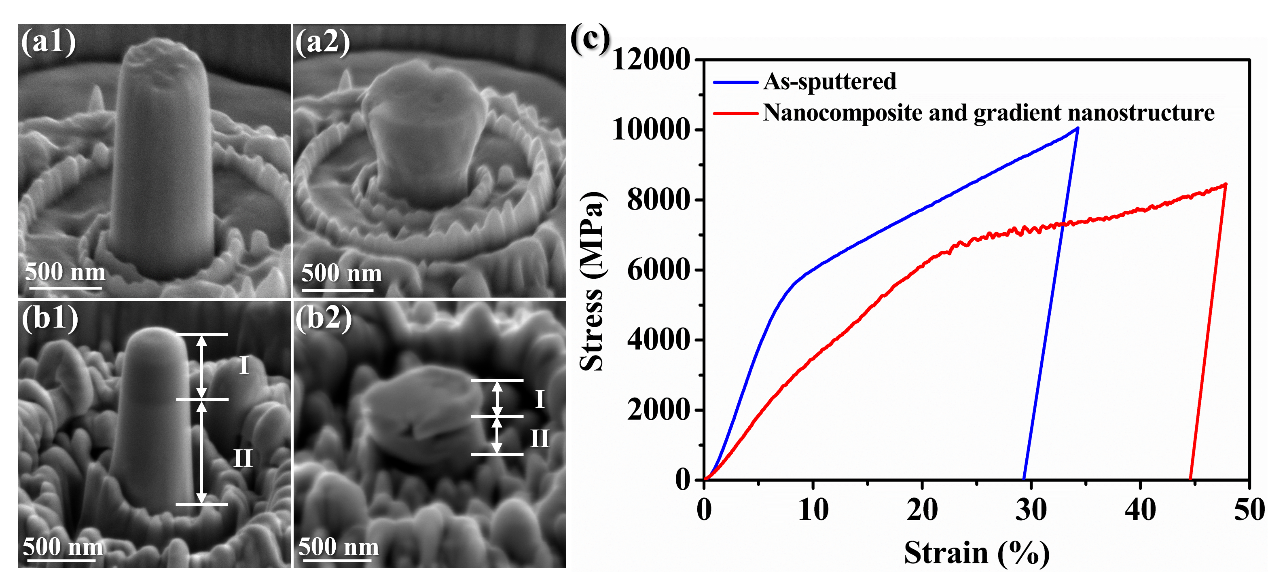

The results found that the TaMoNb film showed a remarkably lower wear rate of 8.37×10-6 mm3/N·m upon wear at 300 °C, which is less than 25% of those at RT and 400 °C. A dense 300 nm-thick nanocomposite layer comprising equiaxed nanograins of only ∼6 nm embedded in the amorphous oxide matrix was formed during wear at 300 °C, below which is a 600 nm-thick plastic-deformation region that exhibits gradient nanostructure (Figure 1). This unique microstructure accommodates appreciable homogeneous deformability (Figure 2), can restrict sliding-induced cracking and localized fracture, and thus significantly improves the wear resistance of the film.

This work offers a new strategy for designing self-adaptive wear-resistant CCAs for application in extreme thermo-mechanical service environments. The research results have important scientific and engineering significance for promoting the development of high-strength, wear-resistant alloy coatings for harsh environments.

Figure 2. Mechanical properties of the sliding wear-induced nanocomposite and gradient nanostructure in comparison with the as-sputtered TaMoNb film with the same nanopillar diameter of 500 nm. (a) SEM images of the nanopillars of as-sputtered TaMoNb film before (a1) and after (a2) compression. (b) SEM images of the nanopillars composed of nanocomposite (I) and gradient nanostructure (II) before (b1) and after (b2) compression. (c) Typical compressive engineering stress-strain curves.

Jiasi Luo, a Ph.D. candidate of the collaborative doctoral program between SUSTech and the Hong Kong Polytechnic University (PolyU), is the first author of this paper. Prof. Fuzeng Ren from SUSTech and Prof. Xusheng Yang from PolyU are the corresponding authors, and SUSTech is the first communication unit.

This work was supported by the National Natural Science Foundation of China (NSFC), Fundamental Research Program of Shenzhen, and Guangdong Basic and Applied Basic Research Foundation. The authors also wish to acknowledge the assistance from the SUSTech Core Research Facilities.

Paper link: https://doi.org/10.1016/j.actamat.2022.118503

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By