Organic Photovoltaics (OPVs) are making waves as strong candidates for the next generation of solar technology, offering a low carbon footprint, quick energy payback, and the ability for large-scale manufacturing through roll-to-roll and open-air printing techniques. With advancements in material development, device architecture, and a deeper understanding of how OPVs work at the molecular level, their power conversion efficiency (PCE) has now surpassed 20%. This progress puts OPVs on the fast track for commercialization, making it a priority in the renewable energy space.

One of the key factors in making any photovoltaic technology commercially available is finding the right balance between cost, efficiency, and stability. While OPVs have achieved impressive efficiency, much of this success relies on the use of fused ring electron acceptors (FREAs), which require complex, multi-step synthesis processes involving hazardous chemicals. This drives up production costs and complicates efforts to scale OPV technology for wider use.

To address this challenge, a research team led by Professor Aung Ko Ko Kyaw from the Department of Electronic and Electrical Engineering (EEE) at the Southern University of Science and Technology (SUSTech) has developed a new class of materials – non-fused ring electron acceptors (NFREAs). These NFREAs, characterized by partially or fully non-fused structures, significantly simplify the manufacturing process by using single-bonded connections rather than fused rings. This not only cuts costs but also opens new avenues for fine-tuning the optoelectronic properties of the materials.

What makes NFEAs particularly exciting is their flexibility in design. While tweaking the alkyl chains in FREAs must be done at the early stages of synthesis, NFREAs allow modifications, such as adjusting alkyl chains, changing the core, or adding halogens at any point in the synthesis process. This adaptability makes it easier to control energy levels, optical bandgaps, and molecular packing, which are critical for improving OPV performance.

However, the single-bonded structure of NFREAs can sometimes hinder molecular planarity, leading to lower charge transport efficiency. To overcome this, Aung Ko Ko Kyaw’s team introduced non-covalent interactions like F…H, N…S, and S…O bonds to lock the molecules into more rigid, coplanar formations. This strategy enhances molecular packing and boosts electron mobility, leading to more efficient charge transfer.

Building on these innovations, the team has successfully designed and tested a range of NFREAs in both binary and ternary blend OPVs. Their work, published in prestigious journals like Advanced Energy Materials, Advanced Functional Materials, and Nano Energy, represents a significant leap forward in the pursuit of cost-effective, high-performance OPV technology.

Revealing the effect of halogenation strategy on the crystallization kinetics and molecular packing

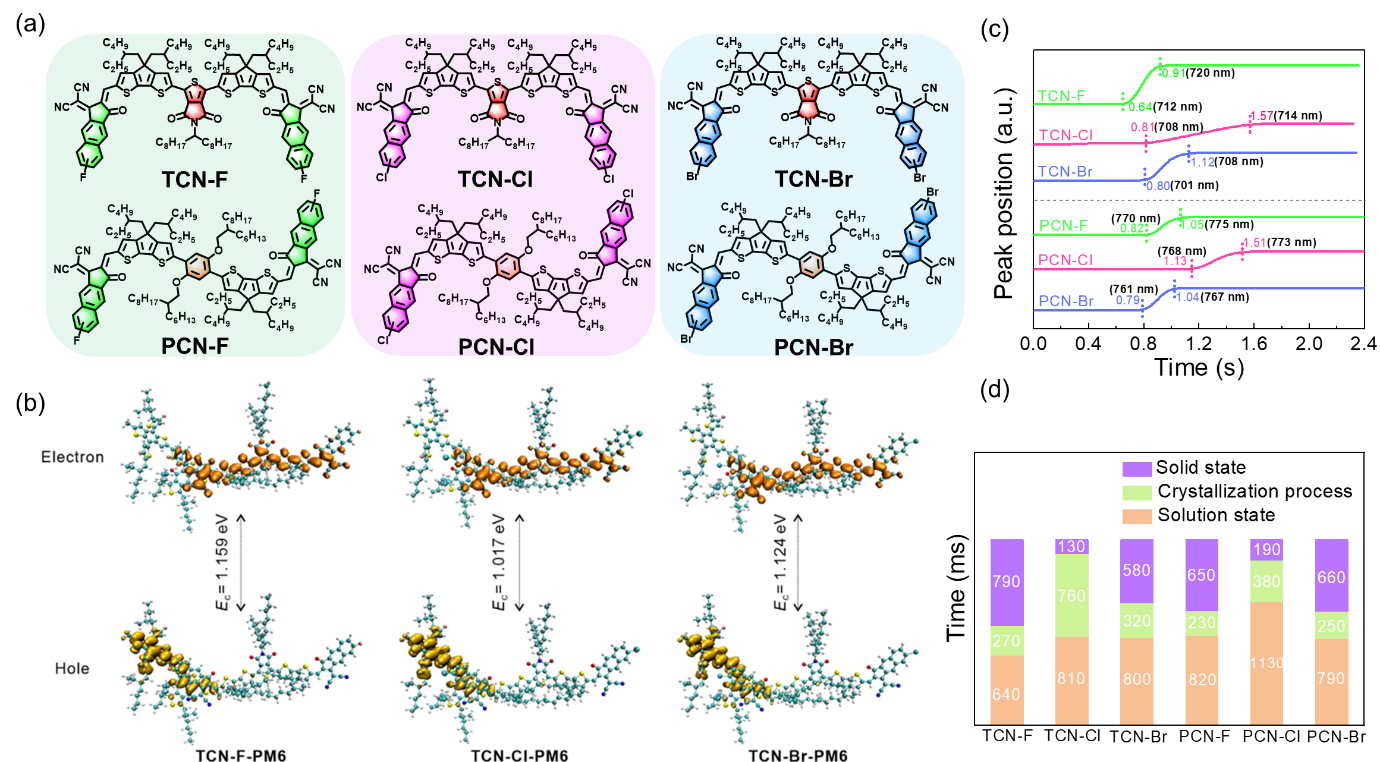

The team’s recent study focused on the role of halogenation in NFREAs. They synthesized a series of NFREAs with fluorine, chlorine, and bromine (Figure 1) to explore their impact on crystallization, molecular packing, and charge transport. Chlorinated NFREAs, in particular, demonstrated remarkable performance, as they significantly delayed crystallization, allowing for more controlled molecular packing and reduced excessive aggregation. This enhanced overall crystallinity and improved phase separation in the active layers.

Furthermore, chlorinated NFREAs were found to possess longer exciton diffusion lengths and small Coulomb attractive energy of electron and hole in the excited state, which played a crucial role in promoting efficient exciton dissociation and minimizing charge recombination. These improvements in molecular structure and charge dynamics contributed to the superior performance of OPVs using chlorinated NFREAs, with power conversion efficiencies (PCEs) reaching 14.85% and 15.30% in binary blend devices.

This represents the highest reported efficiencies for NFREAs with A-π-A’-π-A and A-π-D-π-A structures to date, marking a significant milestone in NFREA-based OPV performance. The research underscores the promise of halogenation—particularly chlorination—as an effective molecular engineering strategy for improving the efficiency and scalability of OPVs.

Their work, entitled “Revealing the Effect of Halogenation Strategy on the Regulation of Crystallization Kinetics and Molecular Packing for High-Performance Organic Solar Cells”, has been published in a top-tier journal Advanced Functional Materials.

Dr. Duo Luo, a postdoctoral researcher in Professor Kyaw’s group, is the first author of the paper. The corresponding authors are Professor Weijie Chi from Hainan University, Professor Baomin Xu from the Department of Material Science and Engineering at SUSTech, and Professor Aung Ko Ko Kyaw. SUSTech is the first corresponding unit of the paper.

Figure 1. (a) The chemical structures of NFRAs using halogenation strategies. (b) The distributions and Coulomb attractive energy of electrons and holes in the excited state of the molecules. (c) The peak position evolution as a function of time of NFREAs films from the in-situ UV-Vis absorption spectrum. (d) The crystallization times for different stages during the film-forming process.

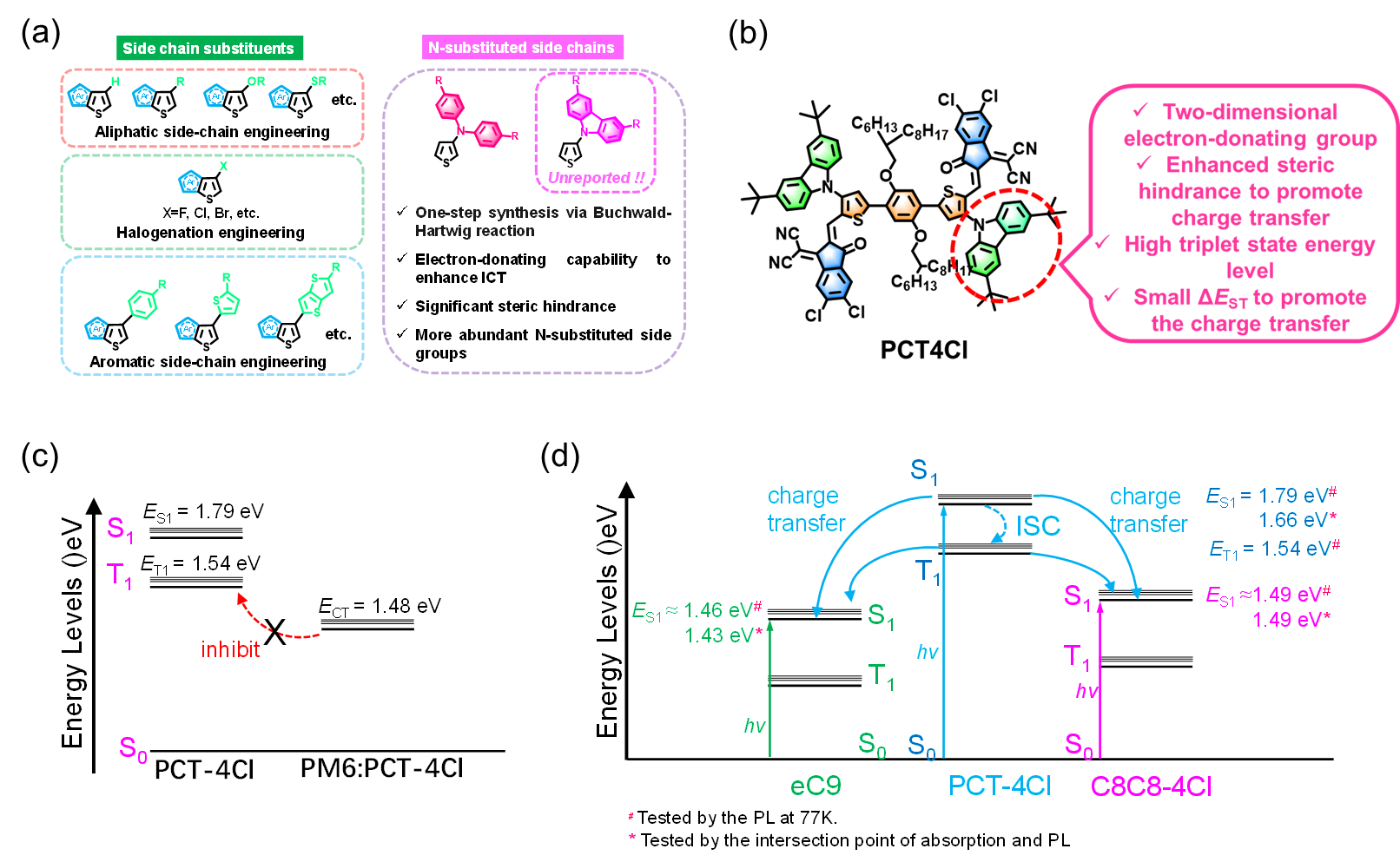

Tert-butyl carbazole modified NFREA with high triplet state energy level for efficient OPV

In another breakthrough for OPV, the research team developed a novel NFREA, PCT-4Cl, featuring a tert-butyl carbazole side-chain (Figure 2). This innovation plays a key role in enhancing the triplet exciton transfer, increasing crystallinity, and improving charge transport within the active layers of OPVs. By incorporating PCT-4Cl into ternary blend films with acceptors such as eC9 and C8C8–4Cl, the team was able to boost PCEs to 18.84% and 15.17%, respectively, which further improved to 19.25% and 15.53% when using a 2PACz hole-transporting layer.

The high triplet energy level of PCT-4Cl facilitates efficient charge transfer, enhancing the performance of both binary and ternary OPV devices. The unique tert-butyl carbazole side-chain not only prolongs exciton diffusion lengths and reduces recombination losses but also controls molecular packing, resulting in better phase separation and enhanced crystallinity in the films. The findings underscore the importance of side-chain engineering for achieving high-performance OPVs and mark a significant step forward in the commercial viability of NFREAs.

The related research results, entitled “Tert-butyl carbazole modified non-fused ring electron acceptor generating high triplet state energy level for efficient organic solar cell”, have been published in Nano Energy.

Dr. Duo Luo is the first author of the paper. Professor Erjun Zhou from the National Center for Nanoscience and Technology, Professor Yiwang Chen from Jiangxi Normal University, and Professor Aung Ko Ko Kyaw are the corresponding authors, and SUSTech is the first corresponding unit of the paper.

Figure 2. (a) The commonly used side chain substituents in the reported literature and the concept of N-substituted side chain. (b) The chemical structure of PCT4Cl with a tert-butyl carbazole side-chain. (c) The Jablonski diagram of the electronic states in PCT-4Cl (ground states (S0), singlet states (S1), triplet states (T1), charge transfer states (CT)). (d) The corresponding S1, T1, and probable charge transfer process between PCT-4Cl, eC9, and C8C8-4Cl.

Thickness-insensitive OPVs enabled by simultaneous D/A interpenetration and stratification

In other research work, the team made major progress in OPVs by developing a strategy to overcome the limitations of thick active layers, a critical challenge for large-scale production. By utilizing a sequential deposition (SD) technique for D/A interpenetration and vertical stratification, they significantly improved the PCE of OPVs featuring NFREA.

The researchers demonstrated that thick active layers—up to 800 nm—could maintain high efficiency without compromising performance, achieving PCEs of up to 14.75% in 300 nm films. This was made possible by the SD method, which allows better vertical distribution of donor and acceptor materials, ensuring efficient charge generation and transport even in thicker films. The SD-processed devices outperformed traditional blend cast devices by achieving higher fill factors (FF) and short-circuit current density (JSC).

To further evaluate the performance, they introduced a new metric called “figure-of-merit-X” (FoM-X), which emphasizes the importance of maintaining efficiency in thick-film devices. With this innovative approach, they set a new standard for thick-film OPVs based on NFREAs, offering a viable path for commercial-scale roll-to-roll manufacturing.

This research, entitled “Thickness Insensitive Organic Solar Cells with High Figure‐of‐Merit‐X Enabled by Simultaneous D/A Interpenetration and Stratification,” has been published in Advanced Energy Materials.

Joint Ph.D. student Xiyun Xie at SUSTech and Hong Kong Polytechnic University (PolyU) is the first author of this paper. Dr. Ruijie Ma and Professor Gang Li from PolyU, Professor Jiaying Wu from the Hong Kong University of Science and Technology, and Professor Aung Ko Ko Kyaw are the corresponding authors.

17.2% efficiency for fully NFREA-based OPV via re-intermixing strategy in D/A stratified active layer

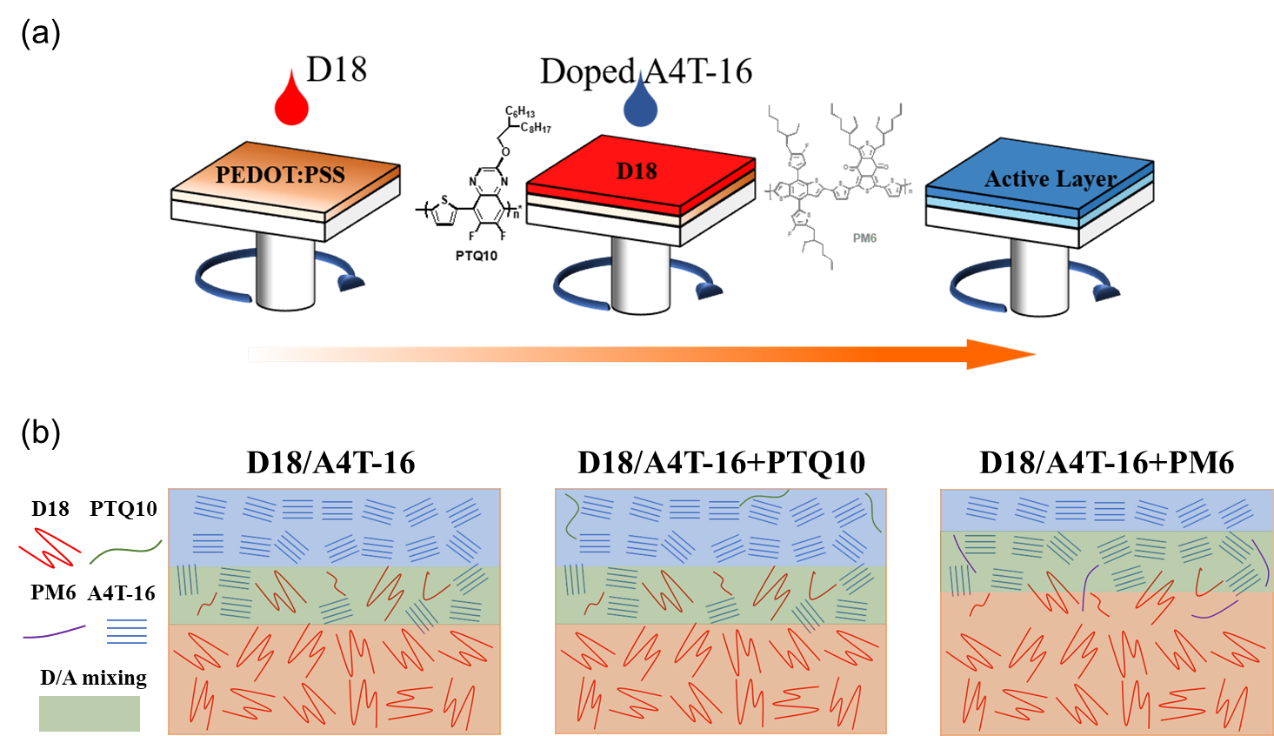

Continuing their cutting-edge work, the research team developed a breakthrough donor/acceptor re-intermixing strategy that has significantly boosted the performance of OPVs using completely non-fused ring acceptors. In this strategy, the secondary donor (PTQ10) is mixed with an acceptor precursor solution (A4T-16) and deposited onto a pre-formed primary donor film (D18) to create a D/A stratified active layer (Figure 3). Additionally, they incorporated polymer donor PTQ11 with fully non-fused ring acceptor TBT26 to form additional charge-generating regions, which enhance charge extraction while suppressing recombination.

By optimizing the vertical distribution of donor and acceptor materials within the active layers, they achieved an impressive power conversion efficiency (PCE) of 17.21%. This re-intermixing method improved both JSC and FF, demonstrating the importance of vertical morphology in solar cell efficiency. The devices employing the re-intermixed active layers exhibited enhanced polaron generation and charge mobility, contributing to the record-breaking PCE values.

The success of this approach not only sets new benchmarks for completely non-fused ring acceptor-based OSCs but also provides a cost-effective route for the commercialization of next-generation solar cells.

The related research results, entitled “17.2% Efficiency for Completely Non-fused Acceptor Organic Solar Cells via Re-intermixing Strategy in D/A Stratified Active Layer”, have been published in Advanced Functional Materials.

Xiyun Xie is the first author of this paper, with Dr. Ruijie Ma and Professors Gang Li and Aung Ko Ko Kyaw serving as the corresponding authors.

Figure 3. (a) Illustration of fabrication process utilizing D/A re-intermixing strategy. (b) Illustration of different morphologies formed by traditional layer-by-layer processing (D18/A4T-16) and our D/A re-intermixing strategy (D18/A4T-16+PTQ10).

NFREA achieving over 15.6% Efficiency OPV by alloy-like phase acceptor

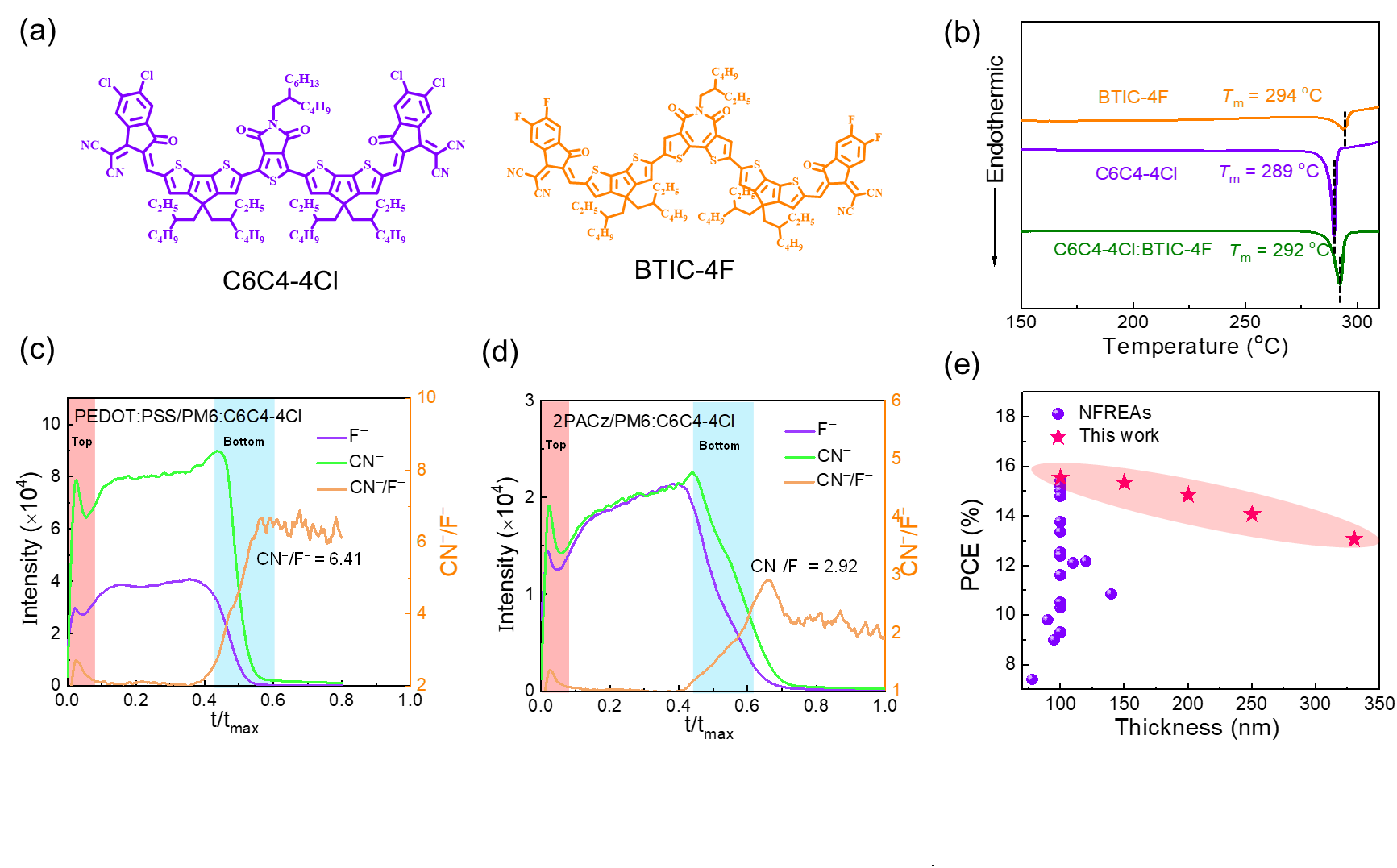

In their continued advancements, Professor Kyaw’s team achieved a remarkable PCE of 15.62% by blending two NFREAs, “C6C4-4Cl” and “BTIC-4F” (Figure 4), with the donor polymer PM6. Their innovative ternary blend approach, which forms an alloy-like phase, offers longer exciton diffusion lengths and improved crystalline properties, promoting efficient charge transfer.

The use of a hole-transporting layer (HTL) called 2PACz played a significant role in boosting the PCE. The 2PACz HTL induces vertical phase separation in the active layer, improving charge extraction and minimizing recombination. The team’s research also demonstrated the scalability of their design for large-scale production. Devices with active layer thicknesses up to 330 nm achieved PCEs of over 13%, making this approach viable for commercial roll-to-roll printing technologies.

This work, entitled “Non-Fused Ring Acceptors Achieving Over 15.6% Efficiency Organic Solar Cell by Long Exciton Diffusion Length of Alloy-Like Phase and Vertical Phase Separation Induced by Hole Transport Layer”, has been published in Advanced Energy Materials.

The first author, Dou Luo, worked alongside corresponding authors Professors Baomin Xu and Aung Ko Ko Kyaw, with SUSTech serving as the first corresponding unit of the paper.

Figure 4. (a) Chemical structures of C6C4-4Cl and BTIC-4F. (b) Differential scanning calorimetry curves with melting enthalpy values of C6C4-4Cl, BTIC-4F, and the blend of the two NFREAs, showing the formation of alloy phase in the blend. (c) TOF-SIMS ion intensity of F− and CN−, and CN−/F− intensity ratio as a function of t/tmax in the PM6:C6C4-4Cl blend film coated on (c) PEDOT:PSS and (d) 2PACz, demonstrating the higher vertical phase separation on 2PACz. “t” is specific sputtering time and tmax is total sputtering time. (e) PCE versus thickness for reported NFREAs compared with our results.

Paper links (In order of appearance above):

Advanced Functional Materials: https://doi.org/10.1002/adfm.202311736

Nano Energy: https://doi.org/10.1016/j.nanoen.2024.109583

Advanced Energy Materials: https://doi.org/10.1002/aenm.202401355

Advanced Functional Materials: https://doi.org/10.1002/adfm.202411286

Advanced Energy Materials: https://doi.org/10.1002/aenm.202203402

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo ByDepartment of Electronic and Electrical Engineering