Stretchable seals are vital components to ensure the stable operation of stretchable electronic and energy devices. However, the elastic surface of conventional sealing elastomers has limited chain mobility and is chemically inert, so it cannot conform to or bind with the foreign surface at the microscopic scale. This results in interfacial air gaps with intense extrinsic water ingression at the interface. Moreover, the loosely packed molecular structure renders polymeric elastomers inherently permeable to gases, leading to bulk penetration. Both side and bulk permeation of moisture and oxygen contribute to rapid device failure.

To address this challenge, Associate Professor Yanhao Yu’s team from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech) has developed a hermetic stretchable seal featuring a viscoplastic surface. By introducing partially compatible polar polymers into a styrenic block copolymer elastomer and controlling their phase separation into polar domains in the near-surface region, an elastic-to-viscoplastic transition on a polymeric elastomer surface was achieved.

This unique viscoplastic surface enables the elastomer to form defect-free interfaces with metals, plastics, and other elastomers—covering typical electrode, dielectric, and substrate materials used in stretchable electronics—regardless of their size, chemical composition, or geometry. This effectively prevents side penetration. The surface viscoplasticity also facilitates seamless integration of water scavengers, including an embedded solid layer composed of molecular-sieve particles and a high-viscosity liquid layer composed of glycerol and Ectoine.

The resulting multilayer seal combines the impermeability of aluminum foil with the stretchability of a rubber band. This breakthrough significantly extends the operational lifetime of perovskite optoelectronics, hydrogel thermoelectrics, and implantable bioelectronics without compromising their stretchability or efficiency.

Their paper, titled “Hermetic Stretchable Seals Enabled by a Viscoplastic Surface Effect,” has been published in Nature Materials.

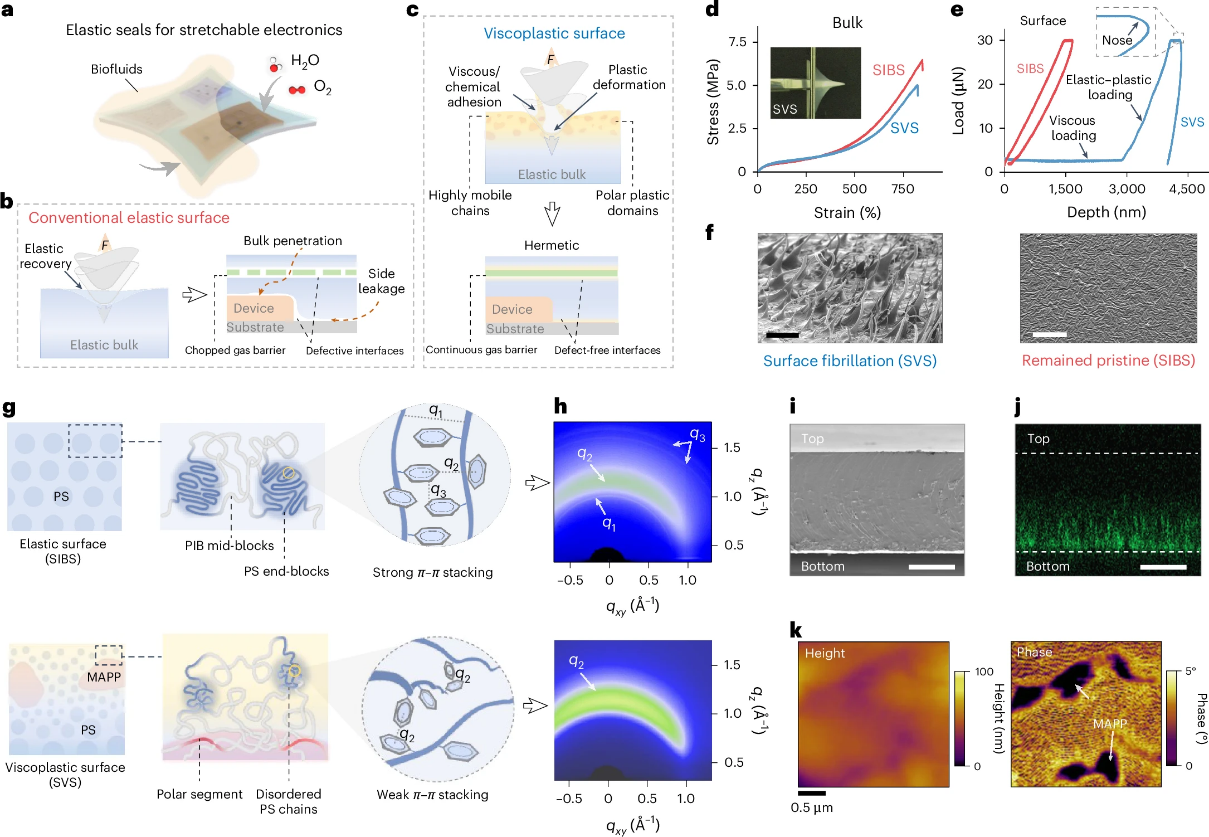

Figure 1. Viscoplastic surface effect for hermetic and stretchable seals

The team selected poly(styrene-isobutylene-styrene) (SIBS) as the starting elastomer since it has large stretchability and the lowest intrinsic water vapor transmission rate (WVTR). The surface-viscoplastic SIBS (SVS) was obtained by introducing maleic anhydride-grafted polypropylene (MAPP) molecules and controlling their phase separation into polar domains in the near-surface region of SIBS.

Mechanical tests confirmed that this structural design achieves surface transformation from a highly elastic to a viscoplastic state while preserving the bulk material’s toughness and elasticity. In-situ nanoindentation and surface self-adhesion peeling experiments further validated the surface phase transition, demonstrating the method’s precision in regulating the surface phase state of SIBS.

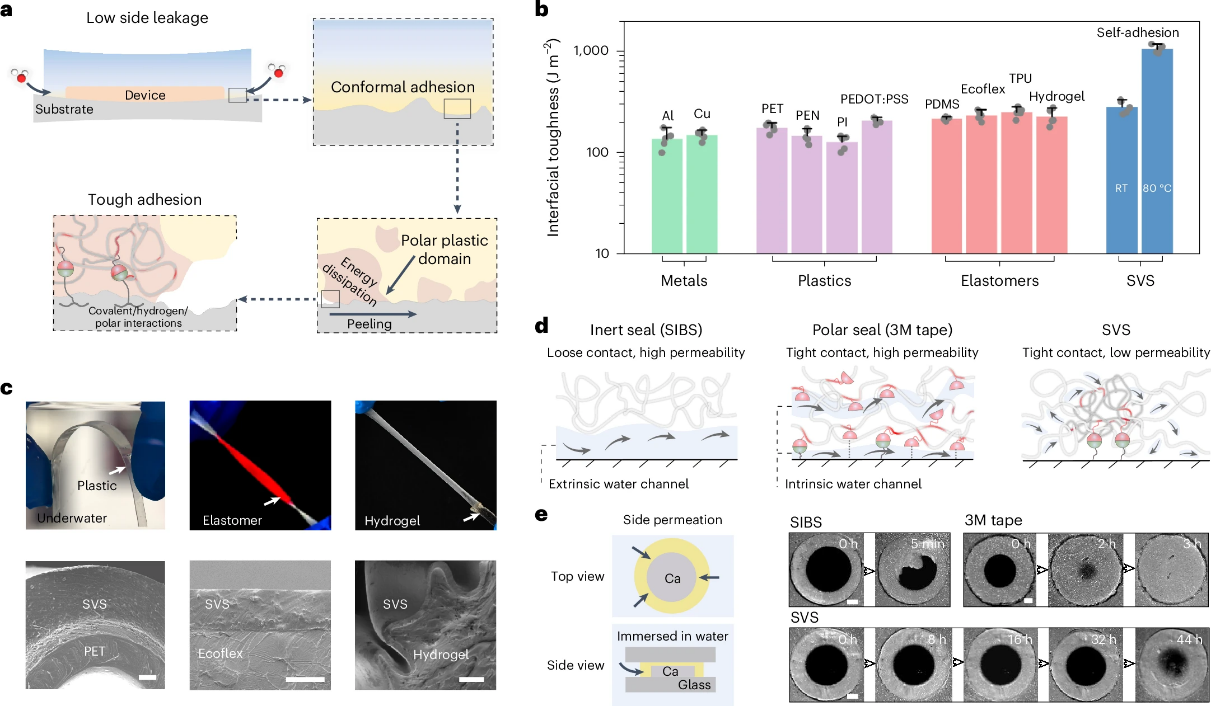

Figure 2. Side permeation evaluation

The viscoplastic surface enables SVS to form conformal, tough, and stretchable adhesions with metals, plastics, and elastomers, covering common electrode, dielectric, and substrate materials used in stretchable electronics. These intimate contacts, combined with the intrinsically low WVTR, allow SVS to effectively mitigate the side leakage. The optical calcium corrosion test revealed that the SVS-sealed sample survived for more than 32 hours, over 15 times and 300 times longer than that of the tape-sealed and SIBS-sealed samples when immersing these sealed calcium disks in water at room temperature.

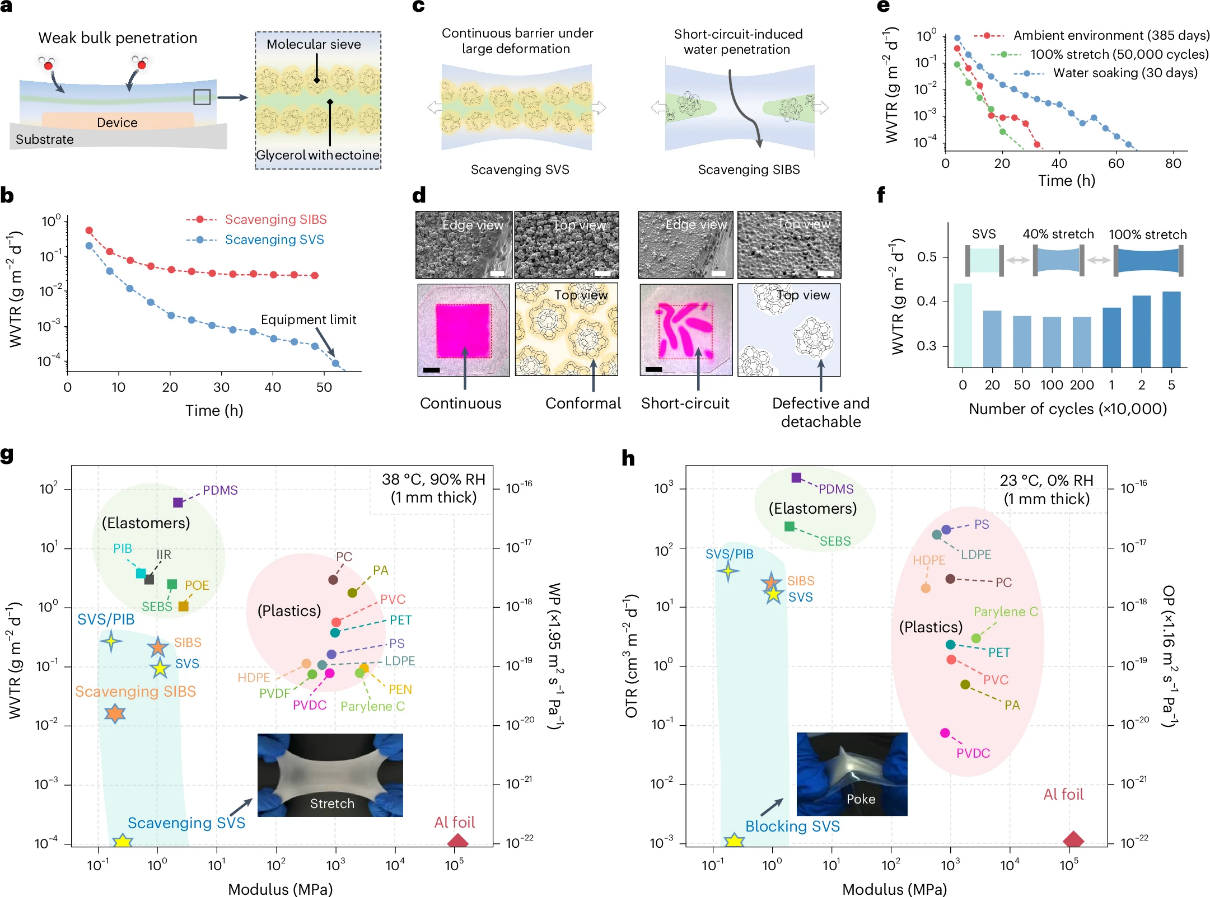

Figure 3. Bulk penetration evaluation

To address the challenge of bulk penetration, the researchers developed a highly stretchable and impermeable composite by exploiting the ease-of-integration feature of SVS endowed by its surface viscoplasticity to assemble water scavengers. This composite includes an embedded solid layer composed of molecular-sieve particles and a high-viscosity liquid layer composed of glycerol and Ectoine. The steady-state WVTR of Scavenging SVS film was below the detection limit of our equipment (9×10-5 g·m-2·day-1), the lowest value among the reported work. Furthermore, the Scavenging SVS showed no WVTR increase after 385 days in ambient air, 30 days underwater, or 50,000 cycles at 100% strain, demonstrating robust longevity.

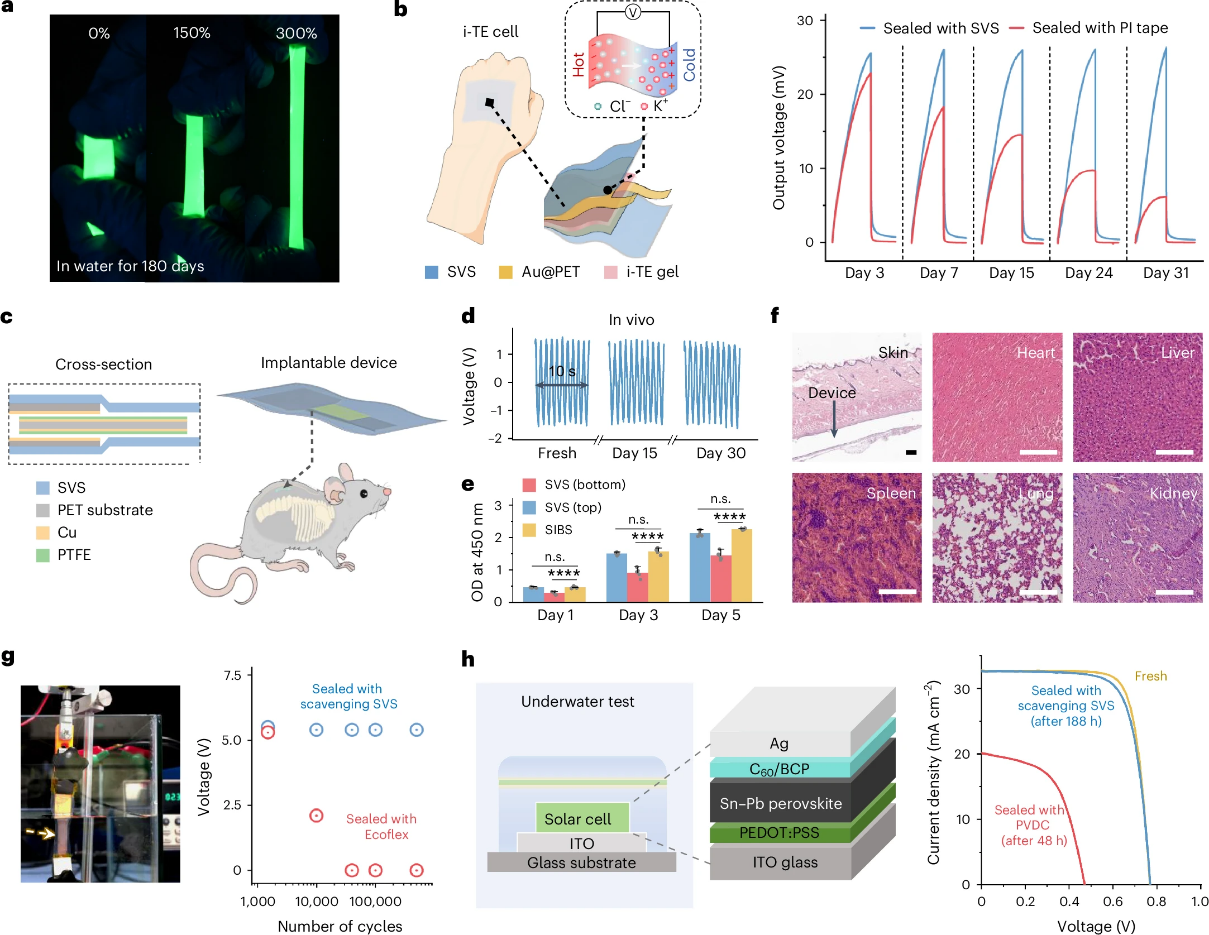

Figure 4. Device protection evaluation

Both SVS and Scavenging SVS exhibited high hermeticity and universal adhesiveness without compromising stability, stretchability, or biocompatibility, positioning them as versatile sealing solutions for electronic and energy devices. The photoluminescence of SVS-sealed cesium lead bromide (CsPbBr3) remained steady after continuous immersion in water (served as an accelerated testing condition) for more than 180 days, outperforming SEBS- and polydimethylsiloxane (PDMS)-sealed CsPbBr3.

In addition, SVS protection extended the working lifetime of an ionic thermoelectric (i-TE) cell made from hydrogel to over 30 days, approximately one order of magnitude longer than that of a polyimide-protected i-TE cell. In vivo, SVS consistently maintained the electrical output of a stretchable electromechanical device for 30 days, confirming its excellent biocompatibility and hermetic performance. Similarly, a tin-lead (Sn-Pb) perovskite solar cell top-sealed with Scavenging SVS retained a stable power conversion efficiency of around 18.4% after 188 hours of water immersion, surpassing the performance of commonly used polyvinylidene chloride (PVDC).

Senior research scholar Rui Xia, doctoral student Chun Li, and visiting scholar Yan Shao are co-first authors of the paper. Associate Professor Yanhao Yu is the corresponding author, and SUSTech is the first affiliated institution.

Paper link: https://www.nature.com/articles/s41563-025-02386-5

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yifei REN

Photo ByDepartment of Materials Science and Engineering