Developments by Southern University of Science and Technology (SUSTech) could see many industries adopt a new approach to polishing metal that is faster, smoother, more efficient, and with fewer defects.

Earlier this year, Assistant Professor Hui Deng (Mechanical and Energy Engineering) worked with doctoral candidate Rong Yi to publish an essential paper in the high-impact academic journal, The International Journal of Machine Tools and Manufacture (IF = 6.039). Their paper was titled “A generic approach of polishing metals via isotropic electrochemical etching.”

While polishing metal seems like a common issue for many people, it serves a vital purpose in many industrial workplaces. The reduction of surface roughness to get a smooth, damage-free, and high-quality surface assists in the production of consumer products and semiconductor chips to ensure their quality.

Flat surfaces are relatively easy to polish, but metal parts with complex shapes and internal cavities are far more challenging to polish. Research has been examining this technical challenge for quite some time. The use of mechanical chemical polishing, laser polishing, and magneto-rheological polishing all have a common problem, known as tool interference.

The goal of this research was to efficiently obtain nano-level smooth surfaces without destroying the accuracy of metal parts. The research group was inspired by a nanometric machining technique known as single-point diamond turning. They focused on the tip trajectory principle, where the machined surface is surrounded by the tip trajectory. The principle says that the interference between the tip and the surface determines the smoothness of the surface.

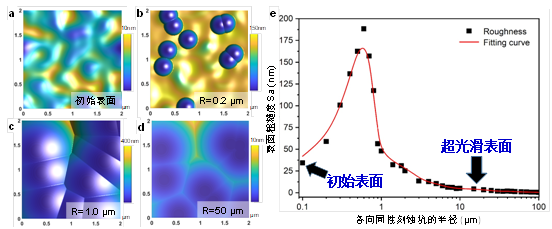

Figure 1. Schematic diagram of isotropic etching profile envelope polishing

The team developed an isotropic etching profile technology (see Figure 1). The team placed a protective layer on the rough surface, a process known as passivation, through the use of the polishing liquid. Then, the workpiece is connected to the anode of a DC power supply. The electric field breaks down the protective layer of the rough surfaces into smaller etching pits until the protective layer is completely removed, revealing the corrosion-free metal below.

Figure 2. Modeling analysis of the polishing process

The team modeled the change in surface morphology and roughness through their unique polishing process (Figure 2). At first, roughness increased due to the formation of etching pits but rapidly fell as polishing progressed. The surface etching sites merged into one another to become a single smooth surface, replacing the initial surface. Their method theorizes that an ultra-smooth, sub-nanometer surface can be obtained.

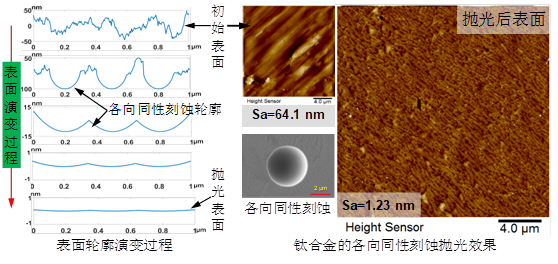

Figure 3. The profile and morphology evolution of the etched profile of titanium enveloping and polishing

The team tested their new technique on titanium (Ti) (Figure 3). Etching pits on the surface of titanium were hemispherical, with the Sa roughness of 1.13 nm. Once the electrolyte and breakdown voltage parameters were optimized, the team was able to isotropically etch its surface. They reduced its Sa roughness from 64.1 nm to 1.23 nm in just 3 minutes.

Figure 4. Polishing effect of various metal materials

To further test their technique, the team experimented with other metals and metal alloys, including nickel-phosphorus (NiP), nickel-titanium (NiTi), stainless steel, aluminum (Al) and proprietary nickel-chromium alloys (NiCr). Their tests showed that the technique could be successfully applied to a wide variety of metals (Figure 4), with all generating a mirror-like effect on the surfaces with sub-nanometer surface roughness.

The results of this research show that this unique isotropic etching technique can be applied to common metal materials as a universal polishing process. It provides significant applications to a diverse range of industries and could significantly reduce costs. In the future, the technology can be expected to be seen in aerospace and automotive manufacturers, while 3D printers could use the technology to solve post-processing challenges of metal parts.

SUSTech doctoral candidate Rong Yi was the first author of the paper. Hui Deng was the correspondent author, with SUSTech as the correspondent unit. Additional contributions came from the University of East Anglia, Shanghai Jiaotong University, and Tianjin University.

This work was financially supported by the research fund for International Cooperation from the Science and Technology Innovation Committee of Shenzhen Municipality, and the Shenzhen High-level Innovation and Entrepreneurship Fund.

Paper link: https://www.sciencedirect.com/science/article/pii/S0890695519311447

Proofread ByYingying XIA

Photo ByDepartment of Mechanical and Energy Engineering, Yan QIU