As demand for ocean exploration grows, underwater unmanned vehicles presents challenges related to long-distance cruising and payload capacity due to vast spaces and inherent fluid resistance. Researchers draw inspiration from aquatic animals, aiming to mimic the tail-flapping mechanisms of fish to achieve extensive cruising range and efficient performance.

Taking the fast-swimming bony fish as an example, their Body and Caudal Fin (BCF) motion utilizes the structural flexibility of the tail through the synchronization of muscle activation and tail oscillation. This enables the storage and release of elastic potential energy, thereby enhancing the transformation of muscle mechanical energy into fluid propulsion energy.

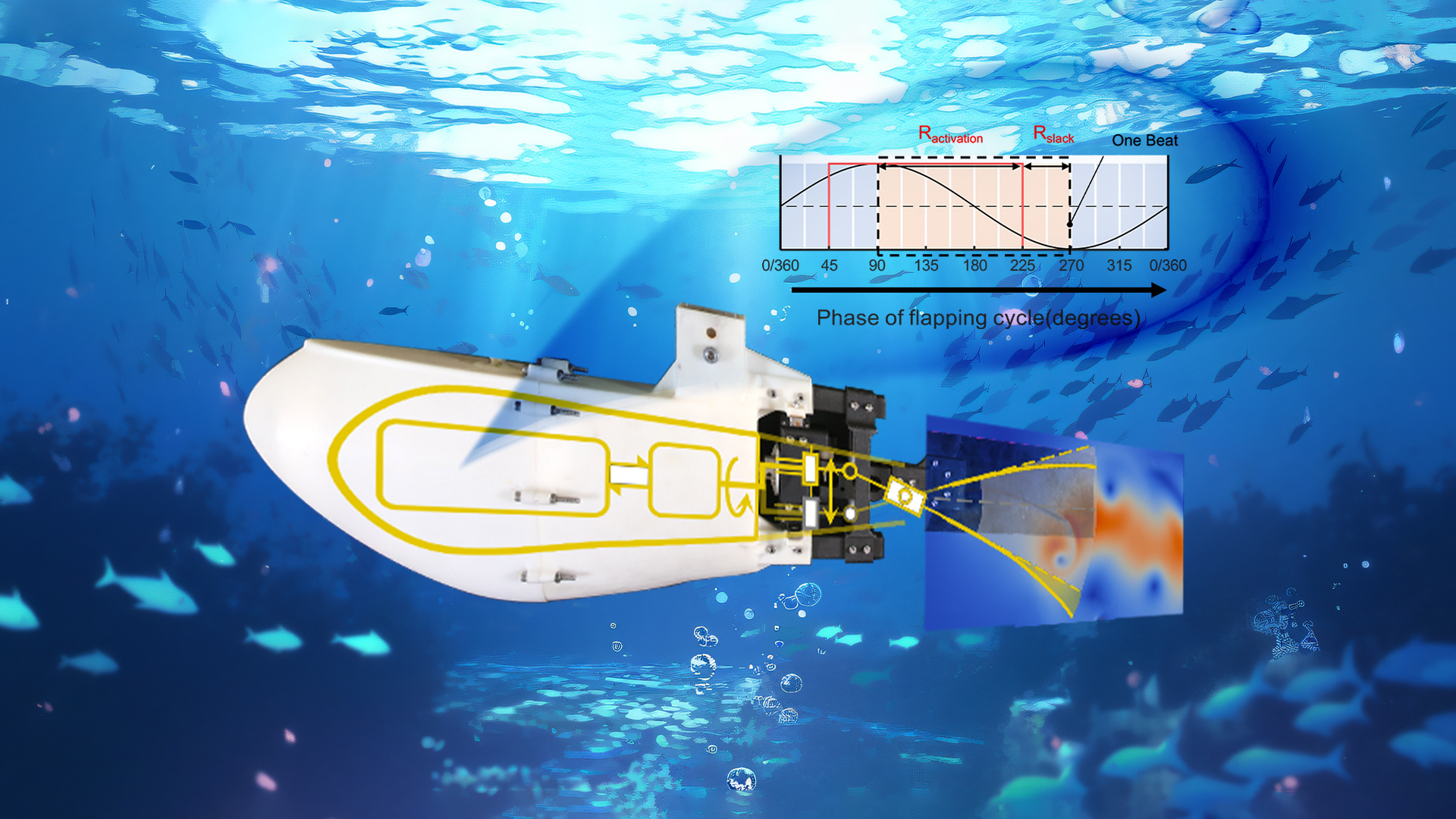

A research team led by Chair Professor Jiansheng Dai from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech), in collaboration with Associate Professor Sicong Liu from the Sino-German College of Intelligent Manufacturing at Shenzhen Technology University (SZTU), has proposed a Power Allocation Strategy (PAS) based on rhythmic muscle activation for robotic fish (Figure 1).

This novel strategy significantly enhances the propulsion performance and energy efficiency of robotic fish by optimizing the power allocation according to the rhythmic muscle activation. The breakthrough represents an advancement in the field of bio-inspired aquatic propulsion.

Their study has been published in the top-tier robotics journal IEEE Transactions on Robotics under the title “Rhythm-based Power Allocation Strategy of Bionic Tail-Flapping for Propulsion Enhancement”.

Figure 1. Fish activate muscles in sequence to generate propulsion and swimming motion, while the DDRFishBot can switch drive patterns across a wider range.

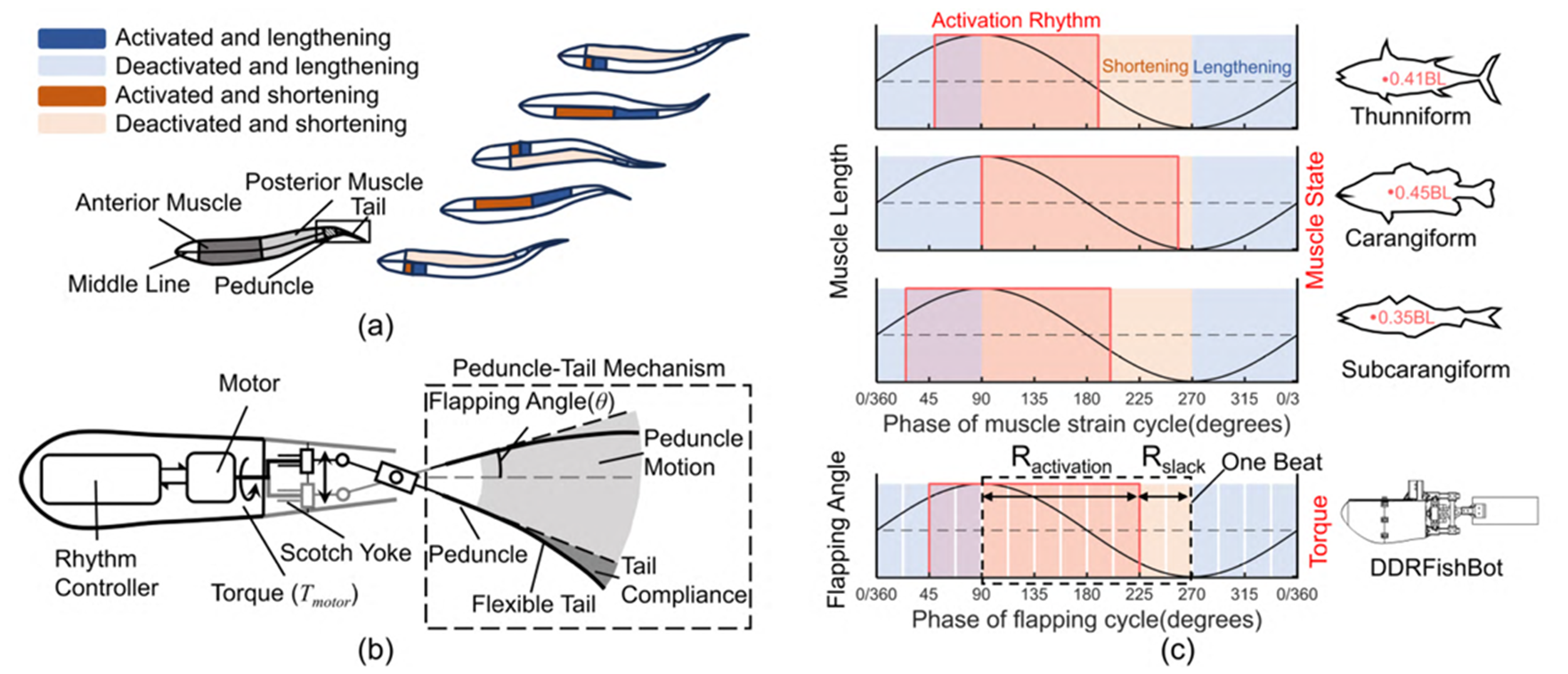

The power allocation strategy regulates tail-flapping behavior by coupling the peduncle motion with tail deformation (Figure 2). It resulted in a 228% increase in the release of Tail-Elastic Potential Energy (T-EPE), a 45.6% boost in propulsion, and a 16.3% improvement in efficiency coefficient. As a preliminary proof of concept, the team developed the robot “BigBayFish” using this strategy. It has maintained the Guinness World Record for the “Fastest 50 m swim by a robotic fish” with a time of 22.16 seconds since August 2021.

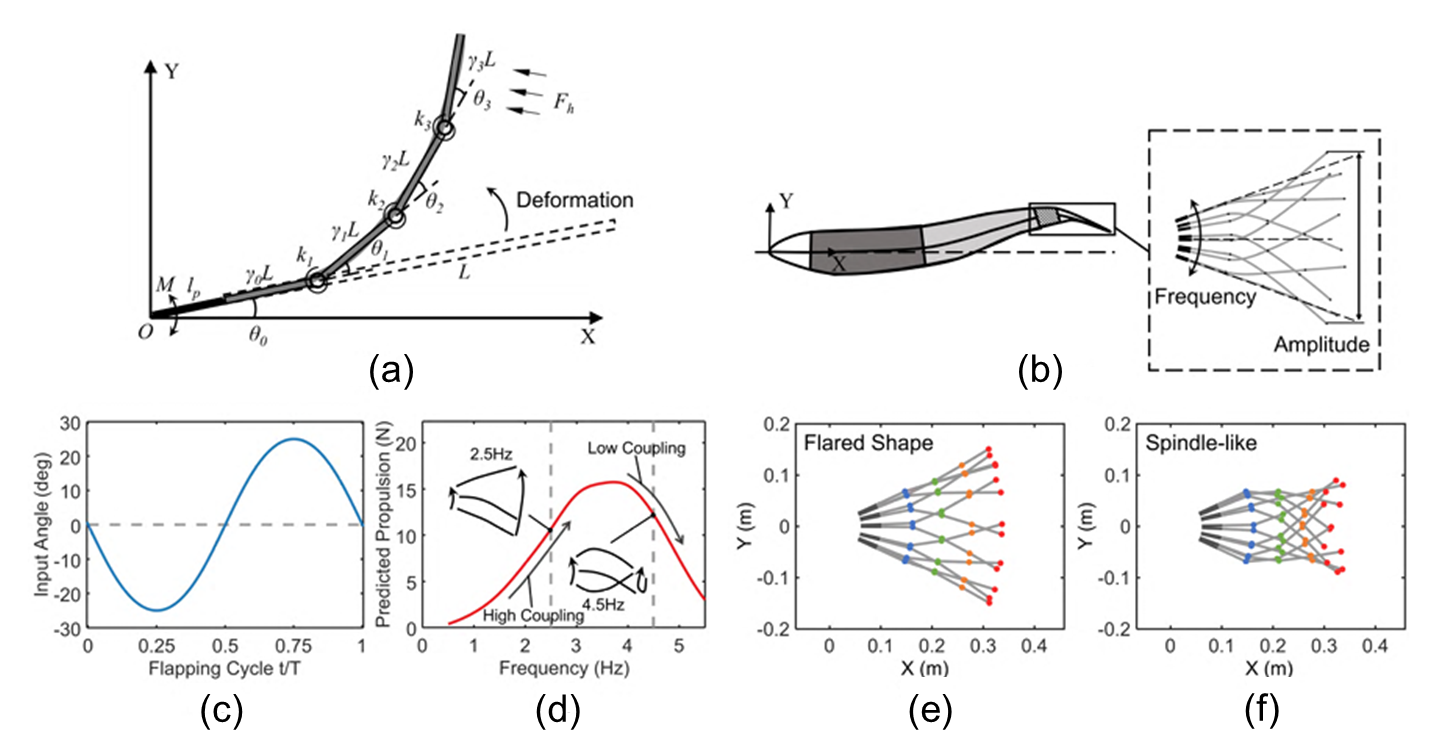

Figure 2. Schematic of the pseudo-rigid-body model and its predicted deformation patterns of the flexible tail.

To evaluate the role of the rhythmic power allocation strategy in biomimetic propulsion systems, the researchers designed and manufactured a direct-drive biomimetic fish robot inspired by the peduncle-tail mechanism. Comparative experiments were conducted against traditional constant-power strategies.

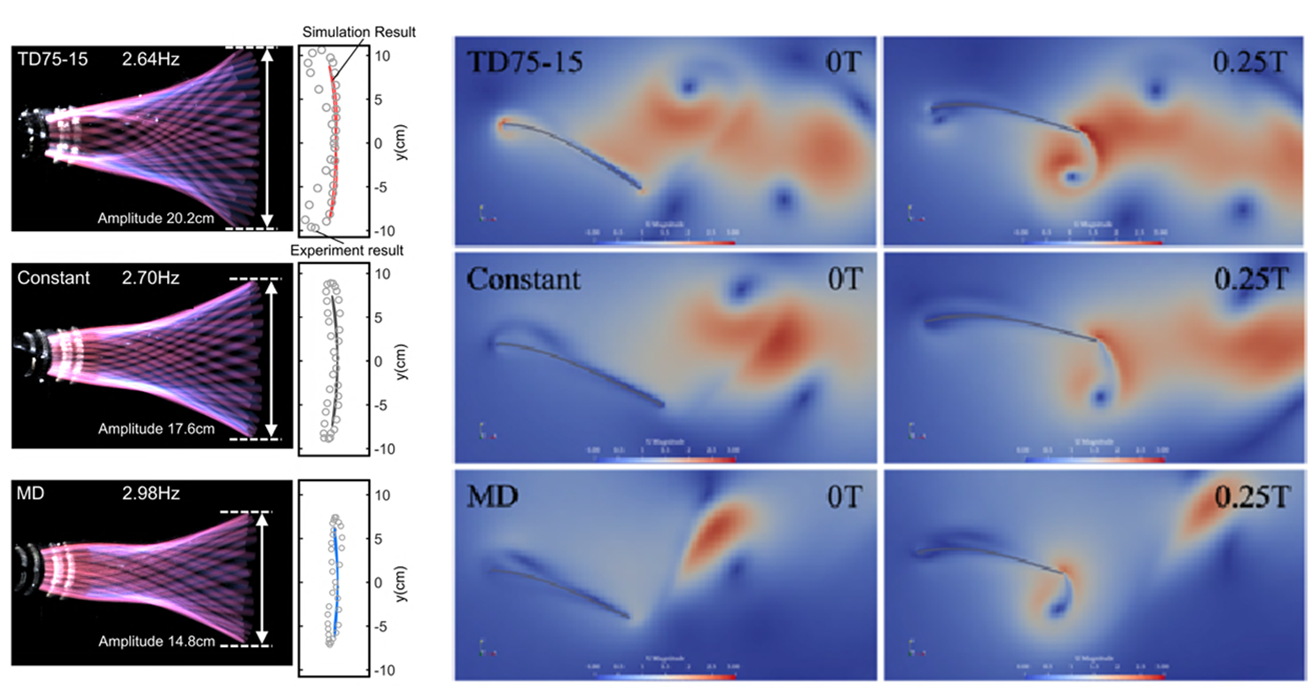

The results show that under equal frequency conditions, PAS significantly improves the elastic potential energy releasing of the tail-flapping, and the T-EPE release increased by up to 228%. This indicates the synergy effect between the T-EPE release process and the actuation rhythm. Through experimental data and numerical simulations using two-dimensional Computational Fluid Dynamics (CFD), this work verified that the rebound behavior of tail-flapping can induce stronger vortices, significantly increasing the momentum transferred to the fluid (Figure 3).

Figure 3. Envelopes generated by the tail-flapping under three strategies (TD75-15, Constant, and MD), along with the corresponding CFD results.

This study is the first to systematically propose a rhythm-based actuation mechanism combined with structural flexibility into underwater biomimetic propulsion systems. It provides a new paradigm for future underwater robots characterized by low power consumption, high efficiency, and simple structure. The strategy exhibits high adaptability and scalability, making it suitable for key propulsion modules in deep-sea inspection, complex environment operations, and intelligent marine equipment.

Master’s student Biao Wu and Ph.D. candidate Chaoyi Huang are co-first authors of the paper. Chair Professor Jiansheng Dai, who is also a Fellow of the Royal Academy of Engineering and Dean of the Institute of Robotics Research at SUSTech, along with Associate Professor Sicong Liu, serve as co-corresponding authors. The Department of Mechanical and Energy Engineering at SUSTech and the Shenzhen Key Laboratory of Intelligent Robotics and Flexible Manufacturing are the primary affiliated institutions.

Paper link: https://doi.org/10.1109/TRO.2025.3577985

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yifei REN

Photo ByDepartment of Mechanical and Energy Engineering