Recently, Southern University of Science and Technology (SUSTech) received confirmation that it will receive funding for its first national-level major scientific research instrument development project from the National Natural Science Foundation of China (NSFC) under the Special Fund for Research on National Major Research Instruments in 2019. The SUSTech project is titled “Development of Microfluidic Digital Droplet Central Processor Chip and Platform System,” and will be led by Professor Xing Cheng from the Department of Materials Science and Engineering.

The research group of Professor Xing Cheng specializes in micro- and nanofabrication technology, including ultra-high resolution lithography (sub-5 nanometer), large-area and low-cost nanofabrication for industrial-scale manufacturing, and 3D printing technology on the micro- and nanometer scale. His group also specializes in the application of micro- and nanofabrication technology in areas such as semiconductor devices, nano-optics, and biomedical engineering. In recent years, the group has carried out innovative research in microfluidics. China and PCT patents are being applied for on the basis of these developments, of which several have been granted in both China and the United States.

Large-scale DNA/RNA sequencing library construction and protein structural determination by mass spectroscopy are fundamental to genomics and proteomics. They all involve the complicated handling of scarce, expensive and small volume samples. The lack of large-scale and highly efficient sample processing techniques is a major bottleneck in today’s biomedical research and applications. In recent years, more and more attention has been paid to the study of single cell omics because of the great differences between cells. Omic analysis of a large number of individual cells requires higher accuracy and throughput of sample processing technology. However, traditional analysis methods are time-consuming and laborious, and it is difficult to meet the needs of modern biomedical research. For some time, academia and industry have been seeking ideal large-scale and efficient sample processing techniques for genomics and proteomics.

In recent years, the rapid development of microfluidic chips is considered as a very important potential platform to solve these problems. Microfluidic chips, also known as chip laboratories, are a kind of science and technology characterized by the manipulation of fluids in micron-scale space. They have the ability to reduce the basic functions of laboratories such as biology and chemistry to a chip that takes up just a few square centimeters. Digital droplet microfluidic chips, which use droplets as microreactors and sample carriers, are considered as potential platforms to solve these problems.

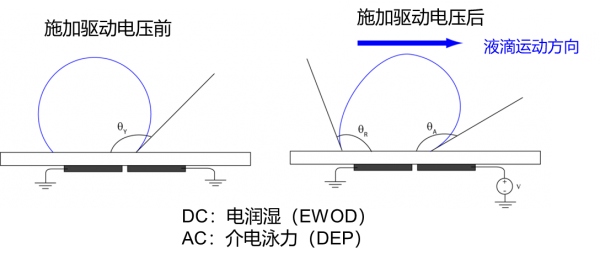

In digital droplet micro-systems, the driving force of droplets is the electro-wetting on dielectric (EWOD) force or dielectrophoretic (DEP) force on dielectric materials. Among them, the driving force of conductive droplets is EWOD force (the contact angle between the front end and the hydrophobic surface of droplets) becomes smaller, while the contact angle between the back end remains basically unchanged, resulting in the deformation of droplets. This means that there is a pressure difference between the air phase (or oil phase) on both sides of droplets and the interface of droplets, which promotes the droplets to move on the plane. The driving force of dielectric (non-conductive) droplets is mainly DEP force (the droplets enter the high electric field gradient region of the medium under the action of the DEP force caused by the external non-uniform electric field to achieve directional movement).

Driving modes of micro-droplets by electrowetting or dielectrophoretic force with bottom electrodes

Driving modes of micro-droplets by electrowetting or dielectrophoretic force with bottom electrodes

Left: Water droplets (EWOD driven); right: DMF solvent droplets (DEP driven)

Due to the high flexibility of digital droplet micro-fluidic technology in droplet control, research teams at Duke University, UCLA, MIT, Cambridge University, University of Toronto and other universities have studied this field. The application prospects of this technology in automatic instruments have also attracted the research and development of famous enterprises at home and abroad, such as Microsoft, Illumina and BOE. Digital droplet microfluidic technology involves many interdisciplinary subjects, such as fluid mechanics, dielectric physics, surface chemistry, micro-nano processing, circuit system, intelligent control, computer software, and biotechnology. The fabrication and manipulation of existing digital droplet chips and platforms are subject to various material and engineering constraints. The number and density of electrodes are at a low level, and the stability and reliability of droplet manipulation are poor, which makes it difficult to meet the requirements of large scale and high throughput.

Professor Xing Cheng worked with Professor Xianming Liu and Professor Yao Lu of the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, to construct a digital droplet central processor chip and peripheral electronic control system. It consists of corresponding hardware and software that combines the highly reliable active matrix circuit technology with microfluidic digital droplets. The aim of the stability and reliability of droplet manipulation is to achieve precise parallel and continuous manipulation of tens of thousands of tiny droplets. Successfully achieving this would greatly reduce the consumption of expensive reagents, and adapt them to different application scenarios through dynamic reconstruction.

After years of collaborative development, the project team has completed 20X20 active matrix digital droplet microfluidic chip with 400 electrode arrays and prototype system, and designed the fluid input and output interface based on a micro-pump to realize the full automatic operation of the prototype system. By optimizing the preparation process of hydrophobic film, stable and reliable operation of water-borne, organic solvents and biological samples can be achieved. Droplets can be continuously moved, merged and split up to thousands of times, achieving practical results (see video demonstration). According to the published information, the prototype of 400-electrode array chip developed by SUSTech is in the leading international level in the aspects of electrode scale, scale of automation, stability and reliability of droplet driving.

Droplet marshalling to form “SUSTech” letters)

Supported by the Fund’s major research instrument development project, the cooperative team plans to develop a 1000X1000 (including 1 million electrodes) ultra-large active matrix digital droplet microfluidic chip platform and hardware and software control system within five years to realize automatic parallel manipulation of more than 10,000 droplets and build an internationally leading high-throughput system. With the support of various specific functions required by the special application platform, the project team will carry out extensive application research on droplet chips and platform systems, including but not limited to genomic and proteomic analysis, single cell sorting and omic analysis, real-time detection of clinical diagnosis, synthetic biology, polysaccharide synthesis, detection and identification of toxins and pathogens, environmental monitoring, screening of new drugs and fine chemical synthesis.

Compared with the central processing unit (CPU) in electronic systems, the project aims to develop a universal and applicable digital microfluidic droplet central processing unit (CFPU). By using electrowetting or dielectrophoresis, the active matrix circuit can locate and manipulate any droplets in the large array without interfering with other droplets through the bottom electrodes, thus realizing the flexible manipulation of droplets, bringing many breakthroughs in the functionality and usability of the microfluidic chip.

Firstly, the droplet fluid CPU chip can be used as a general-purpose fluid control platform. Applications can be accomplished on the chip by changing the content of droplets. By selectively locating the electrodes in the array, the droplet CPU chip can be dynamically reconfigured at any time to accomplish specific tasks in the preset application, enhancing versatility. Secondly, the chip has the ability to handle a large number of parallel chemical and biological reactions simultaneously. Driven by an active matrix circuit, multiple droplets can be controlled simultaneously. Active matrix circuits can be easily extended to thousands of rows and columns, allowing for the manipulation of thousands of droplets. For large-scale and complex biological analysis tasks, it can greatly reduce the labor and time costs of the experiment.

The NSFC Special Fund for Research on National Major Research Instruments aims to encourage and foster the exploratory research and development of instruments with creative ideas, and major research instruments and equipment with original and creative ideas, which should be based on frontier of science and national needs and guided by scientific targets, so as to provide new means and tools for scientific research and enhance indigenous innovation in China.

Proofread ByDepartment of Materials Science

Photo ByDepartment of Materials Science and Engineering, Office of Research, Qiu Yan