New developments in synthetic hydrogels, bonded to engineering materials, have shown robustness similar to the connections between bone and connective tissues in the human body.

Department of Mechanical and Energy Engineering (MEE) Assistant Professor Ji Liu was a co-first author of a major international paper in the high-impact journal, Nature Communications (IF = 12.124). The article was titled “Fatigue-resistant adhesion of hydrogels.” He worked with collaborators at the Massachusetts Institute of Technology (MIT), Syracuse University, and Huazhong University of Science and Technology (HUST).

The paper revealed key yet versatile principles of anti-fatigue hydrogel bonding while achieving the interface fatigue threshold, on par with that of tendon-bone adhesion. This threshold is the minimum energy required to propagate fatigue cracks in a substance.

Hydrogel materials are very similar in their structure and composition to biological tissue, which is why hydrogels are considered ideal substrates for human-computer interaction. Previous research had achieved high toughness bonding of hydrogels to various materials. However, they had been unable to design a hydrogel bond that could survive long-term cyclic fatigue, such as that experienced by biological tissue. Solving this problem has become an urgent challenge for the soft materials field.

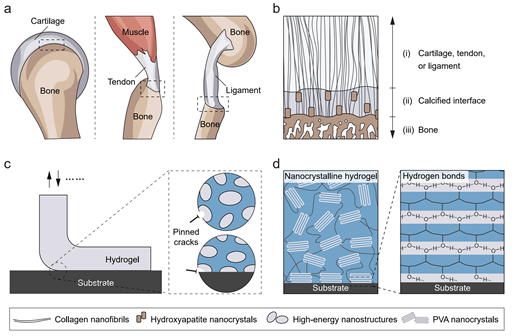

Connective tissue, such as ligaments, tendons, and cartilage, can all form high-toughness and fatigue-resistant connections with bones. Their fatigue thresholds are above 800 joules per square meter (J/m2). Ji Liu and Xuanhe Zhao (MIT) proposed a unique hypothesis for anti-fatigue hydrogel adhesive bonding, in which ordered nanocrystalline domains would be introduced at the edge of bonding areas to limit opportunities for fatigue crack growth.

The researchers used an FDA-approved polymer, known as polyvinyl alcohol (PVA), to achieve the nanocrystalline domains that are preferentially aligned along the direction of the bonded surface. The vertical order of the nanocrystalline domains is central to the hydrogel reaching the desired 800 J/m2 fatigue threshold while maintaining the threshold for over 30,000 peeling cycles. The peeling cycle experiment was used to replicate the movement of human joints.

30,000 cycles of peeling test at 800 J/m2 energy release rate

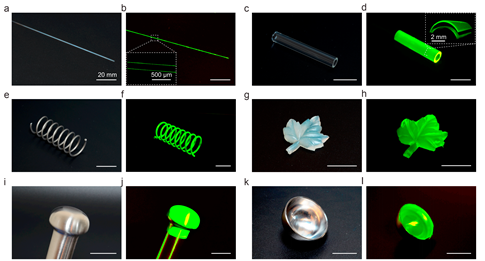

The research team also found that their anti-fatigue hydrogel bonding method can be integrated into other processing methods. They specifically cited dip coating, as it could produce a uniform, anti-fatigue hydrogel coating for different materials and geometric structures. This development provides opportunities for items such as glass fiber optics and tubes, stainless steel springs, leaf-like rubber, and metal ball & socket joints.

Hydrogels offer high water content and a low coefficient of friction, so their introduction reduces the wear against metal. The high strength and toughness, combined with their anti-fatigue bonding, effectively solve the technical challenges previously preventing the use of hydrogel as artificial cartilage.

The universality of the design principle allows its further use in developing hydrogel equipment with long-term value, such as hydrogel coatings and artificial joints.

Assistant Professor Ji Liu is one of the co-first authors of the paper, and SUSTech is the first affiliation. Co-authors include MIT postdoc Shaoting Lin, MIT doctoral candidate Xinyue Liu, and Assistant Professor Zhao Qin of Syracuse University. HUST Professor Jianfeng Zang and MIT Professor Xuanhe Zhao are the corresponding authors of the paper.

This project received support from the Centers for Mechanical Engineering Research and Education at MIT and SUSTech (MechERE Centers at MIT and SUSTech).

Paper link: https://www.nature.com/articles/s41467-020-14871-3

Proofread ByXia Yingying

Photo ByDepartment of Mechanical and Energy Engineering, Qiu Yan