Recently, the research team of Associate Professor Qi Ge from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech) and Associate Professor Biao Zhang from the Northwestern Polytechnical University (NPU) collaborated to publish an inside back cover paper in the high-impact academic journal, Advanced Materials. Their paper was entitled “Mechanically Robust and UV Curable Shape Memory Polymers for Digital Light Processing based 4D Printing.”

They report a mechanically robust and UV curable SMP system that is highly deformable, fatigue resistant, compatible with DLP-based 3D printing to fabricate high-resolution (up to 2 μm), and highly complex 3D structures that exhibit large shape change (up to 1240%) upon heating. More importantly, the developed SMP system exhibits excellent fatigue resistance and can be repeatedly loaded by more than 10,000 times, which can be applied to engineering applications such as aerospace, smart furniture, and soft robots.

Four-dimensional (4D) printing is an emerging fabrication technology that enables three-dimensional (3D) printed structures to change configurations over “time” in response to the environmental stimulus. Compared with other soft active materials used for 4D printing, shape memory polymers (SMPs) have higher stiffness and are compatible with various 3D printing technologies. Among them, ultraviolet (UV) curable SMPs are compatible with digital light processing (DLP)-based 3D printing to fabricate SMP-based structures with complex geometry and high resolution. However, the UV curable SMPs have limitations in terms of mechanical performance, which significantly constrains their application ranges. The development of the mechanically robust and UV curable SMPs can significantly improve the mechanical performance of the SMP-based 4D printing structures. Therefore, it is desired to develop mechanically robust and UV curable SMPs to remove the obstacles of implementing SMP-based 4D printing to engineering applications.

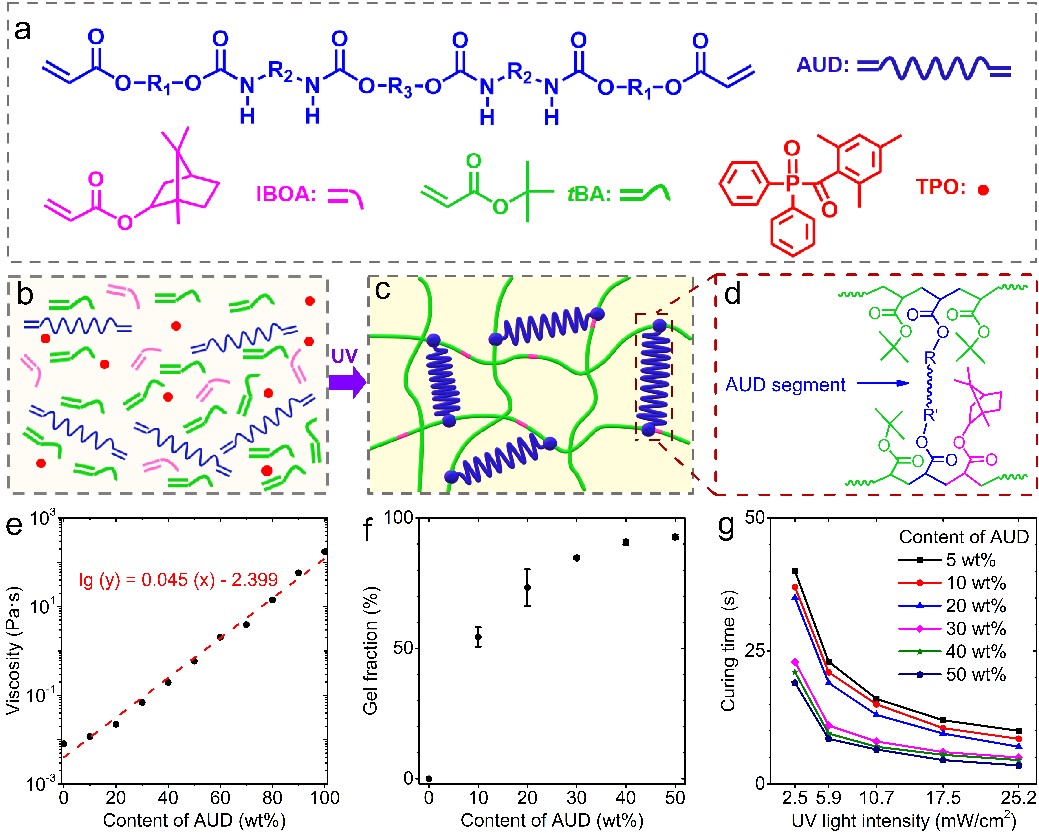

The research team reports a mechanically robust and UV curable SMP system that is highly deformable, fatigue-resistant, and compatible with DLP-based 3D printing to fabricate high-resolution and highly complex 3D structures that exhibit large shape change upon heating. The SMP system mainly consists of the tert-Butyl Acrylate (tBA) and Aliphatic Urethane Diacrylate (AUD), and thus named as the tBA-AUD SMP system. As presented in Figure 1, the tBA-AUD SMPs are highly ultraviolet (UV) curable, thus compatible with DLP-based 3D printing technology which enables the fabrication of high-resolution and highly complex 3D structures. The research team conducted a lot of experiments to study the large deformation mechanism of the tBA-AUD SMP system and explore its engineering application in high-load and large deformation structures.

Figure 1. Mechanically robust tBA-AUD SMP for DLP-based 4D printing

As shown in Figure 2, the 3D printing performance of the tBA-AUD SMP precursor solution was characterized by rheological measurements, gel fraction test, and curing time test. The precursor solution with AUD content below 50 wt% has a lower viscosity, which is suitable for DLP 3D printing. The higher the AUD content, the higher the gel fraction of the tBA-AUD SMP system, and the shorter the time required to cure the precursor solution of the same thickness.

Figure 2. Details and characterizations of tBA-AUD SMP precursor solution

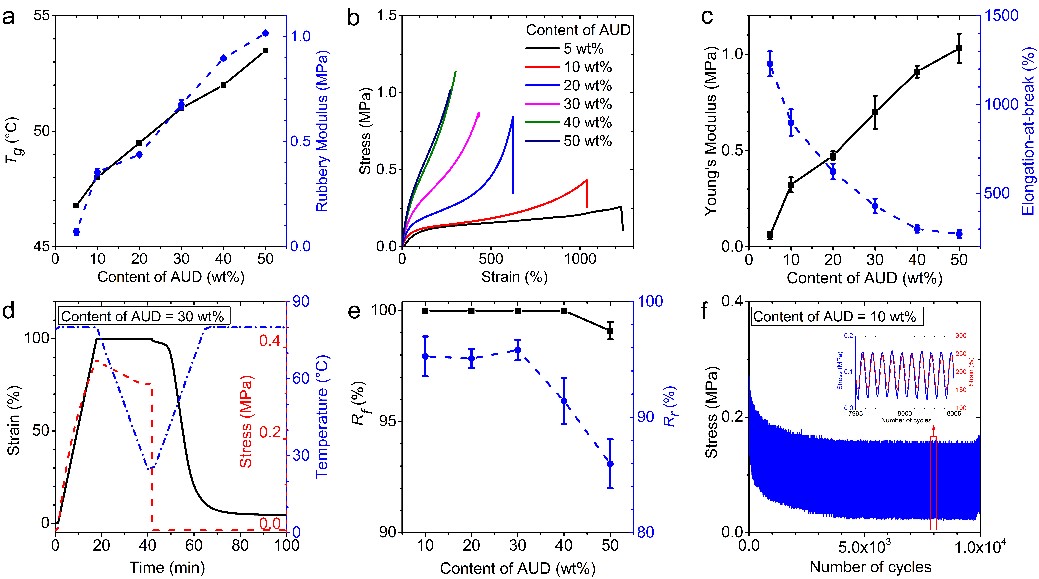

As shown in Figure 3, the large deformation, shape memory, and fatigue resistance of the tBA-AUD SMP system have been calibrated through the dynamic mechanical analysis experiments, uniaxial tensile experiments, shape memory behavior tests, and fatigue tests. The tBA-AUD SMP system has a low elastic modulus and super high elongation-at-break at programming temperature. The tBA-AUD SMP system has a shape fixing ratio of nearly 100%, which can fix the large deformation produced at the editing temperature. It also has a good shape memory performance (shape recovery ratio ~90%). In addition, the tBA-AUD SMP sample can sustain more than 10,000 loading cycles without fracture at 80°C with a cyclic strain from 150% to 250% at a frequency of 0.25 Hz.

Figure 3. Thermomechanical property of the tBA-AUD SMP system

As shown in Figure 4, through Fourier Transformation Infrared Spectroscopy (FTIR) test, the stress relaxation test, and the uniaxial tensile test, the fresh sample and the 10,000-cycle loaded sample are compared to explain the large deformation and fatigue resistance mechanism of the tBA-AUD-SMP system. The combined effect of the high molecular weight and hydrogen bonds of the AUD crosslinking agent gives the tBA-AUD SMP system high deformability and fatigue resistance.

Figure 4. Deformation mechanism for the stretchability of the tBA-AUD SMP system

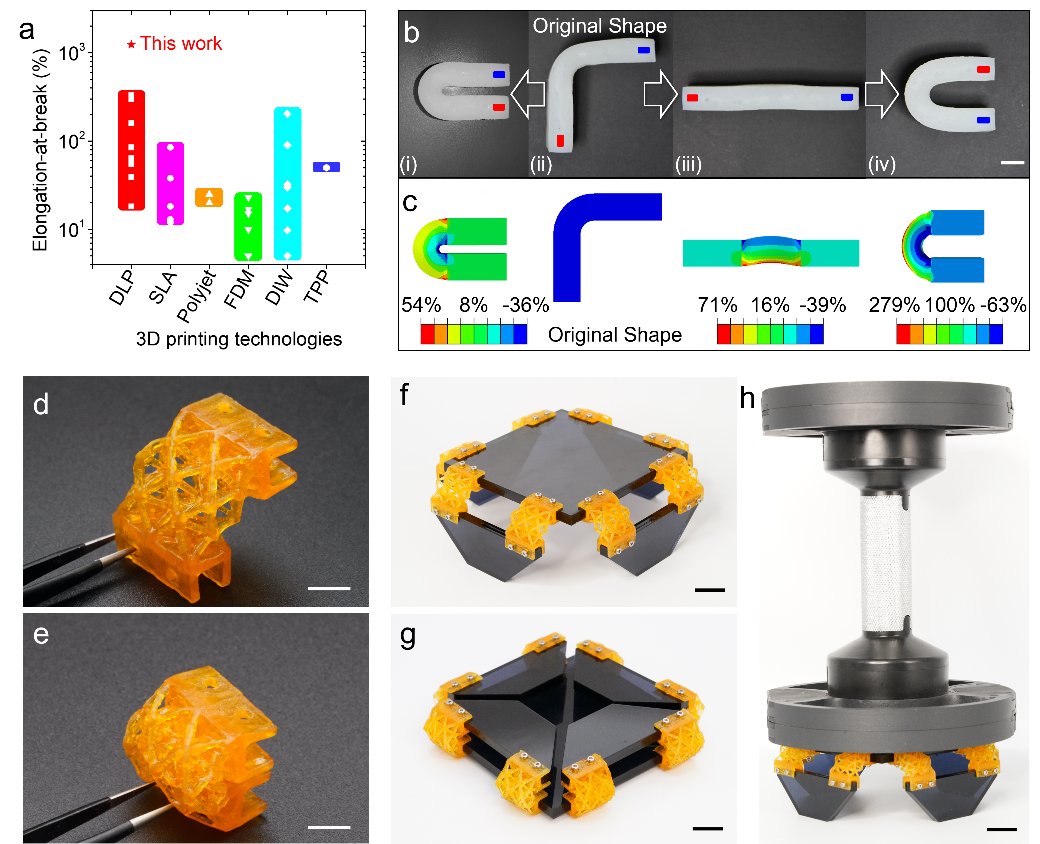

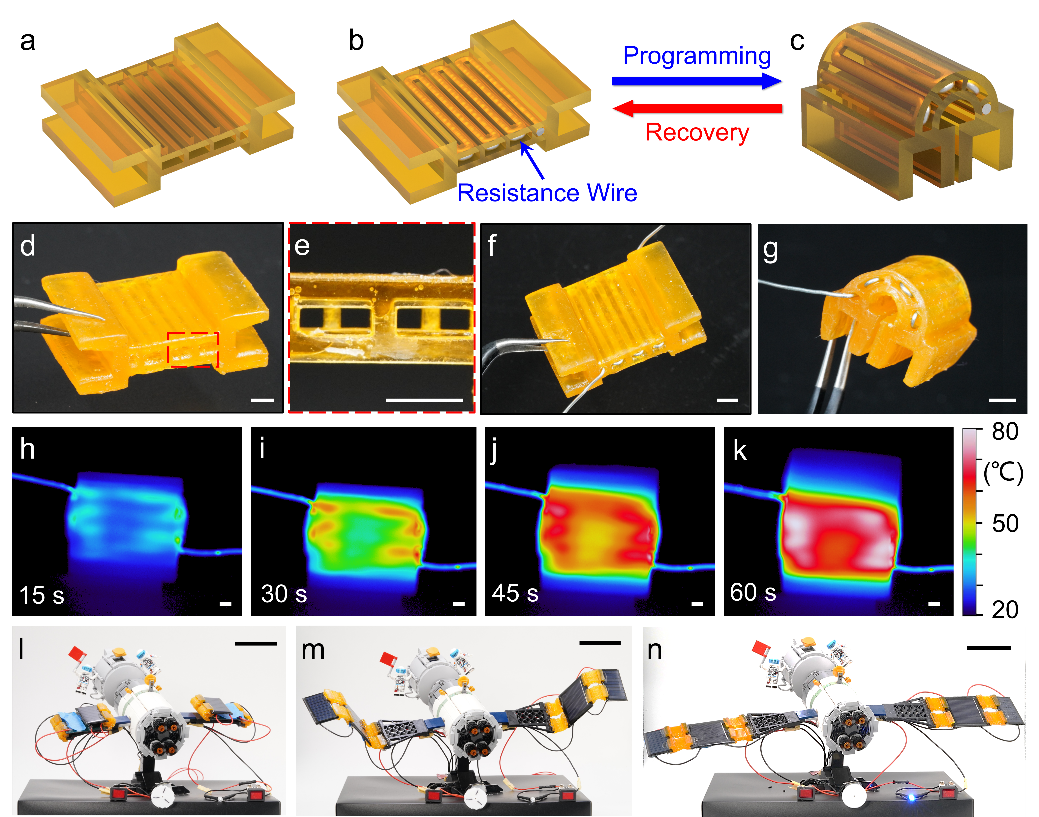

As shown in Figures 5 and 6, the 3D printed tBA-AUD SMP structures have a high degree of deformability and have great potential in engineering applications such as smart furniture and aerospace. The elongation-at-break of tBA-AUD SMP is much higher than various previously reported 3D printable SMPs. The high deformability and high bearing capacity makes the tBA-AUD SMP an ideal material to fabricate smart furniture with SMP hinges. Using the fast thermal response capability of tBA-AUD SMP, smart hinges for deployable solar panels can be printed. By heating the resistance wire passing through the hinge micro-channels, the programmed hinge can recover to its original straight shape within one minute, completing the rapid deployment of solar panels.

Figure 5. Highly deformable tBA-AUD SMP and its engineering application in smart furniture

Figure 6. Demonstration of the application of tBA-AUD SMP to aerospace

The research team has developed a shape memory photopolymer with large deformation and fatigue resistance, suitable for DLP printing. That solves the comprehensive requirements of various 4D printing engineering applications for advanced smart materials, such as high fracture strain, high fatigue resistance, high bearing capacity, and adaptability to advanced manufacturing.

Dr. Biao Zhang, Associate Professor from NPU, Dr. Honggeng Li, a Postdoctoral from SUSTech, and Jianxiang Cheng, a Ph.D. student from SUSTech, are the co-first authors of the paper. Dr. Qi Ge, Associate Professor from SUSUTech, is the corresponding author.

This research was supported by the National Natural Science Foundation of China (NSFC), Shenzhen Key Laboratory of Biomimetic Robotics and Intelligent Systems, Guangdong Provincial Key Laboratory of Human-Augmentation and Rehabilitation Robotics, and the Natural Science Basic Research Program of Shaanxi.

Paper link: https://onlinelibrary.wiley.com/doi/10.1002/adma.202101298

Proofread ByAdrian Cremin, Yingying XIA

Photo By