Recently, Professor Xiao Wei Sun’s research team from the Department of Electrical and Electronic Engineering (EEE) at the Southern University of Science and Technology (SUSTech), Shenzhen China Star Optoelectronics Semiconductor Display Technology Co., Ltd, (CSOT) and the School of Electronic and Computer Engineering at Peking University, collaboratively developed a Selective Electrophoretic Deposition technology (SEPD). In doing so, they achieved more than 1000 ppi panchromatic large quantum dots (QDs) pattern color film and successfully prepared a high-performance QLED device. The research results were recently published in Nature Communications, entitled “Large-area patterning of full-color quantum dot arrays beyond 1000 pixels per inch by selective electrophoretic deposition.”

Colloidal quantum dot (QD) emitters show great promise in the development of next-generation displays. Although various solution-processed techniques have been developed for nanomaterials, high-resolution and uniform patterning technology amicable to manufacturing is still missing. Their research presents large-area, high-resolution, full-color QD patterning utilizing a selective electrophoretic deposition (SEPD) technique. This technique utilizes photolithography combined with SEPD to achieve a uniform and fast fabrication, low-cost QD patterning in large-area beyond 1,000 pixels-per-inch.

The QD patterns are only deposited on selective electrodes with precisely controlled thickness in a large range, catering to various optoelectronic devices. The adjustable surface morphology, packing density, and refractive index of QD films enable higher efficiency compared to conventional solution-processed methods. They further demonstrated the versatility of their approach to integrate various QDs into large-area arrays of full-color emitting pixels and QLEDs with good performance. The results suggest a manufacture-viable technology for the commercialization of QD-based displays.

The research team was inspired by the fact that the polarization and luminescence of the quantum rods need to be driven by high frequency alternating electric field; otherwise, the deposition phenomenon will occur. Through analysis, the team found that the colloidal QDs composed of inorganic semiconductor core and organic ligand shell, the ligand may dissociate in solution, so the QDs surface may be rich in anions or cations. Charged QD can be deposited on an electrode with opposite electrical properties under the action of an electric field. Based on this, the research team developed a novel QD SEPD mapping technology using high-resolution lithographic microelectrode technology combined with mild electrodeposition technology, achieving efficient, uniform, and large-area panchromatic QD film preparation on a single electrode.

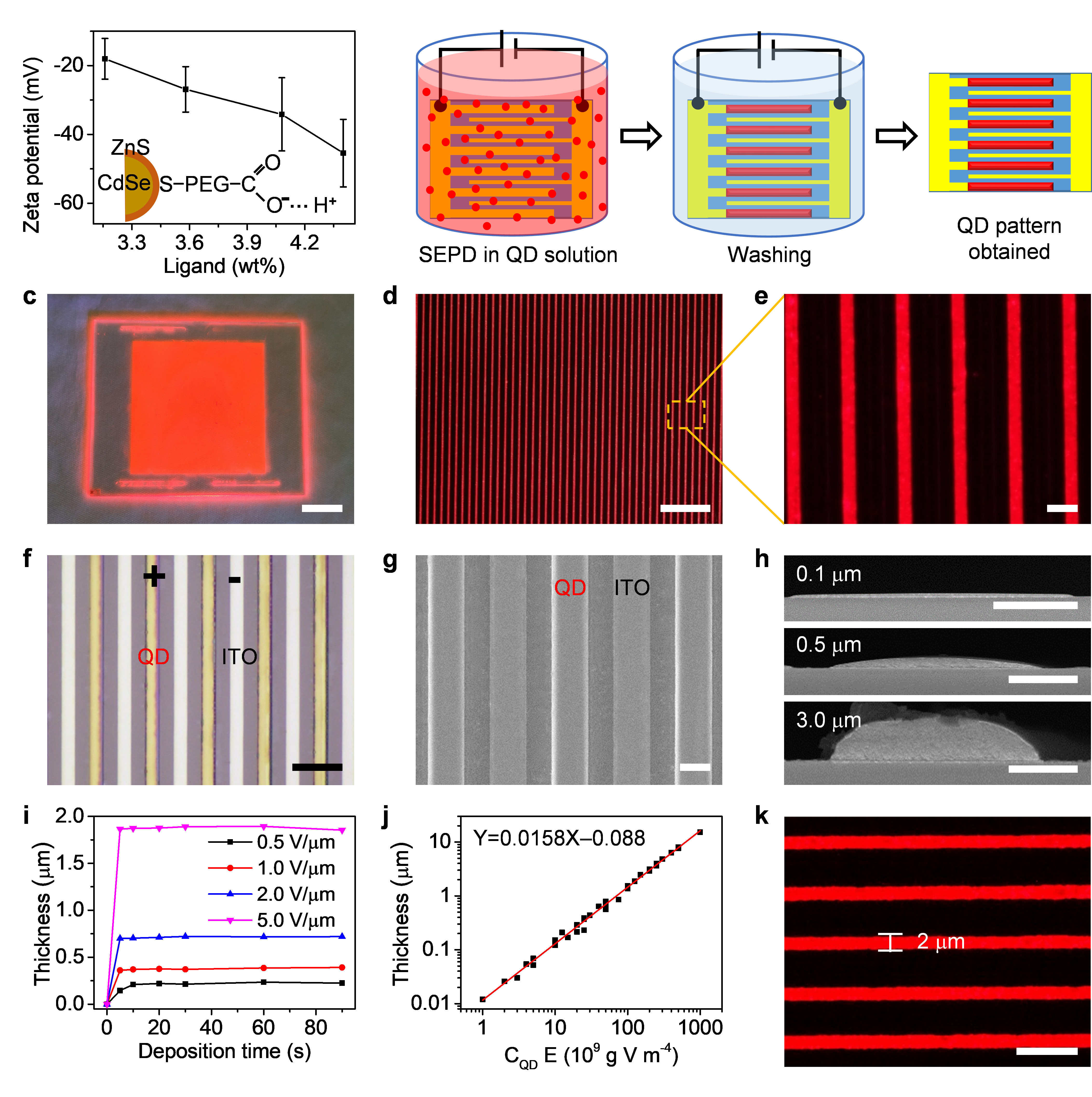

Figure 1. Morphology and dimensions characteristics of QD films prepared by SED

The research team first obtained a single electrical QD through rational solvent and ligand design, effectively avoiding the deposition of positive and negative electrodes simultaneously and the cross-contamination of multi-color quantum dot deposition. The QD films have a controllable and uniform characteristic size (2μm — 20μm) and can be deposited into arbitrary shapes. Meanwhile, the films have good morphology, ordered structure, and good optical properties.

The surface morphology, bulk density, and refractive index (N=1.7-2.1) can be adjusted in a wide range. In this way, quantum dot films under different conditions can be obtained, and higher PL luminescence efficiency can be achieved than traditional solution treatment methods (spin-coating and inkjet printing). By adjusting the electrodeposition voltage and quantum dot concentration, the thickness of the film of the plotted quantum dot can be adjusted accurately in the range of several nanometers to tens of microns.

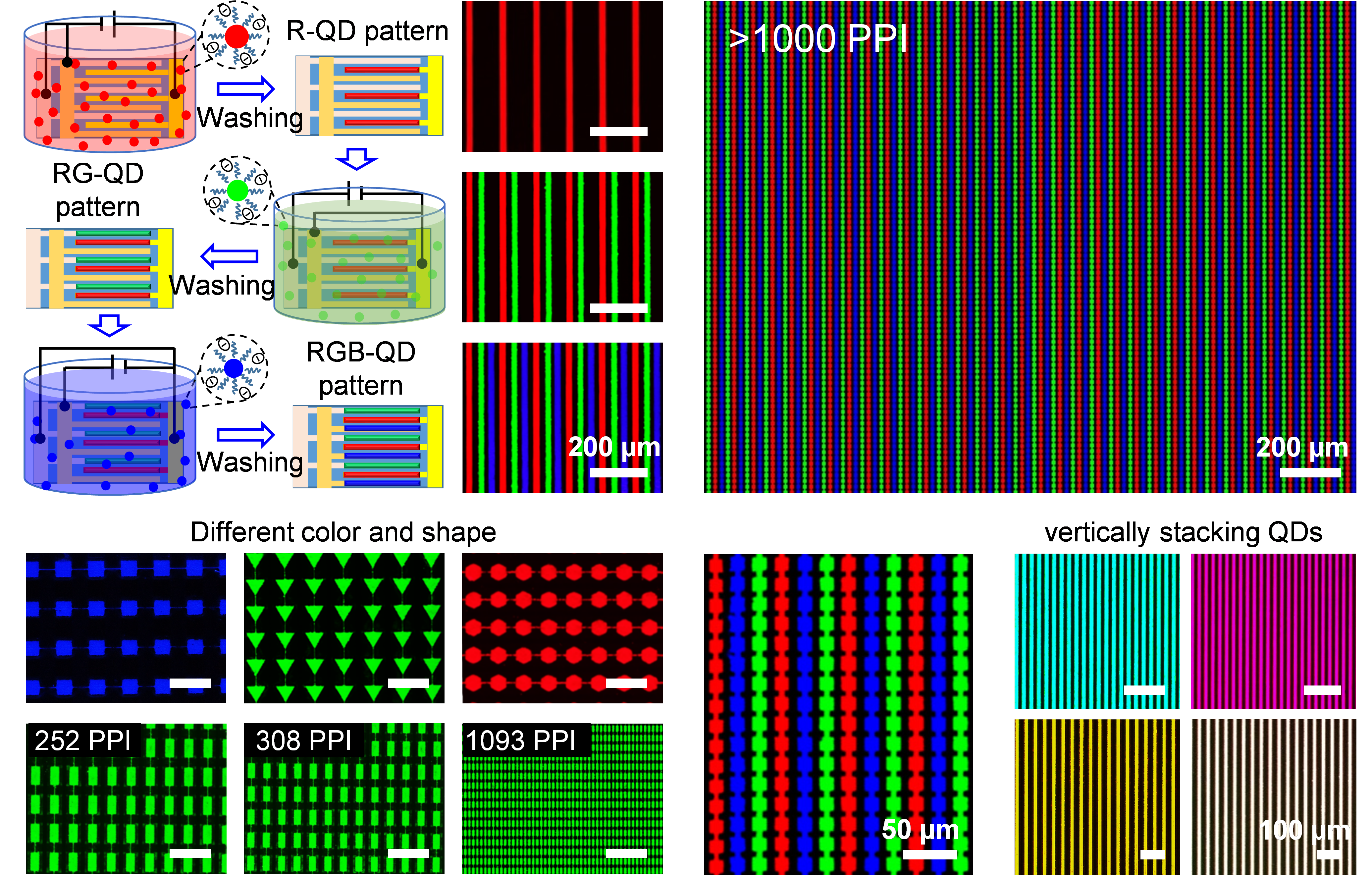

Figure 2. Full colored QD patterned thin-film arrays were prepared by SEPD

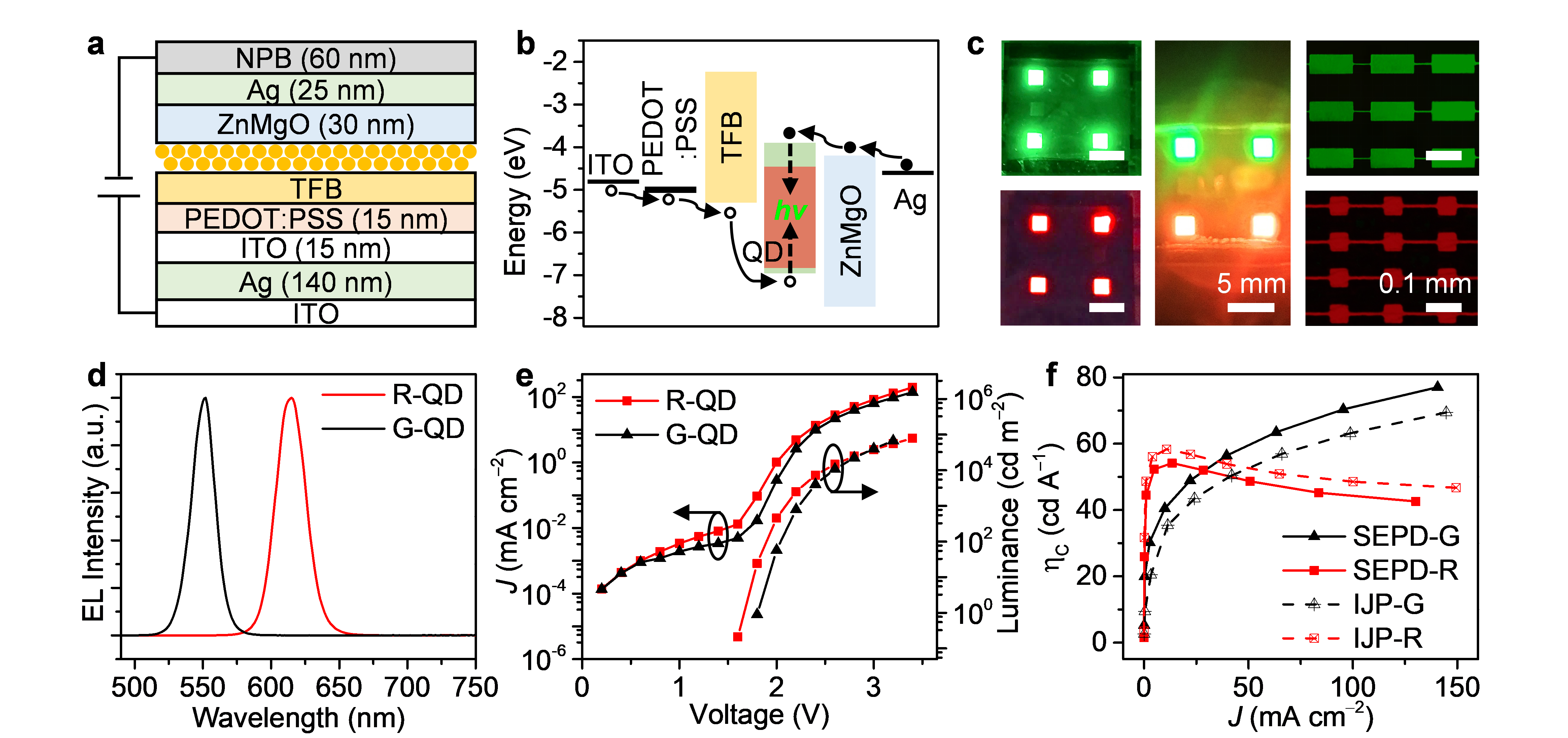

Moreover, the research team integrated quantum dots with different emission characteristics into a large area array to form panchromatic pixels and produced a high-performance QLED electroluminescence device. The current efficiencies of QLED are 77cd/A for green and 54 cd /A for red, which are comparable to those of current inkjet printing devices. The universality of solvent and material selection, controllability of structure, and good performance of devices indicate that SEPD is a promising technique for graphing nanoparticles. This technology can simultaneously meet the requirements of different sizes of liquid crystal display (LCD), Blue OLED display, Blue Micro-LED display color conversion layer, and QLED self-illumination display. It is also suitable for low, medium, and high-resolution display devices. Related technologies also have great application prospects in photovoltaic devices and quantum dot photo-detectors.

Figure 3. Performance characterization of SEPD prepared QLED

Dr. Jinyang Zhao, a visiting scholar from the SUSTech and a senior engineer of the Innovation Center at CSOT, is the first author of this paper. Lixuan Chen from the Innovation Center at CSOT, Professor Shengdong Zhang from Peking University, and Professor Xiao Wei Sun from SUSTech are corresponding authors.

This research was supported by CSOT, TCL Industrial Research Institute, the National Natural Science Foundation of China (NSFC), Guangdong Provincial Key Field R&D Plan, and the Shenzhen Peacock Team Project.

Paper link: https://www.nature.com/articles/s41467-021-24931-x

Proofread ByAdrian Cremin, Yingying XIA

Photo By