Lithium metal anode is considered as a potential anode material for the next generation of rechargeable batteries due to its ultra-high theoretical specific capacity (3860 mAh g-1) and extremely low electrochemical potential (-3.040 V vs. standard hydrogen electrode). However, its practical application is hindered by some inherent defects, including the formation of dendrites in the deposition process, the instability of the lithium metal interface, and the infinite volume fluctuation in the repeated cycling process, which leads to the crash of the solid electrolyte interface.

This uncontrolled dendrite growth of lithium metal will lead to short circuits, low cycle coulomb efficiency, poor cycle life, and safety hazards. As a result, this will seriously hinder the application of lithium metal, especially the limited performance of lithium metal under high currents and high surface capacity. Therefore, it is urgent to find an effective strategy to solve this problem.

Associate Professor Lin Zeng’s research group from the Department of Mechanical and Energy Engineering (MEE) at the Southern University of Science and Technology (SUSTech) has recently made progress in the design and preparation of high-performance lithium metal anode and silicon carbon composite anode.

Their series of achievements were published in Advanced Science, an interdisciplinary journal covering fundamental and applied research in materials science, physics and chemistry, medical and life sciences, as well as engineering.

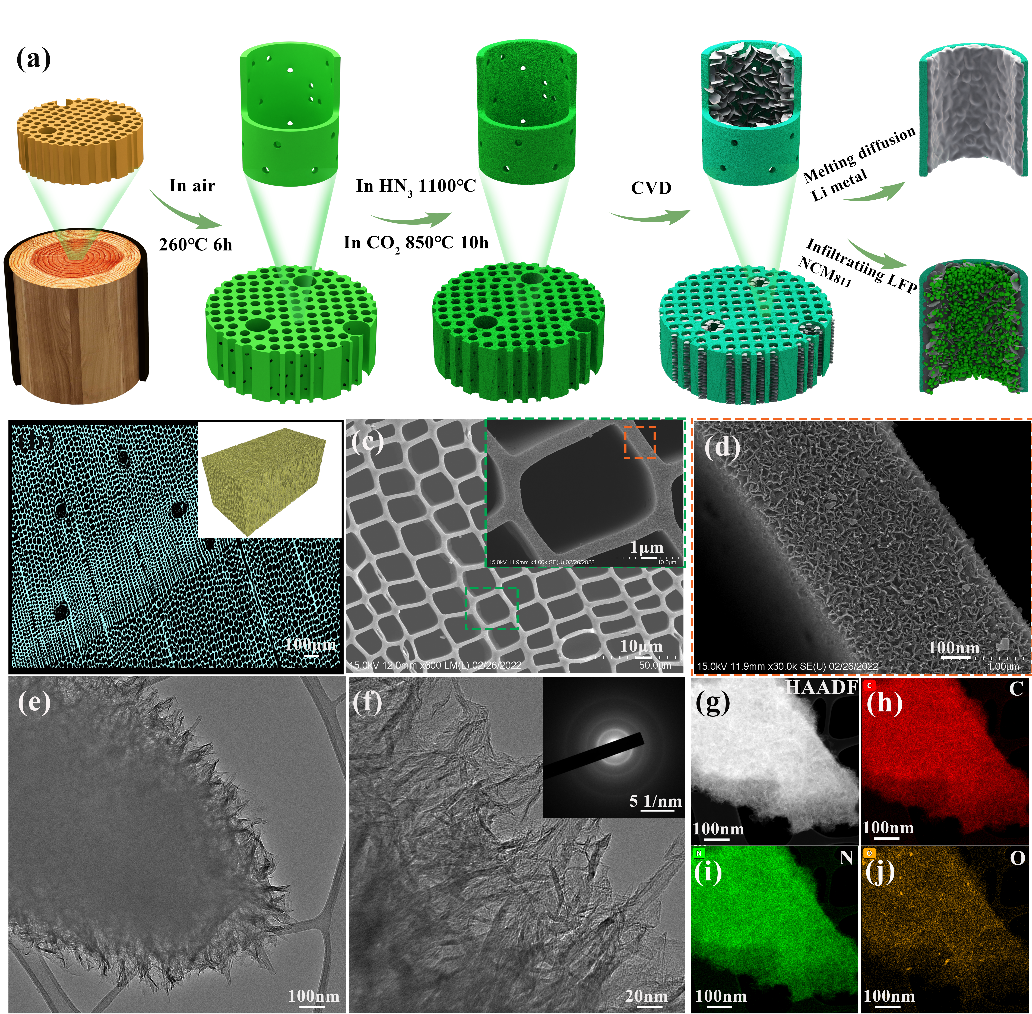

In their first study, entitled “Dual vertically aligned electrode inspired high capacity lithium batteries,” the research team proposed a dual vertically oriented electrode design with high conductivity and mechanical stability to develop a dendrite-free LMA and high-capacity cathode.

In this design, three-dimensional vertical graphene nanowalls with rich oxygen and nitrogen doping were grown on a multichannel carbon framework (VGWs@MCF). At the same time, vertically oriented LiFePO4 and LiNi0.8Co0.1Mn0.1O2 self-supporting cathode electrodes were prepared by a simple vacuum filtration method to promote Li+ transport and reduce Li+ diffusion resistance to minimize the transport path of Li+ in the anode and cathode, and improve the areal capacity and rate performance.

Figure 1. Schematic illustration of the design concept of dual vertically aligned electrodes using a 3D VGWs@MCF host and structure and composition characterizations of VGWs@MCF

Yongbiao Mu, a doctoral student from the Dept. of MEE at SUSTech, is the first author of this paper. Assoc. Prof. Lin Zeng is the corresponding author. Asst. Prof. Meng Lin and Dr. Yuzhu Chen of SUSTech supported the computational simulation part of this work.

This work was supported by the Shenzhen Fundamental Research Programs and the Shenzhen Key Laboratory of Advanced Energy Storage. The authors also acknowledge the technical support from the SUSTech Core Research Facilities.

High performance silicon carbon anode realized by vertical graphene fibers

Lithium-ion batteries have many advantages, such as high energy density, high operating voltage, abundant resources, and long cycle life. They are important means of energy storage and conversion. Silicon is considered as one of the most promising anode materials for the next generation of lithium-ion batteries due to its ultra-high theoretical specific capacity, low electrochemical potential of lithiation/delithiation, abundance, and environmental friendliness. However, the volume of the silicon anode changes greatly during the electrochemical cycle, resulting in serious pulverization of the silicon anode, unstable formation of the solid electrolyte interface, and loss of electrical contact. This brings about problems such as fast capacity decay, poor rate performance, and limited cycle life, which significantly limits the practical application of the silicon anode.

Recently, a variety of silicon carbon composite nanostructures have been reported, such as silicon amorphous carbon, silicon graphene, silicon carbon nanotubes, silicon graphite, and silicon carbon nanofibers. Although the electrochemical performance has been improved, most of the synthesis routes and means of silicon carbon anode still face stability, uniformity, and cost challenges.

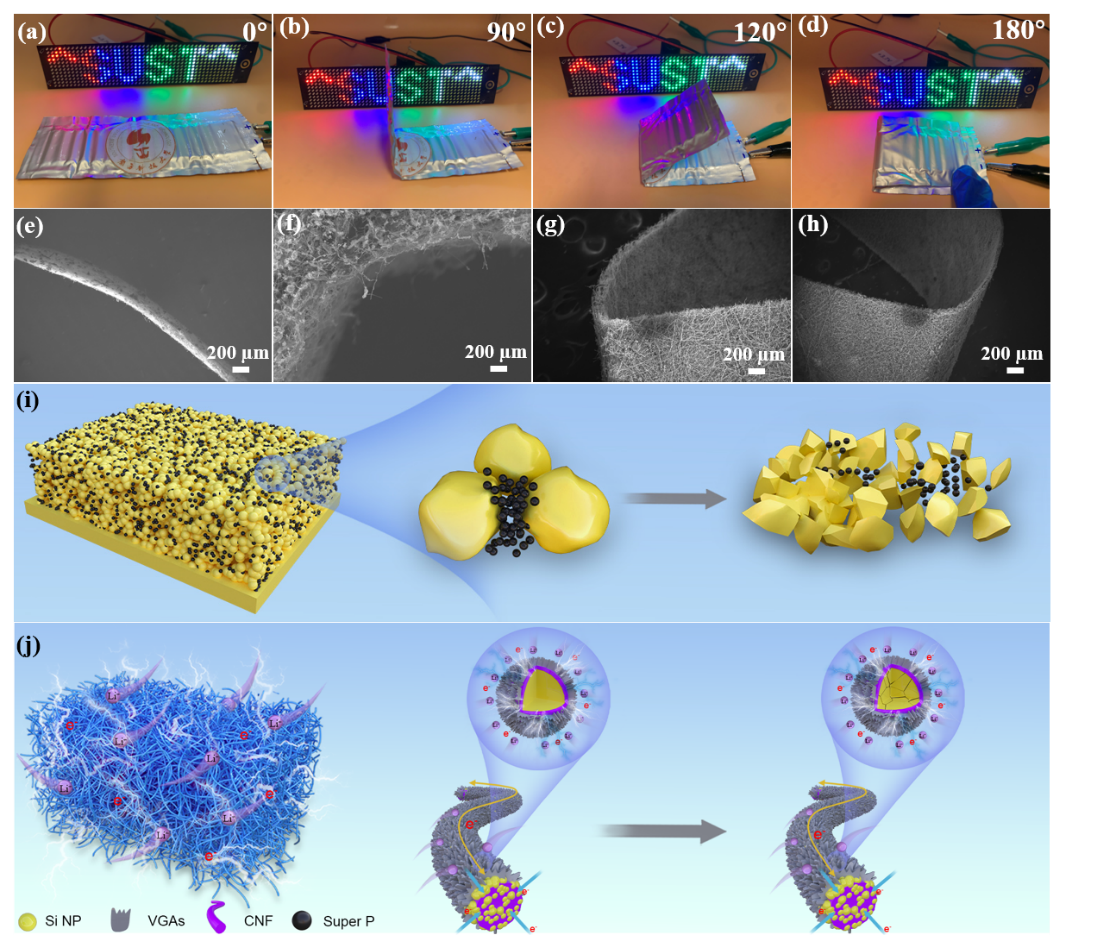

In their second study, entitled “Nitrogen, oxygen encoded vertical graphene arrays coated 3D flexible carbon fibers with high silicon content as an ultrastable anode for superior lithium storage,” Prof. Zeng’s team designed and synthesized a nitrogen-oxygen doped vertical graphene array coated three-dimensional flexible high silicon nanofiber flexible self-supporting electrode, combined with electrospinning and chemical vapor deposition processes.

To solve the volume expansion of pure silicon anode, they introduced the one-dimensional structure of carbon nanofibers and two-dimensional graphene sheets into the nano silicon anode, realizing double coating, and constructed a three-dimensional continuous conductive network. In doing so, this greatly improved the conductivity of the electrode structural stability and electrochemical performance.

The composite silicon carbon fiber with high silicon content (> 90%) was realized by regulating the electrospinning process. The double carbon coating effectively alleviated the volume expansion of silicon particles, and realized high current charge and discharge and long cycle stability.

Figure 2. Display of flexible lithium-ion pouch cells and schematic illustrating the enhanced Li+ and electron transportation mechanisms

In view of the flexibility, VGAs@Si@CNFs electrodes possess good mechanical stability and excellent lithium storage performance. The researchers made flexible lithium-ion pouch cells to verify their practical application potential. VGAs@Si@CNFs film was used as the anode material, and lithium cobaltate was used as the cathode electrode. The flexible lithium-ion battery assembled showed stable open circuit voltage, stable charge and discharge capacity, and cycle stability. Combined with SEM images under different bending conditions, it demonstrated its excellent flexibility and mechanical strength. The flexible pouch battery can light the self-made LED and last for more than 24 hours, proving the superiority and great potential of the composite silicon anode material designed and synthesized in this research.

Doctoral students Yongbiao Mu and Buke Wu, and Research Asst. Prof. Meisheng Han, are the co-first authors of this paper. Assoc. Profs. Lin Zeng and Jiayu Wan from the Dept. of MEE at SUSTech are the corresponding authors.

The study was funded by the National Natural Science Foundation of China (NSFC) and the Natural Science Foundation of Guangdong Province. The authors also acknowledge the technical support from the SUSTech Core Research Facilities.

Paper links (In order of appearance above):

Advanced Science: https://doi.org/10.1002/advs.202203321

Advanced Science: https://doi.org/10.1002/advs.202104685

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By