Liquid metals (LM) have attracted widespread attention and application in various fields due to their unique properties. With relatively low melting points, LM can remain in a liquid state at room temperature, making them highly promising for flexible electronics applications.

The high electrical and thermal conductivity of LM makes it suitable for manufacturing flexible electronic devices such as bendable displays, wearable devices, and flexible circuit boards. Additionally, LM exhibits excellent flexibility and plasticity, making it widely applicable in the field of soft robotics. However, it is important to note that LM is prone to oxidation at room temperature, leading to the formation of a thin oxide layer. This oxide layer can reduce the flowability of LM and cause adhesion to the underlying substrate. Researchers have been exploring methods to maintain the fluidity and free movement of LM to overcome this challenge.

Associate Professor Peng Yu’s research group from the Department of Mechanics and Aerospace Engineering at the Southern University of Science and Technology (SUSTech) recently collaborated with Professor Zuankai Wang’s research group at the Hong Kong Polytechnic University (PolyU) to make significant progress in the field of droplet bouncing.

Their findings, entitled “Liquid metal droplets bouncing higher on thicker water layer” in the journal”, have been published in Nature Communications.

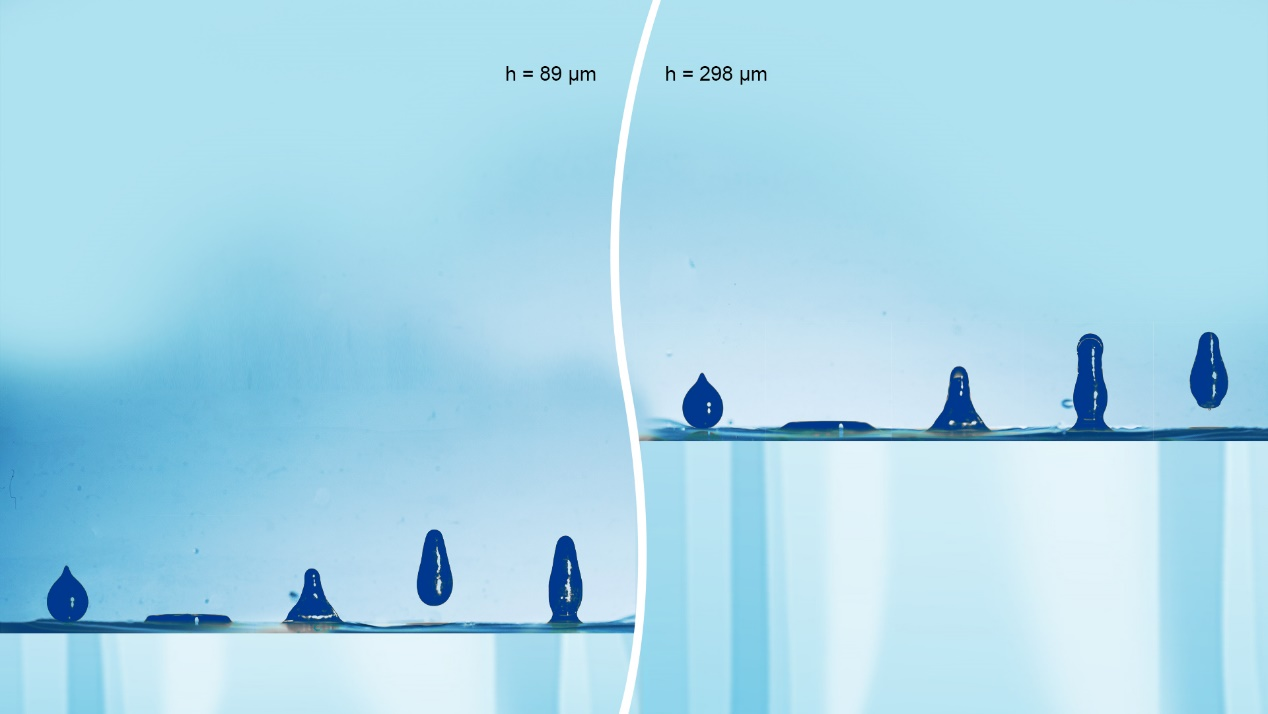

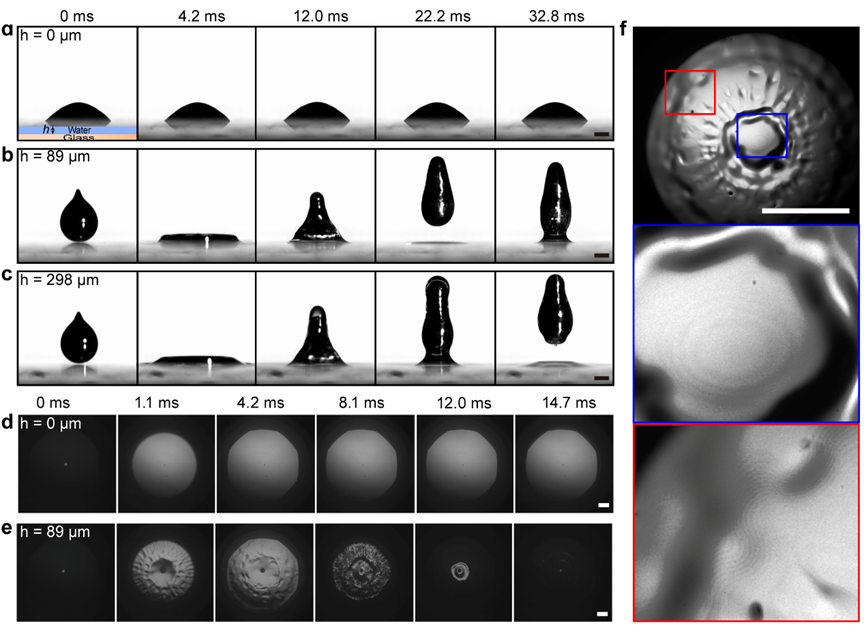

This paper reports an anomalous droplet bouncing phenomenon, where LM droplets can fully bounce on a water film without adhering to the solid surface underneath. Interestingly, the thicker the water film, the higher the bouncing capability of LM droplets (as shown in Figures 1 and 2).

Figure 1. LM rapidly bouncing off the solid surface covered by a water film. (a, b, and c) High-speed camera side view. (d and e) High-speed camera bottom view. (f) Interference pattern of the water film.

Figure 1. LM rapidly bouncing off the solid surface covered by a water film. (a, b, and c) High-speed camera side view. (d and e) High-speed camera bottom view. (f) Interference pattern of the water film.

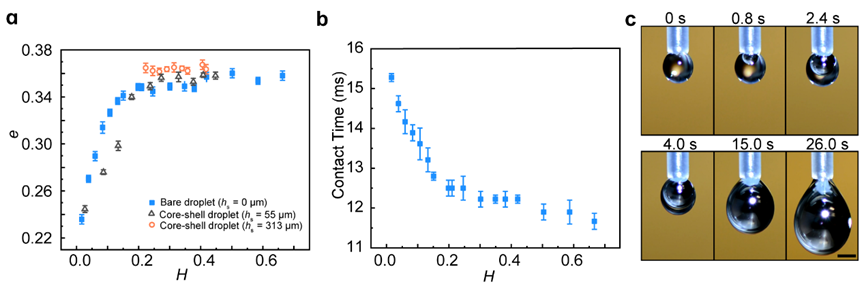

Figure 2. Dynamics characterization of LM droplet bouncing. (a) Variation of restitution coefficient with water film thickness. (b) Variation of contact time with water film thickness. (c) Physical representation of LM droplet generation.

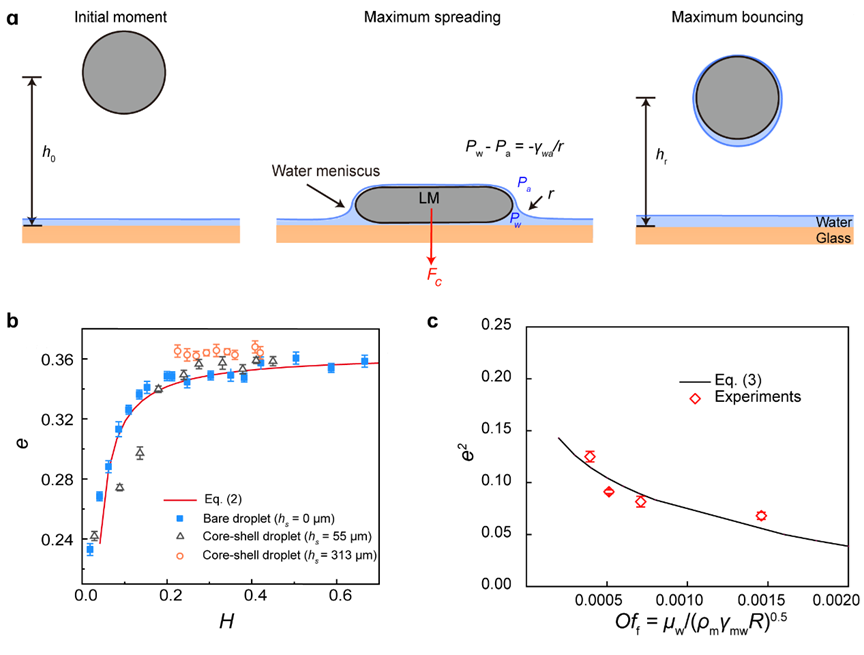

The researchers revealed that the underlying principle of this phenomenon lies in the water film acting as a lubricating layer, preventing contact between the LM droplet and the solid surface. The spontaneous wetting of LM droplets by the water film leads to a negative capillary pressure within the lubricating layer, thereby affecting the restitution coefficient of the LM droplet (as shown in Figure 3). They suggest that this discovery contributes to a deeper understanding of the dynamics of complex fluid droplets and offers new insights for fluid control.

Figure 3. Theoretical model of LM droplet bouncing. (a) Schematic representation of LM droplet bouncing. (b) Variation of restitution coefficient with water film thickness. (c) Variation of restitution coefficient with the Ohnesorge number (Of).

Yuhang Dai, a doctoral student in Assoc. Prof. Peng Yu’s research group, is the first author of this paper. The co-first authors are Dr. Li Minfei and Dr. Ji Bingqiang from Prof. Zuankai Wang’s research group. Prof. Zuankai Wang is the corresponding author, and Assoc. Prof. Peng Yu is a collaborative author. SUSTech is the second affiliation of the paper.

The research was supported by the National Natural Science Foundation of China (NSFC).

Paper link: https://doi.org/10.1038/s41467-023-39348-x

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin

Photo By