Professor Fuzeng REN’s research group, from the Department of Materials Science and Engineering at the Southern University of Science and Technology (SUSTech), has recently published their research work, “In Situ Formation of a Honeycomb-Like Dual-Amorphous Oxide Tribolayer via Tungsten Segregation for Exceptional Cryogenic Wear Resistance in a NbMoTaW Film,” in Nano Letters. The study reveals that a unique honeycomb-like dual-amorphous oxide tribolayer is formed in situ on the NbMoTaW film during cryogenic sliding wear, significantly enhancing its wear resistance at low temperatures. This work provides new insights for designing self-adaptive wear-resistant films for application in extreme stress-cryogenic environments.

The relentless pursuit of materials that perform reliably under extreme conditions has become a central challenge in modern engineering, driven by advancements in aerospace, quantum computing, and cryogenic energy systems. The study of friction and wear at cryogenic temperatures in particular, a regime where conventional lubrication is unavailable has emerged as a critical frontier. Components such as spaceborne bearings, superconducting magnets, and liquid hydrogen fuel systems are routinely exposed to severe mechanical stresses compounded by thermal extremes, leading to embrittlement, loss of deformability, and accelerated wear in conventional alloys and coatings.

Notably, friction-induced oxidation during sliding often produces high-strength oxide tribolayers that serve as protective barriers against direct wear. However, these mono-structured amorphous layers inherently exhibit limited deformability due to the mechanically unstable major shear band. Under cyclic loading, localized stress concentrations trigger brittle cracking, which in turn promotes micro-cutting and accelerates wear.

Recent investigations into metallic glasses and nanostructured alloys suggest that introducing nanoscale compositional or structural heterogeneity can enhance the deformability via mechanisms such as shear band arrest and strain delocalization. The phenomenon of strain-enhanced diffusion during sliding wear has been shown to facilitate solute segregation and compositional separation within the tribolayer. The distinct chemical affinities for oxygen among the constituent elements in compositionally complex alloys (CCAs) promote inhomogeneous oxidation. Noteworthy, the incorporation of oxygen via frictional contact not only enhances the glass-forming ability of specific phases, but also paves the way for in-situ amorphization during sliding wear. If these friction-induced, segregated nano-phases oxidize and amorphize heterogeneously, they can form a strong and deformable dual-amorphous nanostructured surface.

The study proposed a strategy to achieve superior cryogenic wear resistance via in situ formation of a dual-amorphous nanostructure with high strength and deformability. This strategy was validated using a model system of a nano-columnar-grained NbMoTaW CCA film, fabricated via magnetron sputtering. Ball-on-disk dry sliding tests at room temperature (RT) and 77K, followed by detailed composition and cross-sectional microstructure characterization of the wear track, elucidated the self-adaptive wear-resistant mechanism of the film under cryogenic conditions.

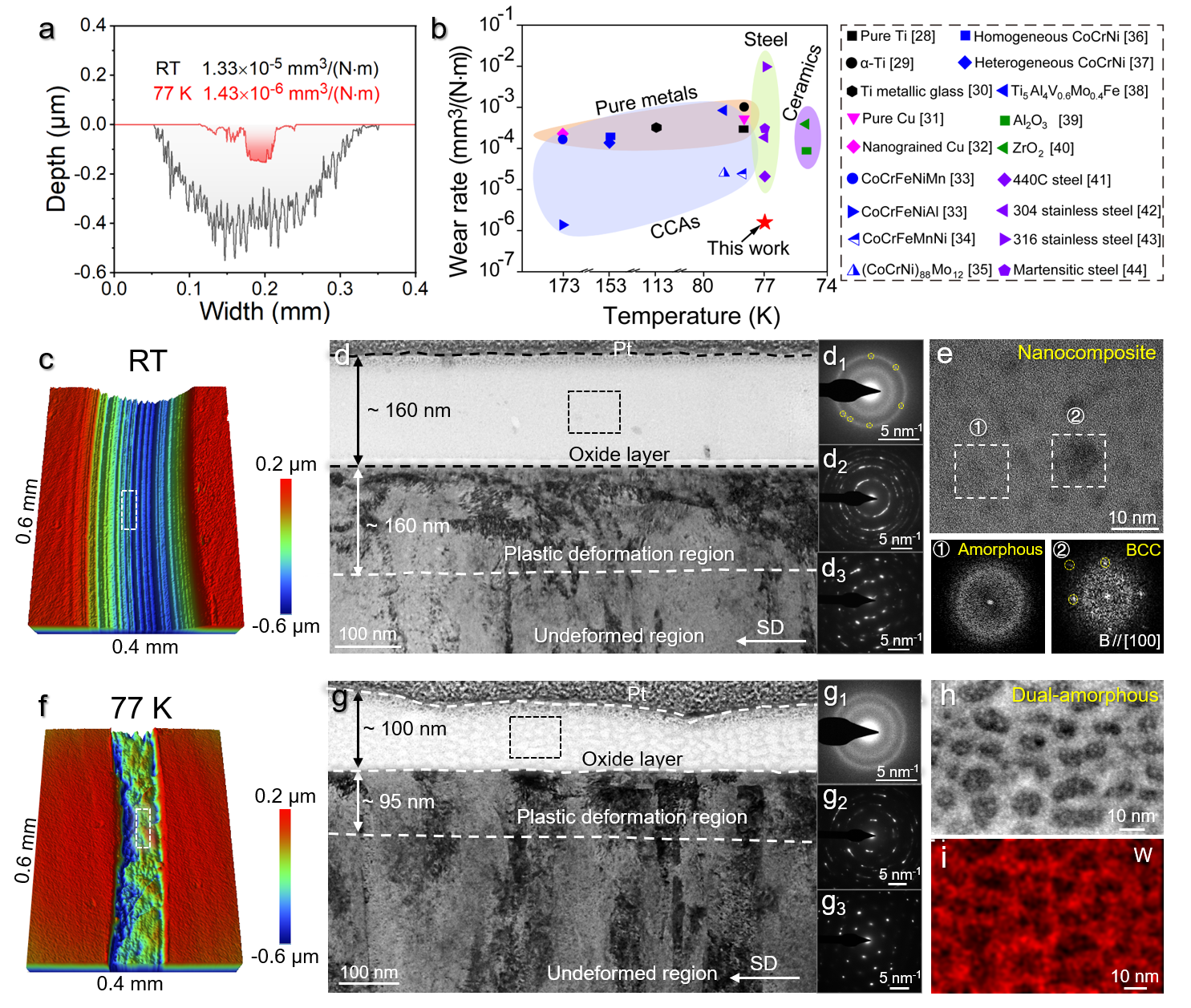

Figure 1. Wear behavior of the NbMoTaW film at RT and 77K. (a) 2D cross-sectional profiles of the wear tracks at RT and 77K. (b) Comparison of wear rates versus temperature (within the cryogenic temperature range of 73 K~173 K) for different alloys reported in the literature. (c) 3D profile of the wear track at RT. (d) ND-SD cross-sectional bright-field TEM image indicating the nanocomposite oxide layer formed at RT; (d1)-(d3) Corresponding SAED patterns for oxide layer, plastic deformation region, and undeformed region, respectively. (e) HRTEM image of the nanocomposite oxide layer, indicating a BCC structured nanocrystal embedded in the amorphous matrix. (f) 3D profile of the wear track at 77K. (g) ND-SD cross-sectional bright-field TEM image indicating the dual-amorphous oxide layer formed at 77K; (g1)-(g3) Corresponding SAED patterns for oxide layer, plastic deformation region, and undeformed region, respectively. (h)-(i) Enlarged HAADF-STEM image of dual-amorphous oxide layer and the corresponding EDS elemental mapping of W element displaying a honeycomb-like structure with W-depleted amorphous “core” and a W-rich amorphous “skeleton”.

The results found that NbMoTaW film showed a tenfold enhancement in wear resistance at 77K relative to RT, with the wear rate reduced to 1.43 × 10-6 mm3/(N·m). Through detailed TEM characterization of sliding wear-induced microstructural evolution, the work demonstrated that cryogenic sliding induces preferential W segregation and heterogeneous oxidation, resulting in the in-situ formation of a ~100 nm-thick dual-amorphous oxide surface layer. The resulting structure consists of ~3.7 nm-thick W-rich “skeletons” enclosing W-depleted “core” domains with an average size of ~6.3 nm (Figure 1). This unique microstructure accommodates appreciable homogeneous deformability (Figure 2), can restrict sliding-induced cracking and localized fracture, and thus significantly improves the cryogenic wear resistance of the film.

Figure 2. Comparison of the mechanical properties of sliding wear-induced tribolayers at RT and 77 K. (a) Representative engineering stress–strain curves under uniaxial compression. (b) SEM images of a nanopillar from the tribolayer formed at RT, shown (b1) before and (b2) after compression. (c) SEM images of a nanopillar from the tribolayer formed at 77K, shown (c1) before and (c2) after compression.

Master’s student Zijian WU and postdoctoral researcher Jiasi LUO from Professor Fuzeng REN’s research group are the co-first authors of the paper. Professor Fuzeng REN is the corresponding author, with SUSTech serving as the first and corresponding institution.

Paper link: https://doi.org/10.1021/acs.nanolett.5c05430

Proofread ByNoah Crockett, Junxi KE

Photo ByYan QIU