The energy utilization of waste heat could be dramatically increased following new research into low-cost materials used in thermoelectrics and the creation of hybrid piezo-thermoelectric energy harvesting devices. The studies have indicated that cheaper materials and advanced hybrid systems could be just as efficient as the current scarce resources used while wasting less heat.

Department of Physics Head Chair Professor He Jiaqing at Southern University of Science and Technology (SUSTech) has led his research group to publish two papers in high-impact journals in recent months on the energy conversion of thermoelectric materials.

Energy and Environmental Science (IF = 33.25) published one of the two papers, titled “Realizing High-efficiency Power Generation in Low-cost PbS-based Thermoelectric Materials.”

Thermoelectric conversion technology seeks to convert thermal energy into electrical energy. It has significant and irreplaceable advantages over other technologies when it comes to waste heat recovery, with a massive range of applications. However, the current set of thermoelectric materials that are commercially viable use substantial amounts of rare elements, significantly increasing the costs of thermoelectric materials.

Chair Professor He Jiaqing led his research group to investigate a lead sulfide (PbS) based thermoelectric material. It is just one-fifth of the cost of traditional lead-telluride (PbTe) based materials, with a comparable thermoelectric performance of 11.2% from waste heat to electrical energy.

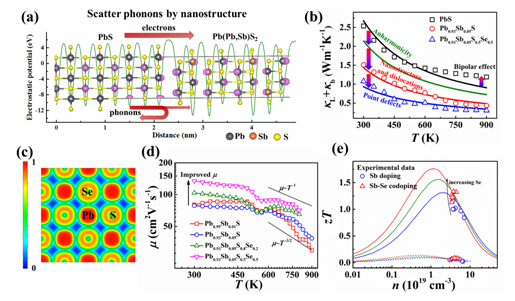

Figure 1 (a) Phonon scattering from a nanostructure. (b) Substantially reduce lattice thermal conductivity through nanostructure-engineering. (c) Alloying Se increases covalent bonding. (d) Alloying Se significantly increases electron mobility. (e) the thermoelectric figure of merit zT is increased substantially when combined with lowering the lattice thermal conductivity and increasing the electron mobility.

Lead sulfide-based materials are very cheap but tend to have low thermoelectric properties. The research group doped the lead sites with antimony (Sb) atoms to introduce dislocations, which provide small-scale nucleation centers. The zigzag second phase formed around the nucleation centers introduced a high density of lattice strains, resulting in very strong scattering for heat-carrying phonons. The similar chemical composition in PbS-Sb thermoelectric materials ensures electron mobility and reduced thermal conductivity. The improved electron mobility pairs positively with energy conversion efficiency and thermoelectric performance, making PbS-based thermoelectric materials reach the requirements for commercial applications.

The research also prepared commercially viable applications of their PbS-based thermoelectric materials. The low performance of PbS-based devices at the low-temperature range has been further improved by combining with commercial bismuth-telluride (BiTe)-based materials. The segmented thermoelectric device was able to achieve a thermoelectric energy conversion efficiency of 11.2%, similar to that of other devices around the world at a significantly lower cost.

Figure 2 (a) The thermoelectric figure of merit zT of four materials used in the preparation of thermoelectric devices. (b) Output voltage and power of the prepared segmented thermoelectric device. (c) Energy conversion efficiency of the fabricated segmented thermoelectric device. (d) The design drawing and the physical picture of the segmented thermoelectric device, the energy conversion efficiency of the long-term work have not deteriorated.

Nano Energy (IF = 15.548) published the other paper, titled “Dynamic piezo-thermoelectric generator for simultaneous harvesting mechanical and thermal energies.”

The continuous development of the Internet of Things (IoT) technology has seen an increased demand for distributed energy supply and power management to support eco-friendly lifestyles. While significant effort has been put into scavenging waste heat, the same cannot be said for research into simultaneously scavenging kinetic energy. By synergistically harvesting and managing wasted thermal and mechanical/kinetic energy through dynamic piezo-thermoelectric generators (dPTEG), IoT electronics could become more efficient and use less power from the grid. Such technology currently lacks the efficiency in converting either mechanical/kinetic or thermal energy.

Chair Professor He Jiaqing worked with colleagues at the National University of Singapore and Lanzhou University, as well as the Department of Materials Science and Engineering at SUSTech, to design radial piezoelectric generators coupled with annular thermoelectric generators, to create and evaluate a prototype dPTEG.

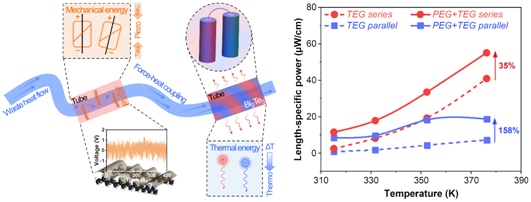

Figure 3 A dynamic piezoelectric thermoelectric coupling model based on a synchronous collection of fluid thermal energy and mechanical energy (left); the use of a piezo-thermoelectric energy harvesting generator to effectively improve the energy utilization of low-grade waste heat fluid (right)

The prototype dPTEG combined a flexible PVDF-based piezoelectric generator with a Bi2Te3-based thermoelectric generator. The piezoelectric generator scavenged the mechanical energy of the waste heat flow firstly before the thermoelectric generator captured the thermal heat through the low-speed flow (Figure 3). Their prototype dPTEG was able to achieve a 35% increase in power density in serial mode and a 158% increase in parallel mode.

These results provide a new model and solution for the simultaneous utilization of mechanical and thermal energy, with numerous industrial applications such as automobile exhaust, geothermal energy, and industrial waste heat.

Department of Physics postdoctoral researcher Jiang Binbin, masters’ student Liu Xixi, and Department of Materials Science and Engineering postdoctoral researcher Wang Qi were the co-first authors of the Energy and Environmental Science paper. Chair Professor He Jiaqing is the correspondent author of the paper, with SUSTech as the correspondent unit. They received support from the Natural Science Foundation of Guangdong Province, Leading Talents of Guangdong Province Program, the Science and Technology Innovation Commission of Shenzhen, the National Natural Science Foundation of China (NSFC), and the Shenzhen DRC Project.

National University of Singapore doctoral candidate Zhou Yi is the first author of the Nano Energy paper. Chair Professor He Jiaqing and Professor Li Gongping are co-correspondent authors of the paper, with SUSTech and Lanzhou University as the correspondent units. The paper received support from the National Natural Science Foundation of China (NSFC), the Leading Talents of Guangdong Province Program, the Science and Technology Innovation Commission of Shenzhen, the Shenzhen Clean Energy Research Institute, the Special Funds for the Cultivation of Guangdong College Students’ Scientific and Technological Innovation, and the Hui-Chun Chin and Tsung-Dao Lee Chinese Undergraduate Research Endowment. Helpful discussions were had with the Shanghai Institute of Ceramics (CAS).

Paper link:

Energy & Environmental Science – https://pubs.rsc.org/en/Content/ArticleLanding/2020/EE/C9EE03410B

Nano Energy – https://doi.org/10.1016/j.nanoen.2019.104397

He Jiaqing team homepage: http://jqhphy.sustech.edu.cn/

Proofread ByXia Yingying

Photo ByDepartment of Physics, Qiu Yan