With the strengthening capacity through harnessing multi-length-scale structural hierarchy, synthetic hydrogels hold tremendous promise as a low-cost and abundant material for applications demanding mechanical robustness. A common route to endow such materials with extraordinary mechanical performance (i.e., strength, modulus, toughness, and fatigue resistance) is through bio-inspired mineralisation. However, the extremely high fraction of inorganic components (i.e., > 70 wt.%) can lead to low water content (i.e., < 30 wt.%) and high rigidity (i.e., modulus > 400 MPa), thus impairing their utilities in various advanced engineering applications.

Associate Professor Ji Liu from the Department of Mechanical and Energy Engineering at the Southern University of Science and Technology (SUSTech), in collaboration with researchers from Ningbo University (NBU), South China University of Technology (SCUT), and University College London (UCL), have recently reported a simple yet effective strategy to fabricate hierarchically-structured hydrogel materials that exhibit a record-high ballistic energy absorption capability (i.e., 2.1 kJ m−1), without sacrificing their high water content (i.e., 85 wt.%) and superior softness (as shown in Figure 1).

This paper, entitled “Impact-Resistant Hydrogels by Harnessing 2D Hierarchical Structures,” was published in Advanced Materials, a high-profile journal in material science.

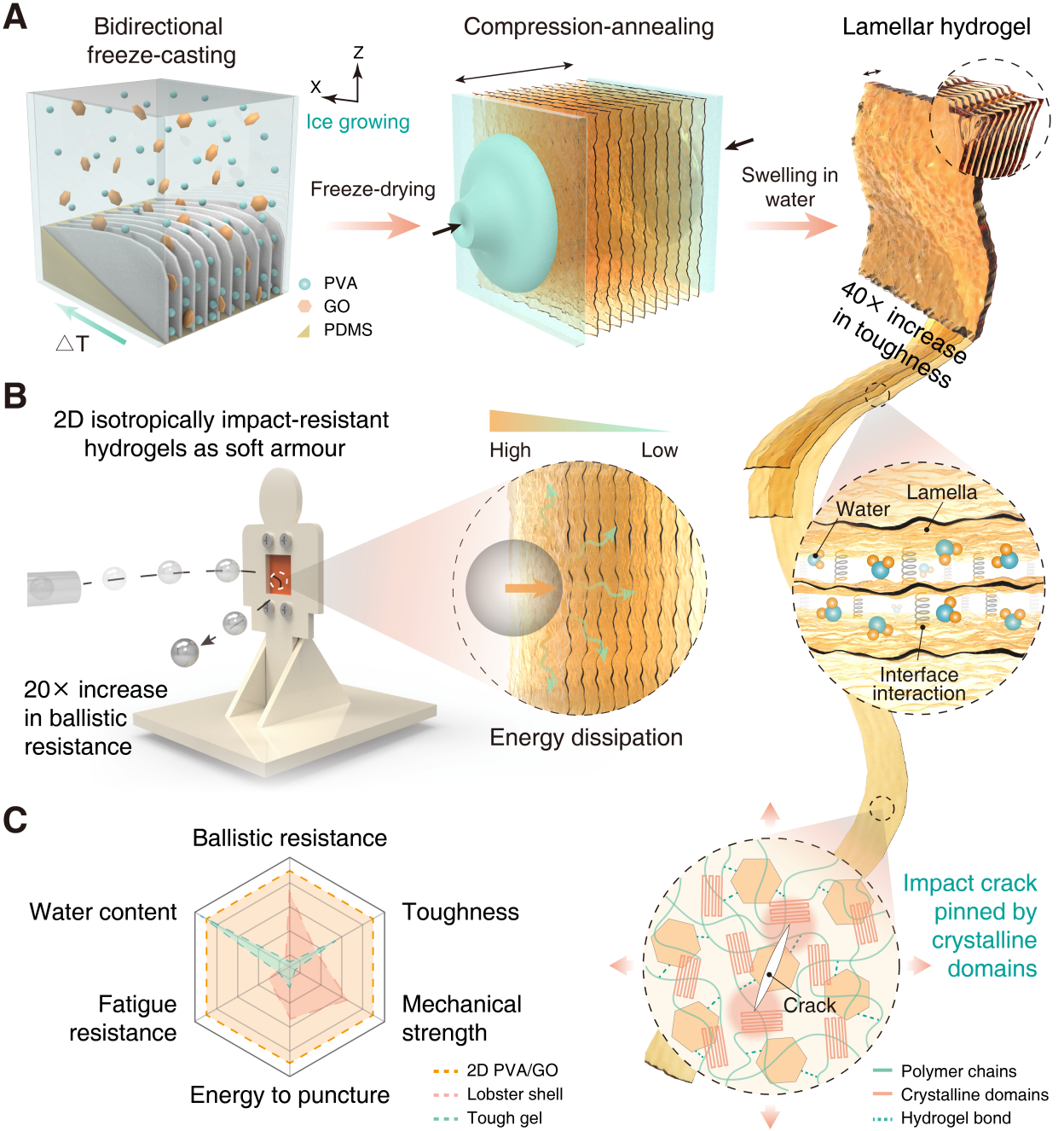

Figure 1. Design and fabrication of impact-resistant hydrogels with 2D lamellar structures

Inspired by the unique structure-property relationship of the underbelly of American lobster, Prof. Liu and his team engineered the preferentially-aligned laminar micro/nanostructures within a hydrogel material through the bidirectional freeze-casting process, followed by compression-annealing process, using the composite material of polyvinyl alcohol (PVA) and graphene oxide (GO) as the exemplary material. The unique combination of impact resistance, high water content, and remarkable softness of the hydrogel materials not simply results from the aligned lamellar structure, but rather the compression annealing process, which simultaneously enhances the interfacial affinity and the crystallinity of the materials. Together with their low-cost and extraordinary energy dissipation capacity, these hydrogel materials present a durable alternative to conventional hydrogel materials for armour-like protection circumstances.

Video 1. A high-speed air-gun ballistic setup and a high-speed camera system to capture the trajectory of the bullet

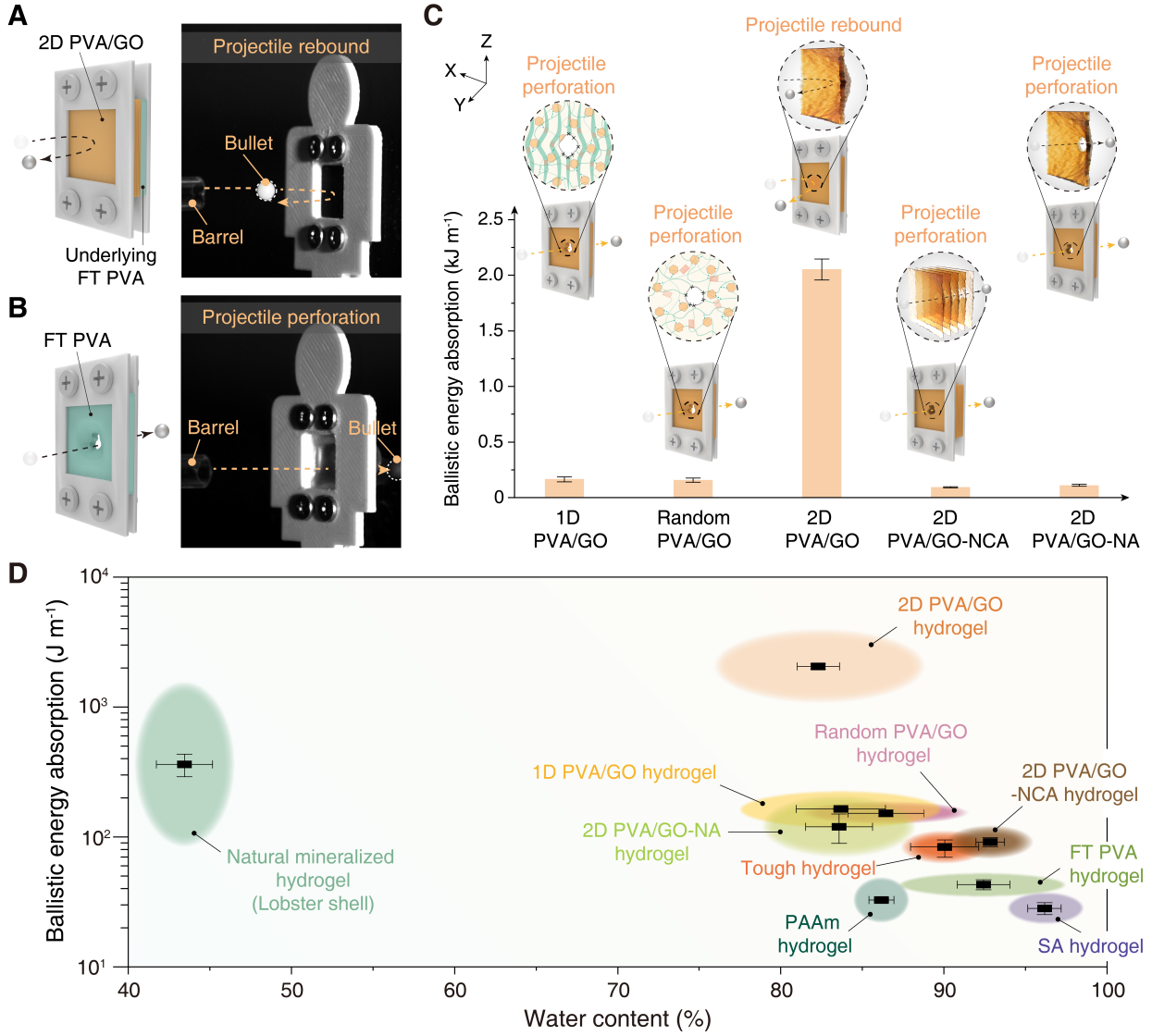

In order to verify its dynamic impact resistance, the researchers developed a high-speed air-gun ballistic setup (Video 1), and a high-speed camera system was used to capture bullet trajectory and measure the velocity of the bullets (Video 2). They also systematically studied the multi-scale micro/nanostructures of these hydrogel materials, and combined with experiments (quasi-static and dynamic impact tests) and theoretical mechanical simulation, revealed the design strategy of impact-resistance hydrogel materials: the cooperative regulation of monolayer structure and interlayer interaction forces, to achieve rapid dissipation of impact energy.

Figure 2. The bullet impact resistance of 2D PVA/GO hydrogel

Video 2. The bullet impact process of 2D PVA/GO hydrogel

This work was led by SUSTech, in collaboration with MIT, NBU, and UCL. Dr. Xiangyu Liang of SUSTech is the first author of this paper, while Assoc. Prof. Ji Liu is the corresponding author.

This work was financially supported by the Science, Technology and Innovation Commission of Shenzhen Municipality, Basic and Applied Basic Research Foundation of Guangdong Province, Natural Science Foundation of Guangdong Province, and Natural Science Foundation of Shenzhen Municipality.

Paper link:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202207587

Prof. Ji Liu’s group link:

https://faculty.sustech.edu.cn/?cat=4&tagid=liuj9&orderby=date&iscss=1&snapid=1

To read all stories about SUSTech science, subscribe to the monthly SUSTech Newsletter.

Proofread ByAdrian Cremin, Yingying XIA

Photo By